Patents

Literature

136results about How to "Avoid mechanical wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

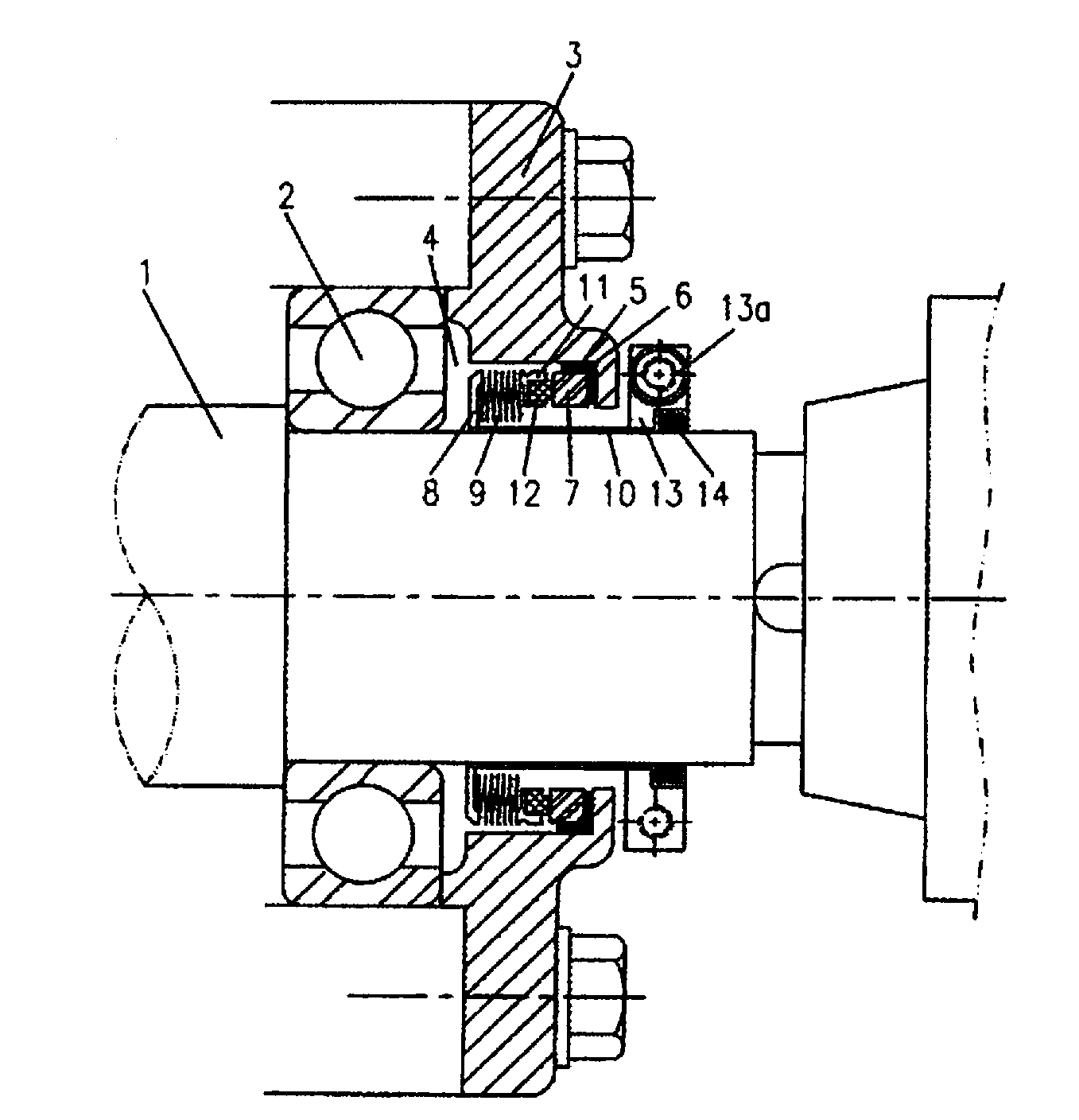

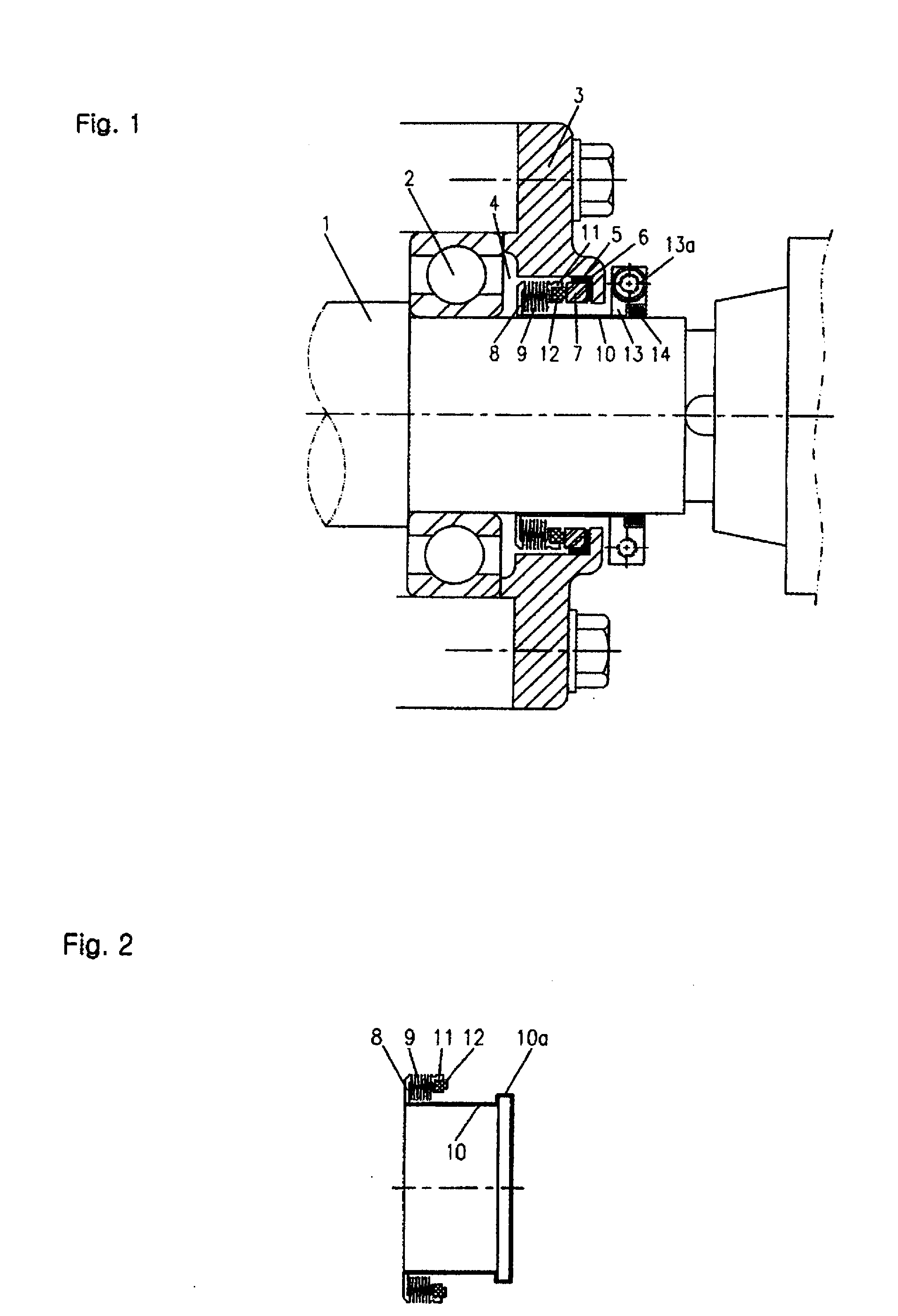

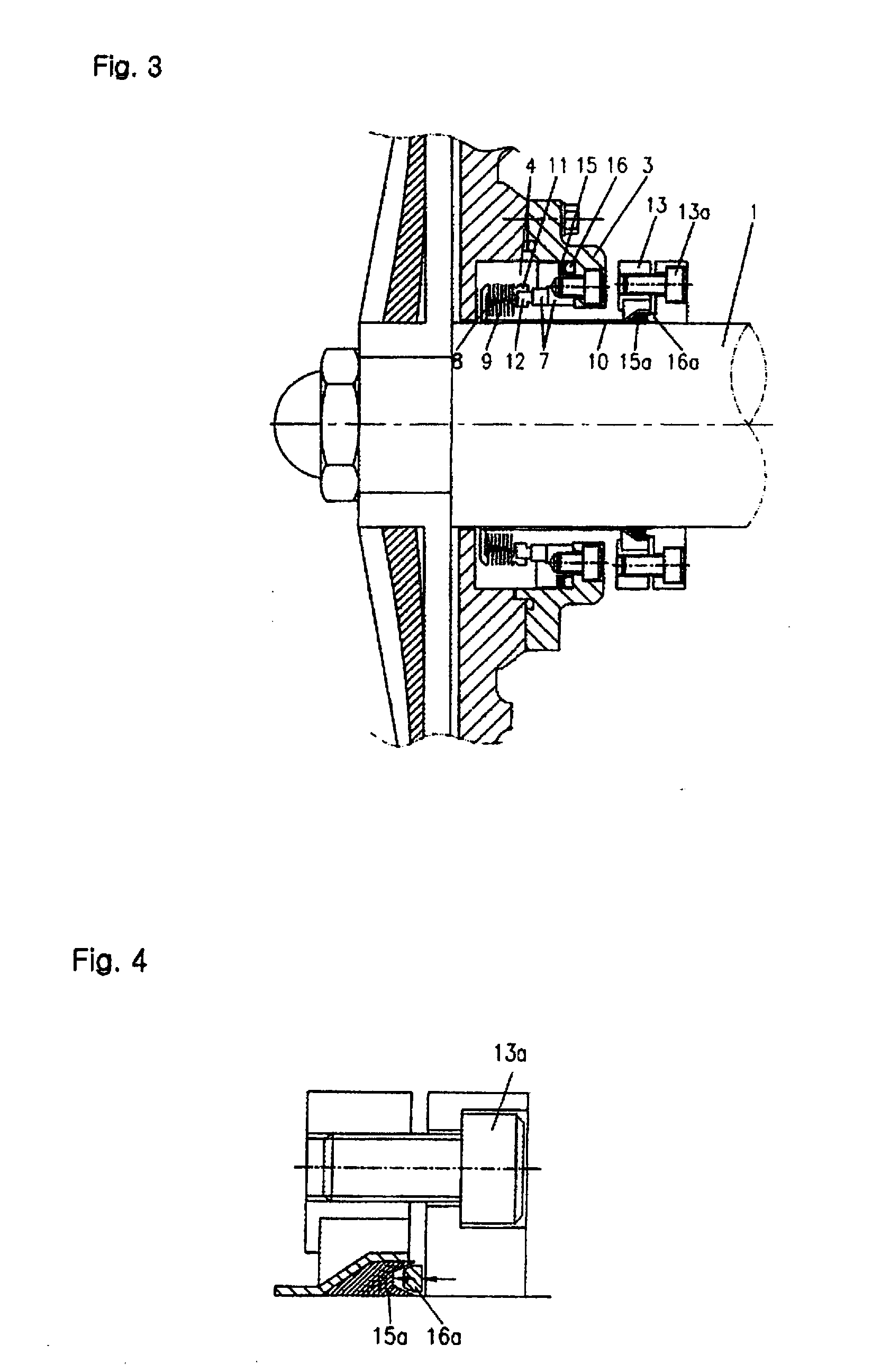

Compact mechanical seal

A mechanical seal having a compact structure is disclosed. The mechanical seal includes a stationary seal part fitted around a rotary shaft such that the stationary seal part is maintained in a stationary state when the rotary shaft rotates, and a rotary seal part sealably fitted around the rotary shaft such that the rotary seal part is rotated together with the rotary shaft when the rotary shaft rotates. The rotary seal part has an annular rotary seal face being in close contact with a stationary seal face of the stationary seal part in a state of being elastically pressed against each other during the rotation of the rotary shaft. The rotary seal part does not frictionally contact with the rotary shaft, so that it is not worn. Accordingly, the mechanical seal can be reliably used for a prolonged period of time.

Owner:KIM HAN SIK

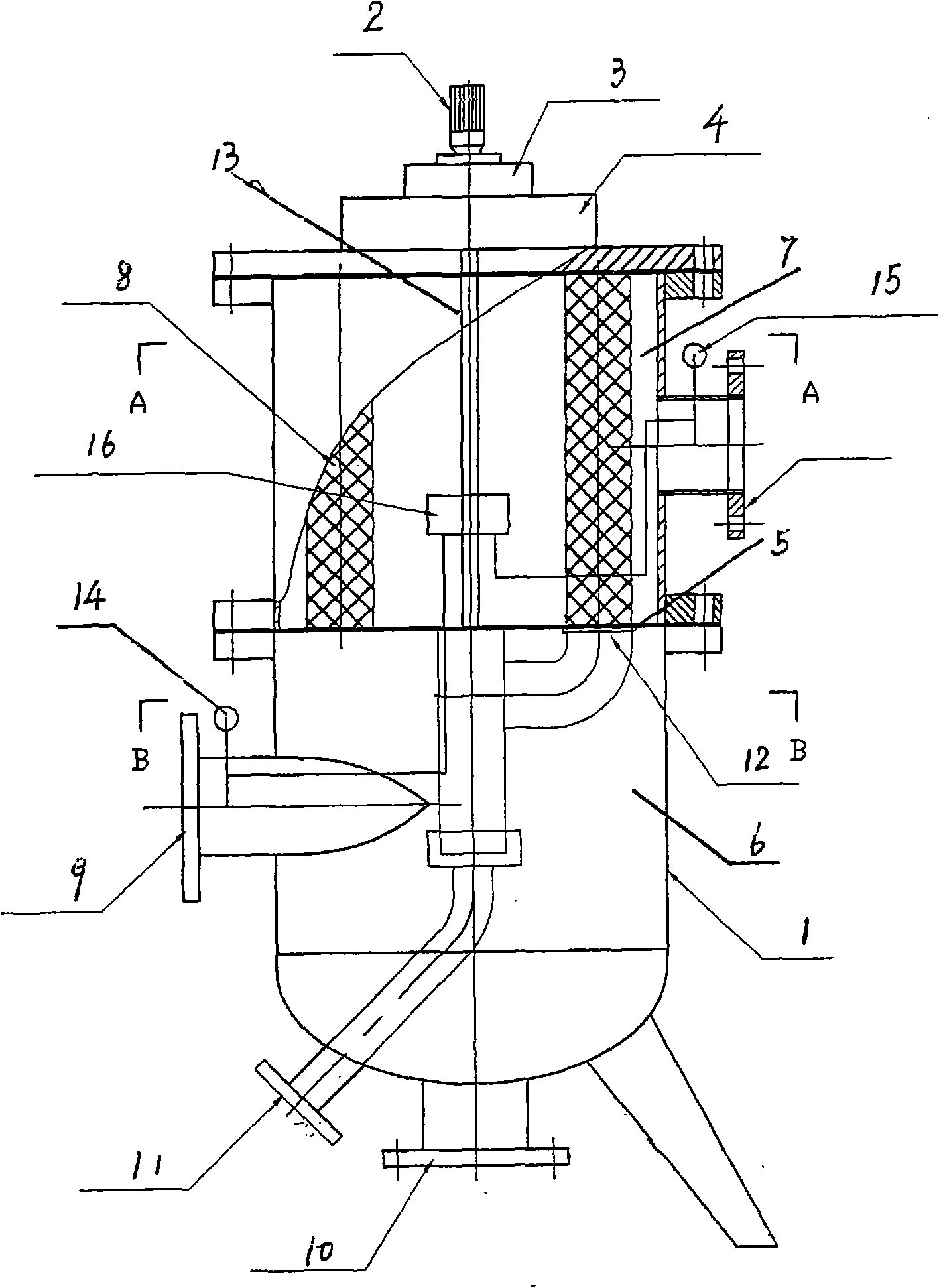

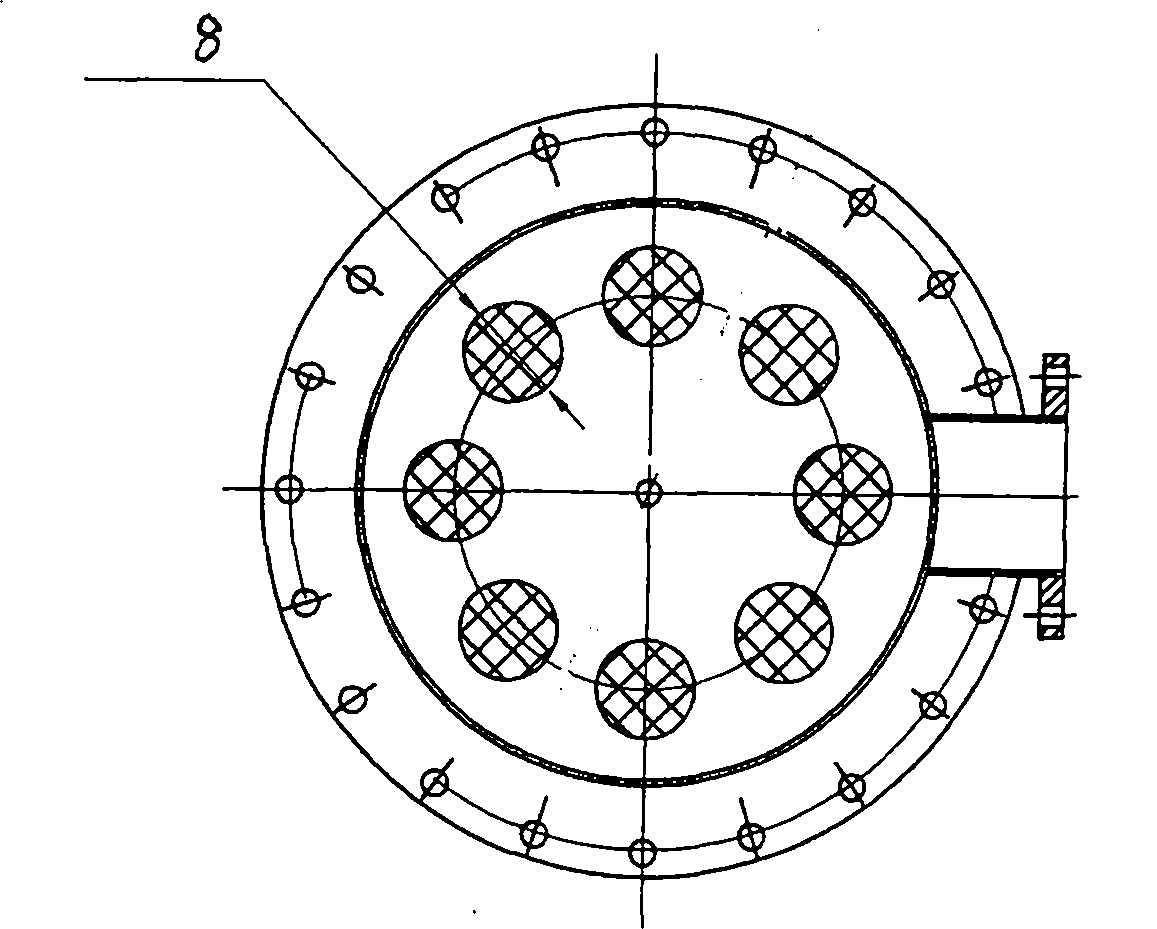

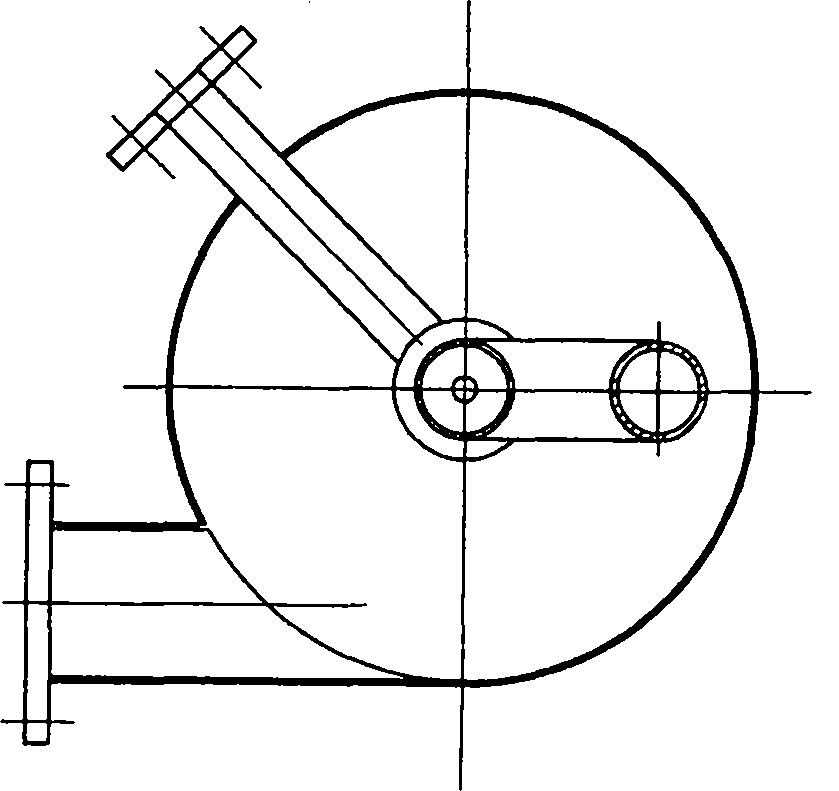

Differential-pressure swirl-type backwashing filtration system

InactiveCN102107100ANot easy to bruiseExtend your lifeStationary filtering element filtersFiltrationDrive shaft

A differential-pressure swirl-type backwashing filtration system. An indexing mechanism and a transmission mechanism are disposed on the top of a filter cylinder body; the internal cylinder body is divided into a water-inlet chamber and a water-outlet chamber by a clapboard; eight filter cores are disposed in the water-outlet chamber and are distributed uniformly and circumferentially; a water inlet is disposed along a tangent of the cylinder wall of the water-outlet chamber; a sewage draining exit and a dirt discharging exit are disposed in the water-inlet chamber; a sucking disc is disposed between the dirt discharging exit and the clapboard, and is driven to rotate by a transmission shaft of the transmission mechanism. The device adopts eight groups of filter core structures, and by using the hydrodynamics principle, the device has the advantages of less no-load pressure loss, less backwashing water consumption, good filtering effect, compact structure, and reliable operation, and can perform backwashing under low differential pressure.

Owner:天津富斯特环保设备有限公司

Piston ring and surface spongy tin plating technique thereof

The invention relates to a piston ring and a surface spongy tin plating technique thereof. The technical scheme thereof is as follows: the surface of a piston ring body is provided with a chromium plating layer, the outer surface of the chromium plating layer is provided with a spongy reticulate pattern, and the outer surface of the spongy reticulate pattern is provided with a tin plating layer. The invention comprises the following procedures: preplating, etching, chromium plating, washing, removal of hydrogen, hole loosing, washing and drying and tin plating treatment. The invention utilizes a reticulate pattern groove on the surface of the piston ring to store lubricating oil, thus greatly reducing the friction coefficient between the piston ring and a cylinder sleeve, improving oil absorbing property, and prolonging the service life of the piston ring and the cylinder sleeve; and compared with the prior art, the invention prolongs the service life of the piston ring and the cylinder sleeve by more than three thousand hours, improves the power of an internal combustion engine by more than 30 percent, saves oil by 25 percent, is capable of reducing the exhaust amount of gas / smoke of the internal combustion engine, reduces the environment requirements of atmosphere pollution, solves the mechanical wear of the piston ring during running-in period and obtains more perfect use performances.

Owner:XIANGFAN XINLI HENGXING PISTON RINGS

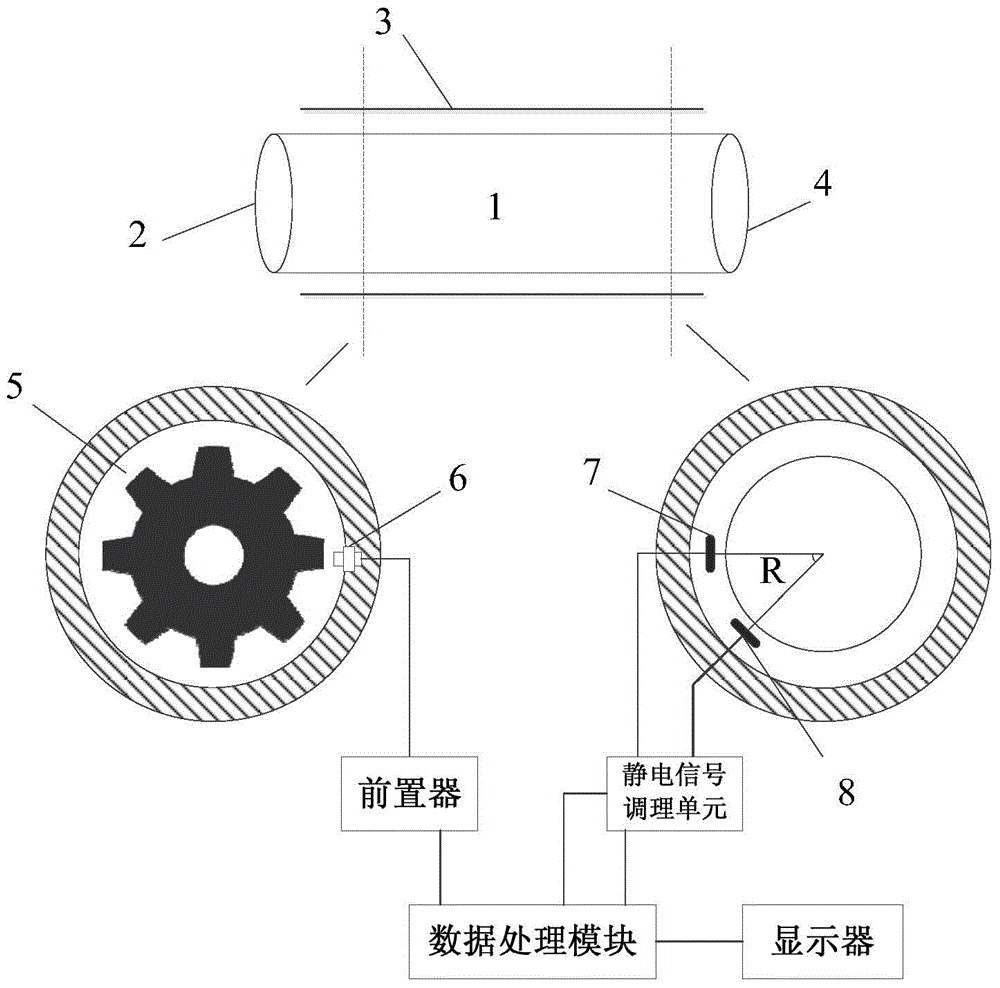

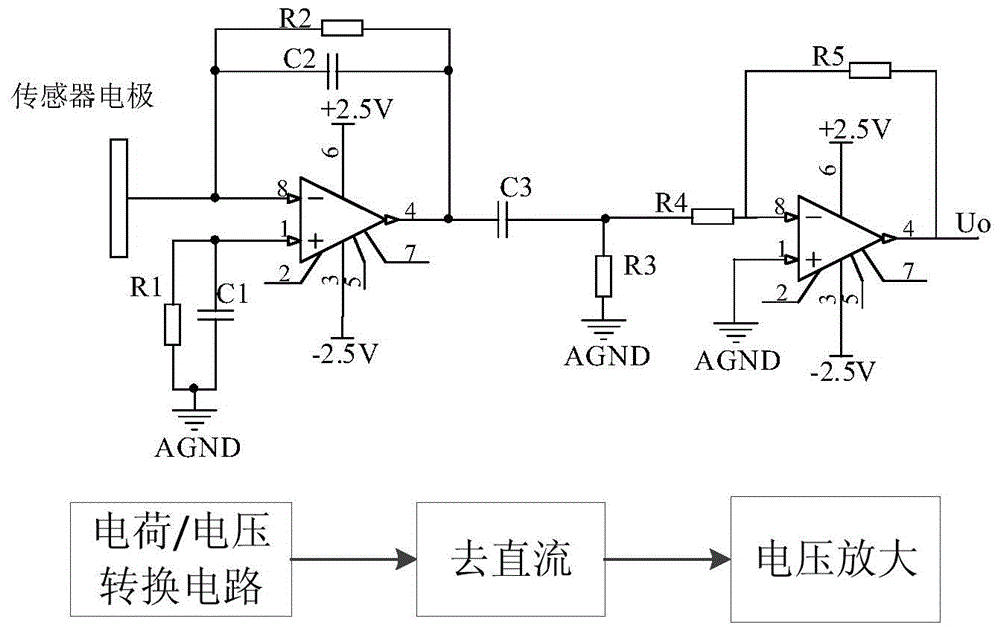

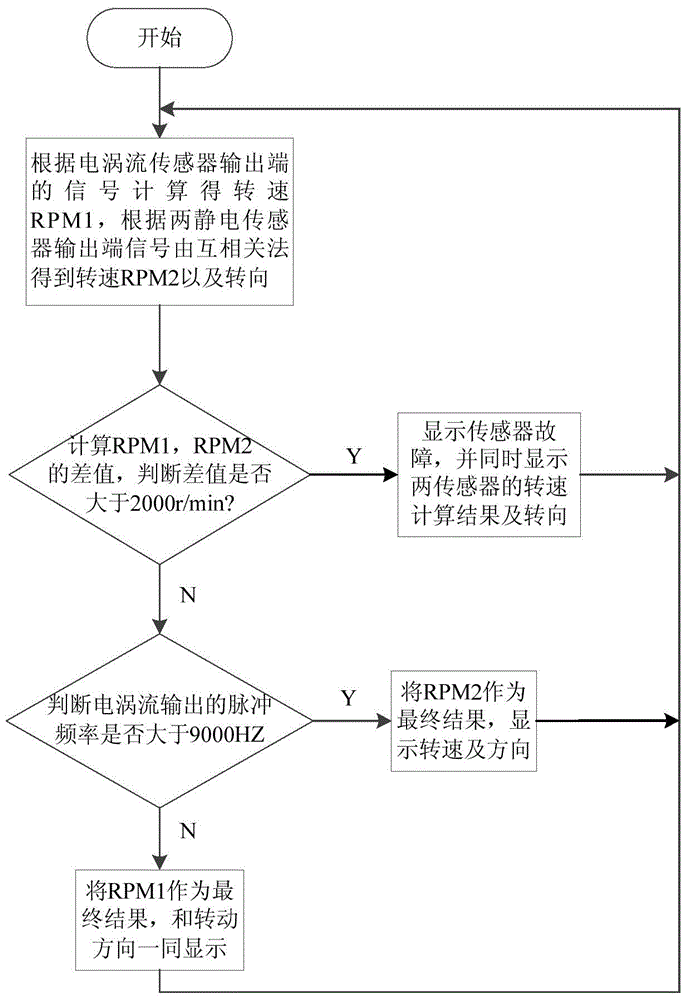

Device and method for measuring rotating speed of large rotating equipment

InactiveCN104459187AAvoid mechanical wearReduce weightDevices using electric/magnetic meansVoltageEddy-current sensor

The invention discloses a device and method for measuring the rotating speed of large rotating equipment. Integrated electrostatic sensors and an eddy current sensor are adopted for measuring the rotating speed, wherein the eddy current sensor is used for sensing the rotating movement of a speed measuring gear and outputting a voltage signal, and the integrated electrostatic sensors are used for sensing an electric charge signal generated by friction between the surface of a rotating object and the air and converting the electric charge signal into a voltage signal; the two types of signals are output to a data processing module, preliminary rotating speed calculation, sensor fault judgment and rotating speed range judgment are carried out on the signals, and the accurate rotating speed of the rotating object to be detected is obtained finally and displayed on a displayer. According to the device and method, non-contact measurement is adopted, the advantage of high accuracy of measuring a high rotating speed through an electrostatic method and the advantage of high accuracy of measuring a low rotating speed through the eddy current sensor are integrated, the rotating speed can be reliably and stably measured no matter whether the large rotating equipment operates at a zero rotating speed or a low rotating speed or a high rotating speed, and meanwhile the rotating direction of a rotating shaft can be obtained and displayed.

