Novel stirrer with cleaning function

A mixer and functional technology, applied in the field of mixers with cleaning function, can solve the problems of high cost, increased power consumption, defective products, etc., and achieve the effects of avoiding deformation, prolonging life, and avoiding mechanical wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

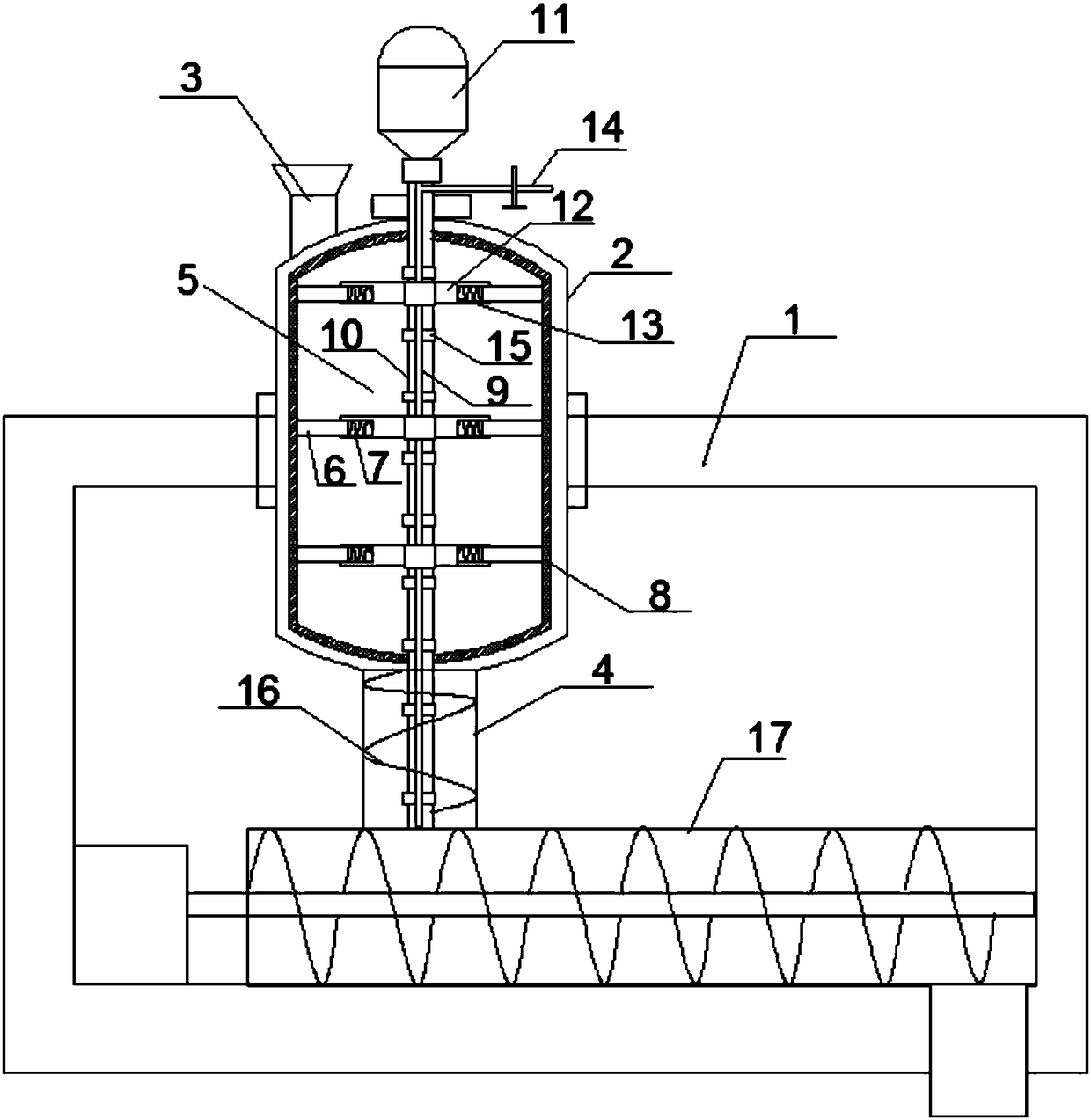

[0021] The technical scheme adopted by the present invention is as follows: a new type of mixer with cleaning function, comprising a bracket 1, a housing 2 fixedly connected to the upper part of the bracket 1, a feed inlet 3 arranged on the top of the housing 2, a 2. The discharge port 4 at the bottom and the stirring device 5 arranged in the housing 2 also include a connecting rod 6, a spring 7 and a scraper 8. The stirring device 5 includes a rotating shaft 10 with a cavity structure 9 for driving The driving device 11 of the rotating shaft 10 and the stirring paddles 12 symmetrically arranged on the rotating shaft 10, the two ends of each of the stirring paddles 12 are respectively provided with connecting grooves 13, and each of the connecting grooves 13 is connected to the connecting rod 6 by the spring 7 The other end of each connecting rod 6 is fixedly connected to the scraper 8, and a water inlet pipe 14 communicating with the cavity structure 9 is provided on the rotat...

Embodiment 2

[0024] On the basis of Embodiment 1, the length of the connecting rod 6 is 1 / 5-1 / 4 of the stirring paddle 12 , and one end of the connecting rod 6 extends to the inside of the connecting groove 13 . This can make the connecting plate and the stirring paddle 12 stably connected.

Embodiment 3

[0026] On the basis of Embodiment 1, the rotating shaft 10 extends to the bottom of the discharge port 4 , and a screw conveying paddle 16 is arranged on the rotating shaft 10 inside the discharge port 4 . By adopting the screw conveying paddle 16, the fully mixed concrete can be automatically conveyed to the outside of the shell 2, which avoids the concrete blocking the discharge port 4. During the cleaning process of the mixer, the screw conveying paddle 16 can accelerate the residue in the discharge port 4 Cleaning of concrete residues inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com