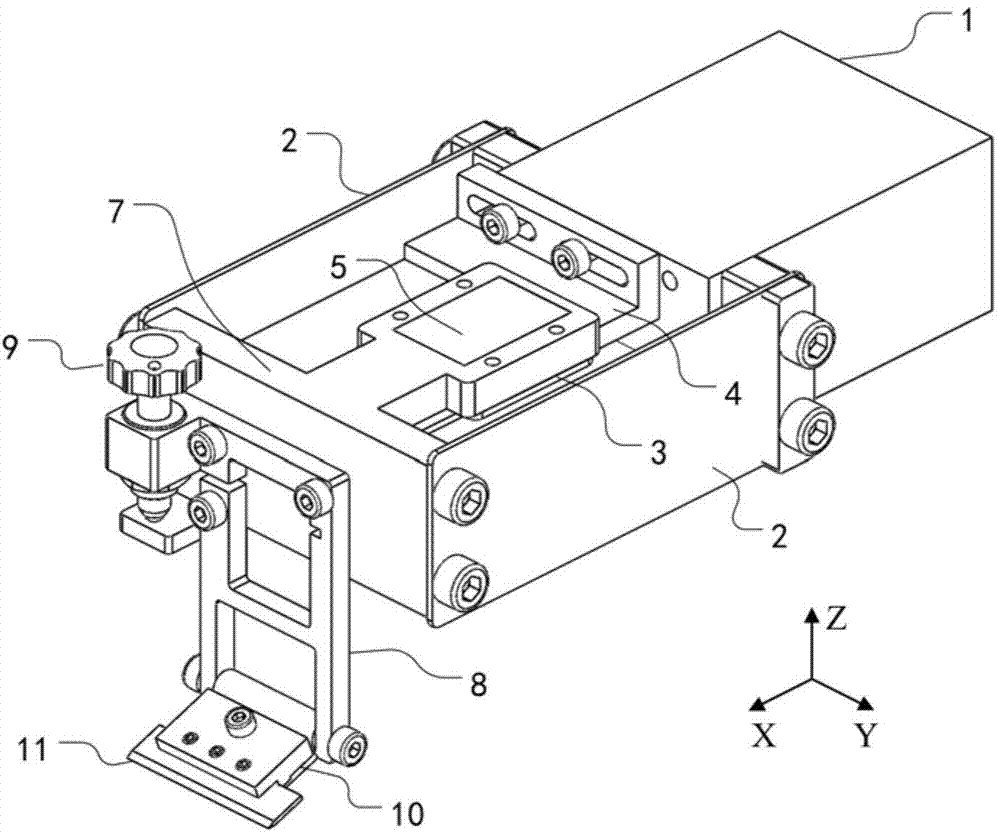

High-precision vibration slicing machine

A slicer, high-precision technology, applied in the field of research and medical equipment, can solve the problems affecting the slice quality, the Z-direction error of the vibrating slicer, etc., to avoid mechanical wear, reduce the Z-direction error, and reduce the effect of sample tissue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