Owner:XI AN JIAOTONG UNIV

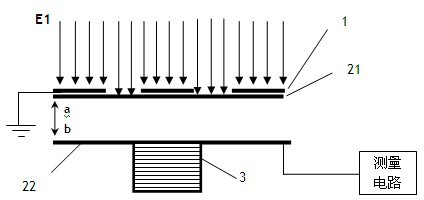

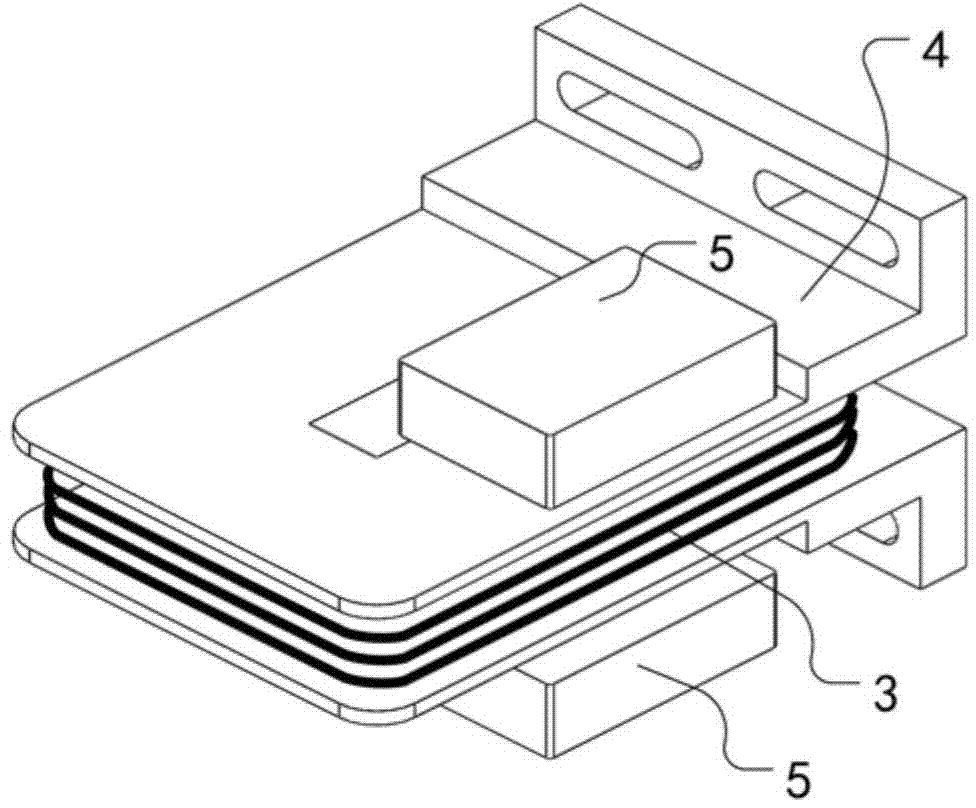

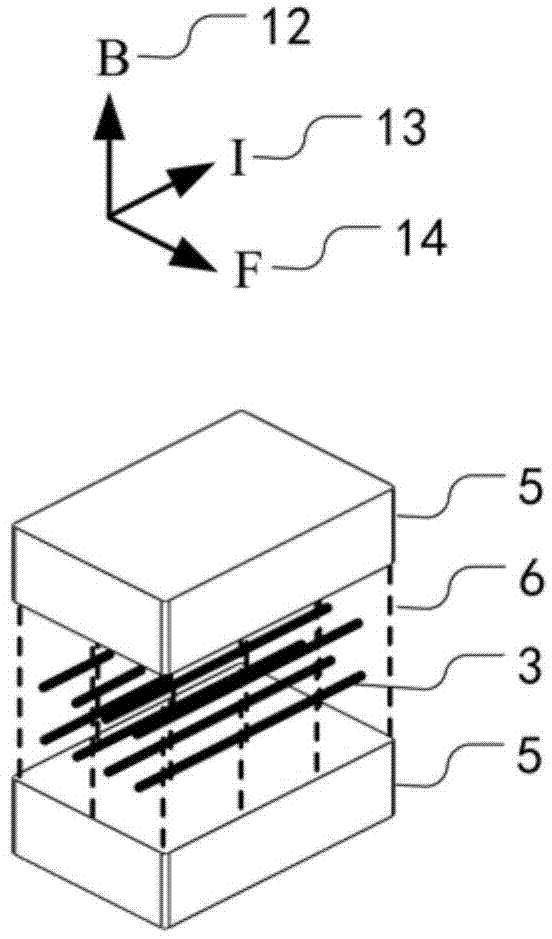

Rectilinear vibration modulation minitype electrostatic field sensor

InactiveCN102323490AEasy to measureSmall sizeElectrostatic field measurementsMechanical engineeringMechanical abrasion

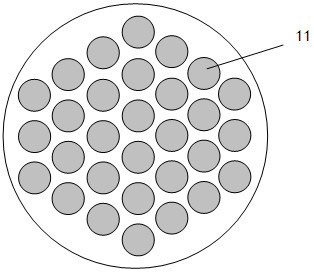

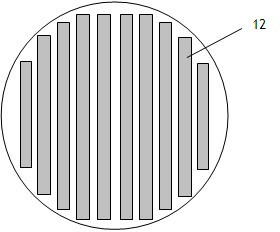

The invention provides a rectilinear vibration modulation minitype electrostatic field sensor, which aims to solve the problem of mechanical abrasion of a field grinding type electric field instrument. The rectilinear vibration modulation minitype electrostatic field sensor comprises a shielding electrode, an induction electrode, a piezoelectric stack, a piezoelectric stack mounting plate, a position adjustment thread and a mounting base, wherein the shielding electrode is arranged on the mounting base and is grounded; the induction electrode is arranged parallel to the shielding electrode; the lower part of the induction electrode is connected with the piezoelectric stack; the piezoelectric stack is fixed on the piezoelectric stack mounting plate; the piezoelectric stack mounting plate is connected with the mounting base through the position adjustment thread; and a plurality of circular holes or a plurality of elongated slot-shaped slits are formed in the shielding electrode.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

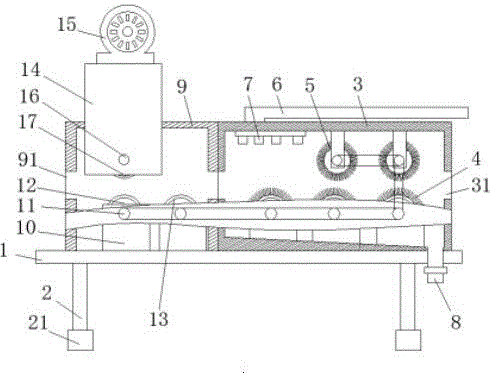

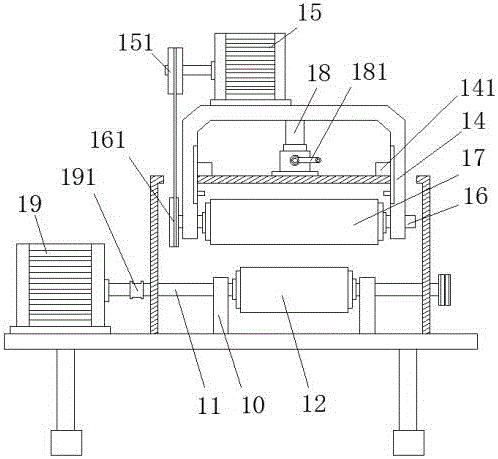

Scrubbing device for tinned steel strips

PendingCN106733773AImprove stabilityFast transmissionCleaning using toolsCleaning using liquidsTinningEngineering

The invention discloses a scrubbing device for tinned steel strips. The scrubbing device comprises a supporting table, a cleaning box, a dustproof box, a first motor and a second motor, the top of the supporting table is fixedly connected with the cleaning box and the dustproof box from right to left, and three sets of lower brush rolls arranged at intervals are fixedly connected to the bottom of an inner cavity of the cleaning box. The distance between an upper conveying roller and a lower conveying roller can be adjusted, and the conveying distances required by stable conveying of the tinned steel strips of different sizes can be achieved; the upper conveying roller and the lower conveying roller can rotate reversely, so that the tinned steel strip are conveyed in an extruded mode, the overall stability and the conveying speed during conveying of the tinned steel strips are improved to a great extent, and the scrubbing speed of the tinned steel strips is increased to a great extent; and accordingly, the tinned steel strips can be smoothly and quickly scrubbed, and the scrubbing effect of the tinned steel strips is good.

Owner:WUXI DONGHE METAL PROD

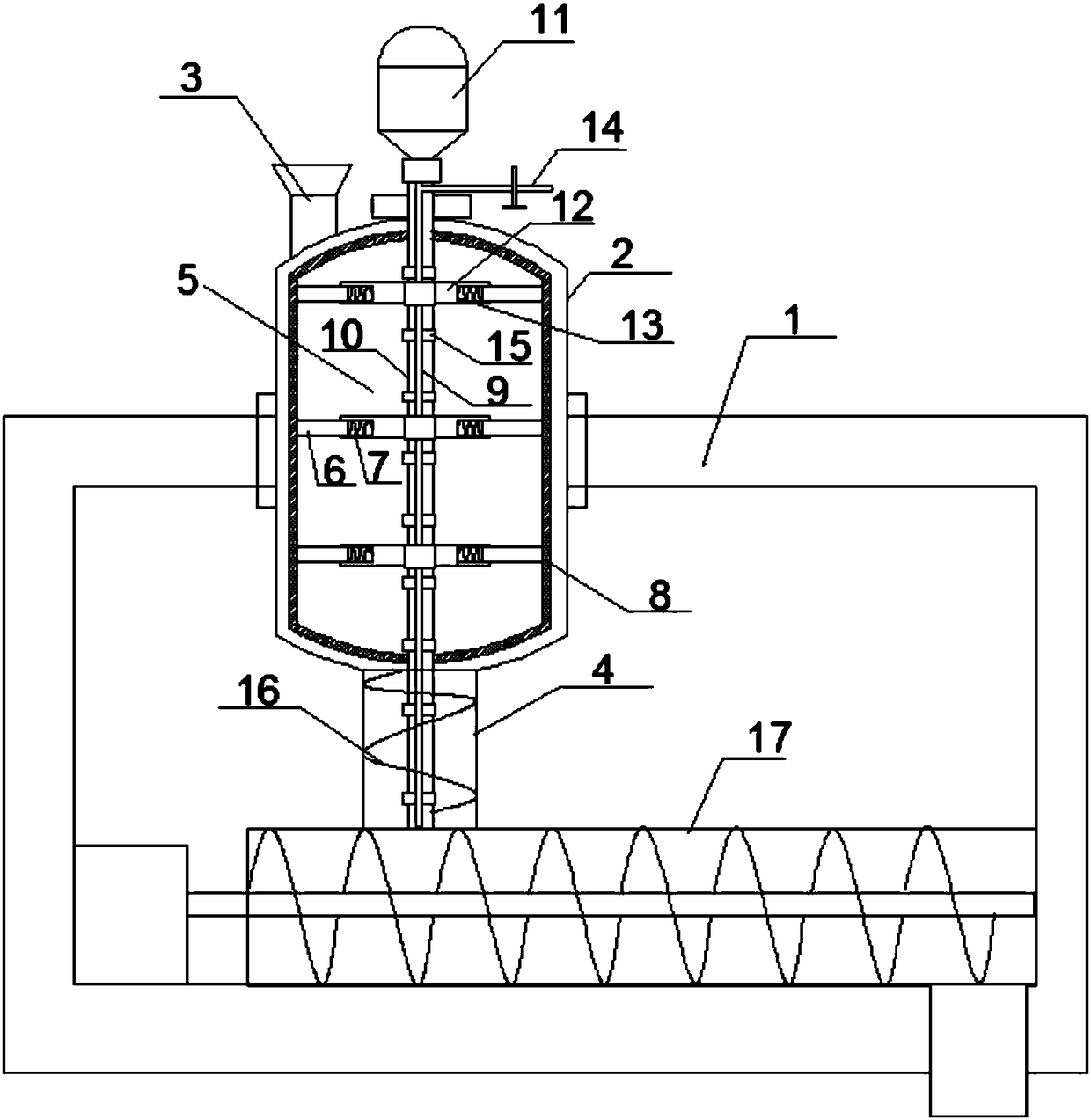

Novel stirrer with cleaning function

InactiveCN108202412AAvoid mechanical wearExtend your lifeDischarging apparatusTransportation and packagingSpray nozzleEngineering

The invention discloses a novel stirrer with a cleaning function. The novel stirrer comprises a support, a casing, a feeding opening, a discharging opening, a stirring device, connecting rods, springsand a scraper, wherein the casing is fixedly connected with the upper part of the support; the feeding opening is formed in the top of the casing; the discharging opening is formed in the bottom of the casing; the stirring device is arranged in the casing; the stirring device comprises a rotating shaft with a hollow structure, a driving device for driving the rotating shaft as well as stirring paddles which are symmetrically arranged on the rotating shaft; connecting slots are respectively formed in two ends of each stirring paddle; each connecting slot is connected with one end of the corresponding connecting rod through the corresponding spring; the other end of each connecting rod is fixedly connected with the scraper; a water inlet pipe communicated with the cavity structure is arranged on the rotating shaft positioned outside the casing; spray nozzles communicated with the cavity structure are uniformly arranged on the rotating shaft, thereby avoiding the problems of mechanical wear, high power consumption and increased cost and prolonging the life of the stirrer.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

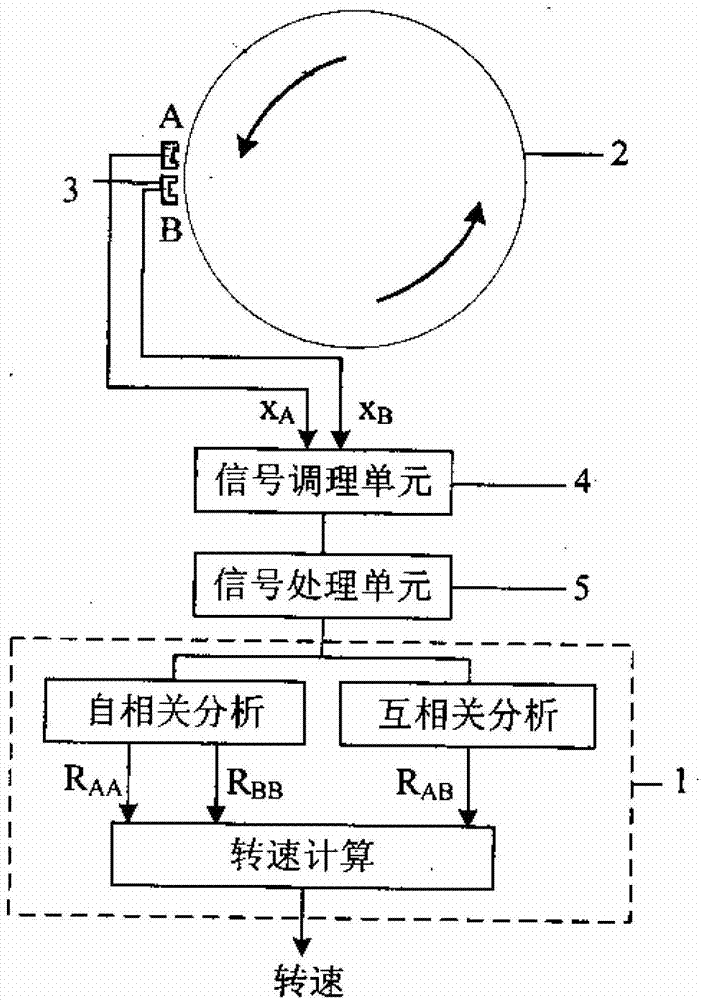

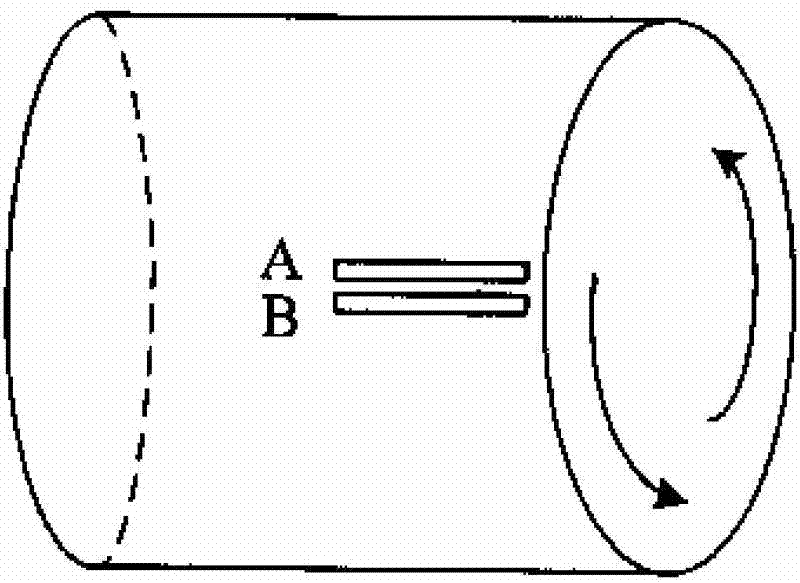

Device and method for measuring rotating speed of rotating object by adopting electrostatic sensor

InactiveCN102854336AReal-time speedReal-time monitoring speedDevices using time traversedPhysicsSignal processing

The invention discloses a device and a method for measuring the rotating speed of a rotating object by adopting an electrostatic sensor. The method is as follows: a single electrostatic sensor electrode or double electrostatic sensor electrodes is / are arranged near a detected rotating part, and is / are used for sensing the rotation information of the rotating object at the position where the electrodes are positioned, the electrode of the electrostatic sensor is connected to a microprocessor in series via a single signal conditioning unit and a signal processing unit, electrostatic signals are amplified and filtered through the conditioning unit and are sent to the microprocessor through the signal processing unit, and relevant analytical calculation is carried out on the electrostatic signals through the microprocessor so as to obtain the rotating speed of the detected rotating object finally. Compared with the conventional rotating speed measuring device, the device is simple in structure, extremely low in cost and convenient to install, is not limited by the size dimension of a detected part and not easy to influence by environmental factors, belongs to noncontact measurement and has relatively high accuracy.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High-precision vibration slicing machine

ActiveCN104729874ASimple structureImprove performanceWithdrawing sample devicesElectricitySingle degree of freedom

The invention relates to a high-precision vibration slicing machine. The machine comprises a base, a single-degree-of-freedom vibration structure, an electromagnetic driving structure, a blade adjusting rack and a blade, wherein the single-degree-of-freedom vibration structure comprises two thin-piece-shaped spring steel plates and a vibration end; one ends of the two thin-piece-shaped spring steel plates are respectively fixed to two ends of the base, while the other ends of the two thin-piece-shaped spring steel plates are connected through the vibration end, so as to achieve single-degree-of-freedom vibration; two permanent magnets of the electromagnetic driving structure are fixed on the vibration end; a coil framework of the electromagnetic driving structure is fixed on the base; an elastic structure body of the blade adjusting rack is fixed on the vibration end; the blade is fixed on the blade adjusting rack; the angle of the blade can be precisely adjusted through the blade adjusting rack. The machine is simple in structure; the Z-direction zero of the blade in vibration can be effectively controlled, so that the vibrating slicing precision can be improved, and the damage to the sample structure during slicing can be reduced.

Owner:WUHAN OE BIO CO LTD

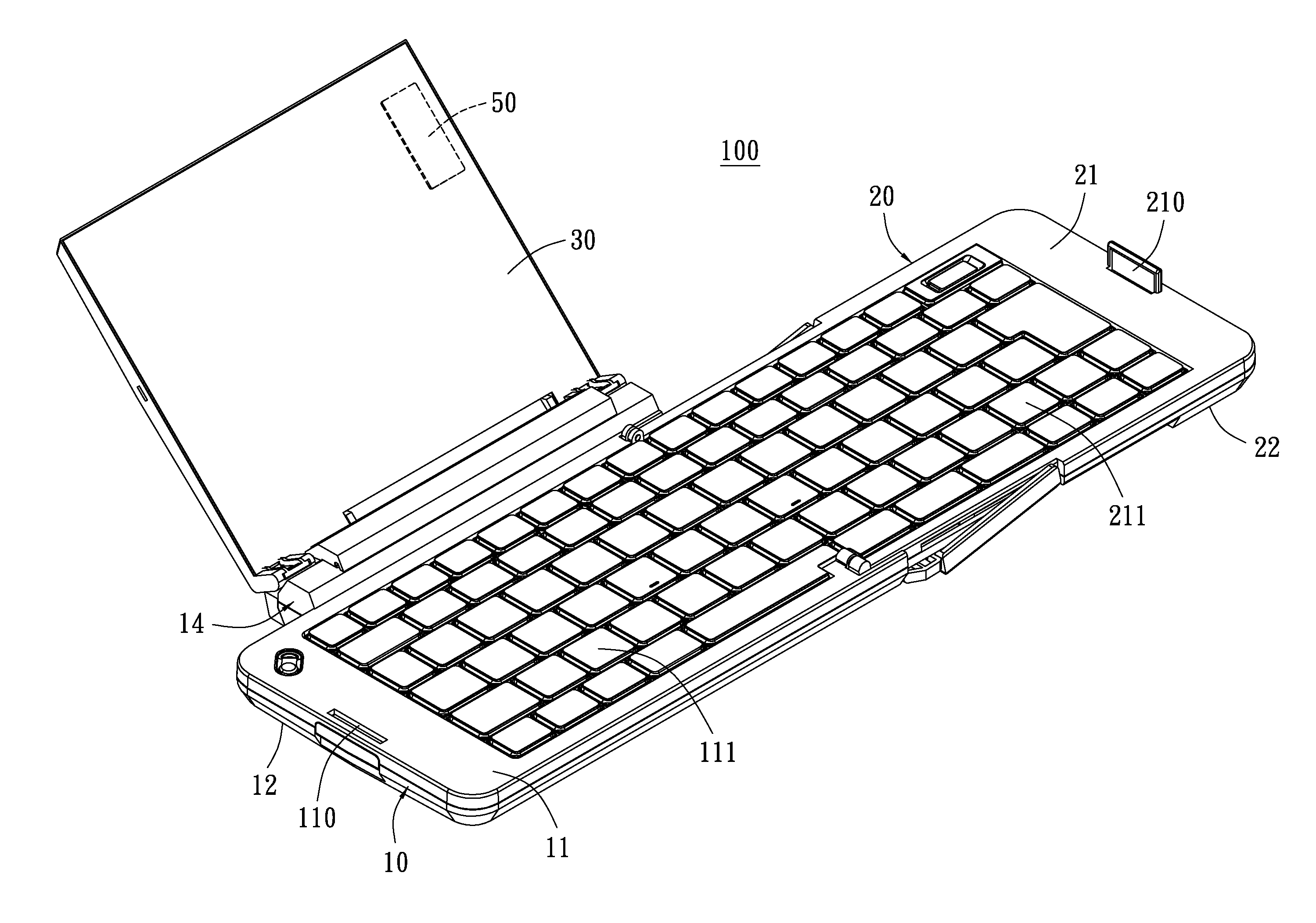

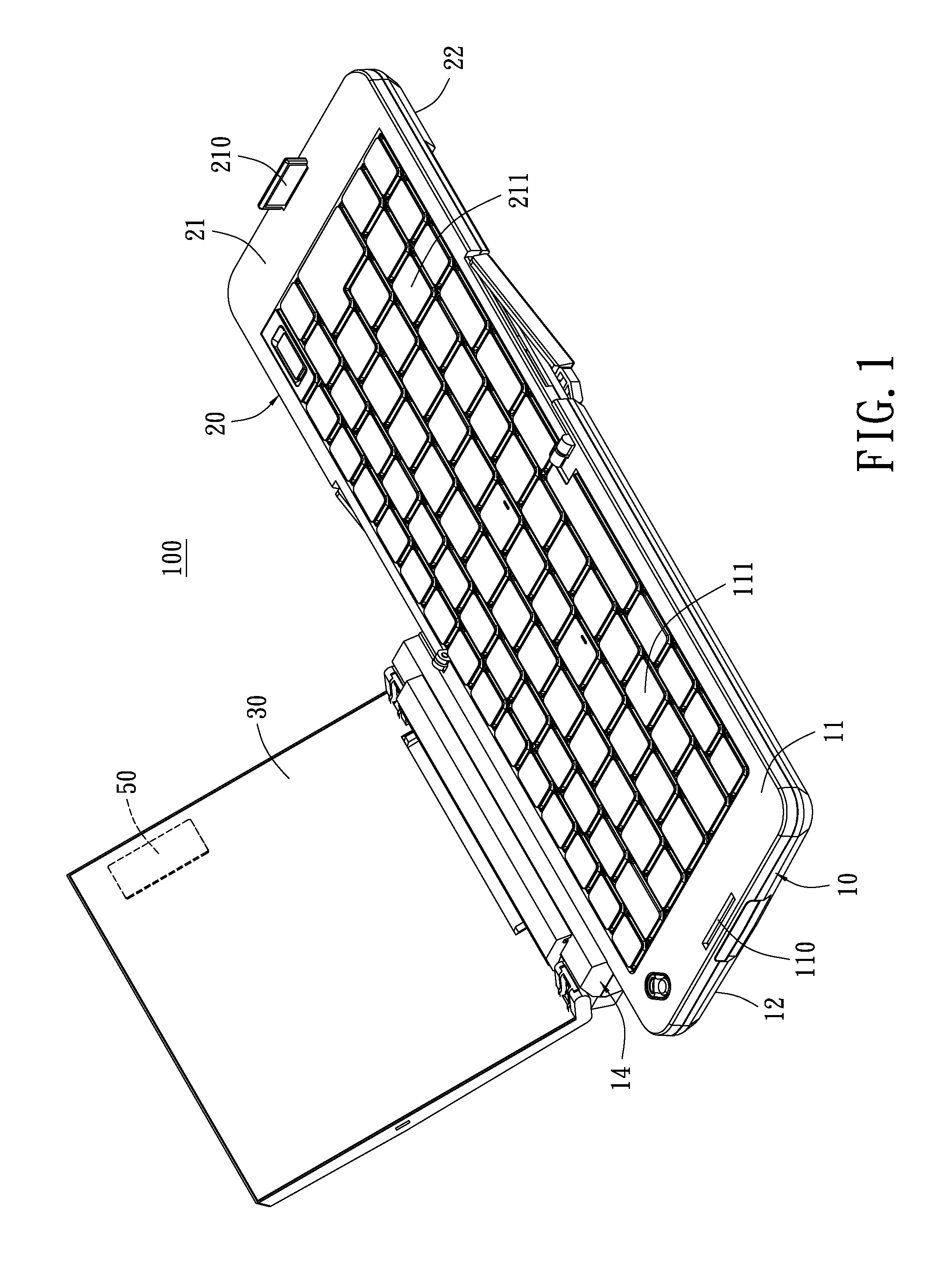

Foldable keyboard

ActiveUS20140055936A1Avoid fracturesKeep for a long timeDigital data processing detailsElectrical apparatus contructional detailsSoftware engineeringEngineering

A foldable keyboard includes a first input module, a second input module, a folding support member, a magnetic element and a ferromagnetic element. The magnetic element and the ferromagnetic element put on the second input module and the folding support member separately that the folding support member can close with the second input module. Using magnetic element avoid wearing away by traditional fastener and reducing the complexity of production.

