Image forming device and its paper discharge mechanism

A paper discharge and paper discharge technology, which is applied in the field of image forming devices and paper discharge mechanisms, can solve the problems of paper jams and low productivity, and achieve the effect of reducing paper jams and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

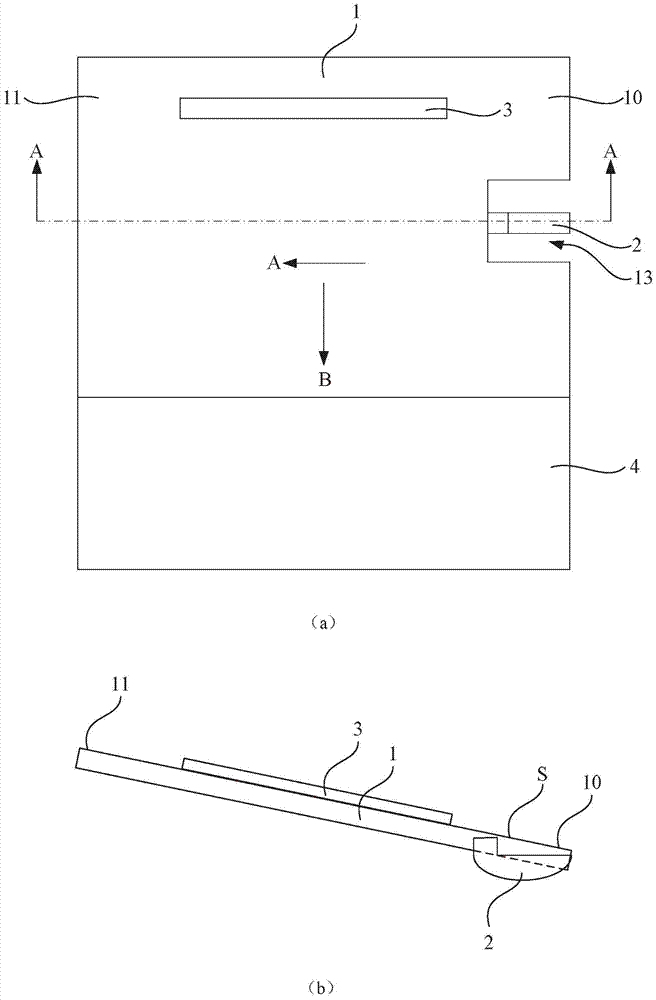

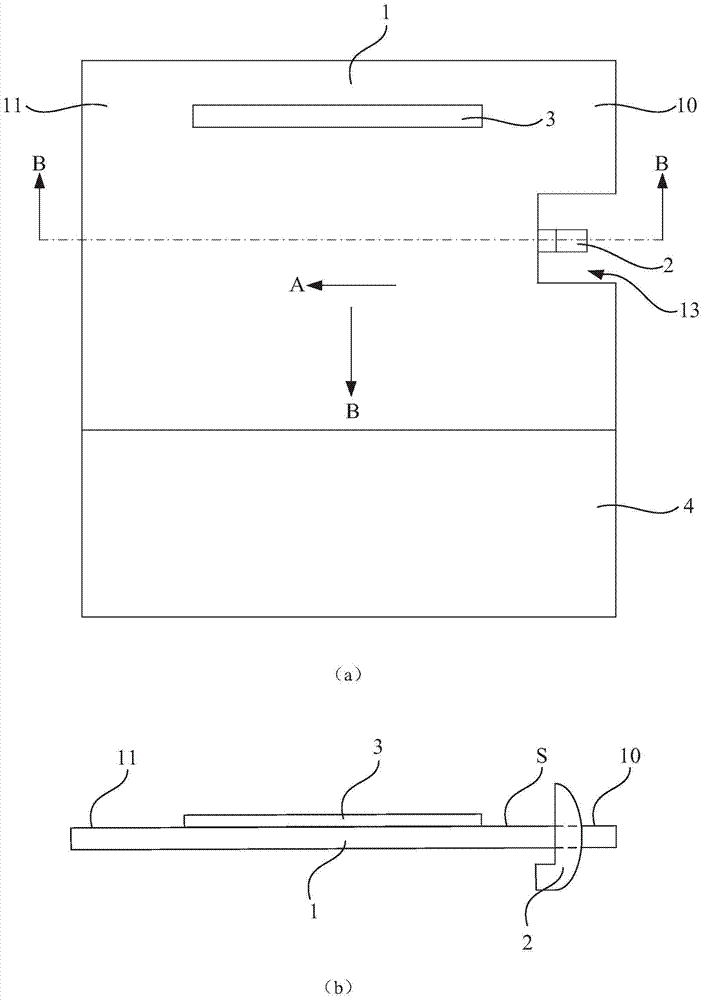

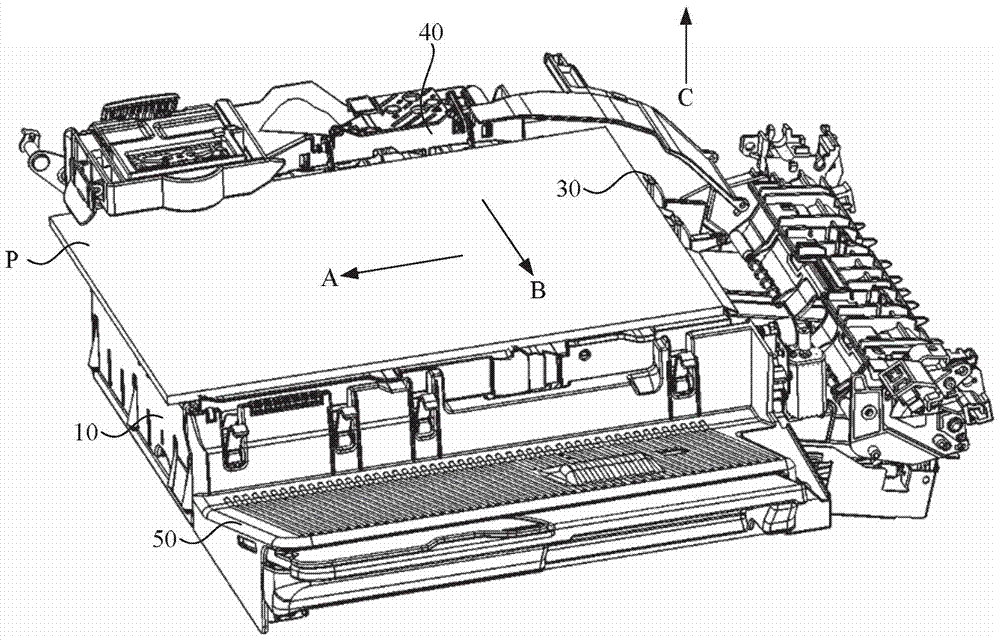

[0052] refer to image 3 , Figure 5 As shown, the paper discharge mechanism of the present embodiment includes:

[0053] The tray 10 is used to carry the paper P discharged along the discharge direction A from the paper outlet (not shown) of the image forming apparatus. In the post-processing state, the tray 10 is located at a horizontal position, combined with Figure 7 As shown in , the tray 10 is in the initial inclined position in the paper discharge state;

[0054] The adjustment part 20 is linked with the tray 10 and used to adjust the tray 10 to the horizontal position and the initial inclined position;

[0055] combine Figure 4 As shown, the storage part 100 is arranged at the upstream end of the tray 10 along the discharge direction A;

[0056] The holding part 30, in the post-processing state, the holding part 30 protrudes from the storage part 100 to the carrying surface S of the tray 10, so that the upstream end of the paper P on the tray 10 along the dischar...

no. 2 example

[0105] The difference between the second embodiment and the first embodiment lies in the interlocking part, and in the second embodiment, when the adjustment part adjusts the tray from the horizontal position to the initial inclined position, the adjustment part does not carry The interlocking parts move together, and the interlocking part and the adjustment part do not share one driving source, but use separate driving sources.

[0106] Specifically, such as Figure 13 to Figure 14 As shown, in the process of adjusting the tray 10 from the horizontal position to the initial inclined position by the adjustment part 20, the driving source in the adjustment part 20 drives the lifting part 21 to rotate along the direction E, and at the same time, the linkage part (not shown in the figure) The driving source in (shown) drives the holding part 30 to rotate in the direction D (counterclockwise in the figure), by controlling the rotation speed of the holding part 30, before the tray ...

no. 3 example

[0111] The difference between the third embodiment and the first embodiment lies in the interlocking part, and in the third embodiment, before the position of the tray is adjusted by the adjusting part, the interlocking part drives the holding part to the storage position. Ministry.

[0112] like Figure 15 to Figure 17As shown, in the post-processing state, the tray 10 is at the horizontal position, and the push-out part 40 pushes out the paper from the tray 10 along the paper discharge direction B. After the paper is pushed out by the push-out part 40, before the tray 10 is adjusted from the horizontal position to the initial inclined position by the adjustment part, the push-out part 40 will move in the direction opposite to the discharge direction B, so that the push-out part 40 is reset to the initial position .

[0113] like Figure 17 As shown, during the reset process of the push-out part 40 , the linkage part (not shown) drives the holding part 30 to rotate along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com