Semi-dry flue gas purification system and method based on carbon material oxidative denitration

A flue gas purification system, semi-dry technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as safety hazards and escape, and achieve a small footprint, compact equipment, and low water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

[0045] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0046] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

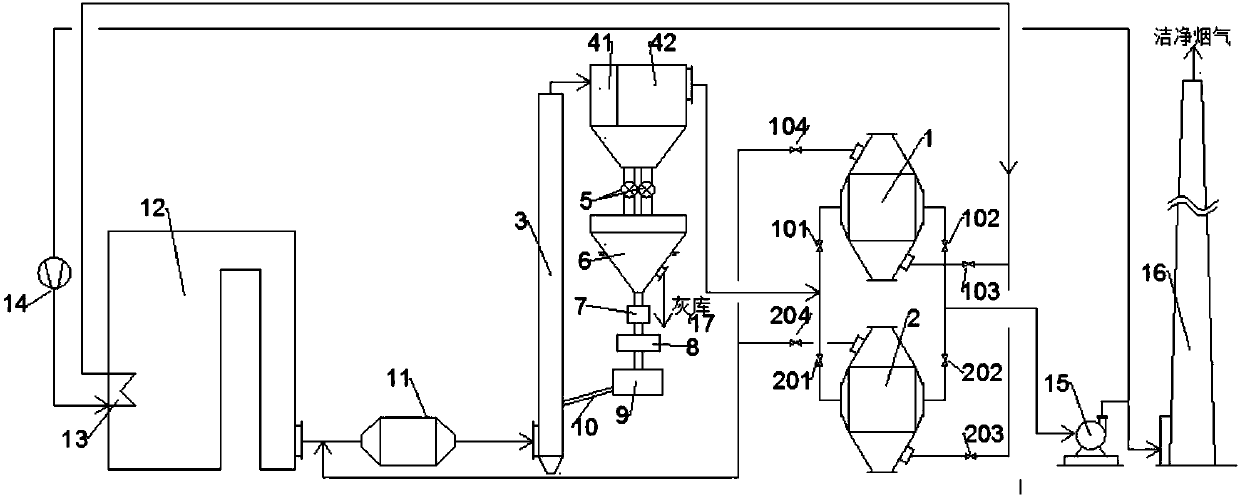

[0047] Such as figure 1 Shown is a schematic structural view of the semi-dry flue gas purification system of the present invention, the removal system is connected to the boiler 12, the tail flue of the boiler 12 is connected to the air preheater 11, and the outlet of the air preheater 11 is connected to the standpipe In the desulfurization reactor 3, the active calcium in the fly ash is used to remove the SO in the flue gas. 2 , SO 3and other acid gases. The outlet of the desulfurization reactor 3 is connected with a dedusting unit for dedusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com