Owner:DEXIN

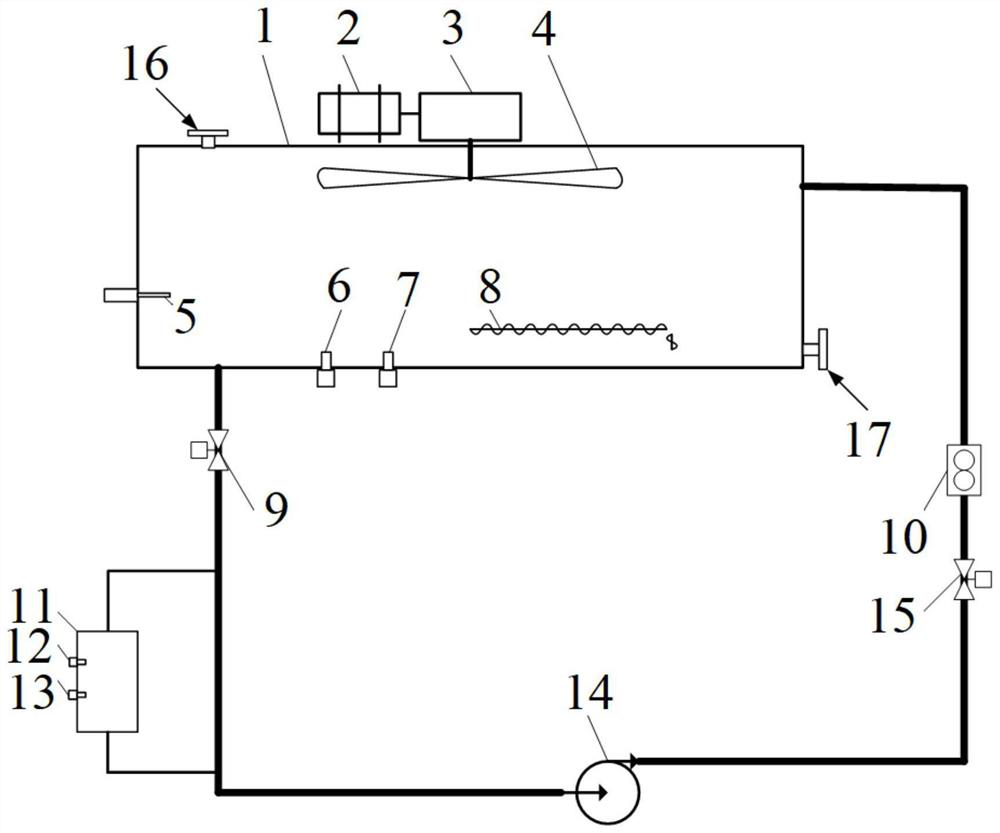

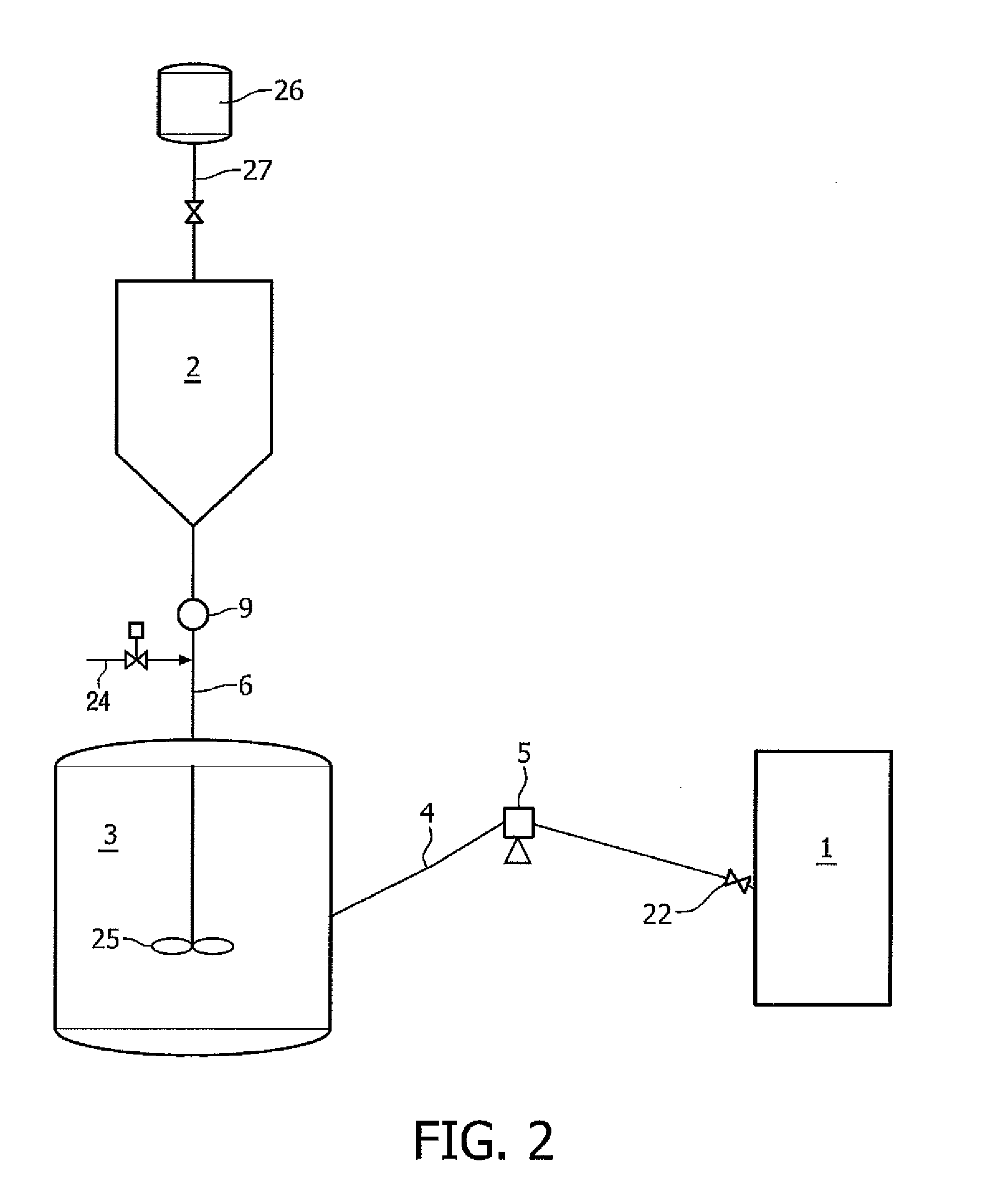

Test device for simulating lubricating oil quality faults on line and using method thereof

PendingCN112505303AAvoid mechanical wearTimely maintenanceMaterial testing goodsOil canOil viscosity

The invention discloses a test device for simulating lubricating oil quality faults on line and a using method thereof. The test device comprises an oil tank, and the oil tank is provided with an oiladding port and an oil discharging port. The test device is characterized in that a stirring blade is arranged in the oil tank, the stirring blade is connected with a driving mechanism, a temperaturesensor, a lubricating oil viscosity sensor, a water content sensor and an electric heating pipe are further arranged in the oil tank, the two ends of the oil tank are communicated through a pipeline,and a first adjustable electric valve, a granularity detection unit, an oil pump, a second adjustable electric valve and a flow meter are connected to the pipeline in series. The test device has the following beneficial effects that the aging and deterioration faults of oil due to long-term work or water mixing can be identified; the failure of the oil tank due to respiration or pipeline sealing can be identified; sudden invasion of metal particles and external pollution particles caused by abrasion of a friction pair can be identified; the system can normally operate for a long time under thecondition of lubricating oil pollution; and complex faults of the lubricating oil can be detected.

Owner:SHANGHAI MARINE EQUIP RES INST

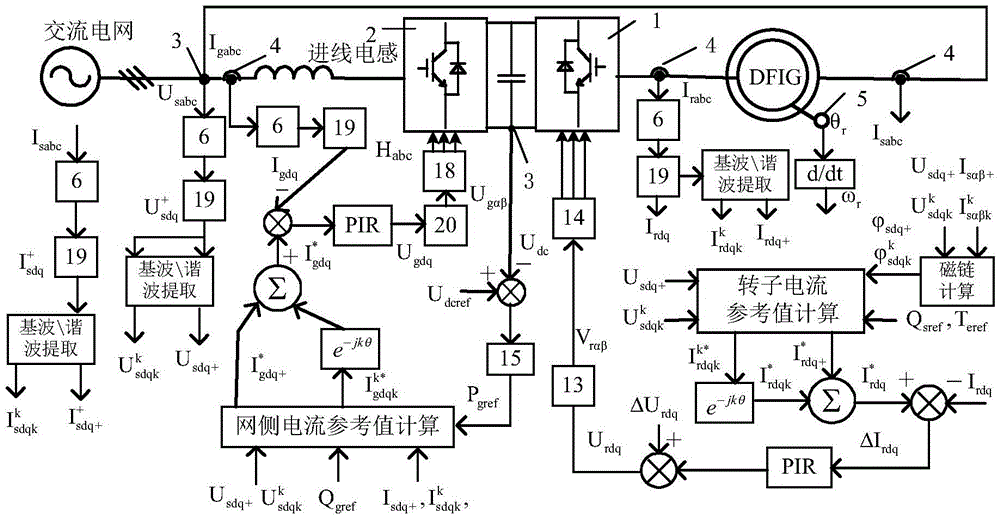

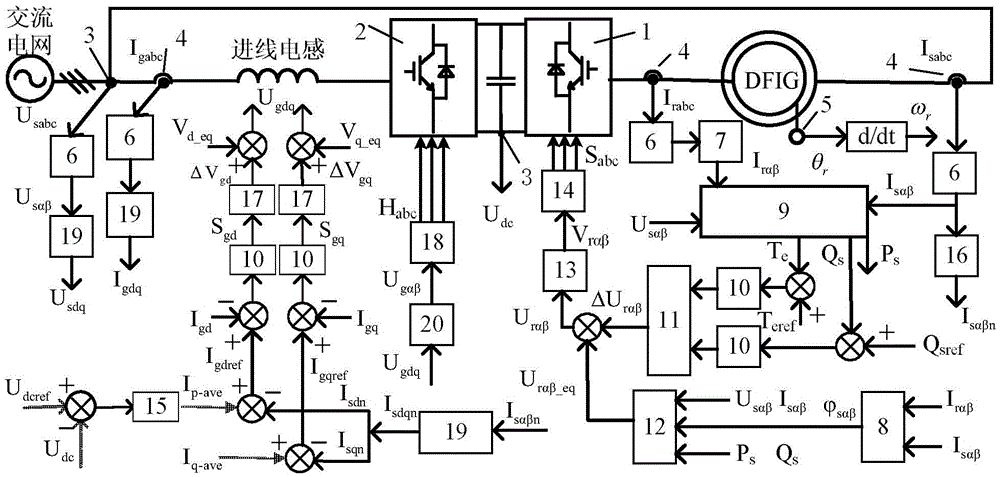

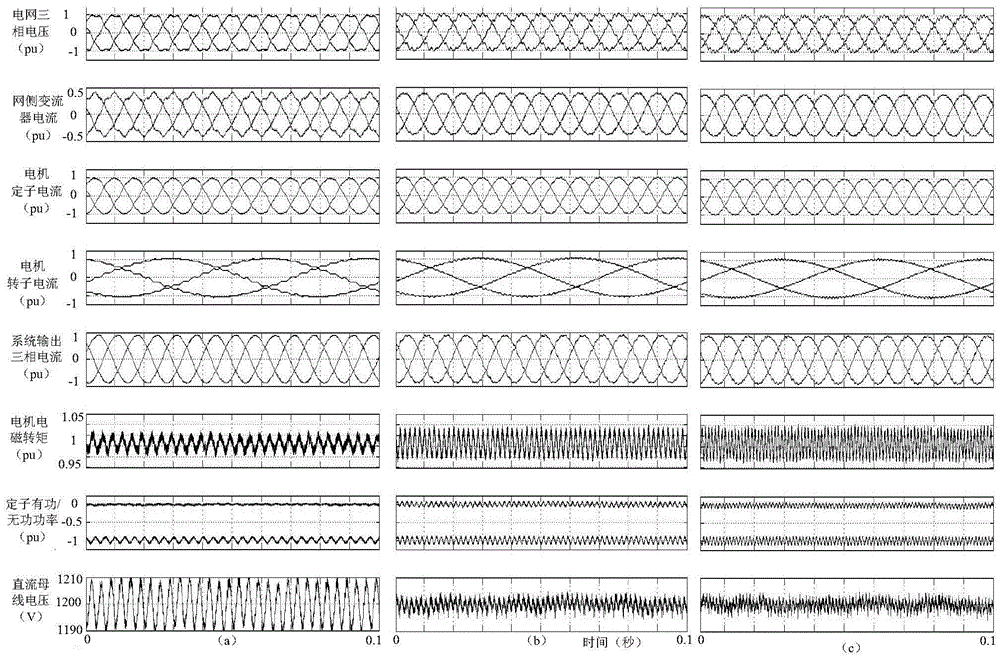

DFIG system control method based on repetition sliding mode

ActiveCN105552951AAvoid mechanical wearGuarantee stabilityElectronic commutation motor controlVector control systemsElectromagnetic torqueProlongation

The invention discloses a DFIG system control method based on a repetition sliding mode. A repetition controller is added to a construction sliding mode face, so the system has the capability in controlling any harmonic wave. Through the method, motor electromagnetic torque ripples caused by power grid voltage harmonic waves and harmonic waves of the output current of the system can be eliminated, and prolongation of the life of the blower fan machinery and wind-electricity grid connected harmonic wave standards can be satisfied. According to the method, extraction for each harmonic component is not required, adding extra resonance controllers is not required, control on any subharmonic wave can be realized, and the method makes the system be applicable.

Owner:HANGZHOU DIANZI UNIV

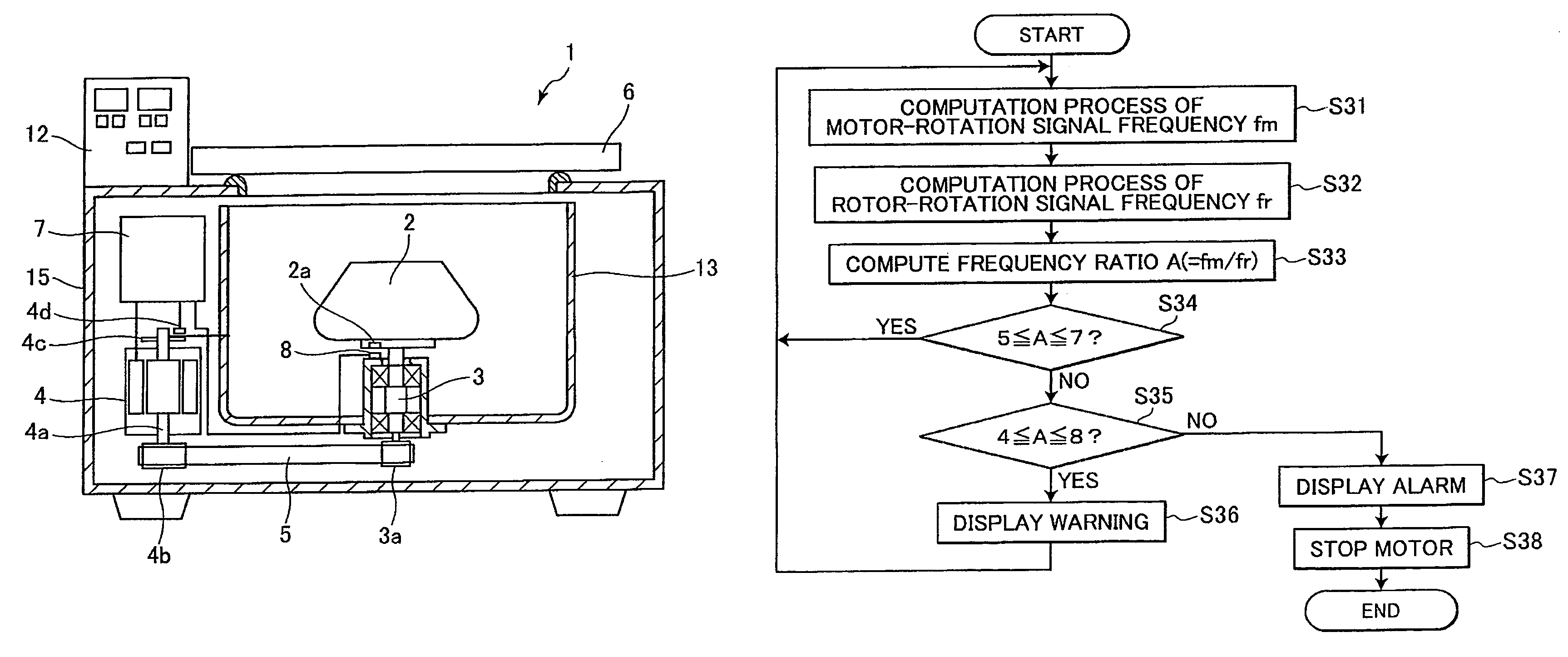

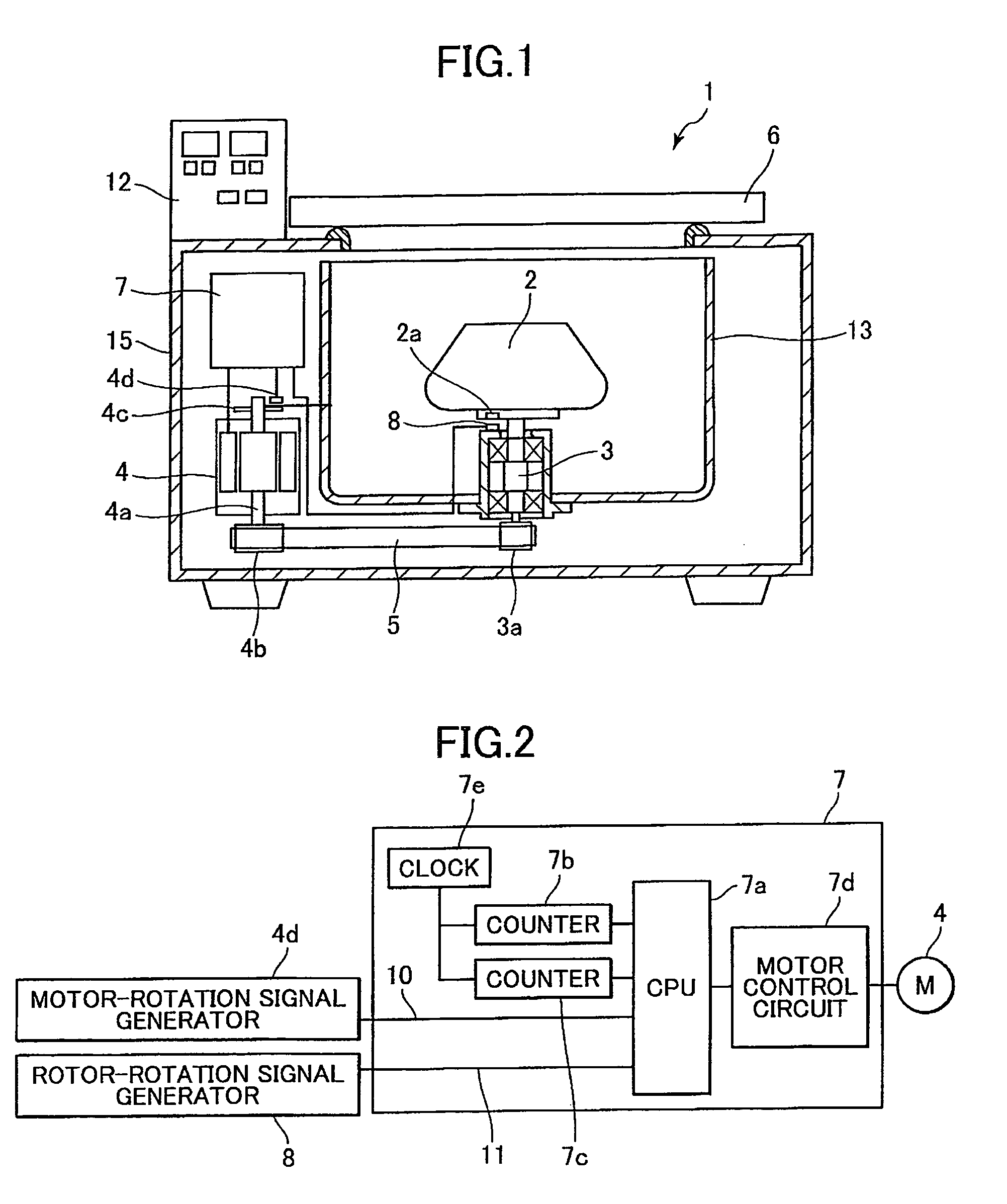

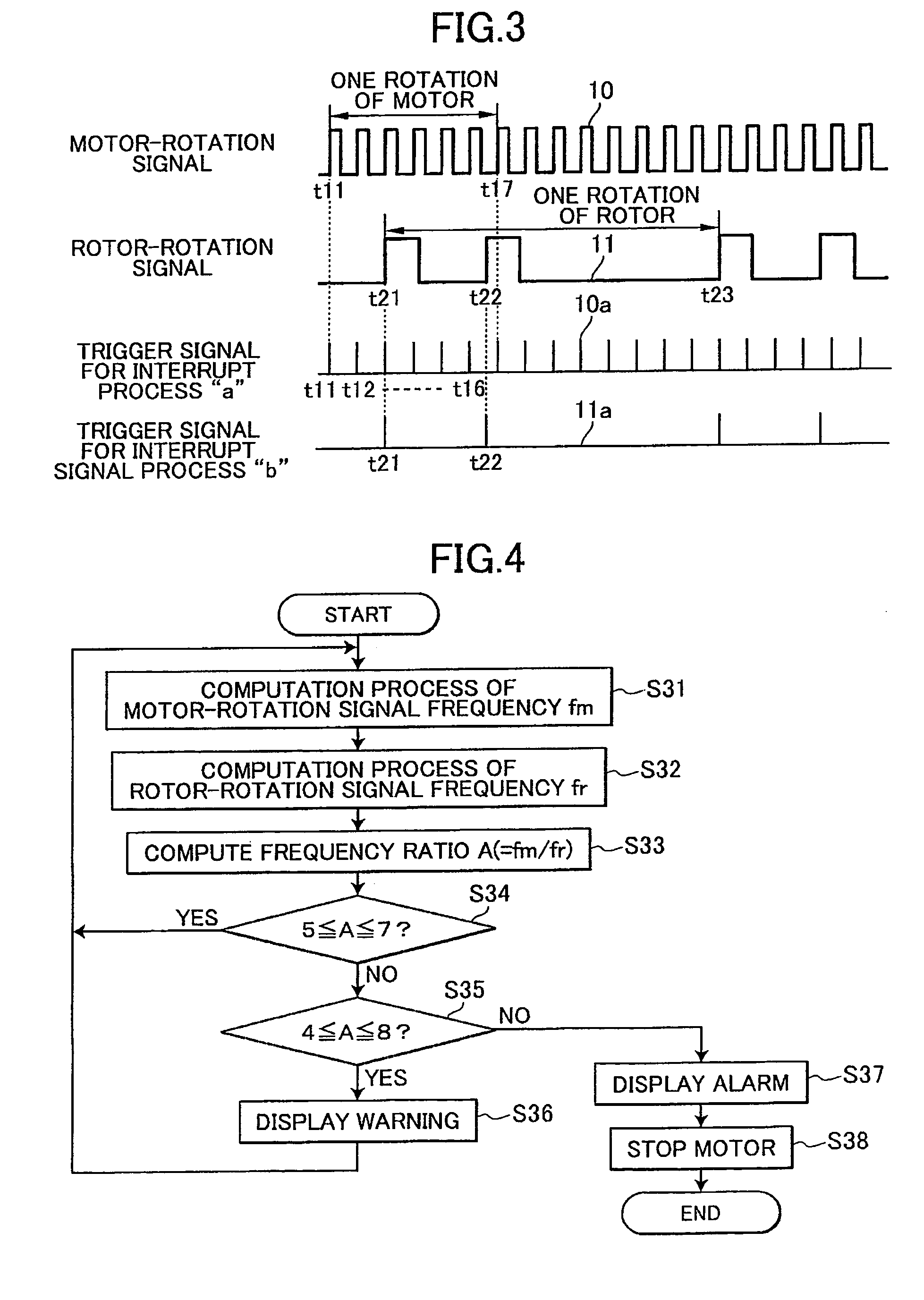

Belt driven centrifugal separator with multi-stage, belt deterioration alerting display

