Patents

Literature

141results about How to "Not easy to bruise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

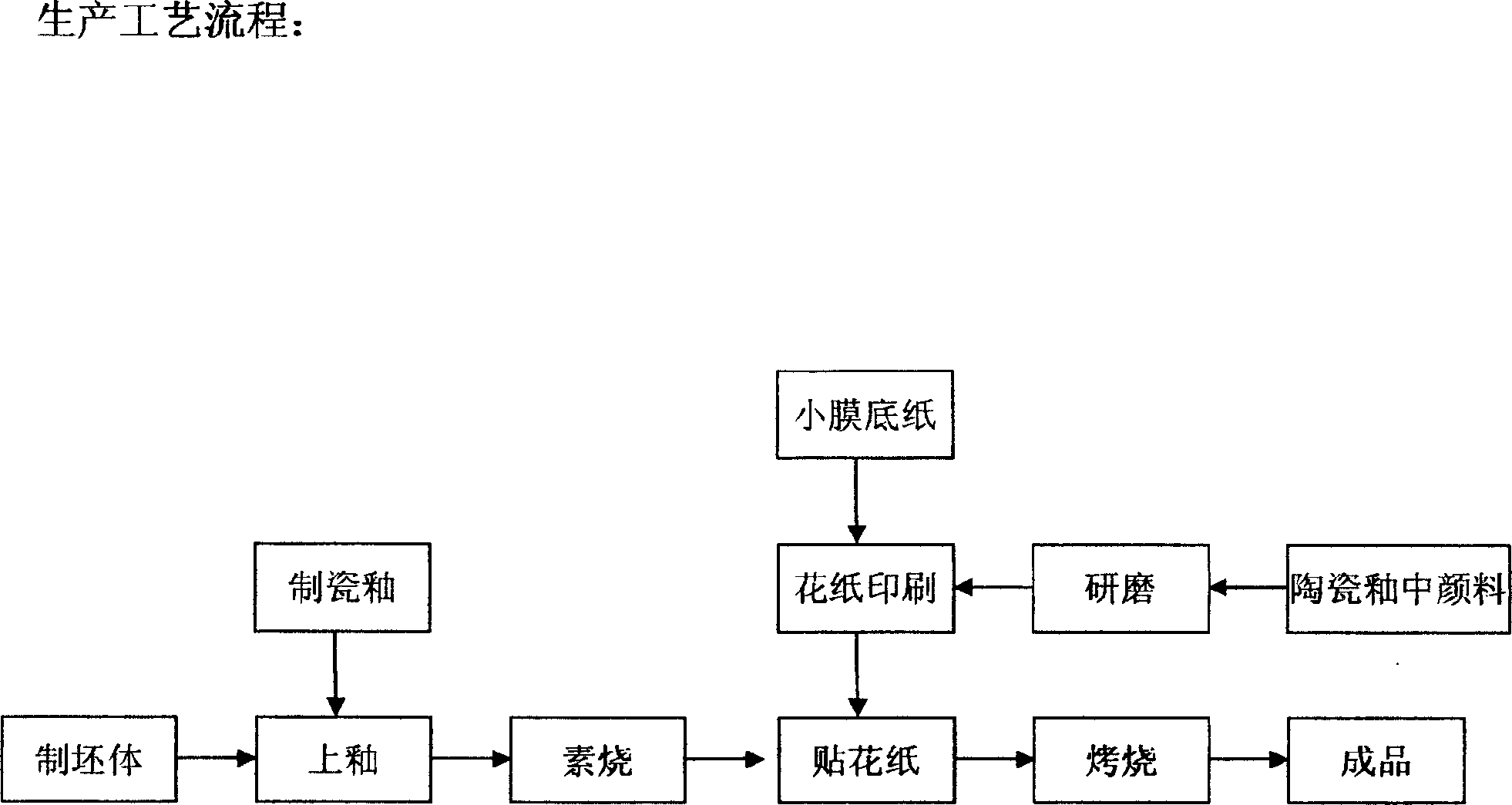

Glaze coloured decoration daily use poocelain and its production method

InactiveCN1911855AMeet technical requirementsMeet the process requirementsHigh volume manufacturingThermal stability

The present invention relates to ceramic product, and is especially one kind of in-glaze color decorated daily use porcelain product and its production process. The materials for the in-glaze color decorated daily use porcelain include Longyan clay, weathered potash feldspar, Jiepai clay, potash feldspar, calcined alumina, Guizhou clay and quarztz. The production process of the in-glaze color decorated daily use porcelain product includes the steps of making biscuit, preparing glaze and in-glaze color paper, glazing the biscuit, firing biscuit, adhering the in-glaze color paper, and baking to obtain the product. The in-glaze color decorated daily use porcelain has rich bright colors, smooth and fine glaze surface, low Pb and Cd leaching out amount, high strength, and other advantages.

