A kind of oiling machine and heat treatment process using the equipment

A technology of oiling machine and frame, which is applied in the field of bearing processing, can solve the problem of low oil injection quality of bearings, and achieve the effect of improving the quality of oil injection and improving quality

Active Publication Date: 2022-06-03

新昌沛斯轴承配件有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of the above-mentioned related technologies, the inventor believes that there are the following defects: when the operator pours several bearings onto the first conveyor belt, there may be some bearing ring sides that conflict with the first conveyor belt, and other flat bearings are placed Blocking, resulting in poor quality of oil sprayed on the bearings in the atomizer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0049] The embodiment of the application discloses an oiling machine. Referring to Figure 2, an oiling machine includes a frame 1, and the upper edge of the frame 1 bears

[0069] S5: Check the oiled bearing and put it into storage.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

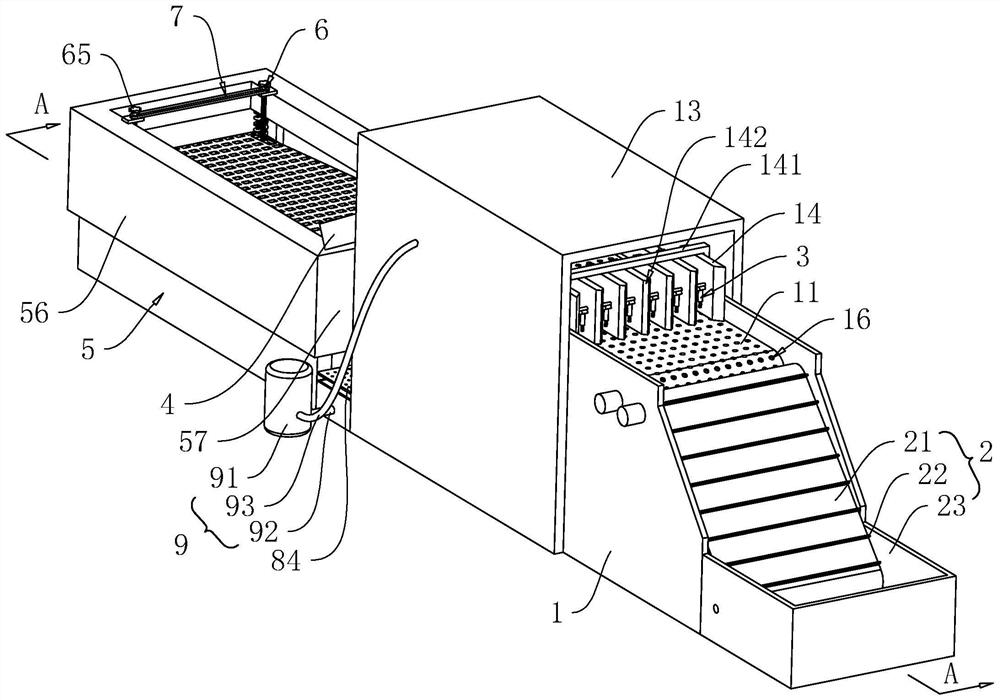

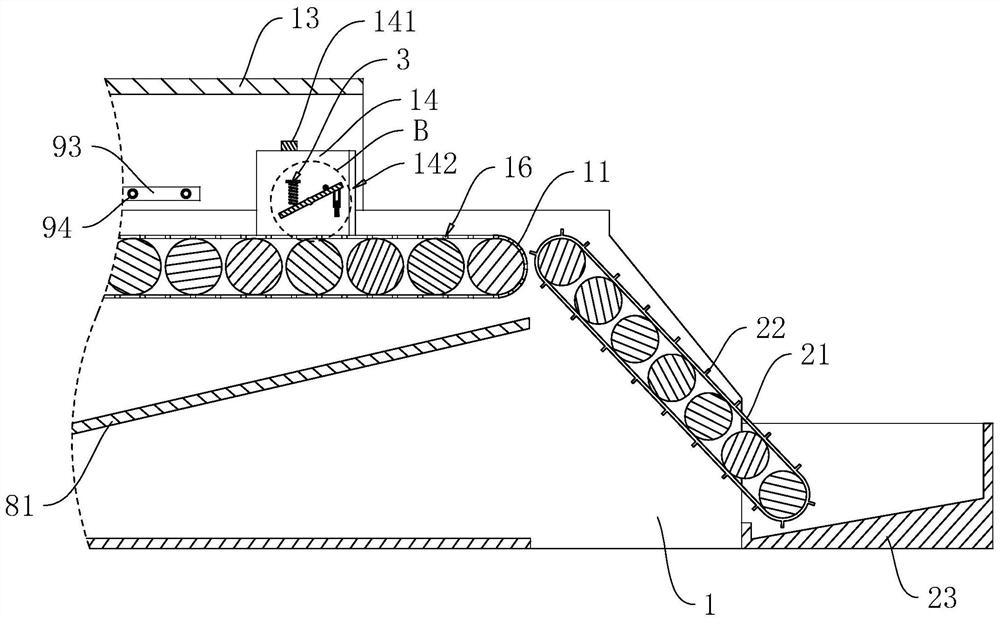

The application relates to an oiling machine and a heat treatment process using the equipment, which includes a frame on which an oil storage tank, a first conveyor belt for driving several bearings, and a first conveyor belt for atomizing the oil in the oil storage tank And spray into the atomizing device in the oil storage tank, the frame is provided with a transmission device, the transmission device includes a second conveyor belt, a number of driving plates and a material storage box, the material storage box, the second conveyor belt are arranged in sequence along the transmission direction of the first conveyor belt, The material storage box is located below the first conveyor belt and is arranged