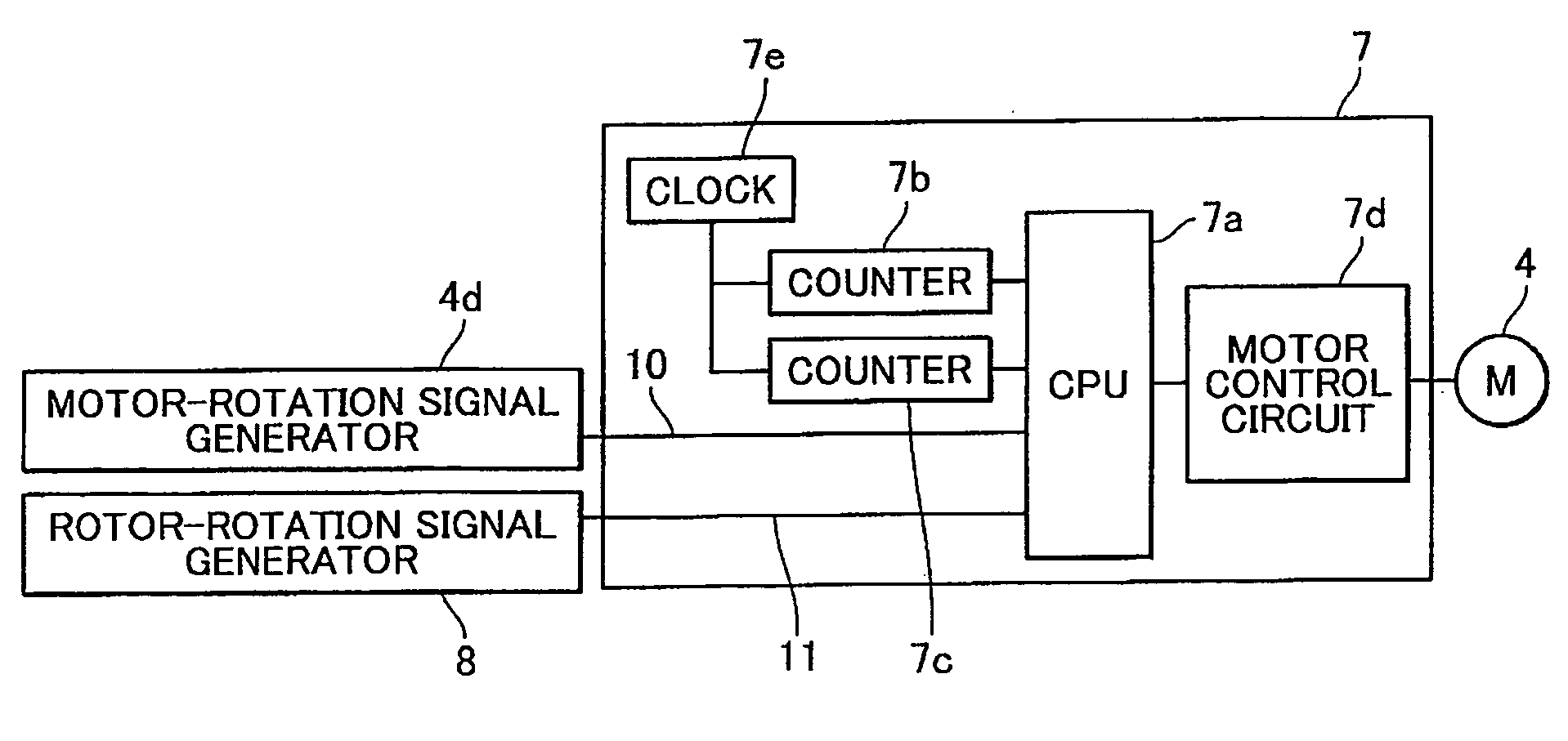

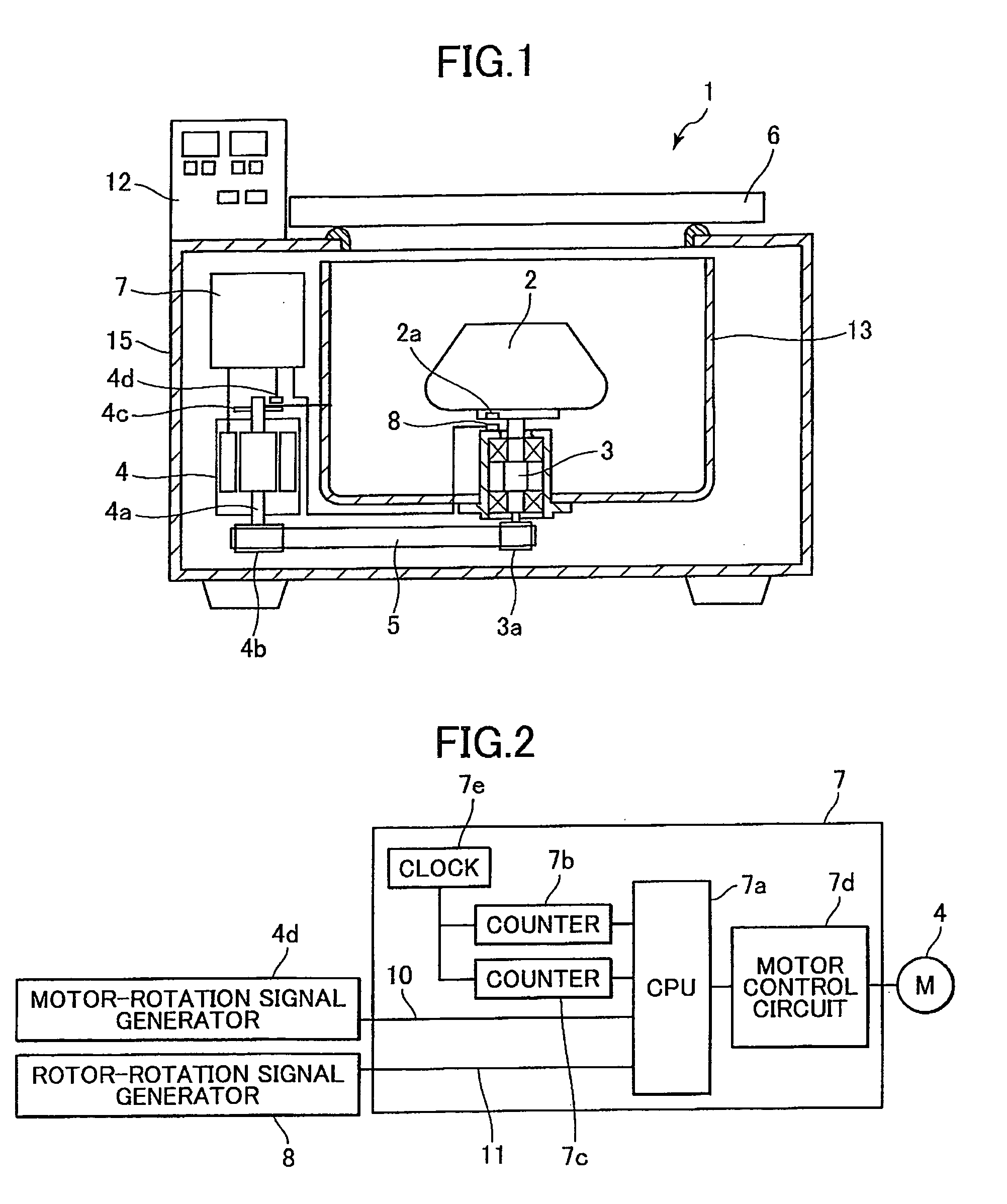

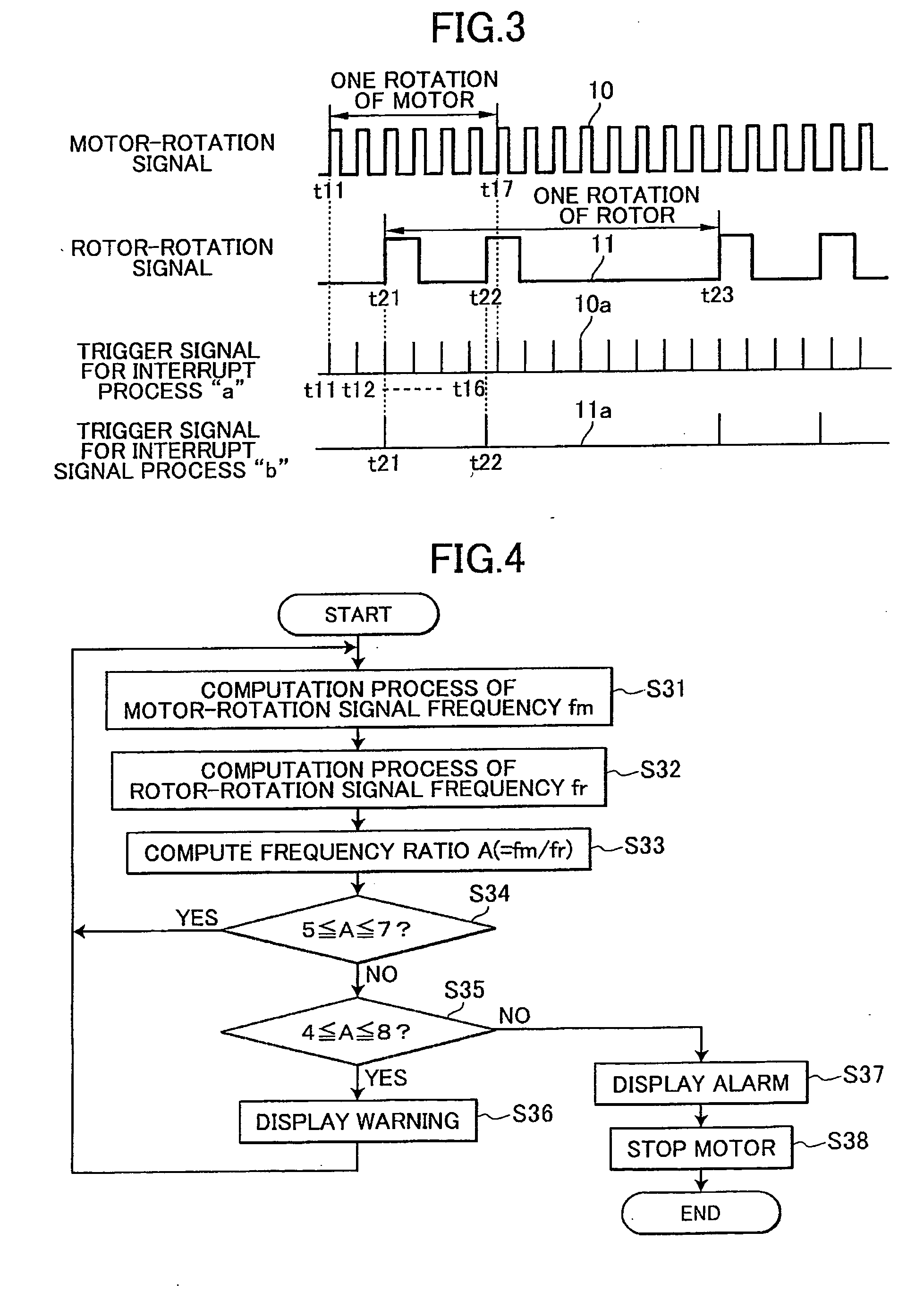

InactiveUS7372219B2Accurate detectionAvoid mechanical wearMotor/generator/converter stoppersDC motor speed/torque controlAlarm messageFrequency ratio

Owner:KOKI HLDG CO LTD

Belt driven centrifugal separator with multi-stage, belt deterioration alerting display

InactiveUS20070075667A1Accurate detectionAvoid mechanical wearMotor/generator/converter stoppersDC motor speed/torque controlAlarm messageFrequency ratio

In a centrifugal separator of the type in which driving power of a motor is transmitted to a rotor via a power transmission mechanism, such as a belt, a motor-rotation signal frequency fm and a rotor-rotation signal frequency fr are computed, on the basis of which a frequency ratio A (fr / fm) is computed. When the frequency ratio A exceeds the upper limit of a first predetermined range, a warning message is displayed to prompt the user to perform maintenance. When the frequency ratio A exceeds the upper limit of a second predetermined range, an alarm message is displayed and the motor is stopped.

Owner:KOKI HLDG CO LTD

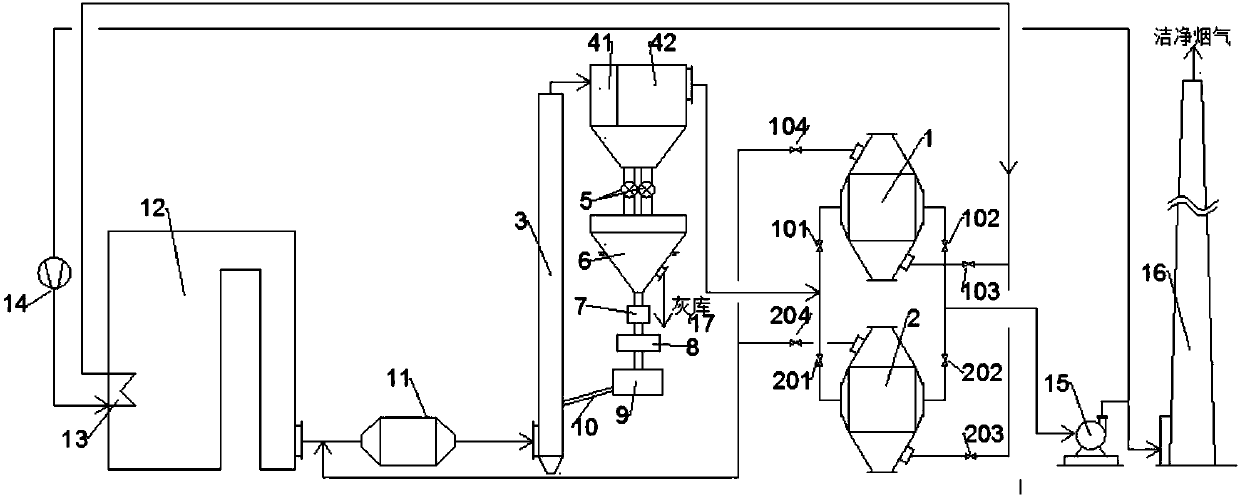

Semi-dry flue gas purification system and method based on carbon material oxidative denitration

PendingCN108014613ANo need to deal withSmall footprintCombination devicesGas treatmentCouplingFlue gas

The invention discloses a semi-dry flue gas purification system and method based on carbon material oxidative denitration. The semi-dry flue gas purification system based on the carbon material oxidative denitration includes a desulfurization reactor, a dust removal unit, a spent absorbent storage, activation and humidification unit, and a denitration reactor; the outlet of the desulfurization reactor and the dust removal unit are connected; the flue gas outlet of the dust removal unit is connected with the denitrification reactor; the outlet of the denitration reactor is connected in turn with an induced draft fan and a chimney; the outlet of a dust hopper of the dust removal unit is connected with the spent absorbent storage, activation and humidification unit. The semi-dry flue gas purification system realizes the coupling of denitrification, desulfurization and dust removal technologies, and has the advantages of compact equipment and small floor area. A semi-dry method is used, water consumption is small, and the final product is solid. Waste water is not needed. The process is simple and can be widely used in the process of industrial flue gas treatment.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

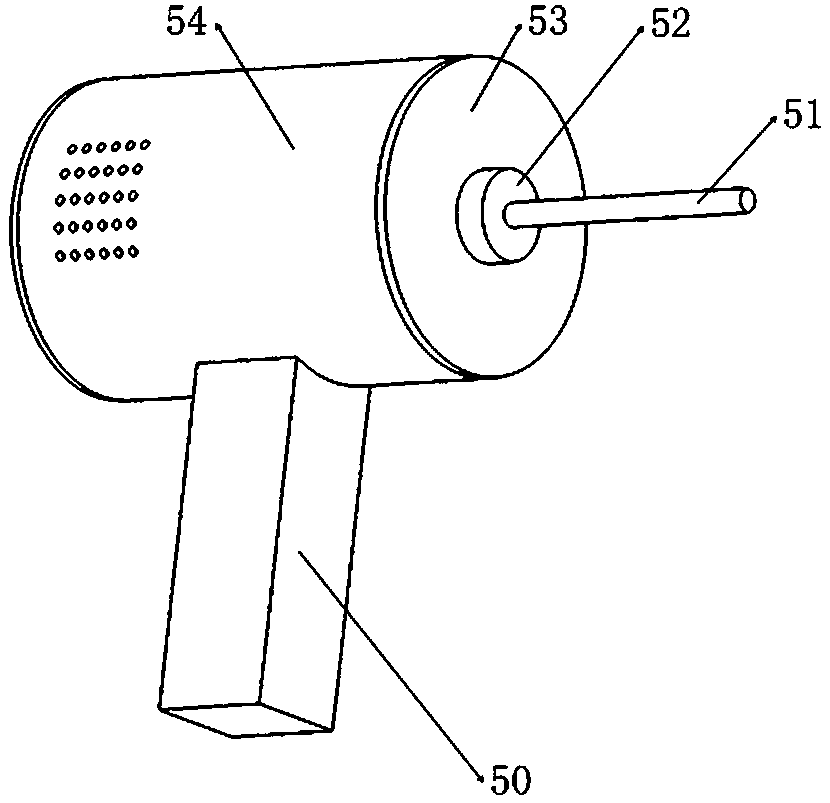

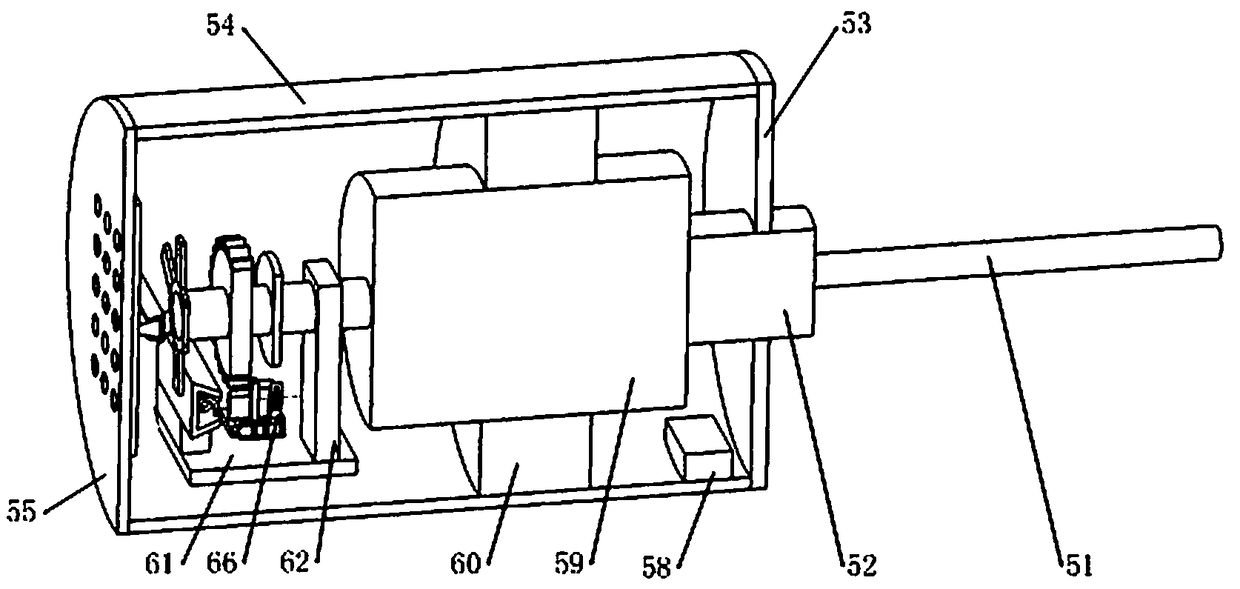

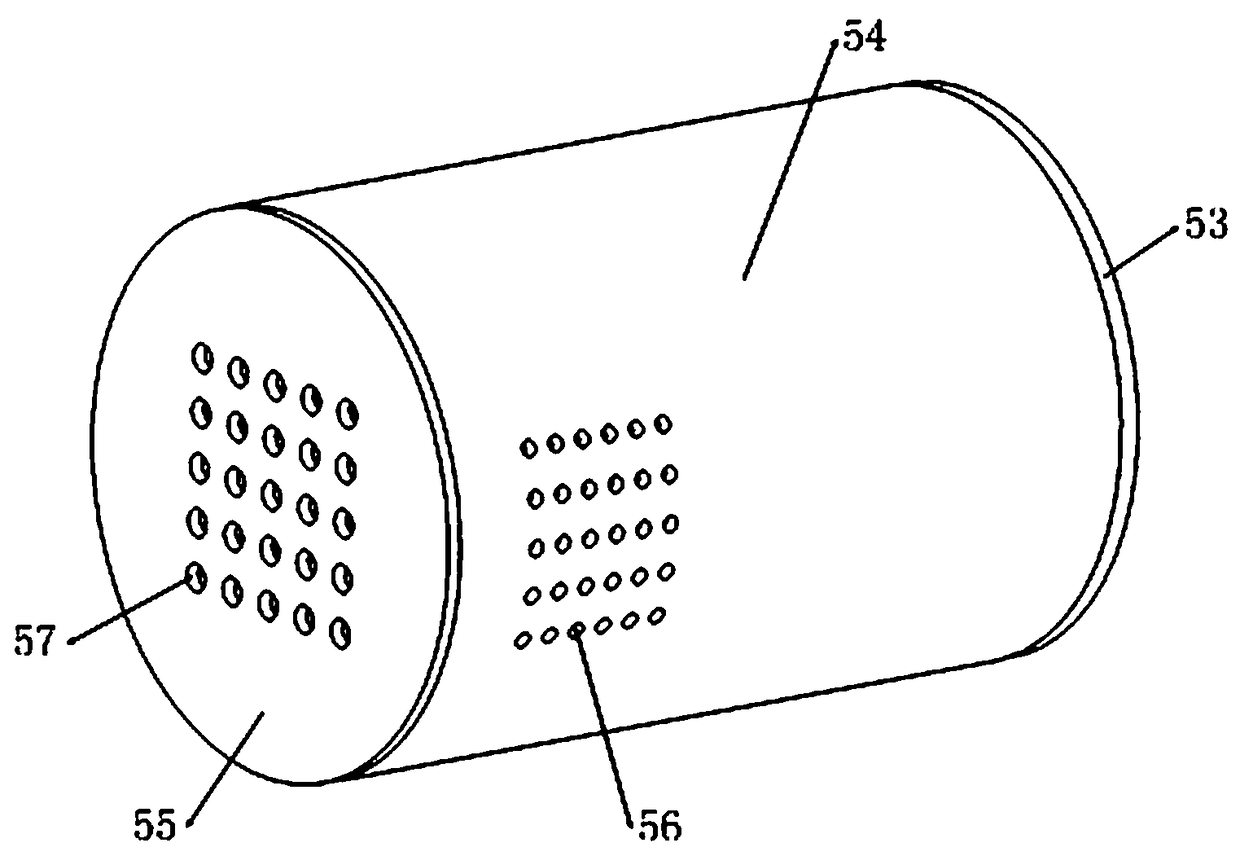

Dustproof electric drill

InactiveCN109290609ANormal coolingMeet the needs of normal workPortable power-driven toolsDriving apparatusDrive shaftEngineering

The invention belongs to the technical field of electric drills, and particularly relates to a dustproof electric drill. The dustproof electric drill comprises a driving shaft, a friction wheel, a driving gear, a second dustproof mechanism, a first dustproof mechanism and an actuating mechanism, first matching holes are matched with air exhaust holes, and second matching holes are matched with airinlet holes. The dustproof electric drill is characterized in that when the electric drill is not used, multiple rows of the second matching holes formed in an arc-shaped baffle and multiple rows ofthe air inlet holes formed in a cylinder shell are distributed in a staggered mode, multiple rows of the first matching holes formed in a square baffle and multiple rows of the air exhaust holes formed in a back cover are distributed in a staggered mode, the purpose of preventing dust in outside air from entering the cylinder shell is achieved, and the condition that heat dissipation of the electric drill is not facilitated after a large amount of dust in the outside enters the electric drill is avoided; and when multiple rows of the second matching holes formed in the arc-shaped baffle communicate with multiple rows of the air inlet holes formed in the cylinder shell and multiple rows of the first matching holes formed in the square baffle communicate with multiple rows of the air exhaustholes formed in the back cover, an exhaust fan can normally conduct heat dissipation on the electric drill, and the normal working requirement of the electric drill is met.