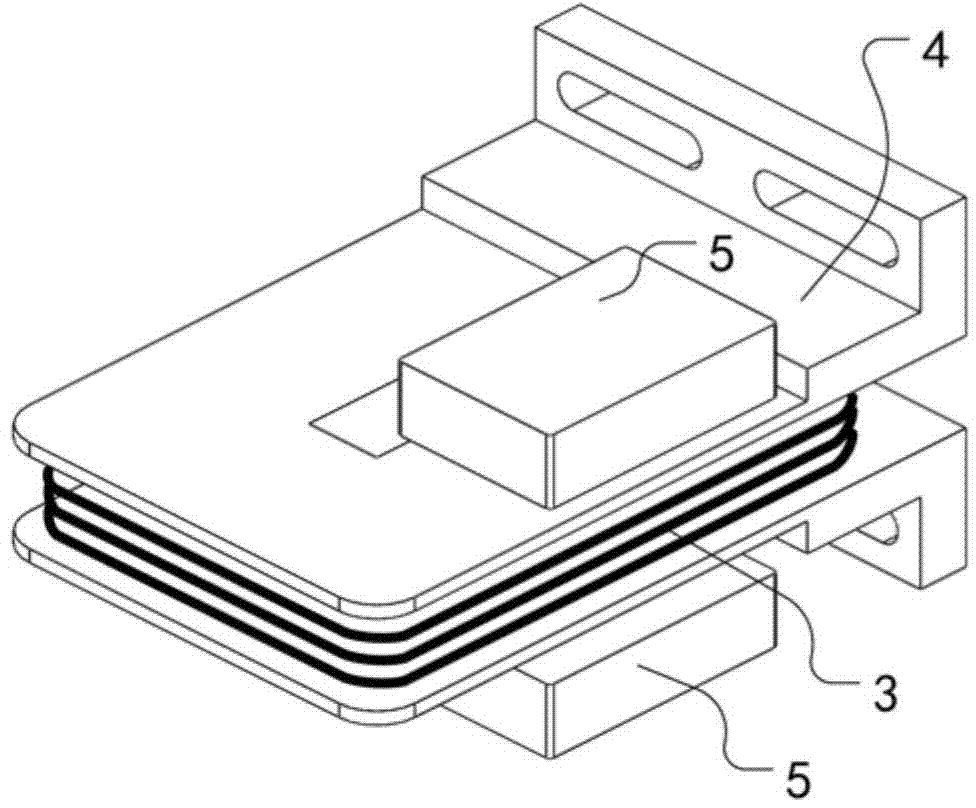

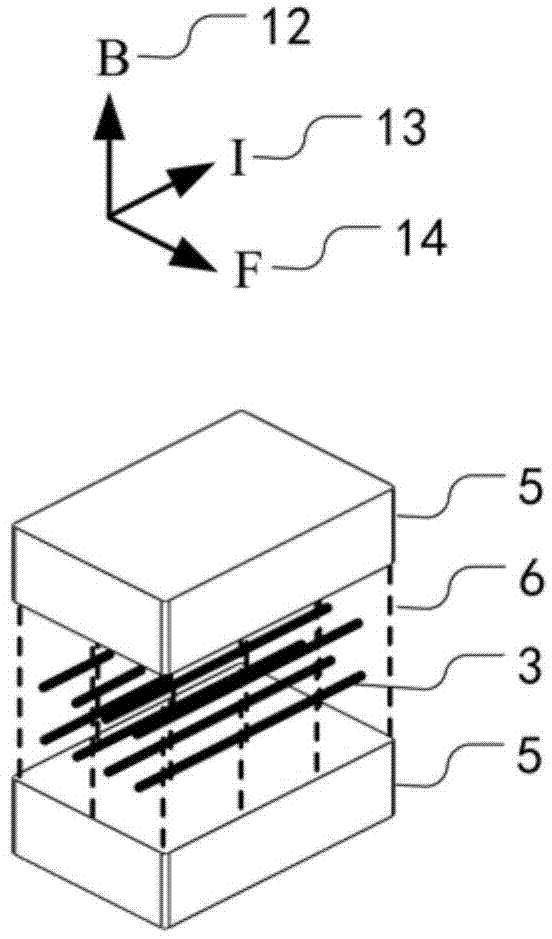

[0031] The base is made of aluminum, and the spring steel sheet is made of carbon spring steel with an elastic modulus of 200kN mm -2, The external dimensions are 95×50×1.6mm, the vibration end is made of aluminum, and the natural vibration frequency of the single-degree-of-freedom vibration system is 80Hz. The coil is made of enamelled copper wire with a diameter of 0.35mm, a total of 1100 turns, and a resistance value of 32Ω. The coil bobbin is made of aluminum. The size of the permanent magnet is 20×30×10mm, and the residual magnetic strength is 1.4T. The driving force generated by the electromagnetic force driving structure is 46N / A. The fine-tuning screw adopts the fine-tuning screw with the specification of 170TPI produced by Newport Company, and the sensitivity is 0.4 μm. The elastic structure and the blade fixture are stainless steel processing parts. The blade is a zirconia blade from Electron Microscopy Sciences.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com