Owner:林伟河

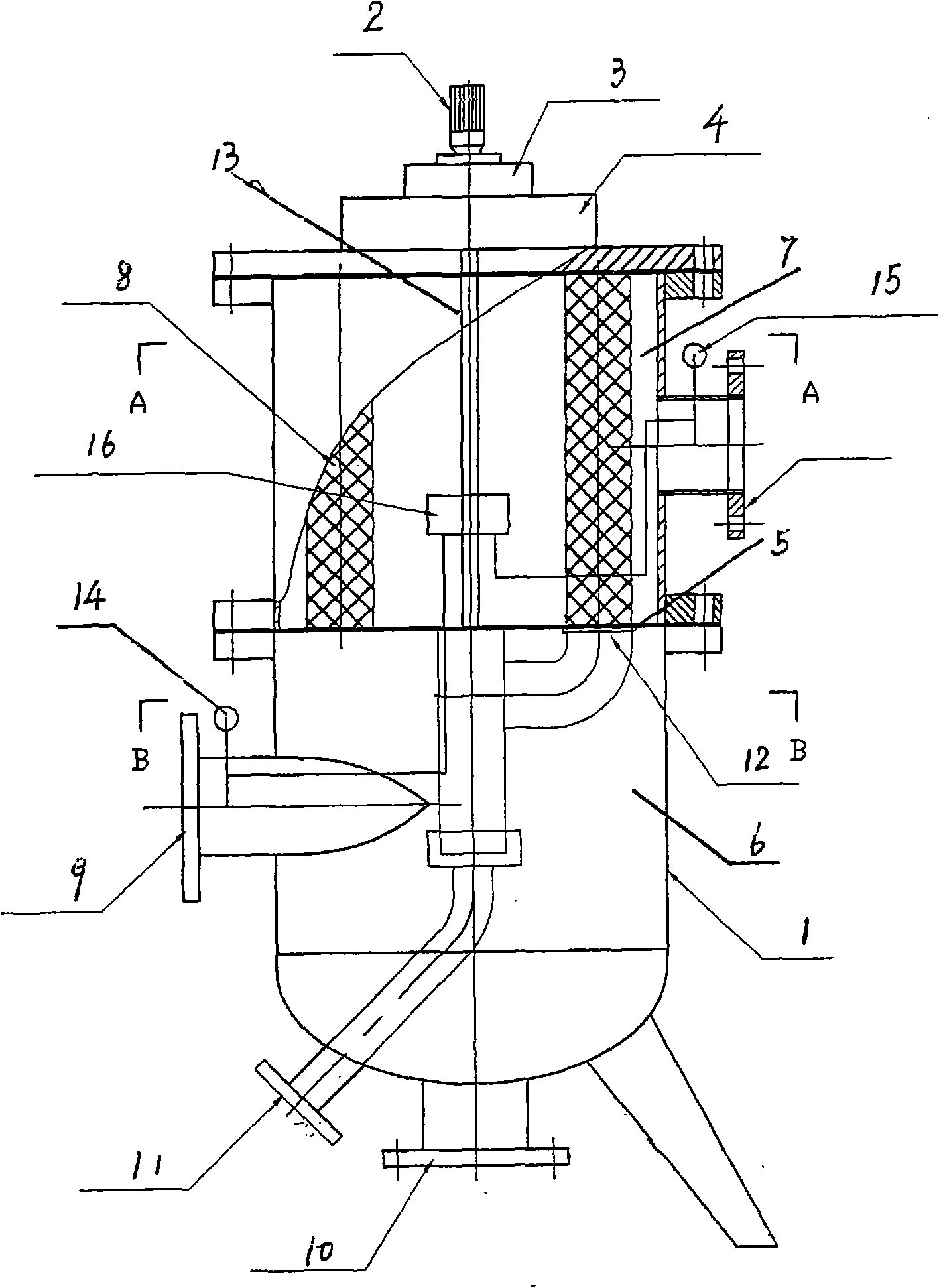