on the frame; one end of the second conveyor belt is located in the material storage box, and the other end is located at the first conveyor belt place, and several drive plates are arranged on the second conveyor belt, and the drive plate and the second conveyor belt A space is formed between the bearings for limiting placement, and the distance between the surface of the driving plate away from the second conveyor belt and the second conveyor belt is smaller than the radius of the bearing. The present invention has the effect of reducing the occurrence of the bearing standing up when the bearing is processed.

Description

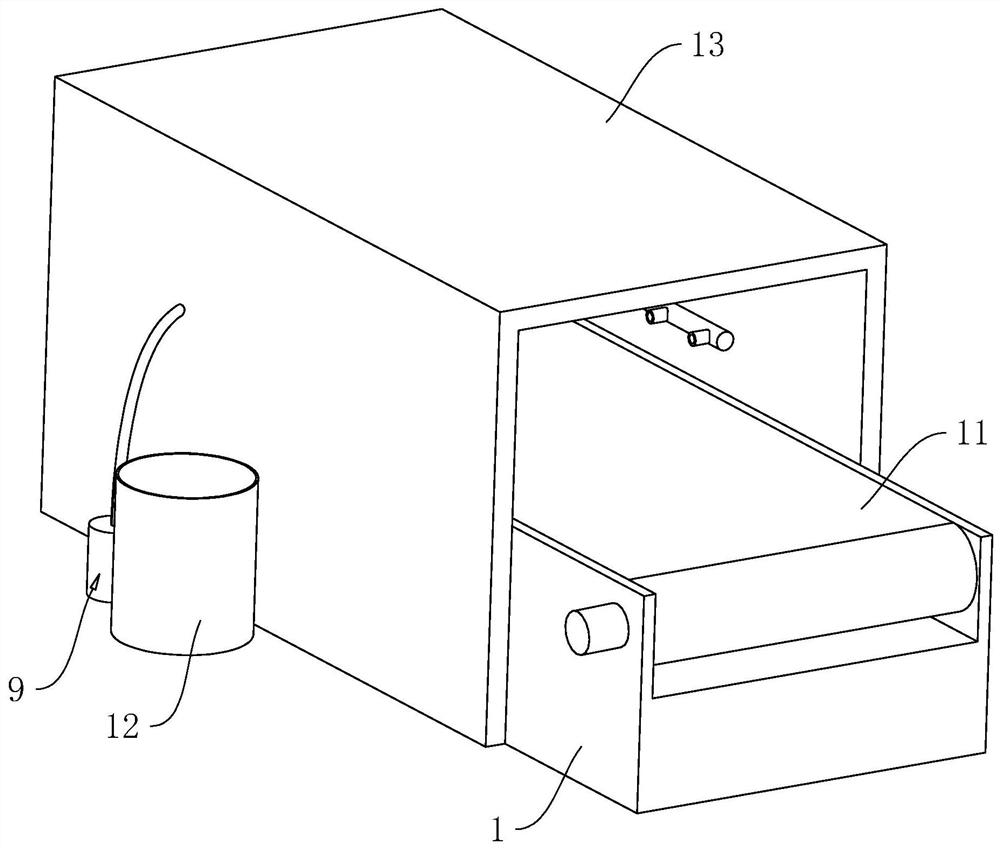

An oiling machine and a heat treatment process using the same technical field The application relates to the field of bearing processing, especially relate to a kind of oiling machine and the heat treatment worker applying this equipment art. Background technique After heat treatment is carried out to the bearing outer ring and the inner ring, the outer ring and the inner ring of the bearing need to be heated by an oiler. Do the fuel injection. Referring to the related art of Fig. 1, the oiling machine comprises a frame 1, and the fuel injection tank 13 and the oil storage tank 12 arranged on the frame 1 are used for The first conveyor belt 11 driving several bearings and the atomizing device 9, the atomizing device 9 is communicated with the oil storage tank 12, and the atomizing device 9 will The oil in the oil storage tank 12 is atomized and then sprayed into the oil injection tank 13 to spray the bearings on the first conveyor belt 11 . [0004] In use, the ope...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05B9/04B05B13/02B05B14/00B05D7/24B05D1/02B05D3/00C21D9/40

CPCB05B9/0403B05B13/0221B05B14/00B05D7/24B05D3/002B05D1/02C21D9/40

Inventor 王云飞王明波戚辉朱炳超李坚

Owner 新昌沛斯轴承配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com