Owner:昕致潮贸易(深圳)有限公司

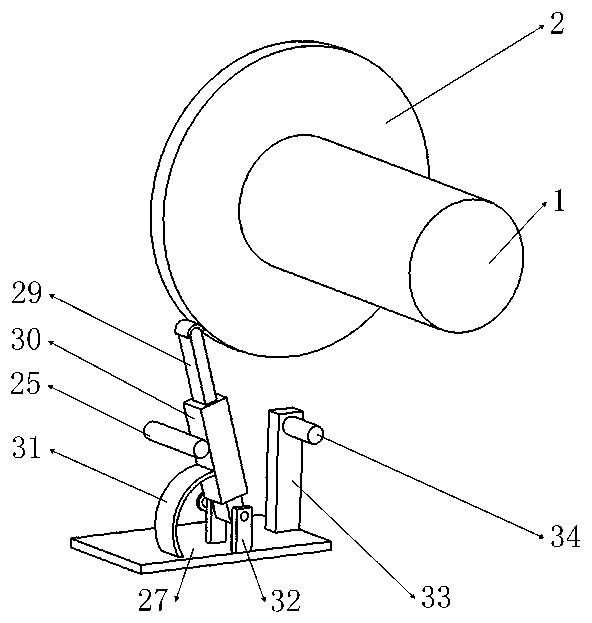

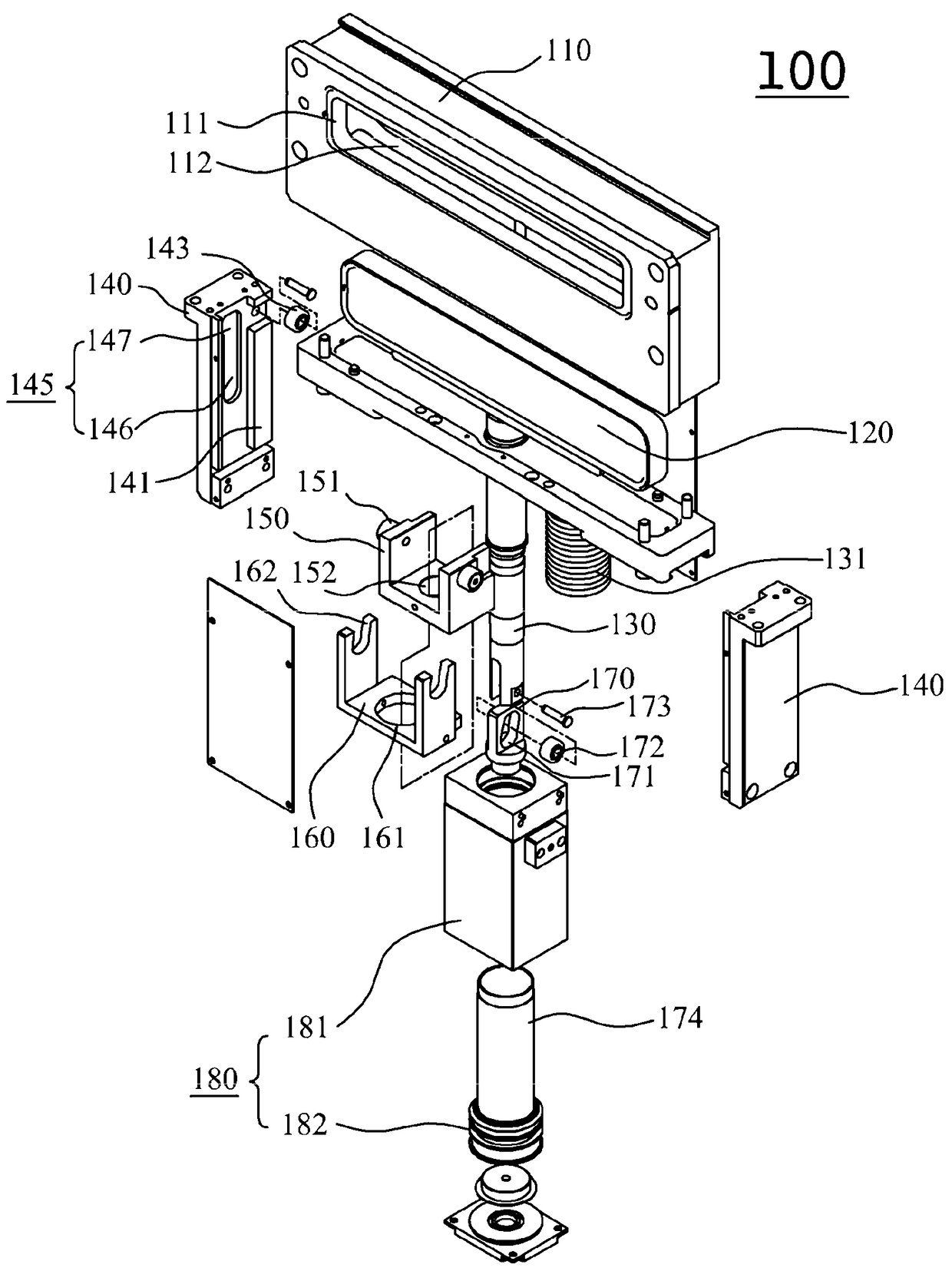

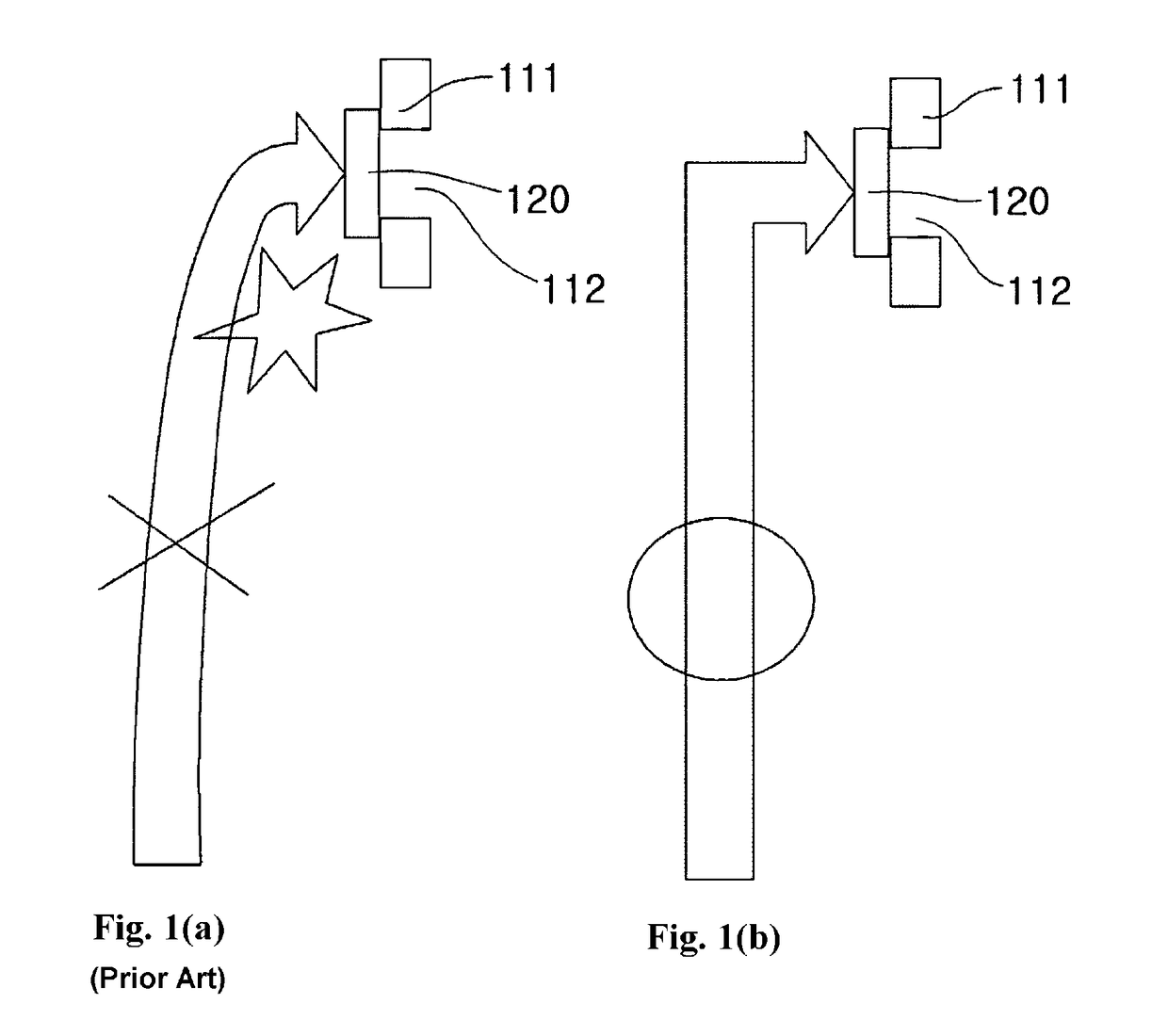

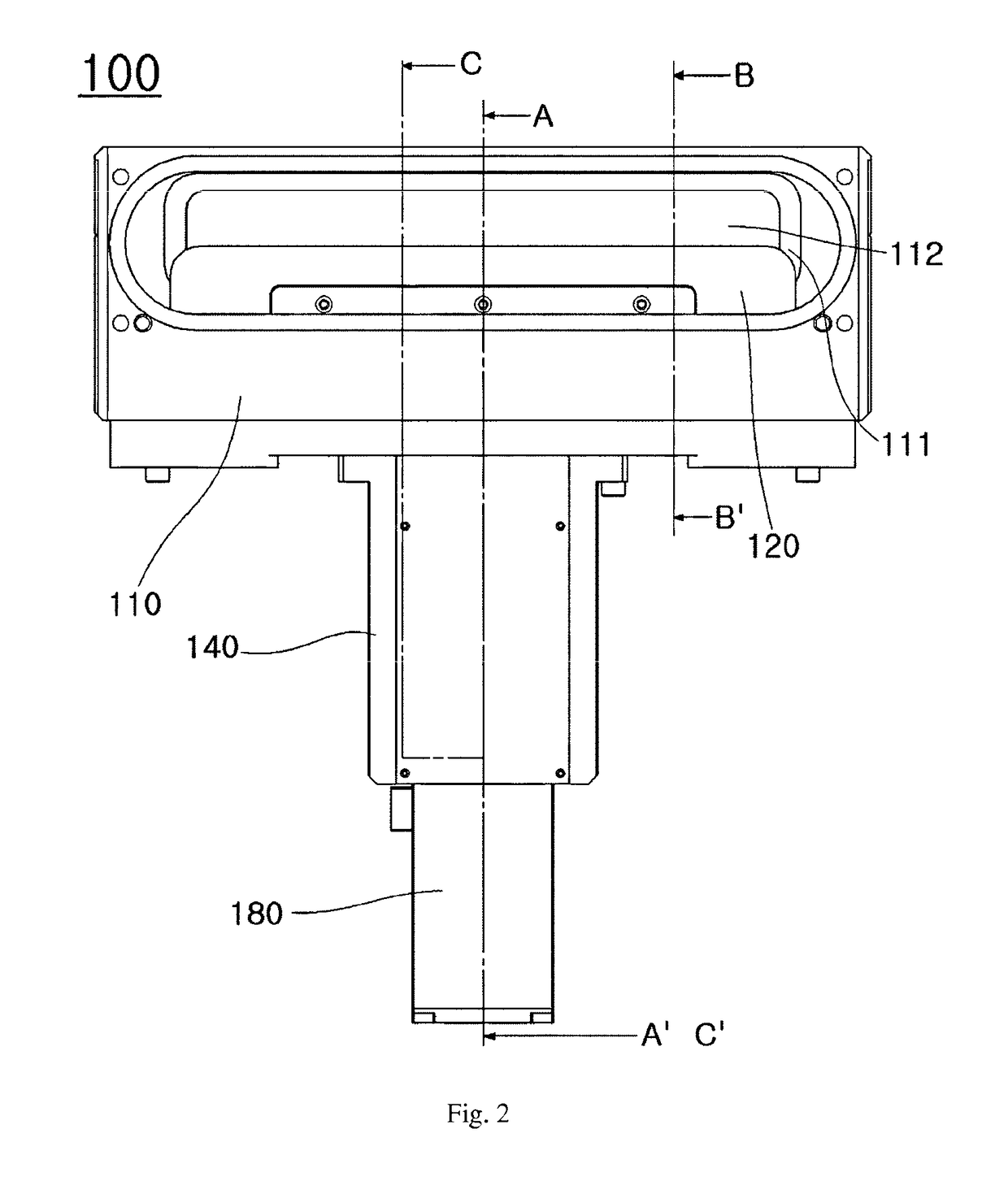

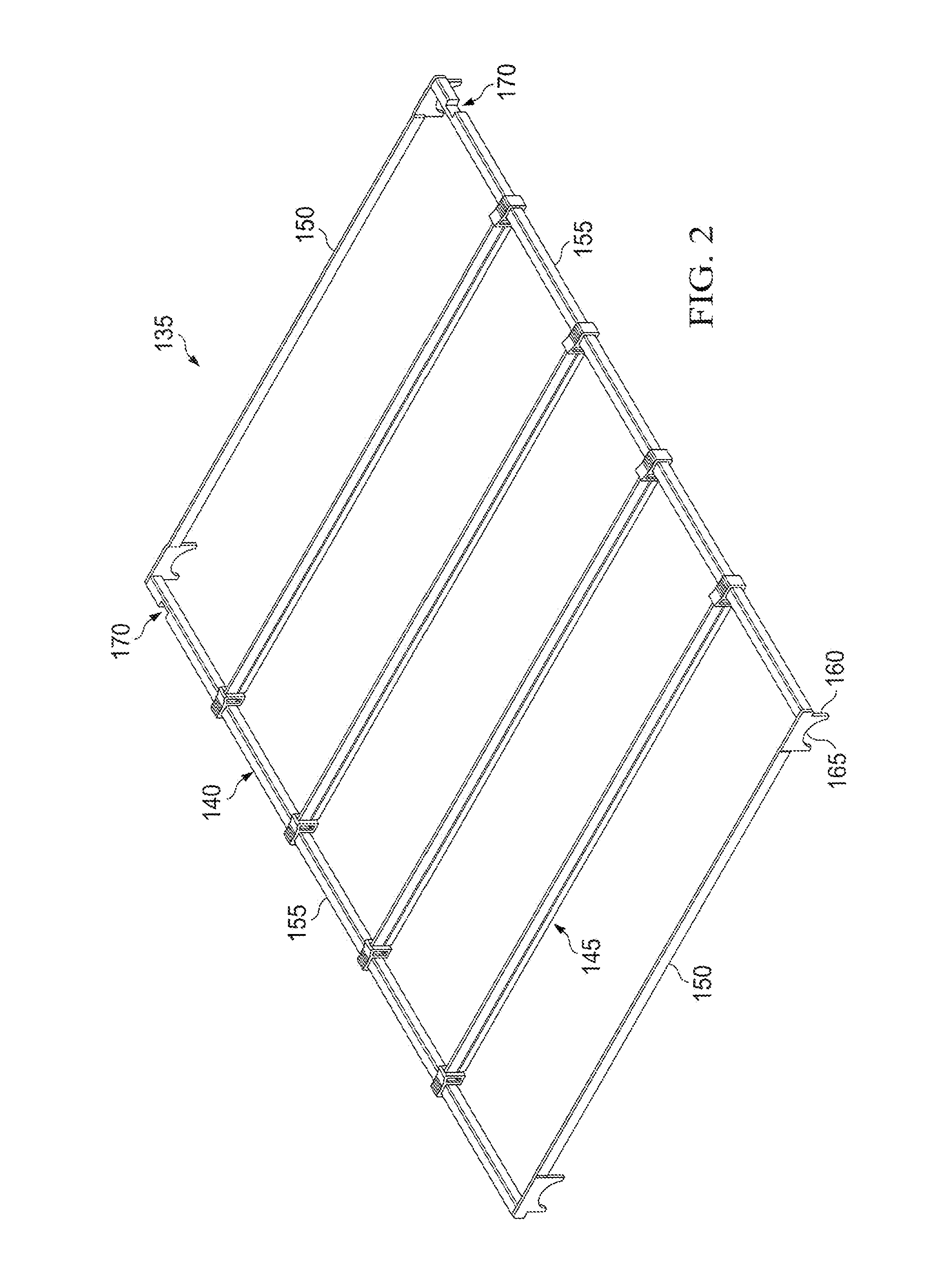

Gate Valve

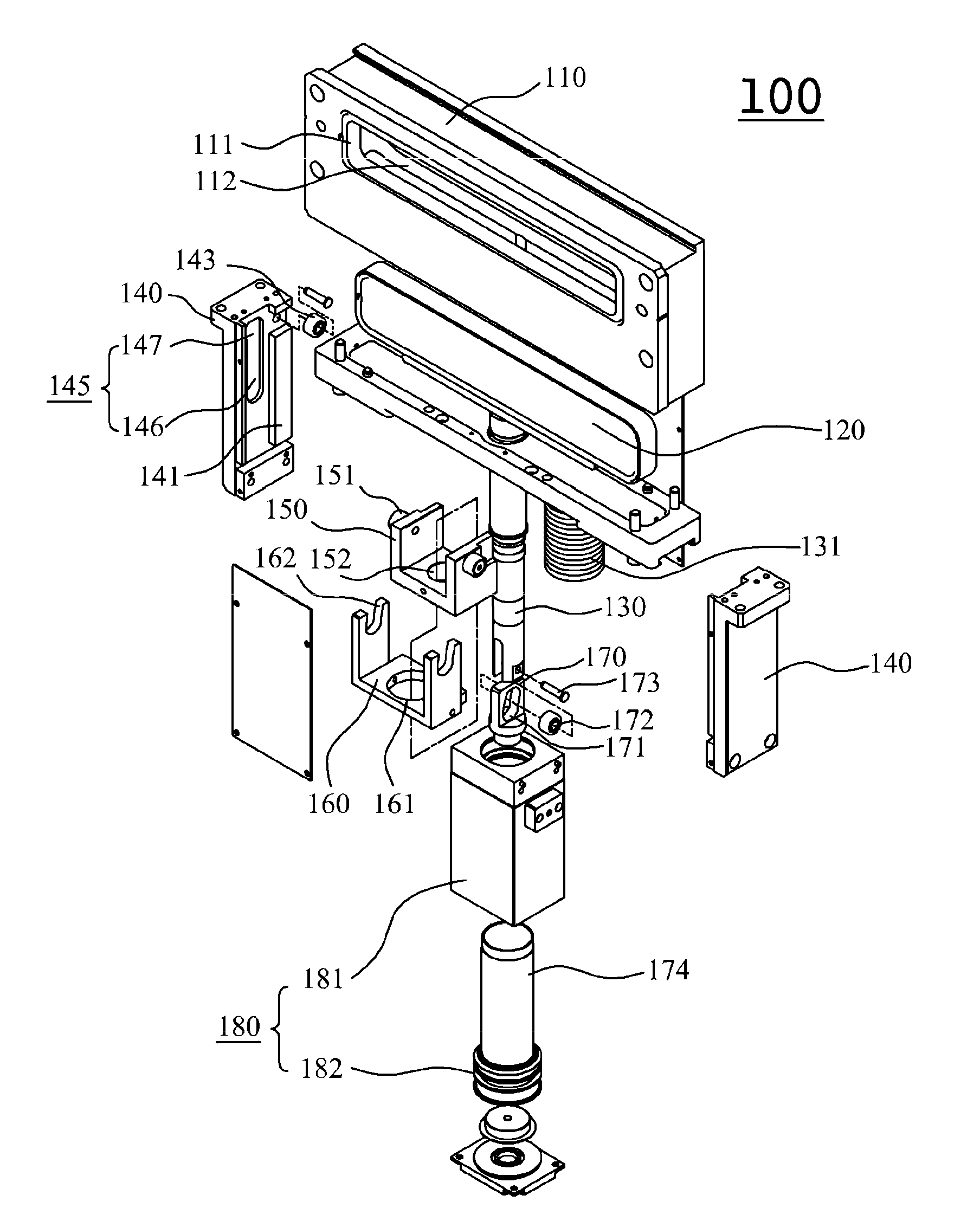

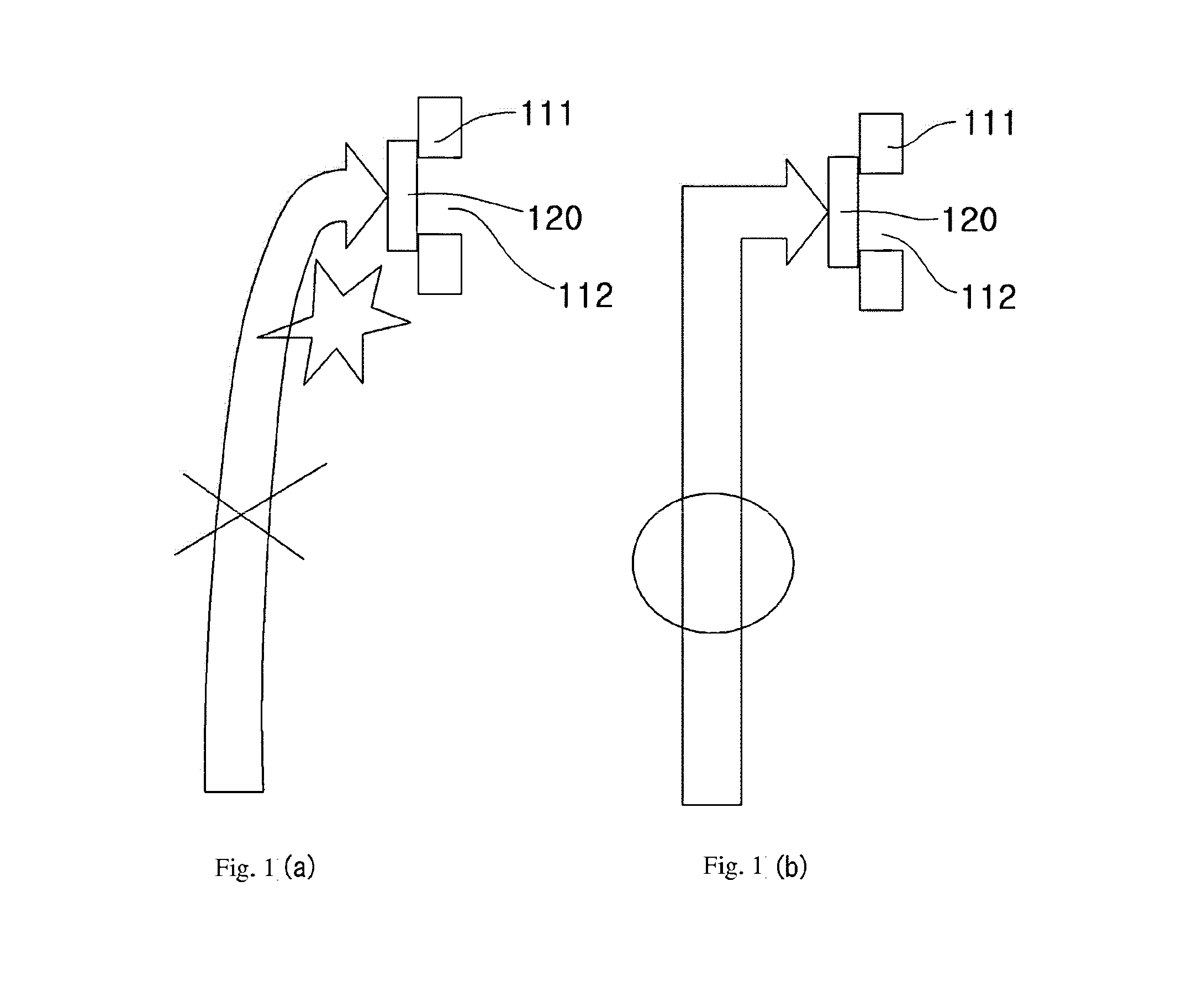

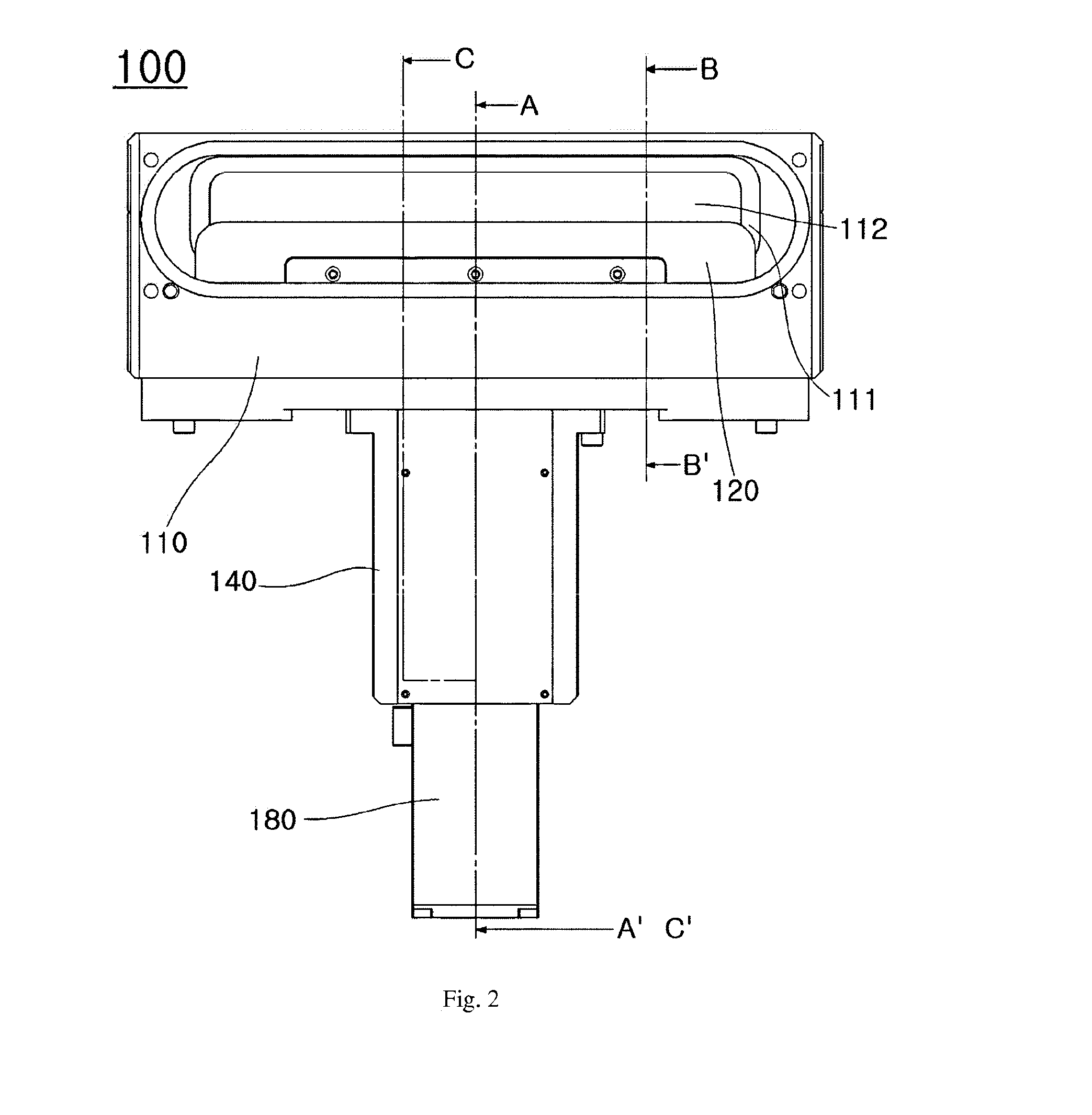

ActiveUS20160305555A1Efficient in operationReliable structureOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingEngineeringGate valve

Disclosed is a gate valve which comprises a valve blade 120 which is configured to close the opening 112 in a valve housing 110; a valve rod 130 which is connected to the valve blade 120 and is configured to move in upward and downward directions and a horizontal direction; a guide housing 140 which is connected to an outer side of the valve housing 110; an L-motion block 150 which is engaged and connected to the valve rod 130, with a guide roller 151 being installed at both sides of the L-motion block 150; a cam block 160 which is installed in the interior of the guide housing 140; a driving rod engaging roller 172 which is installed at an lower end of the valve rod 130; a driving rod 170 in which the driving rod engaging roller 172 is inserted and guided and which has a driving rod slanted groove 171 obliquely formed in a closing direction “C” in a downward direction; an elasticity providing unit 175 which is configured to provide elasticity between the L-motion block 150 and the driving rod 170; and an upward and downward driving unit 180 which drives upward and downward the driving rod 170.

Owner:PRESYS

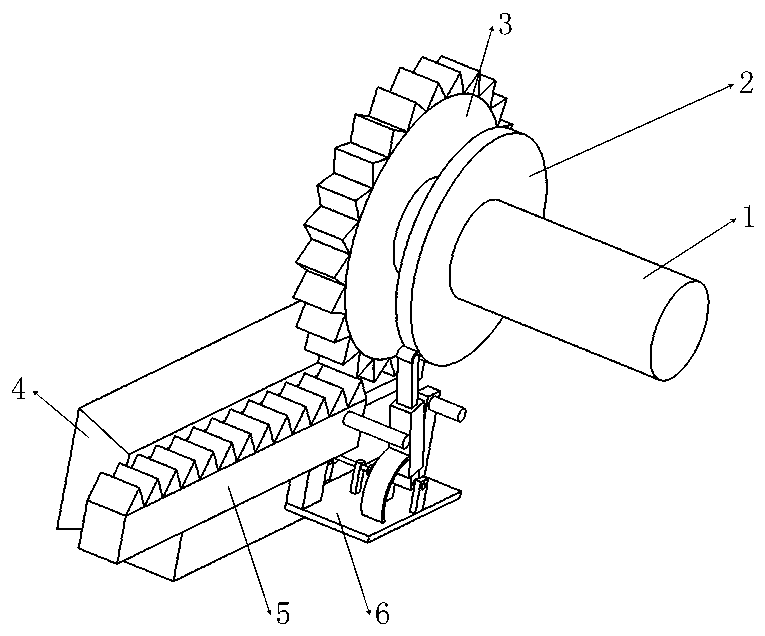

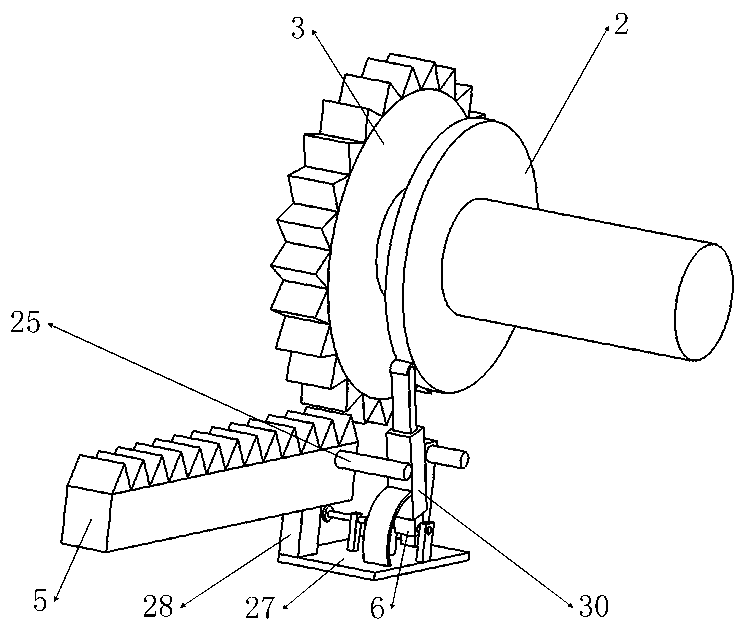

Protective rack mechanism used for small-load machinery

InactiveCN109578538AToggle avoidKeep toggle to avoidGearing detailsFriction gearingsGear driveMechanical abrasion

The invention belongs to the technical fields of rack, and particularly relates to a protective rack mechanism used for small-load machinery. The protective rack mechanism comprises a friction wheel,a drive gear, a first trapezoidal slide rail, a drive rack, a protective mechanism, a first trapezoidal slide block, a first spring and a limiting block, wherein after the drive gear drives the driverack to move to a limit position, i.e., when a limiting plate on the drive rack is on a position limited by the limiting block, the drive gear cannot continuously pull a tooth at the tail end of the drive rack while the design that the limiting plate is limited by the limiting block enables the drive rack to keep on a position to be reached after being driven by the drive rack, and further can enable the drive rack to pull to a precise position by the drive gear. The limiting plate is matched with the limiting block for limiting, so that the drive gear is prevented from continuously pulling the tooth at the tail end of the drive rack, and mechanical abrasion, caused when the tooth at the tail end of the drive rack is continuously pulled, is avoided, and therefore, a condition that the drive rack cannot be precisely pulled to an accurate position by the drive gear is avoided.

Owner:深圳市安达工业设计有限公司

Process chamber gate valve

ActiveUS9765897B2Stable structureAvoid interferenceOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingGate valve

A gate valve for a process chamber includes a valve blade for closure of an opening communicating to the process chamber. The valve blade is employed to seal the opening in a valve housing. The valve blade moves first in a vertical direction and then in a horizontal direction normal to the opening when sealing against the opening. The valve blade moves first in the horizontal direction and subsequently in a vertical direction when disengaging from the opening.

