Device and method for measuring rotating speed of large rotating equipment

A technology of rotating equipment and rotating speed, which is applied in the direction of devices using electric/magnetic methods, can solve the problems of the limitation of speed measurement capability and the difficulty of meeting the precise measurement requirements of high speed and low speed at the same time, so as to avoid mechanical wear and wide Speed measurement range, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

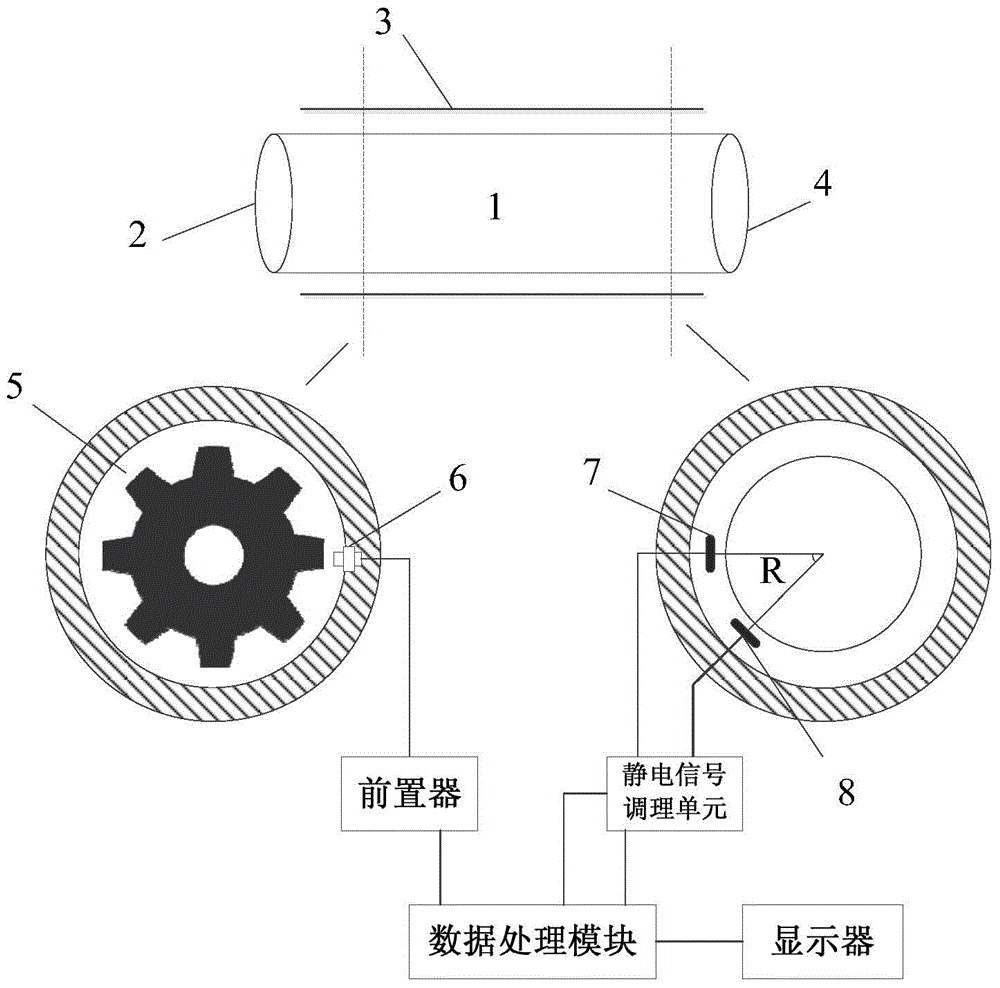

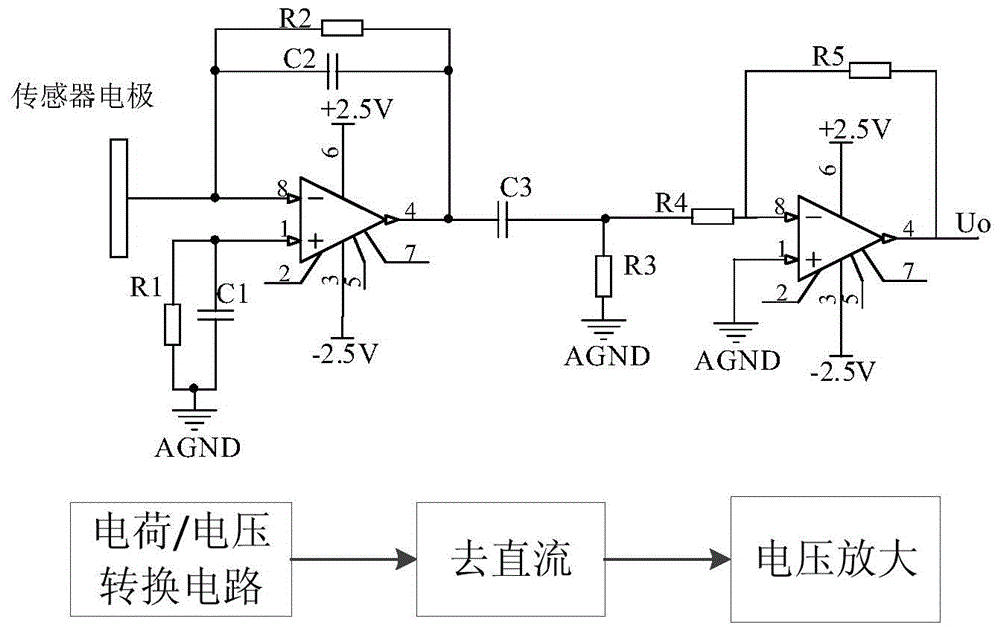

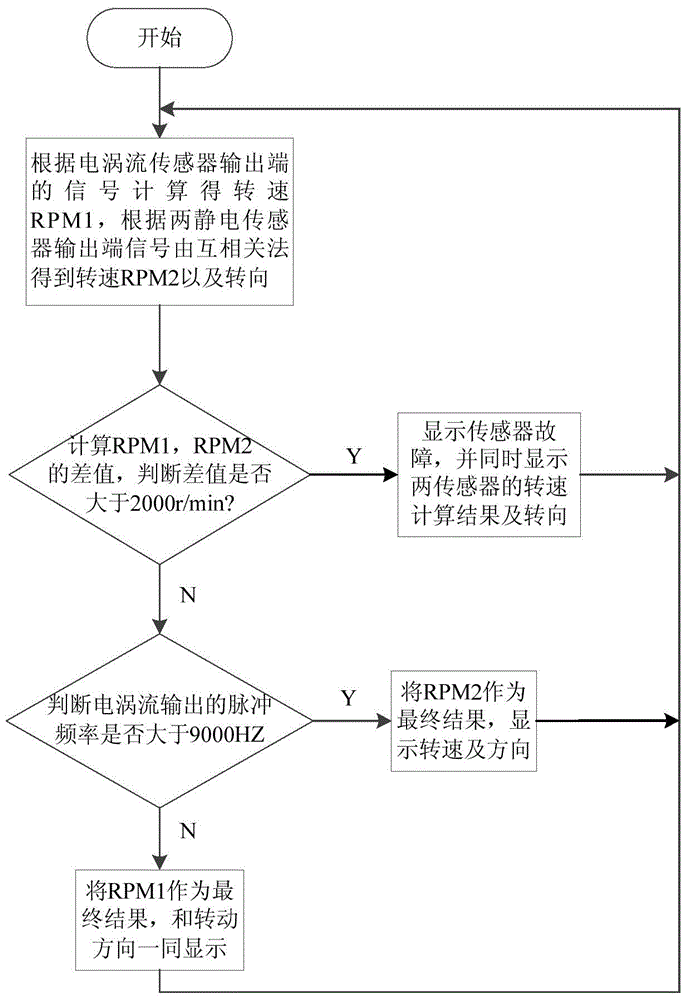

[0027] reference figure 1 , A device that uses electrostatic and eddy current sensors to measure the speed of large rotating equipment, including an eddy current sensor 6, two integrated electrostatic sensors 7, 8, and a speed measuring gear 5. Wherein, the speed measuring gear 5 is installed on the end surface 2 of the rotating shaft 1 to be measured, the eddy current sensor is fixed on the inner side of the casing relative to the flange of the speed measuring gear, and the distance between the sensor probe and the gear flange is 2mm to 5mm. The integrated electrostatic sensors 7, 8 are fixed on the inner side of the casing 3 at the periphery of the imaginary section 4 of the rotating shaft 1 to be tested. The axial distance between the imaginary section 4 and the end face 2 of the rotating shaft is at least 6cm, and the distance between the electrode of the electrostatic sensor and the rotating shaft to be tested is 2mm To 6mm. The center angle of the two integrated electros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com