Paper pressing device

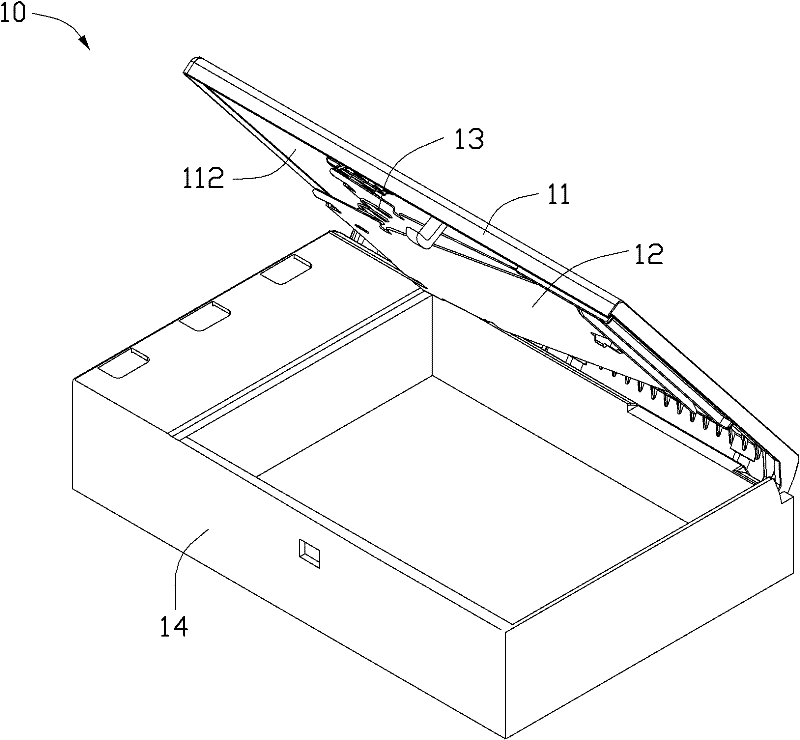

A technology of pressing paper and pressing components, applied in the field of paper pressing devices, can solve the problems of large friction between paper and paper pressing fixing sheet 12, inconvenient for users, large contact area, etc., so as to reduce paper jams and reduce friction. The effect of small force and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings.

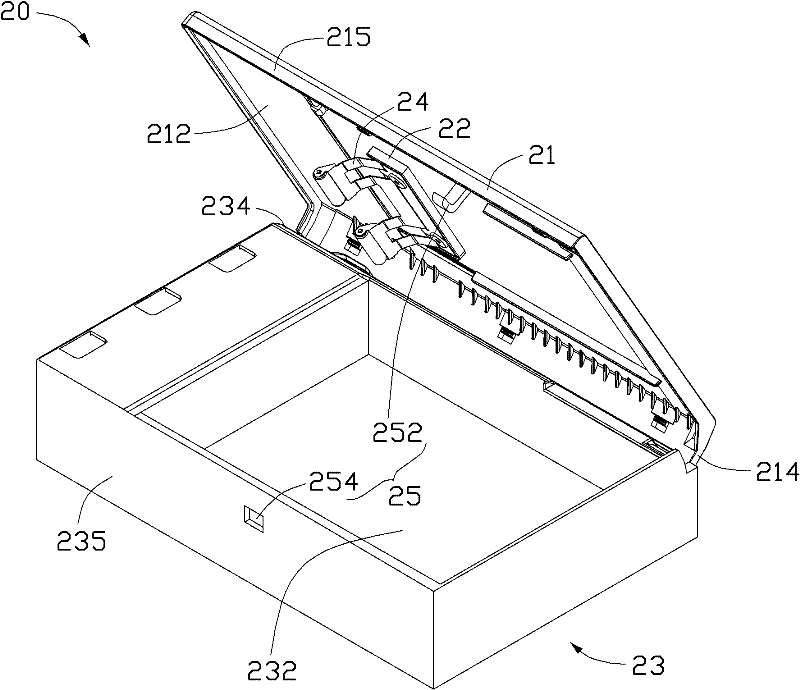

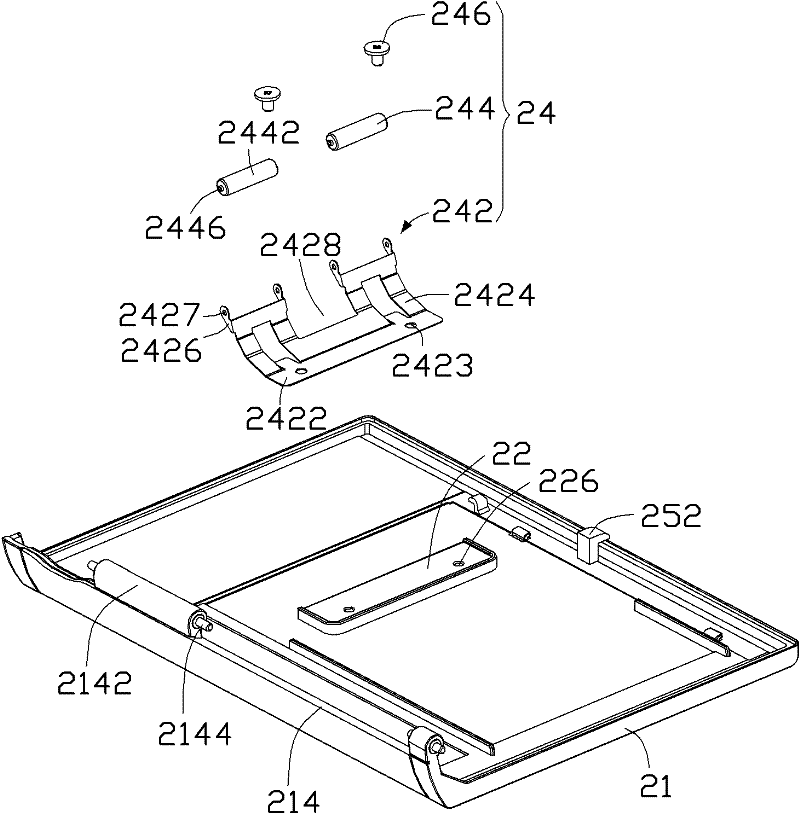

[0011] Please also refer to figure 2 and image 3 , the paper platen device 20 provided in the embodiment of the present invention can be set in some printing devices such as printers, copiers, scanners or Polaroid cameras. The paper pressing device 20 includes a front cover 21 , a connecting member 22 , a rear cover 23 capable of engaging with the front cover 21 , a pressing component 24 , and a locking portion 25 .

[0012] The front cover 21 has a square shape and includes a pivoting side 214 , a rotating side 215 opposite to the pivoting side 214 , and an inner wall 212 . In this embodiment, the pivoting side 214 is provided with two rotating rods 2142 , and two ends of the rotating shaft 2142 are respectively provided with a rotating shaft 2144 .

[0013] The connecting member 22 is fixed on the inner wall 212 and at least one first screw hole 226 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com