Owner:PRESYS

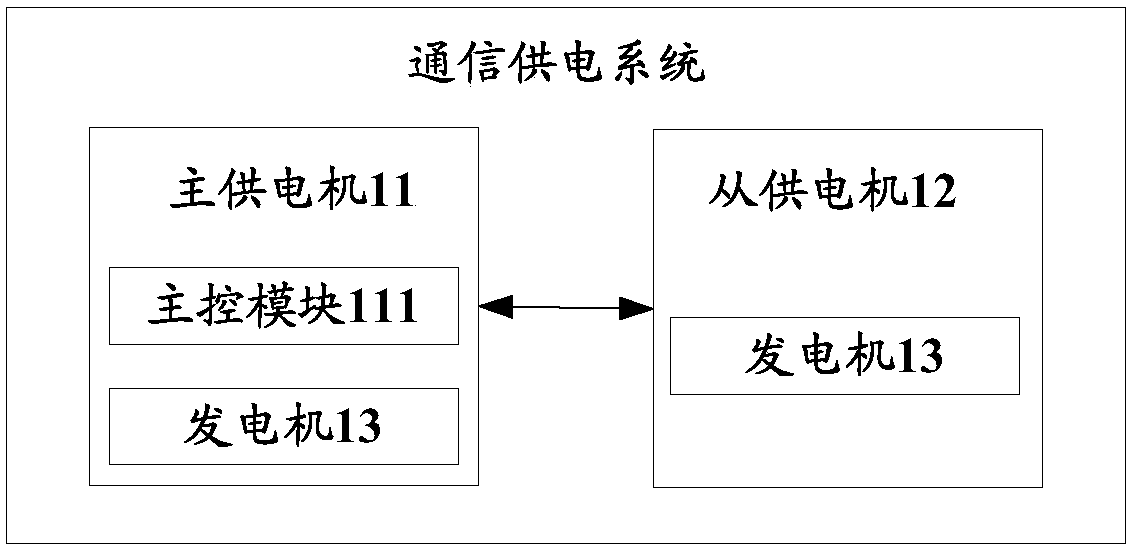

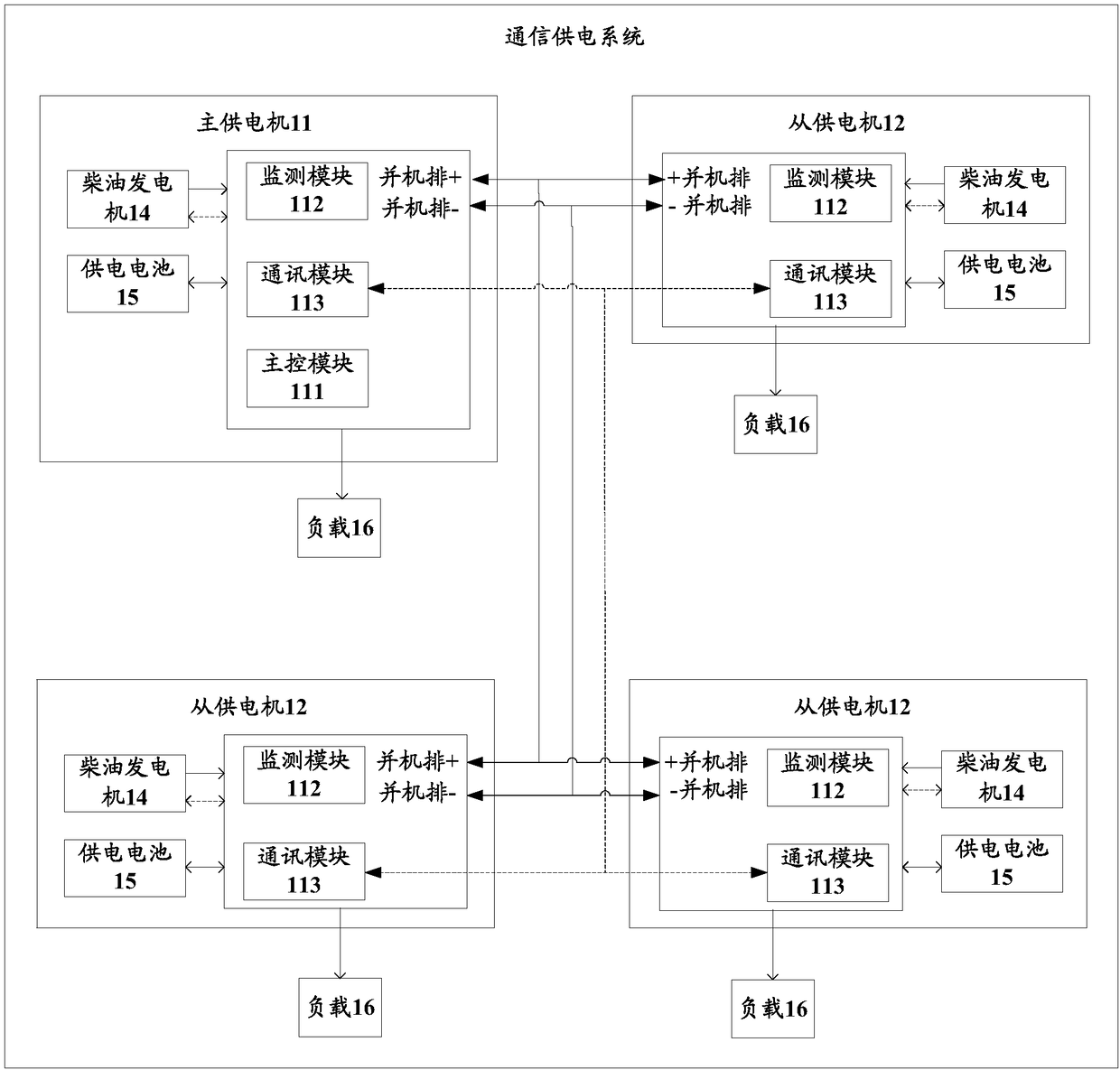

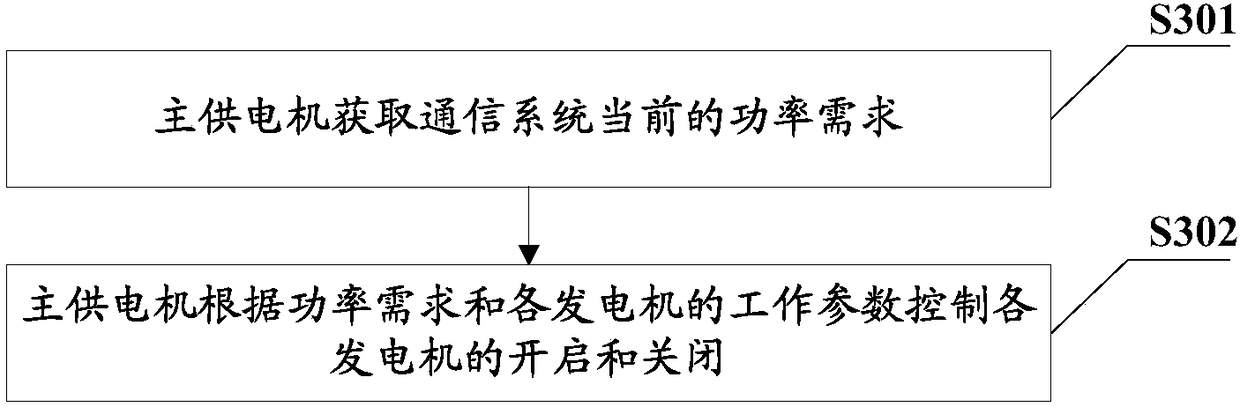

Communication power supply system and power supply control method thereof

ActiveCN108400580AAvoid mechanical wearGuaranteed effective power generation efficiencyDc source parallel operationEffective powerCommunications system

The invention provides a communication power supply system and a power supply control method thereof. The power supply output ends of multiple power supply machines are connected in parallel, and eachpower supply machine comprises a generator for supplying a power supply; a main power supply machine obtains the current power requirement of a communication system and then controls on and off of each generator according to the power requirement and the working parameters of each generator; the main power supply machine controls on and off of each generator according to the power requirement ofthe current system and the power parameters of each generator and the like; and equivalently, the corresponding generator can be started or closed according to actual needs, so that a condition that some generators are always in a low-load operation state can be avoided as far as possible, thereby further avoiding unnecessary mechanical abrasion, ensuring effective power generation efficiency of the generators, and lowering operational and subsequent maintenance cost.

Owner:ZTE CORP

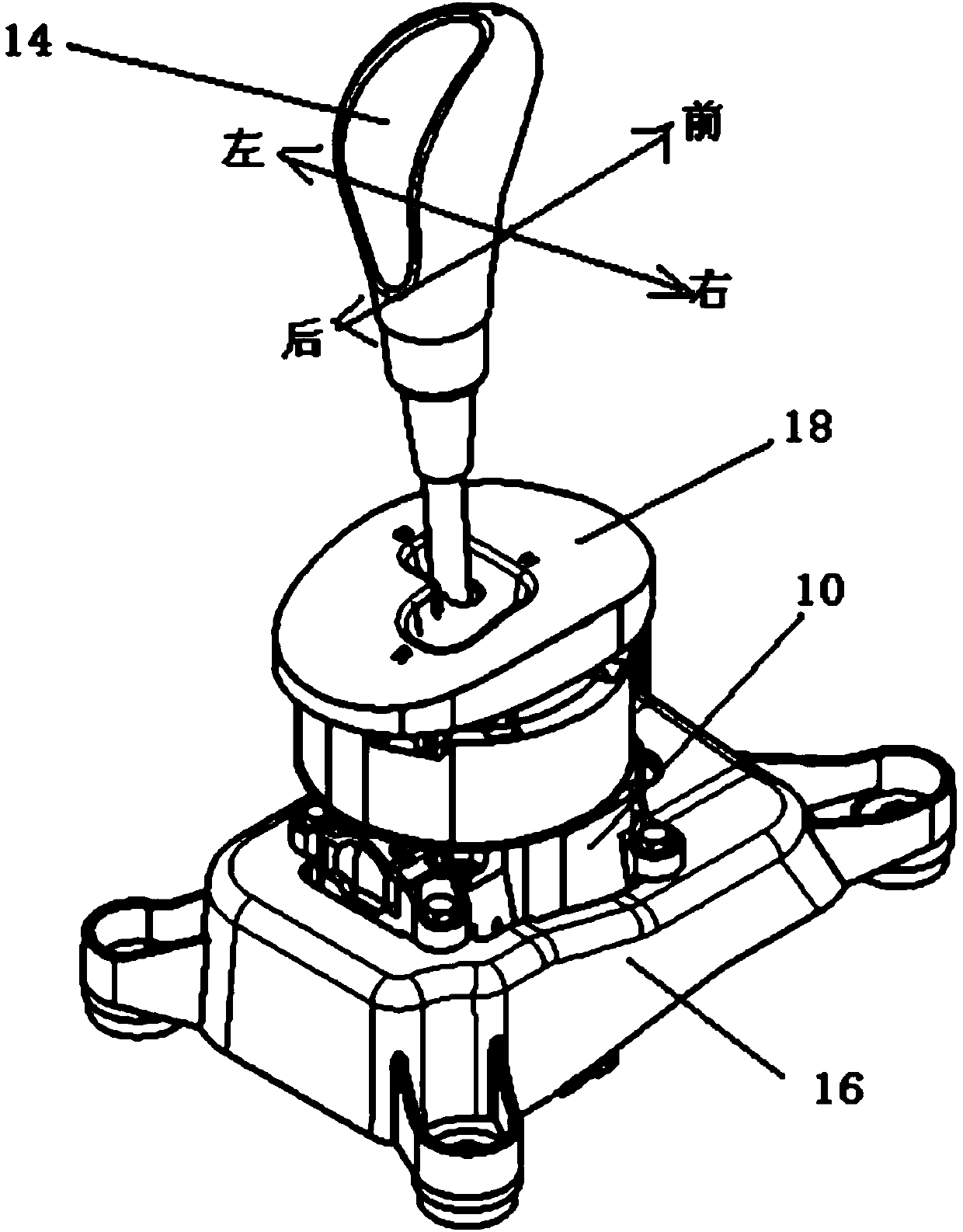

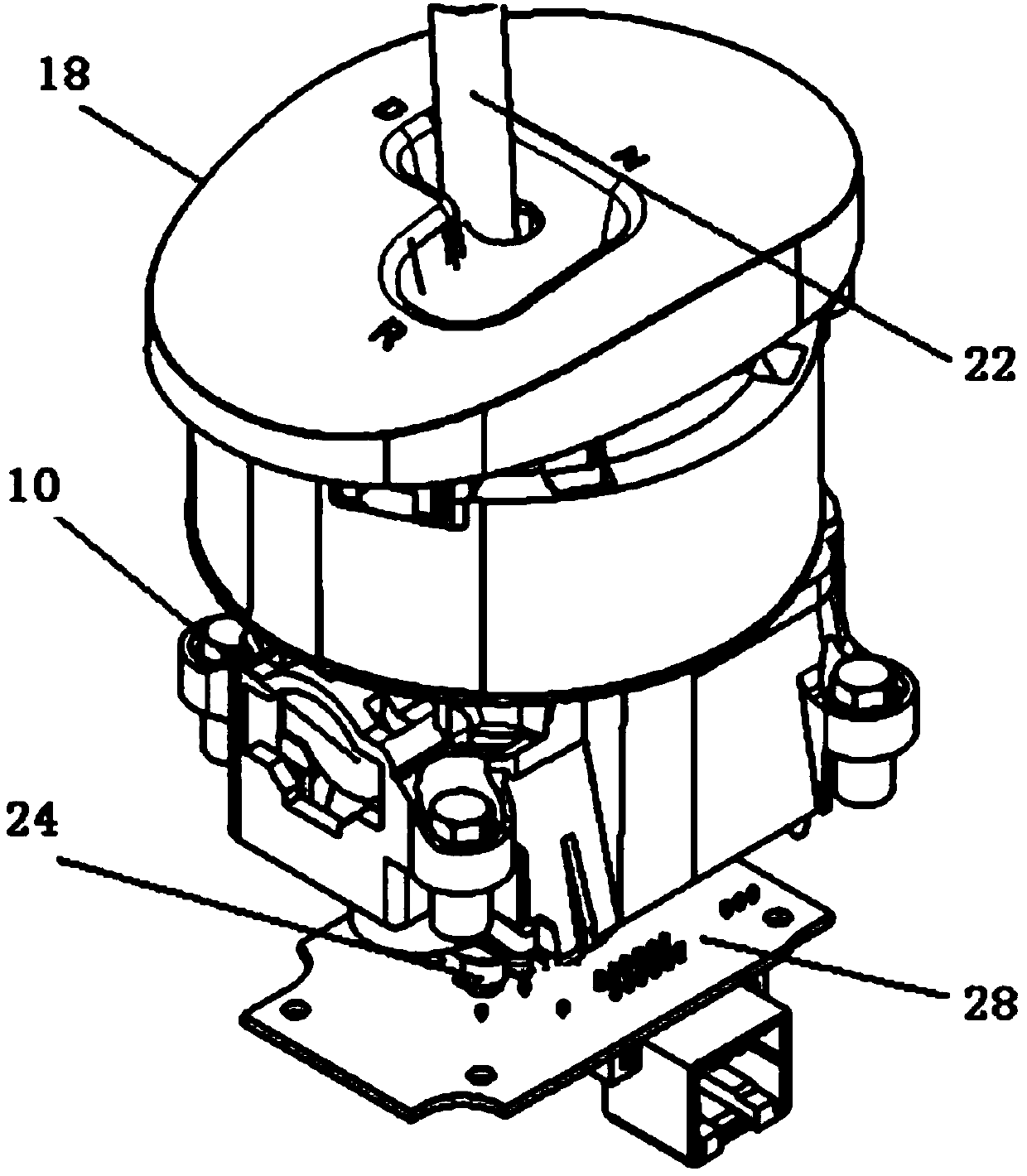

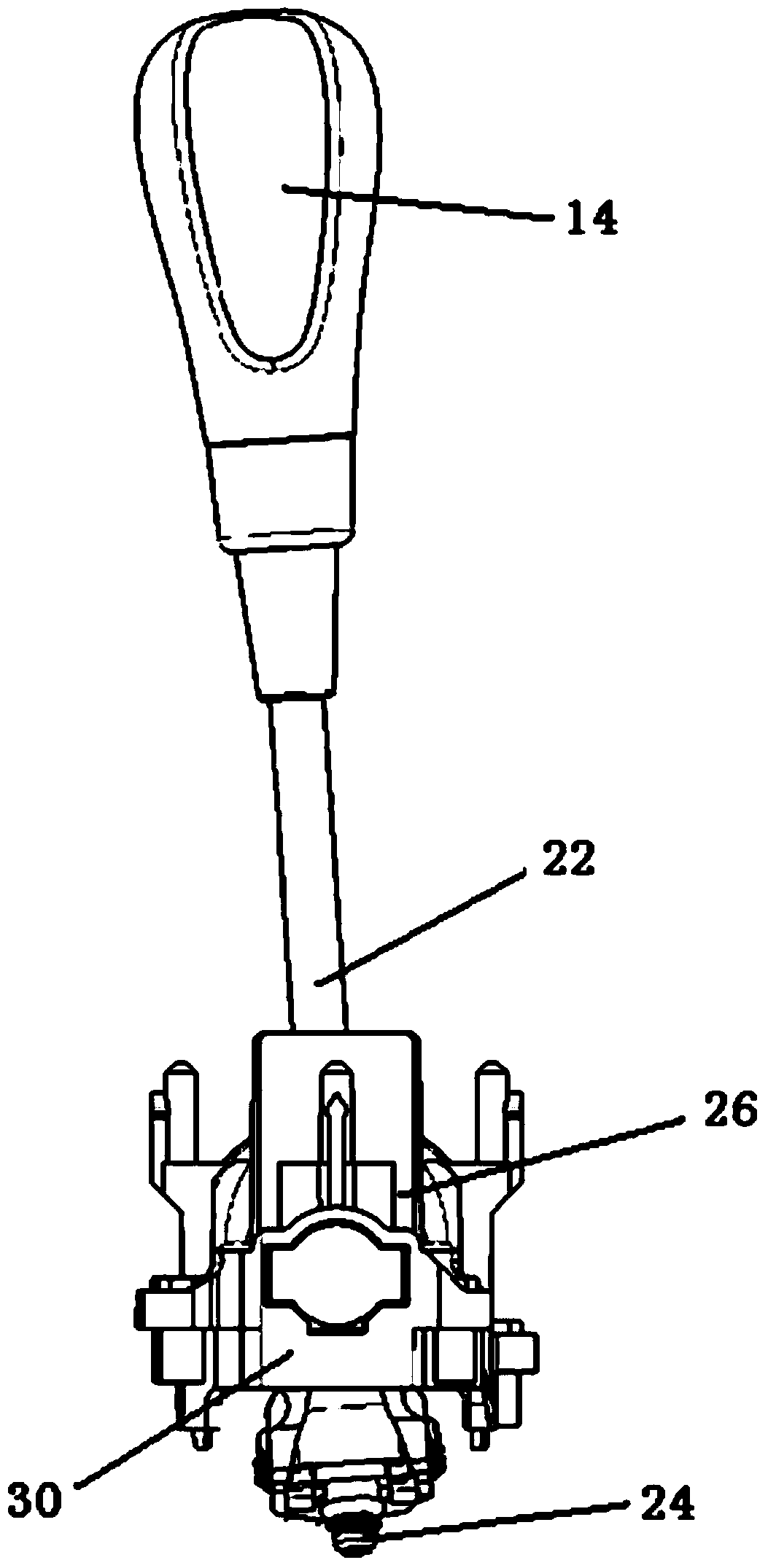

Electronic gear selection and shifting control mechanism for electric car

InactiveCN103963639AAvoid mechanical wearExtended service lifeControl devicesEngineeringElectric control

The invention relates to an electronic gear selection and shifting control mechanism for an electric car. The electronic gear selection and shifting control mechanism for the electric car comprises a gear shifting panel, a connection base and a reversing seat; the reversing seat comprises a gear shifting track groove, a handle lever and a control circuit board; a permanent magnet is arranged at the bottom of the handle lever; the control circuit board is provided with Hall sensing components; two electric signals with different types are correspondingly output each time the permanent magnet moves to a static position. The electronic gear selection and shifting control mechanism for the electric car can be easily matched with an electric control system, is convenient to arrange, can output redundant signals, integrates backup light control, and is long in service life, and gear shifting signals are accurate.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

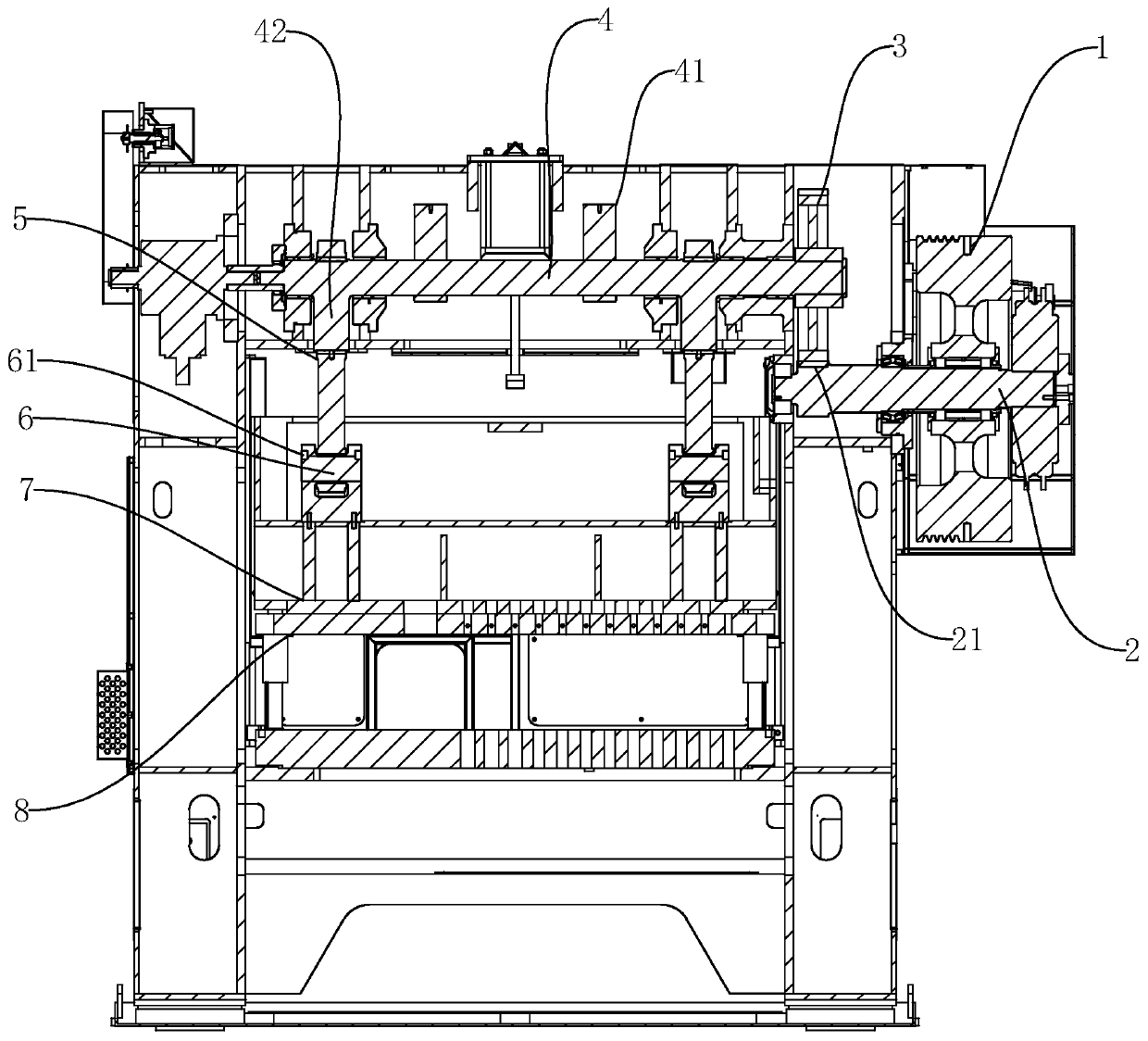

High precision dual transmission mechanism

PendingCN109808211AMeet the process requirementsReduce scrap ratePress ramComputer moduleMulti segment

The invention provides a high precision dual transmission mechanism comprising a main shaft, a pair of connecting rods, a pair of hinge pins and a movable module. The connecting rods extend toward themovable module from the both sides of the main shaft, and one end of each connecting rod is connected with the main shaft; and the other end of the connecting rod is connected with the movable modulethrough the corresponding hinge pin, and each hinge pin is of a cylindrical structure; and the connecting rods are rotated around the hinge pins. According to the high precision dual transmission mechanism, the shortcomings of the prior art are overcome, and the machining precision is improved; the technological requirements which need to reach during machining of precision accessories are met, so that the rejection rate of processed product is reduced; an original structure is not changed in the method greatly; the manufacturing cost of the mechanism is reduced, and the assembly or fabrication efficiency is improved; a multi-segment main shaft is replaced with a single shaft, so that the manufacturing synchronism is improved; and the product difference caused by non-synchronization of the multi-segment structure is avoided effectively.

Owner:XIANGSHAN YIDUAN PRECISION MACHINERY CO LTD

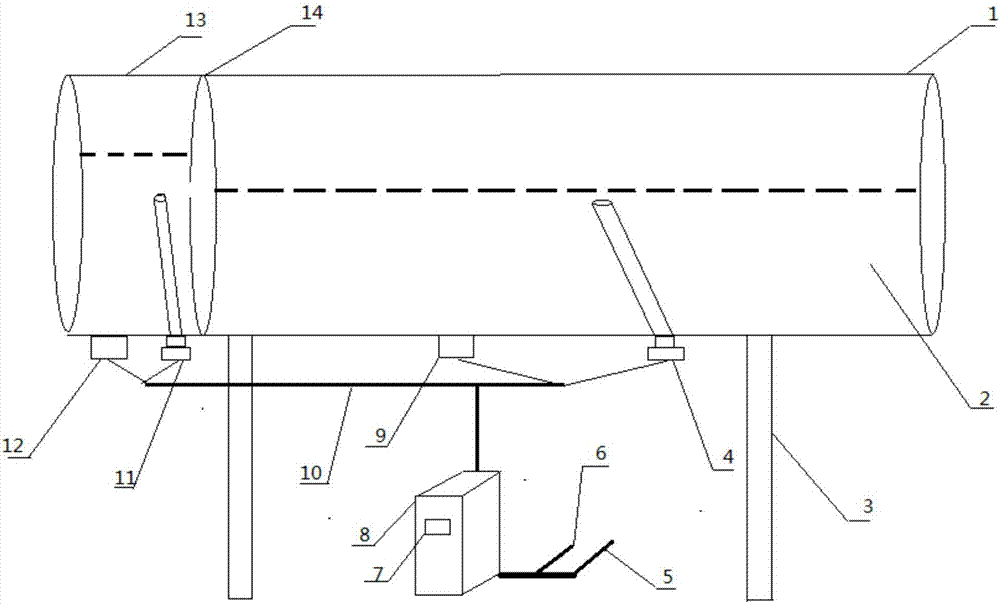

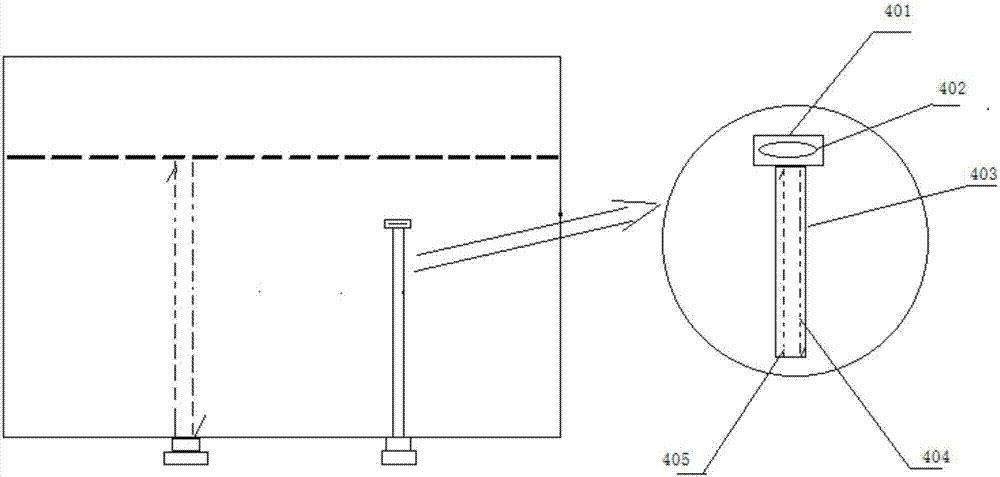

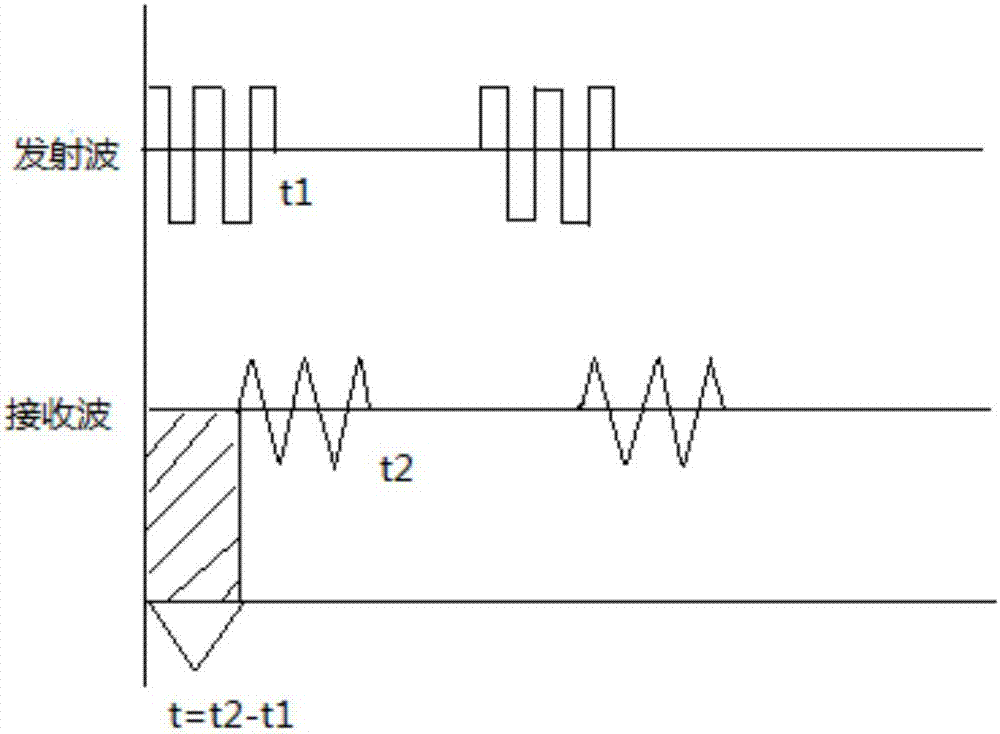

Measuring device and method for power-transformer-oil-storage-cabinet liquid level

InactiveCN107014467AAvoid mechanical wearOvercoming technical drawbacksMachines/enginesLevel indicatorsShielded cableMeasurement device

The invention discloses a measuring device and method for the power-transformer-oil-storage-cabinet liquid level. The measuring device comprises ultrasonic probes installed at the bottom of a power-transformer oil storage cabinet and calibration probes, the calibration probes are installed inside an oil storage cabinet and communicated with inside insulating oil, the ultrasonic probes and the calibration probes are connected with a data processor through a sensor shield cable, and the data processor is connected with a main engine of a master-control room; the ultrasonic testing method based on the sonar principle is used in liquid level probes, ultrasonic signals directly penetrate through the metal wall of the oil storage cabinet, the wall of the oil cabinet does not need to be punched and installed, mechanical wear caused when a traditional floating-ball-pointer-type mechanical structure runs for a long time is voided, and the technical defects of an original liquid-level measuring device are fundamentally overcome. The measuring method is scientific, accurate and high in measuring accuracy and processor responding speed, and the measuring requirements of the liquid level of a current power-transformer oil storage cabinet of 330 kv or above can be met.

Owner:XIAN UNIV OF SCI & TECH

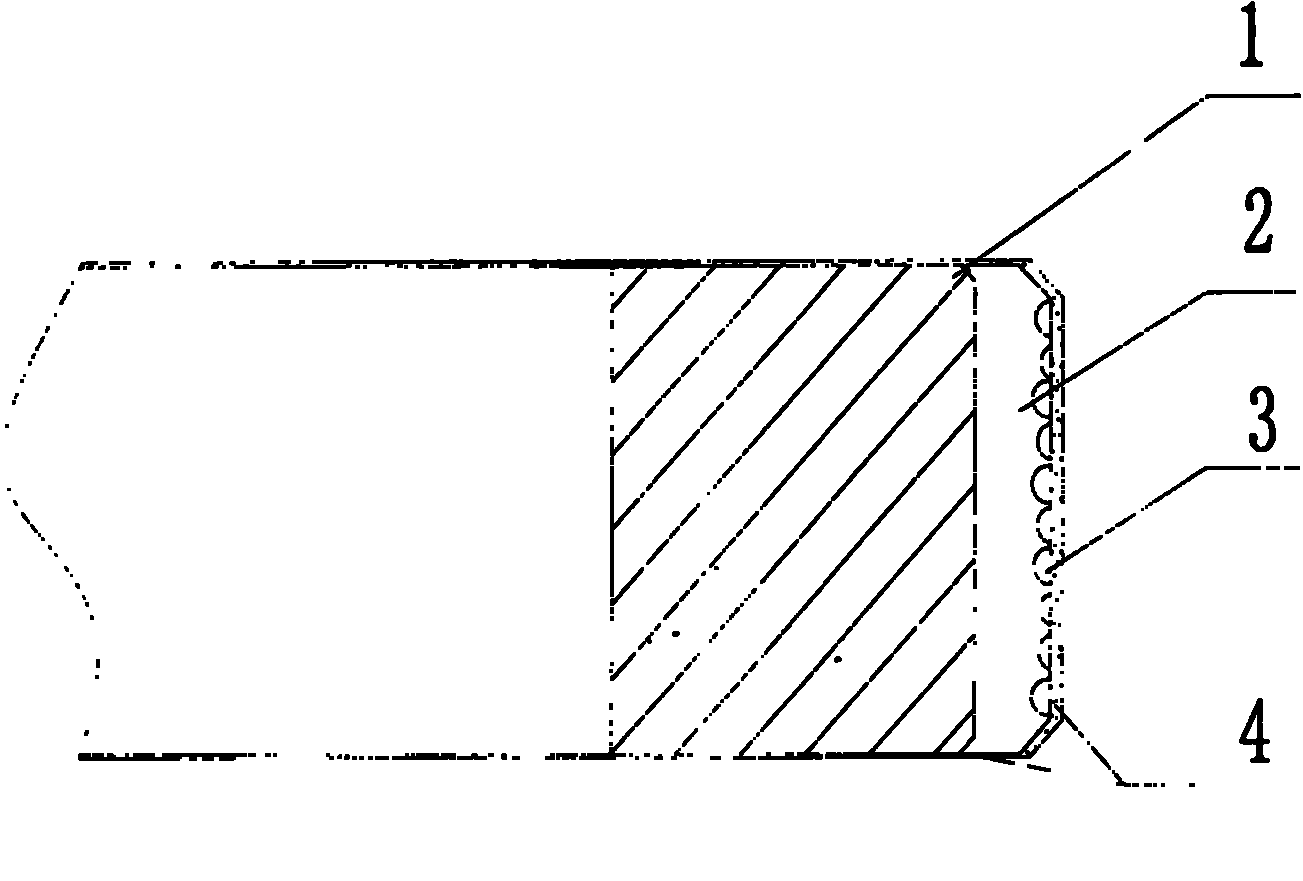

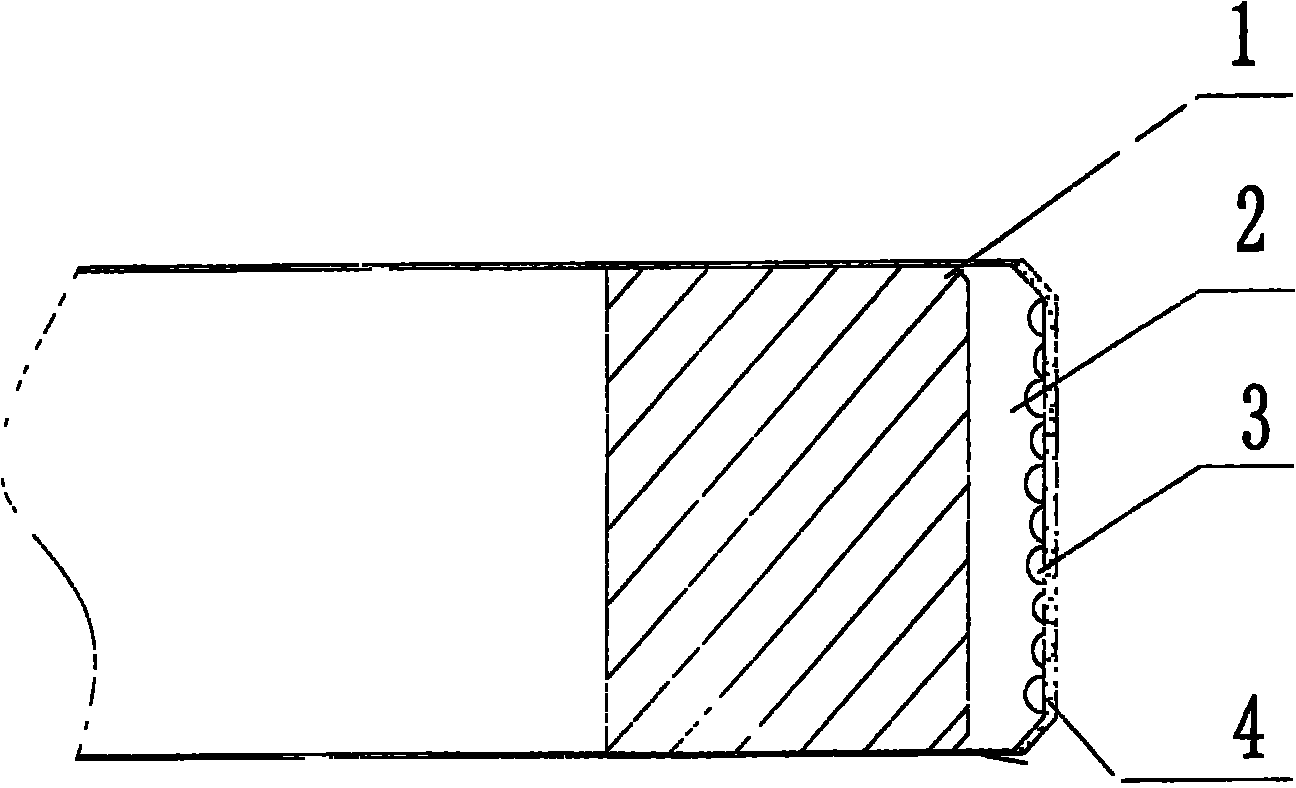

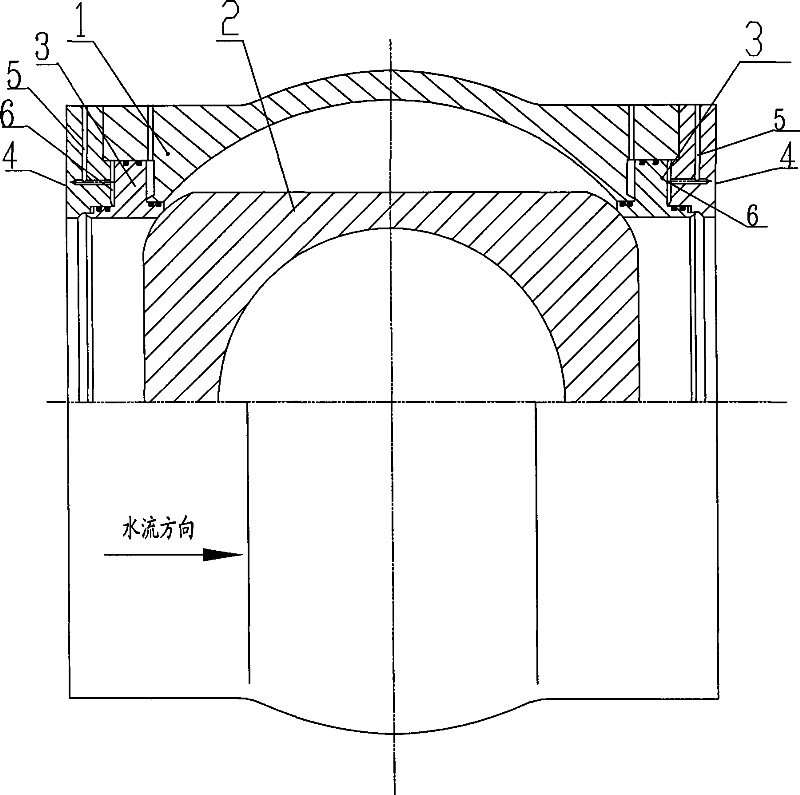

Movable ball valve sealing pair

A movable ball valve sealing pair, comprising a master valve body (1) and ball-shaped spool (2) mounted in flow passage of the master valve body via a valve rod, and a sealing valve base (3) mounted on two ends of the master valve body flow passage via a end-face press-ring (4). The sealing valve base (3) is a ring-shaped sphere metal sealing valve base, a sealing pair is formed of the ring-shaped sphere of the sealing valve base (3) and sphere sealing surface of the ball-shaped spool (2), characterized in that the sealing valve base (3) is a piston type movable valve base, which fits the sphere sealing surface of the ball-shaped spool (2) in a axial liquid-force flotation mode. Characteristics of the sealing pair are that structure is rational, sealing is reliable, mechanical abrasion during valve on-off process can be avoided and valve on-off torque is decreased, ball valves with design requirements of large nominal diameter and high work pressure can be satisfied.

Owner:赵紫光

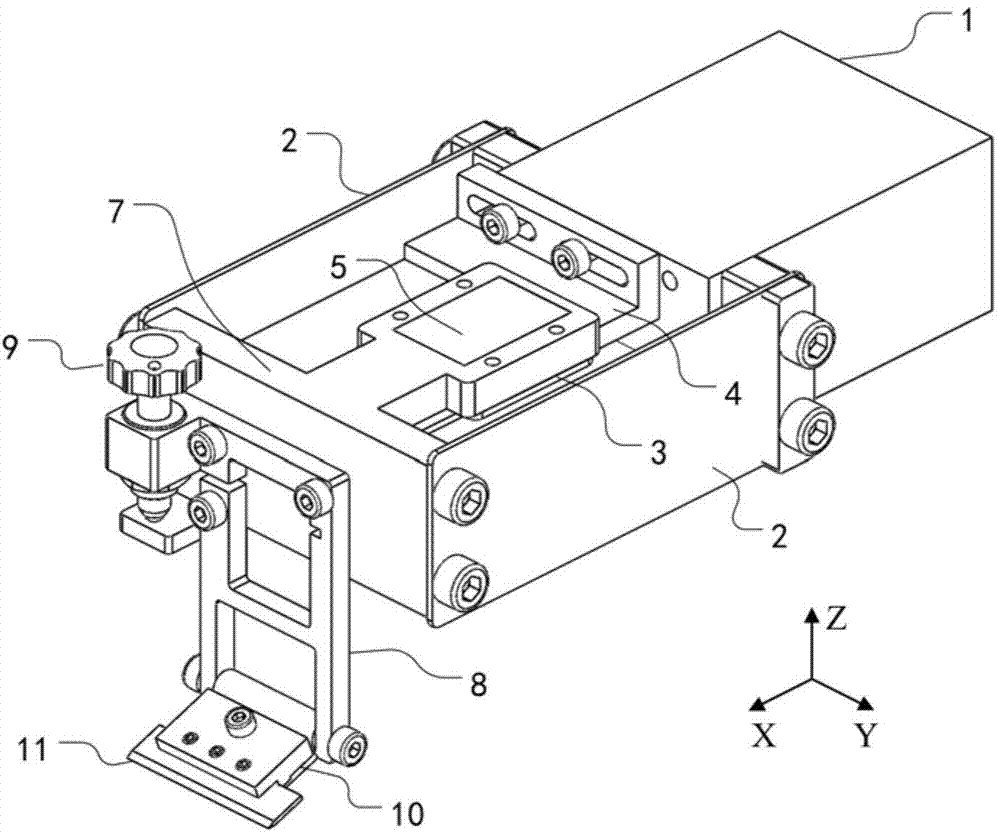

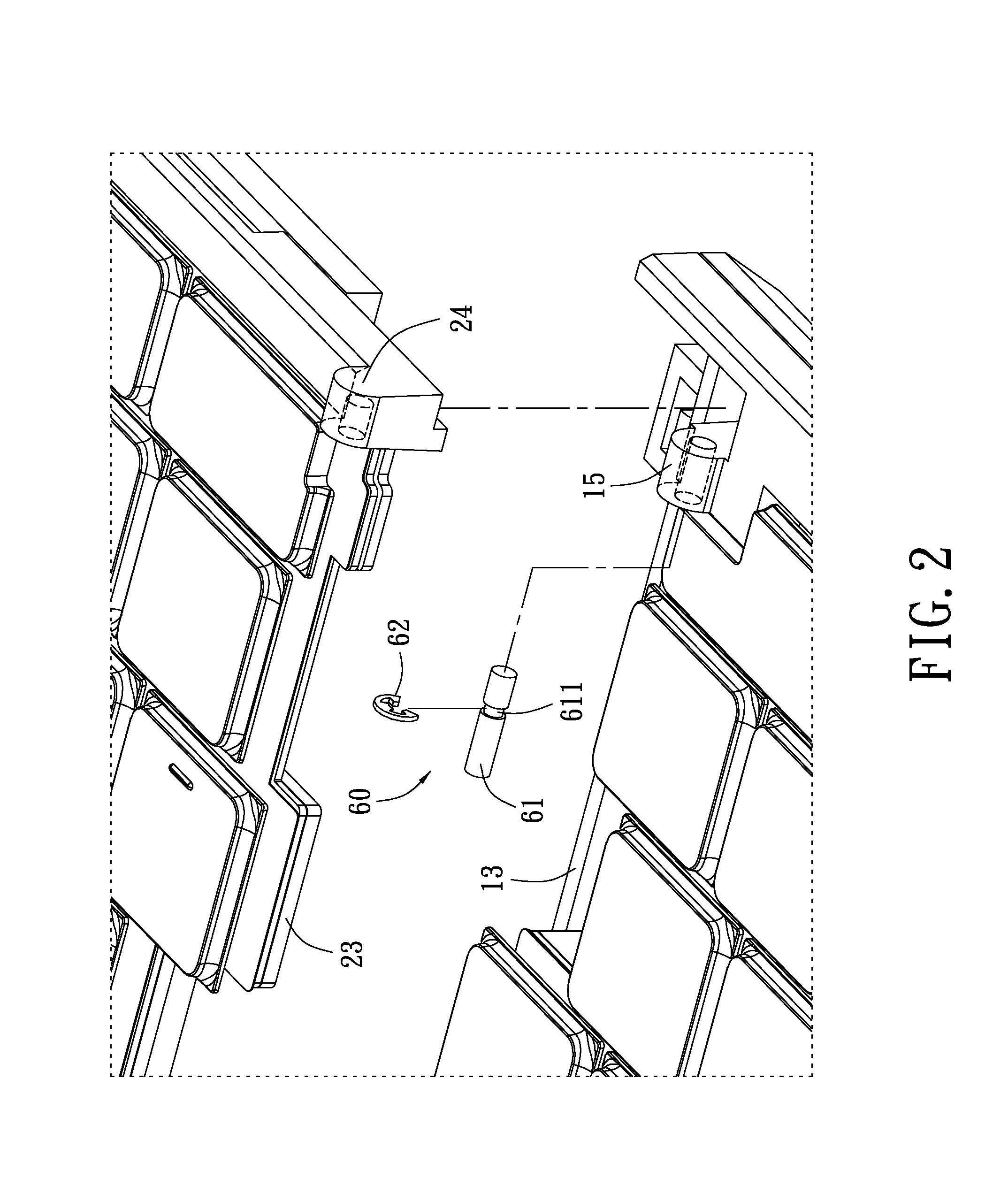

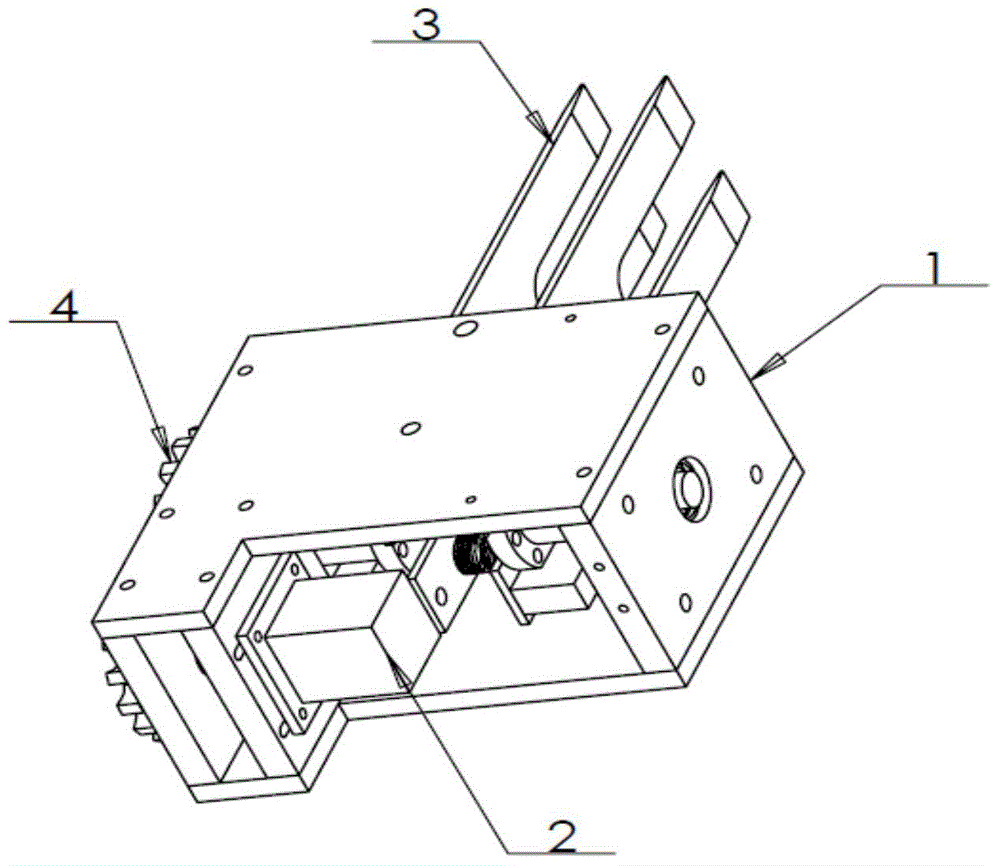

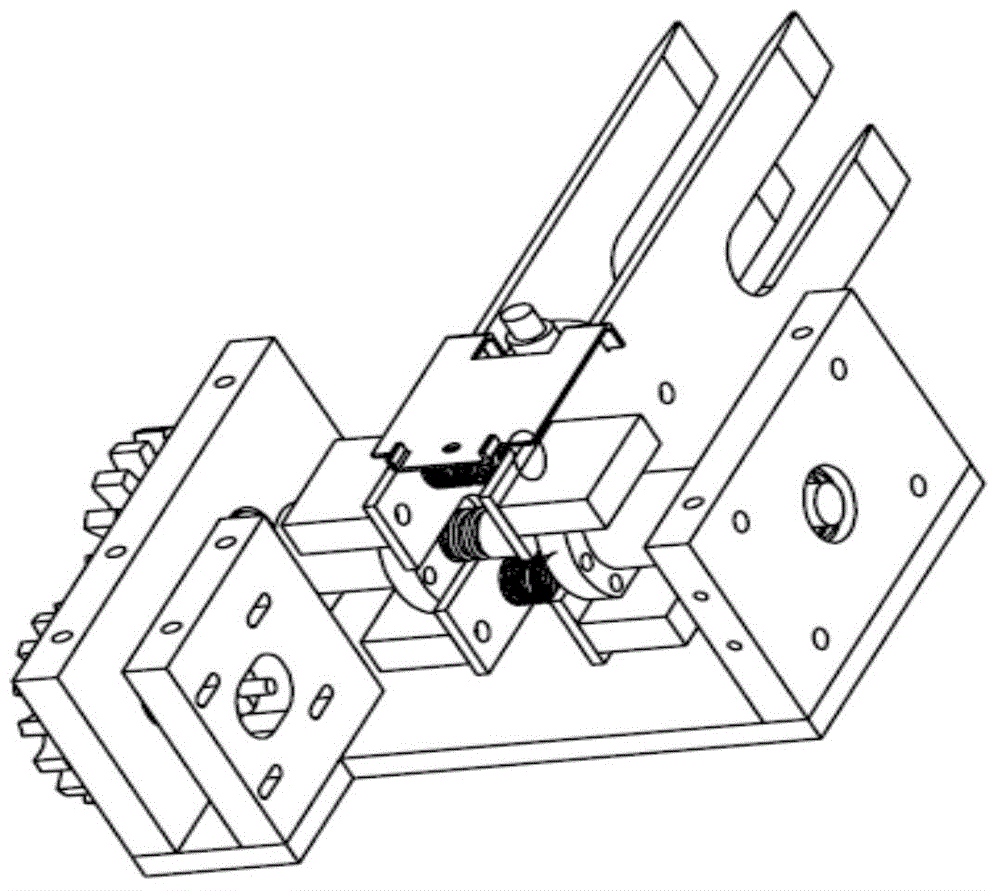

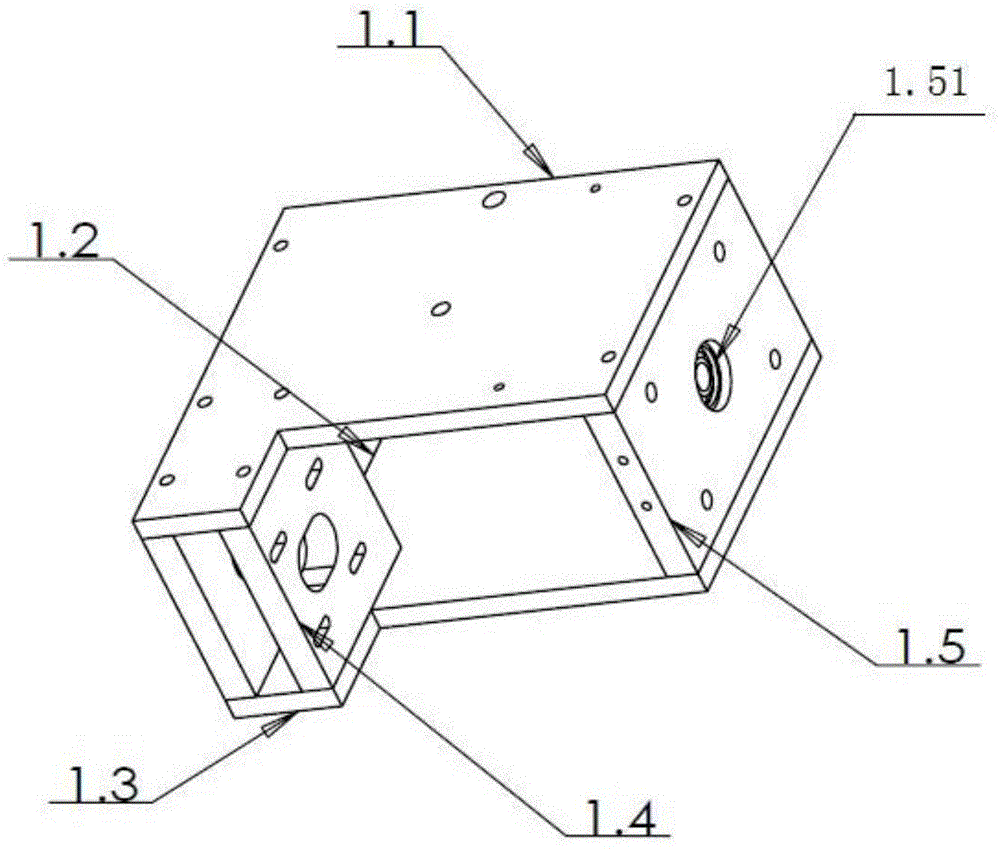

A book grabbing manipulator device in a book ATM machine

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

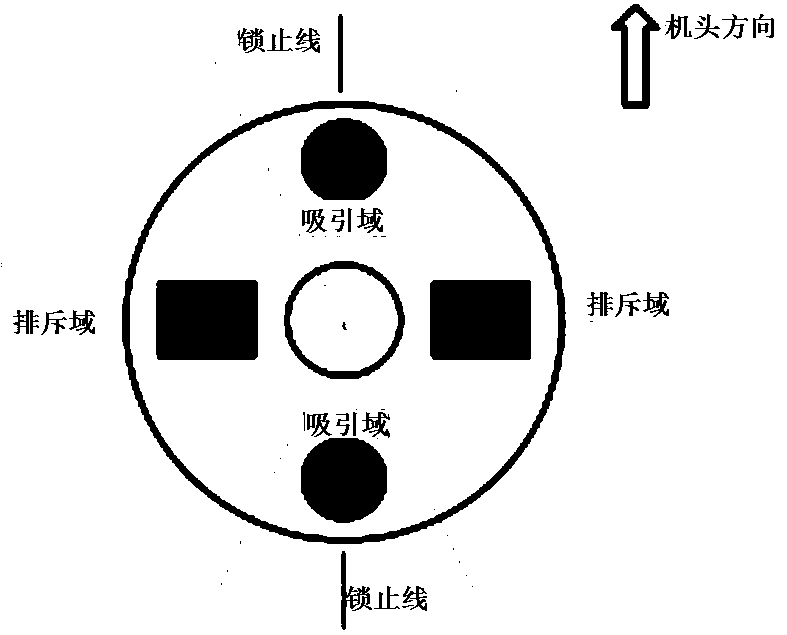

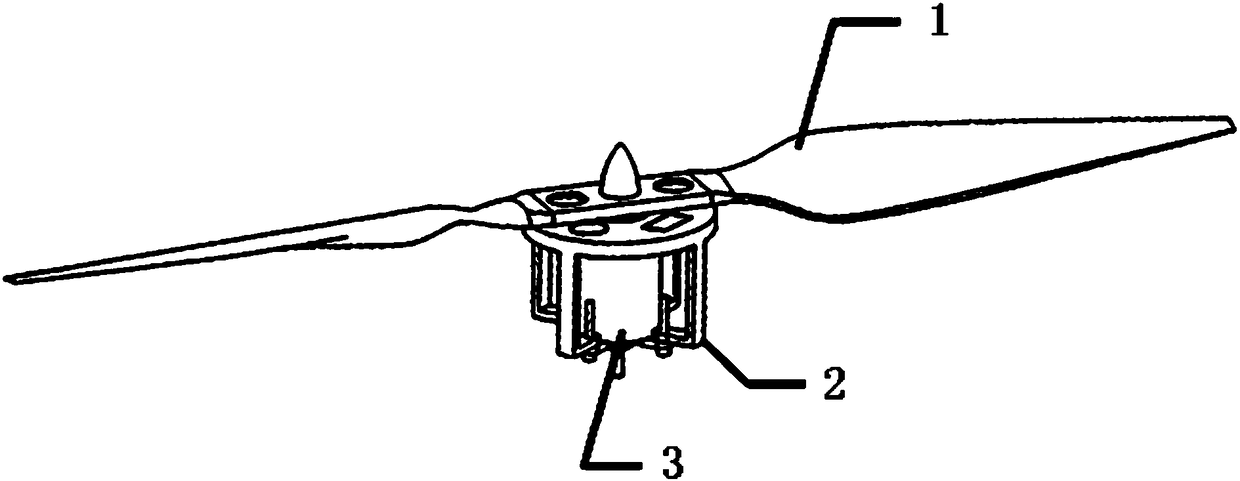

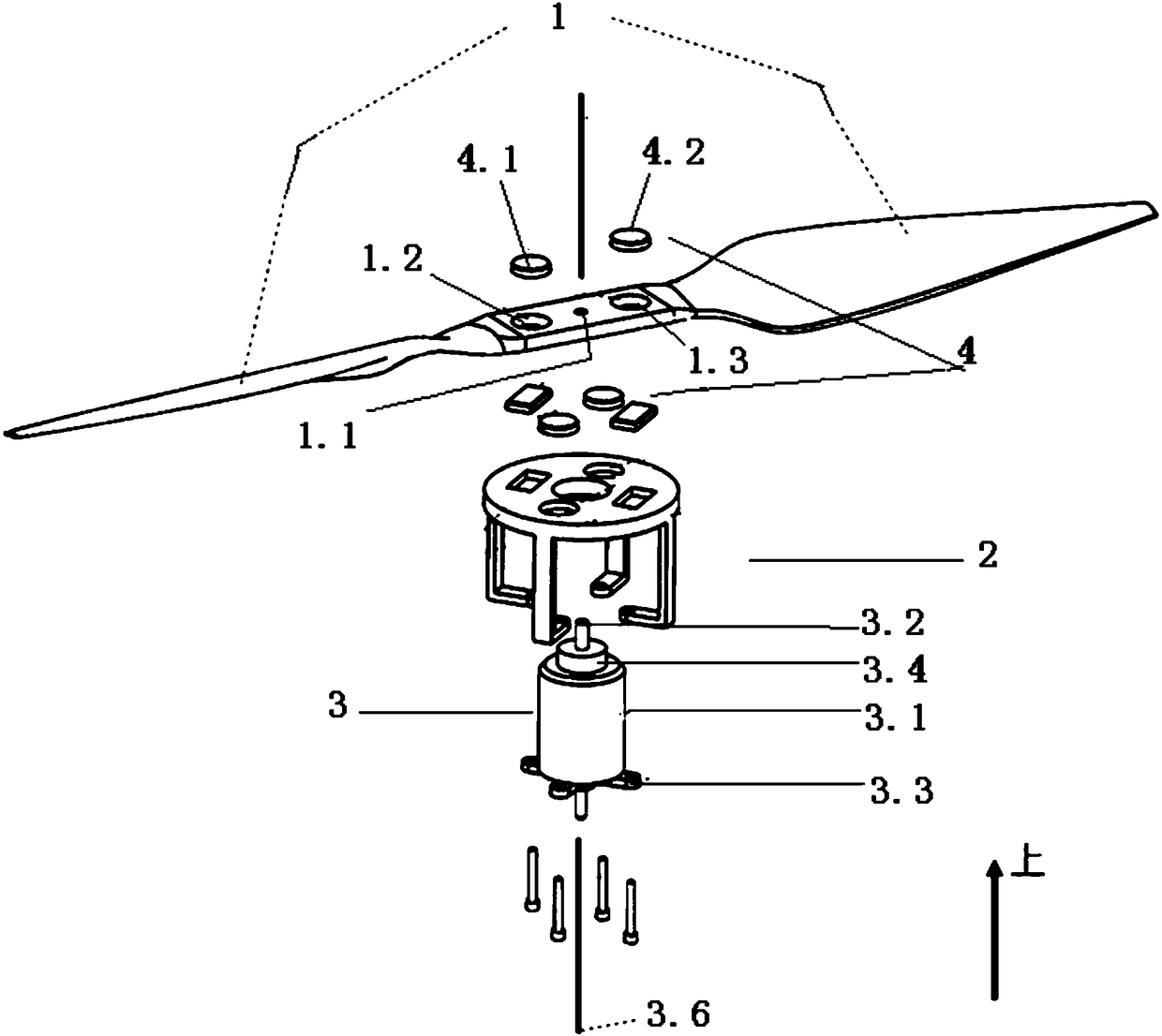

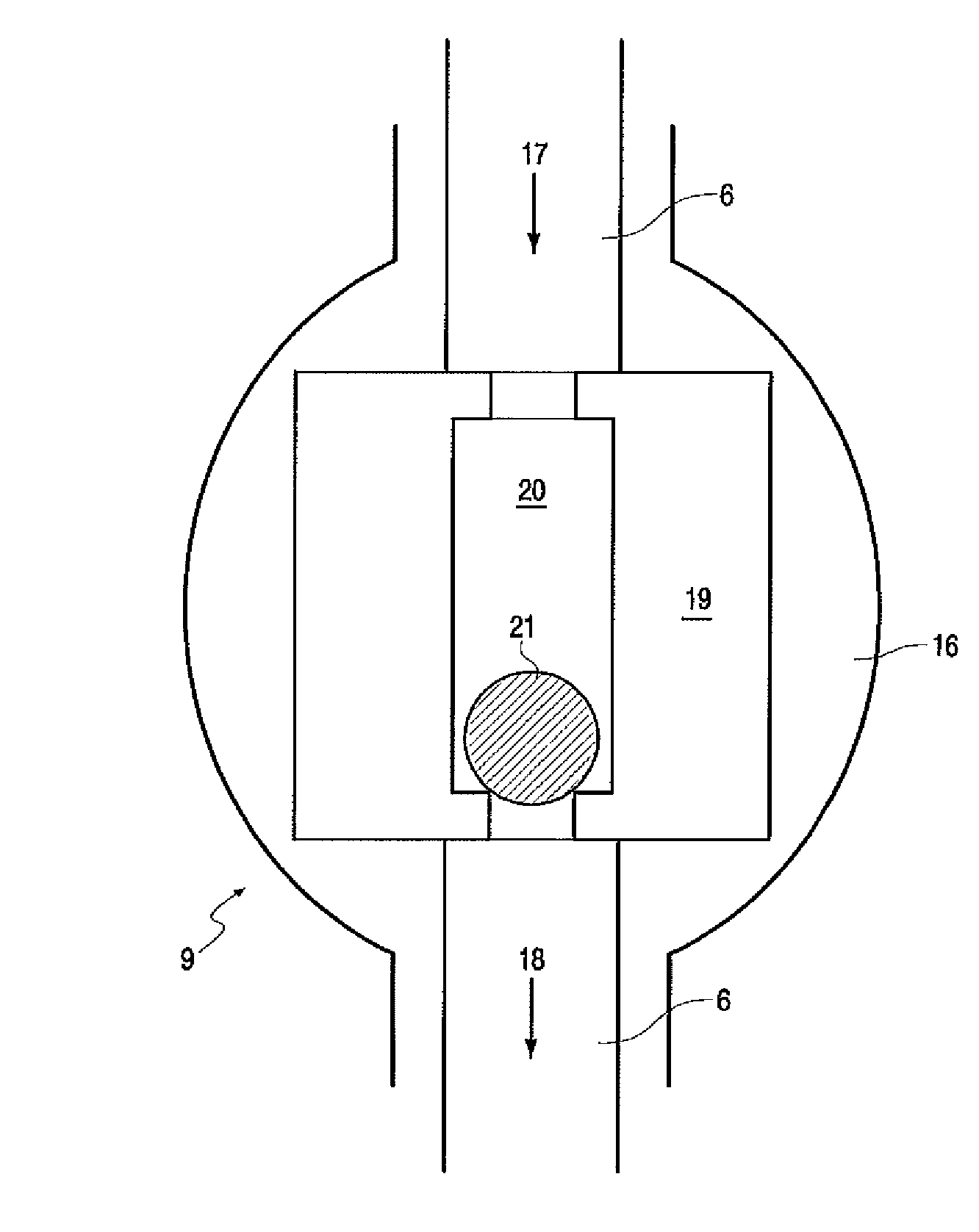

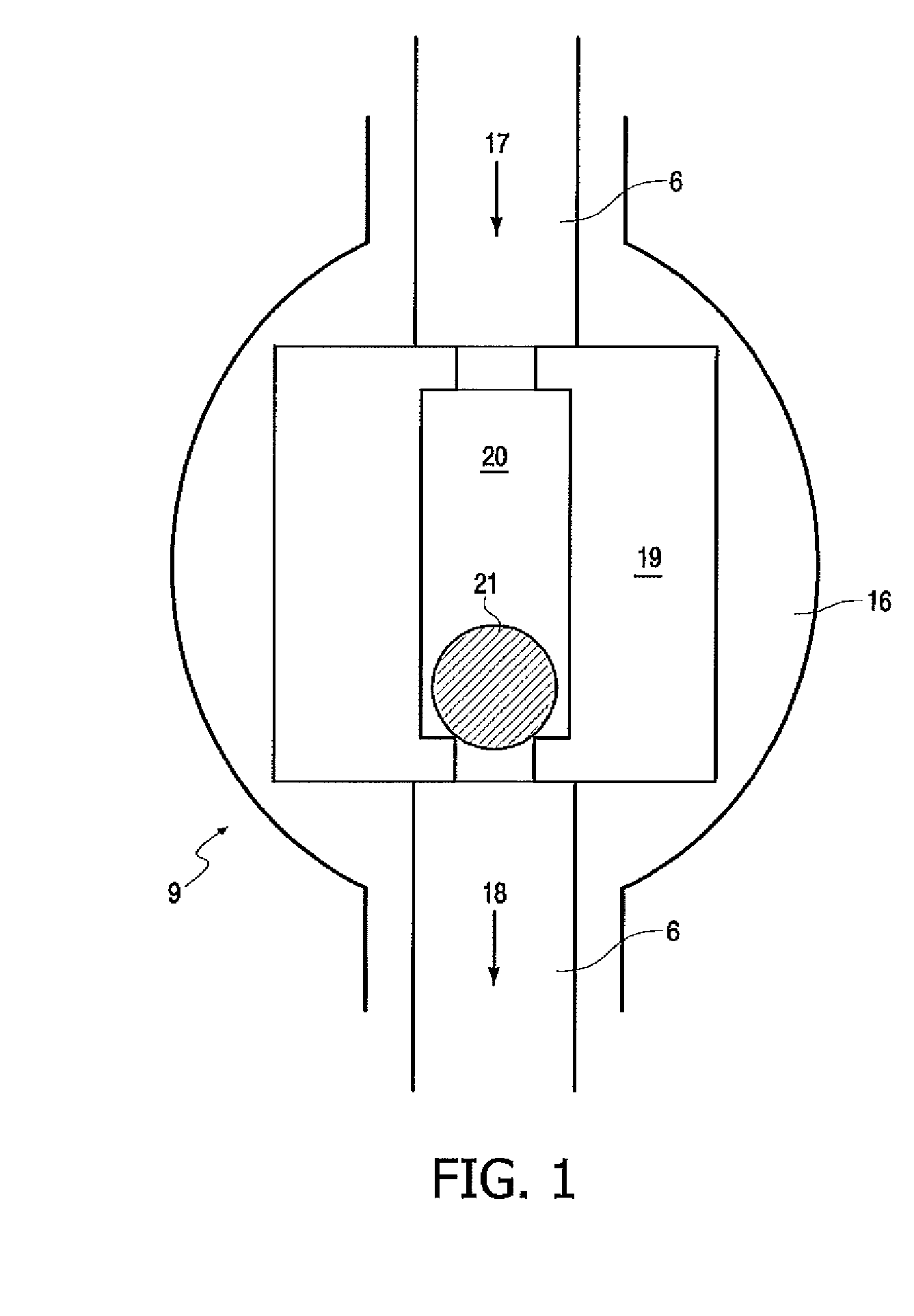

Non-contact separation type unmanned aerial vehicle propeller locking device and locking method

ActiveCN108482646ASimple structureReduce weightPropellersEfficient propulsion technologiesCircular discElectrical polarity

The invention provides a non-contact separation type unmanned aerial vehicle propeller locking device and a locking method. The locking device comprises a propeller, a locking frame, a motor mechanismand permanent magnet groups, wherein the permanent magnet groups comprise a first permanent magnet group, a second permanent magnet group and a third permanent magnet group; the first permanent magnet group is mounted at the root part of the propeller; the second permanent magnet group and the third permanent magnet group are mounted on a locking disk of the locking frame; a polarity arrangementmode of the second permanent magnet group is the same as that of the first permanent magnet group; the polarity arrangement mode of the third permanent magnet group is opposite to that of the first permanent magnet group. The non-contact separation type unmanned aerial vehicle propeller locking device provided by the invention has the advantages of simple structure and light weight; meanwhile, thepropeller is locked by adopting a non-contact mode, so that mechanical wear is avoided; the locking device has the advantages of large locking torque, short locking time, zero additional power loss,low fault rate, convenience in removal and maintenance and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Catalyst metering device

ActiveUS8742036B2Simple reaction conditionsSimple processPipeline systemsChemical/physical/physico-chemical stationary reactorsHardnessIron based alloy

The invention relates to a catalyst metering device with a valve formed of an iron-based alloy steel hardened to a Rockwell hardness C of at least 60. The device can be used for metering of a catalyst for an ethylene polymerization reaction. The invention further relates to ethylene polymerization wherein the catalyst is metered in a catalyst metering device with a iron-based alloy steel hardened valve, as well as to a ethylene polymerization reactor comprising such a catalyst metering device.

Owner:TOTAL RES & TECH FELUY

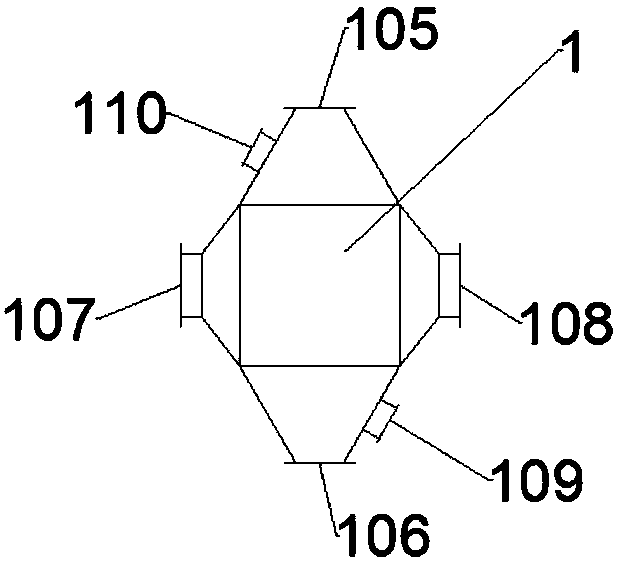

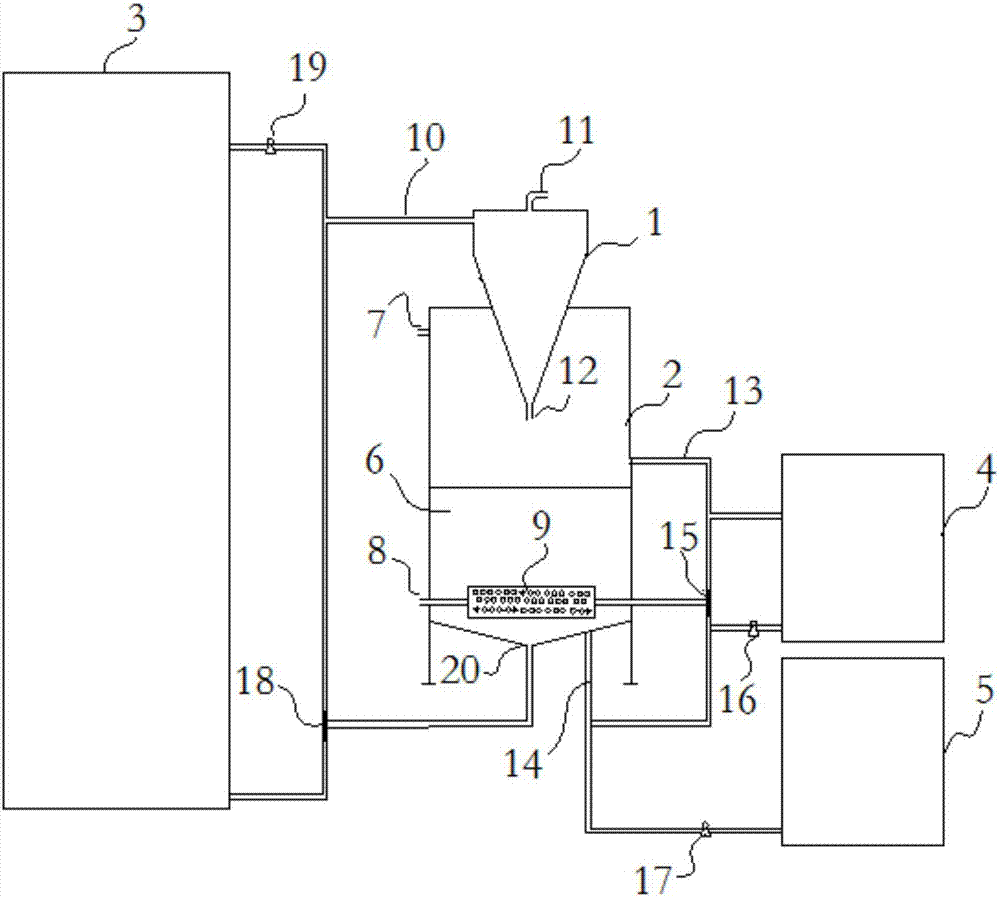

Fixed bed counter-current regeneration device of ion exchange resin and application method of fixed bed counter-current regeneration device

ActiveCN106881159AGuarantee comprehensive and efficient applicationSimple structureWater/sewage treatment by centrifugal separationSpecific water treatment objectivesDesorptionApplication engineering

The invention discloses a fixed bed counter-current regeneration device of ion exchange resin and an application method of the fixed bed counter-current regeneration device and belongs to the field of ion exchange resin regeneration. The fixed bed counter-current regeneration device comprises a cyclone separator, a regenerative reactor, an all-mixed resin reactor, a desorption liquid storage tank and a regenerant storage tank; the cyclone separator is arranged at the top of the regenerative reactor; the upper part of the cyclone separator is communicated with the all-mixed resin reactor; a resin inlet is formed at the bottom of the cyclone separator; a resin bed and a resin filter are arranged in the regenerative reactor; a resin outlet and a regenerant inlet are formed in the bottom of the regenerative reactor; the resin outlet is communicated with the all-mixed resin reactor; the regenerant inlet is communicated with the desorption liquid storage tank and the regenerant storage tank separately; and a regenerant outlet is also formed in one side of the regenerative reactor and is communicated with the desorption liquid storage tank. The resin regeneration efficiency can be effectively improved through the separator in a counter-current manner, the yield of a desorption liquid is reduced, mechanical wear of the resin is avoided and the fixed bed counter-current regeneration device can be matched with large-scale ion exchange resin application engineering.

Owner:NANJING UNIV +1

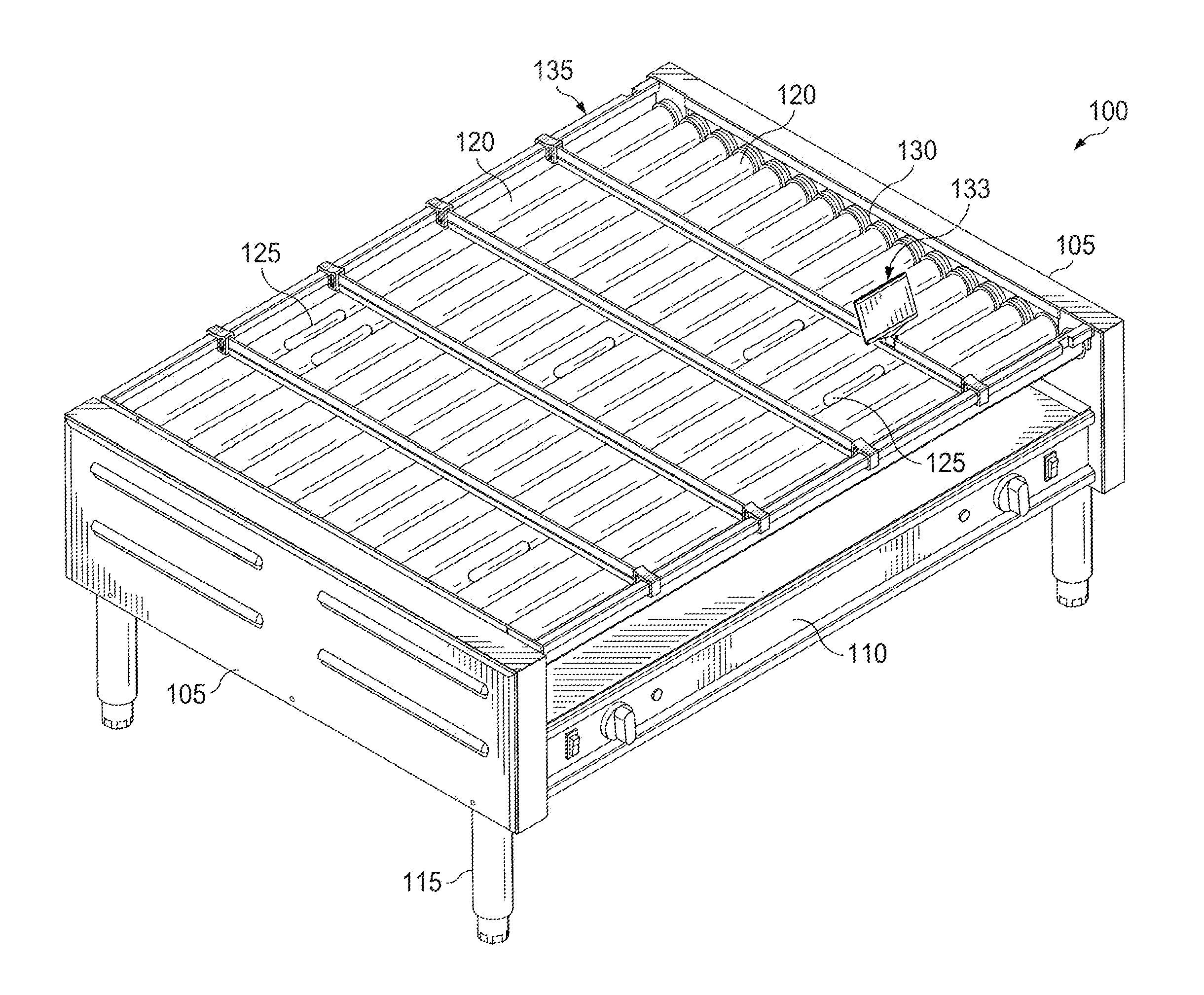

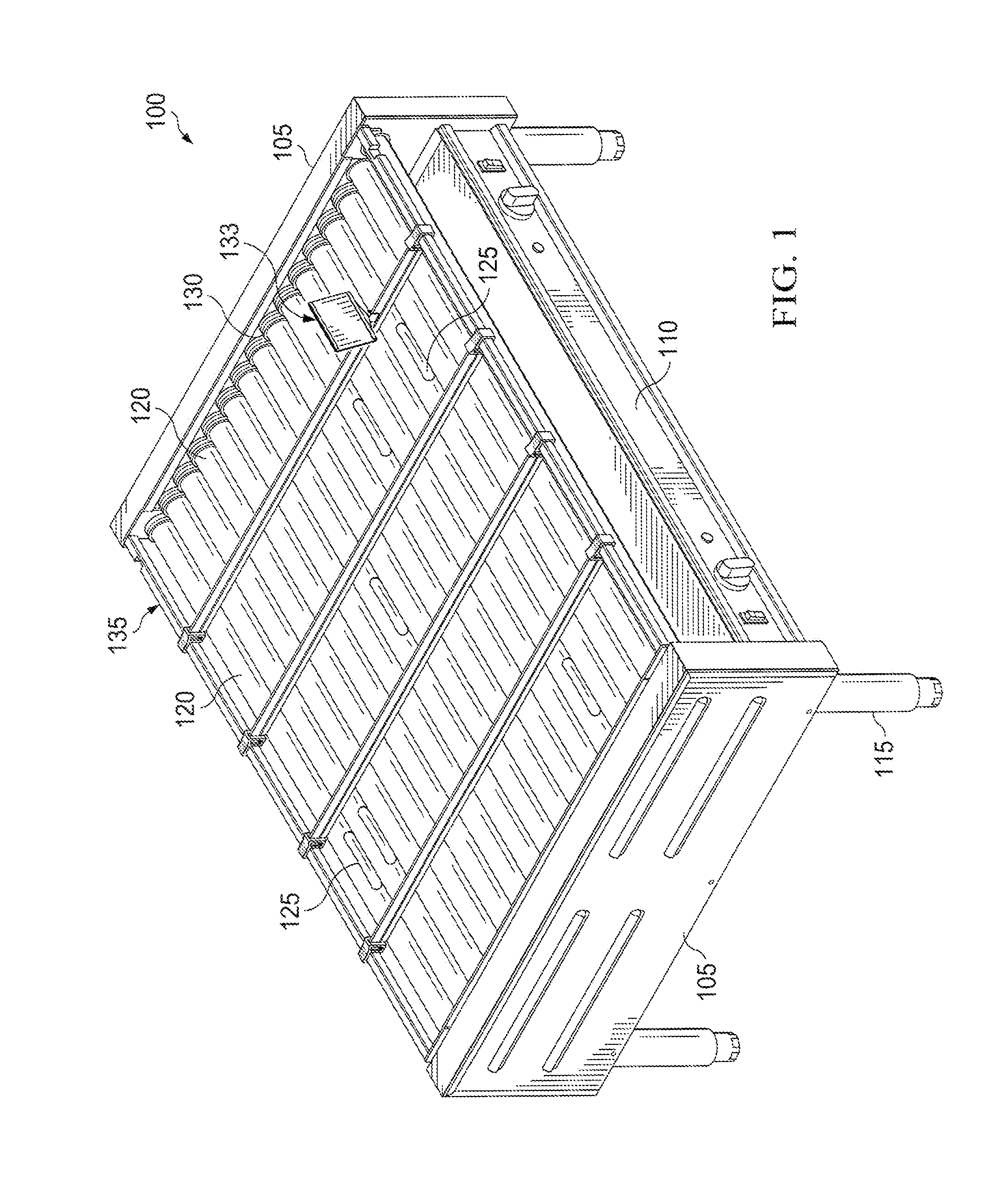

Roller Grill Divider

InactiveUS20130327227A1Avoid forceAvoid mechanical wearMeat processingFood shapingEngineeringCooked food

A roller grill divider assembly includes a frame adapted to rest upon on a roller grill and one or more dividers securable to the frame. The roller grill includes multiple tubes having outer surfaces adapted to transfer heat to a pre-cooked food product. The one or more dividers are in contact with the multiple tubes and are adapted to adjust along a length of the frame to multiple positions such that the pre-cooked food product is substantially prevented from passing beneath the one or more dividers.

Owner:ADCO IND TECH

Environment-friendly near dry cutting liquid and preparation method thereof

The invention relates to the technical field of near dry cutting liquid, and specifically relates to an environment-friendly near dry cutting liquid and a preparation method thereof. The environment-friendly near dry cutting liquid is characterized by being prepared from the following raw materials in percentage by weight: 20-40% of dialkyl thiophosphate, 20-40% of carbaminate, 20-40% of poly alkylene glycol, 2-5% of carboxamide, 1-2% of sodium benzoate, 1-2% of hydantoin and 15-35% of deionized water. Compared by the prior art, the environment-friendly near dry cutting liquid provided by theinvention has the advantages of very good lubricity and extreme pressure and anti-wear performance, and high-end requirements of a metal processing technique can be satisfied by using a very little amount of cutting liquids; and the dosage of the lubricant can be reduced to be below 10% of that of the traditional lubricant by matching with a near dry cutting device, and thus, the harms to the environment and workers are reduced.

Owner:常州海纳环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com