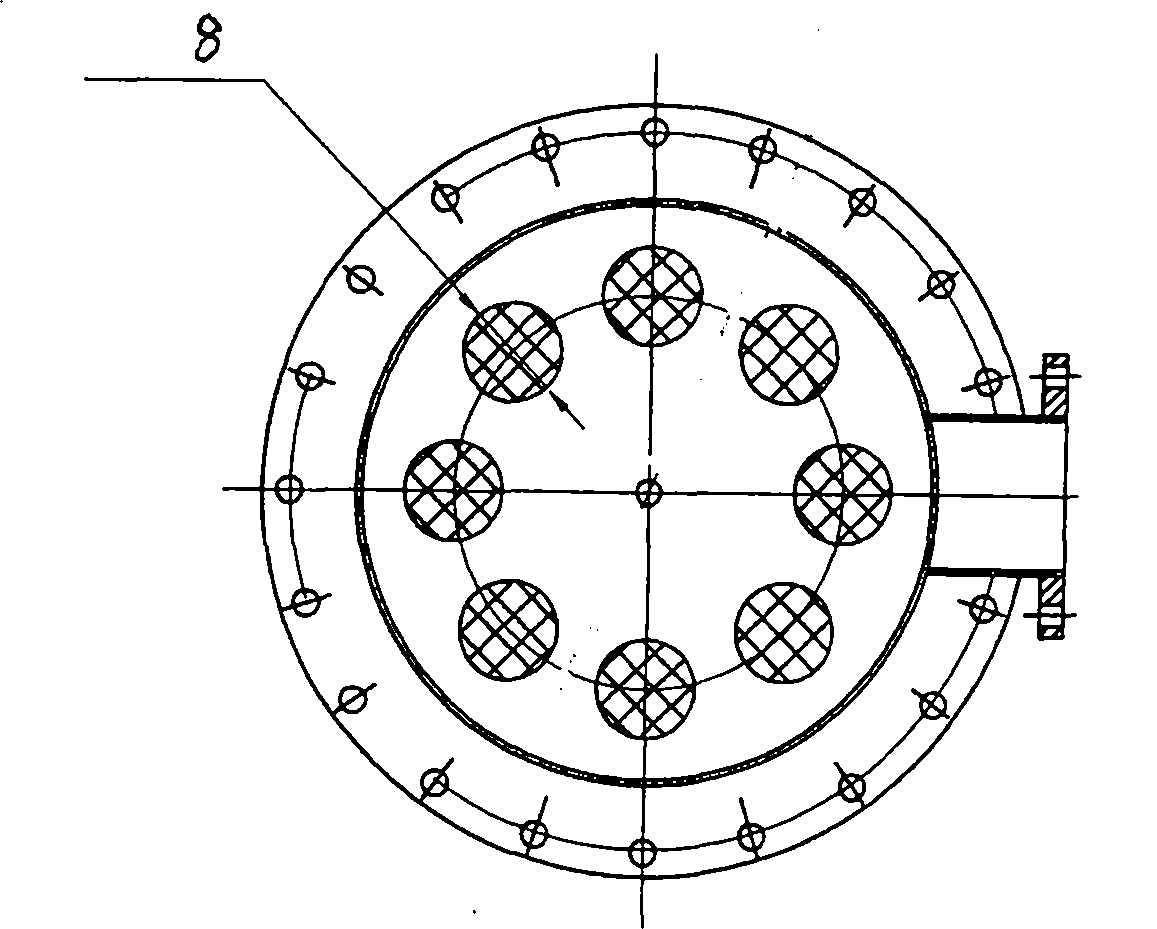

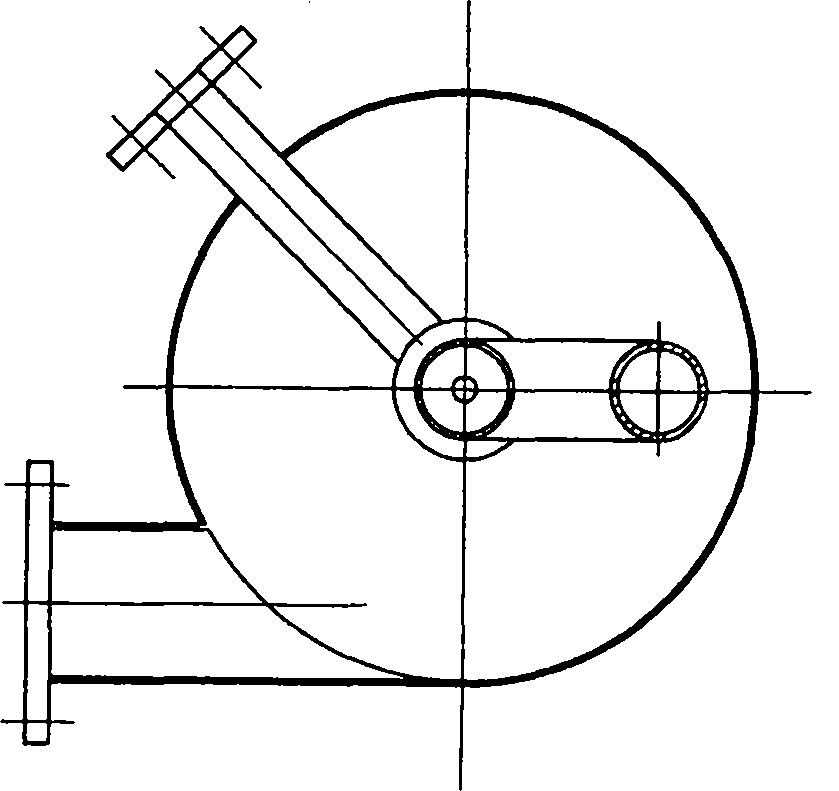

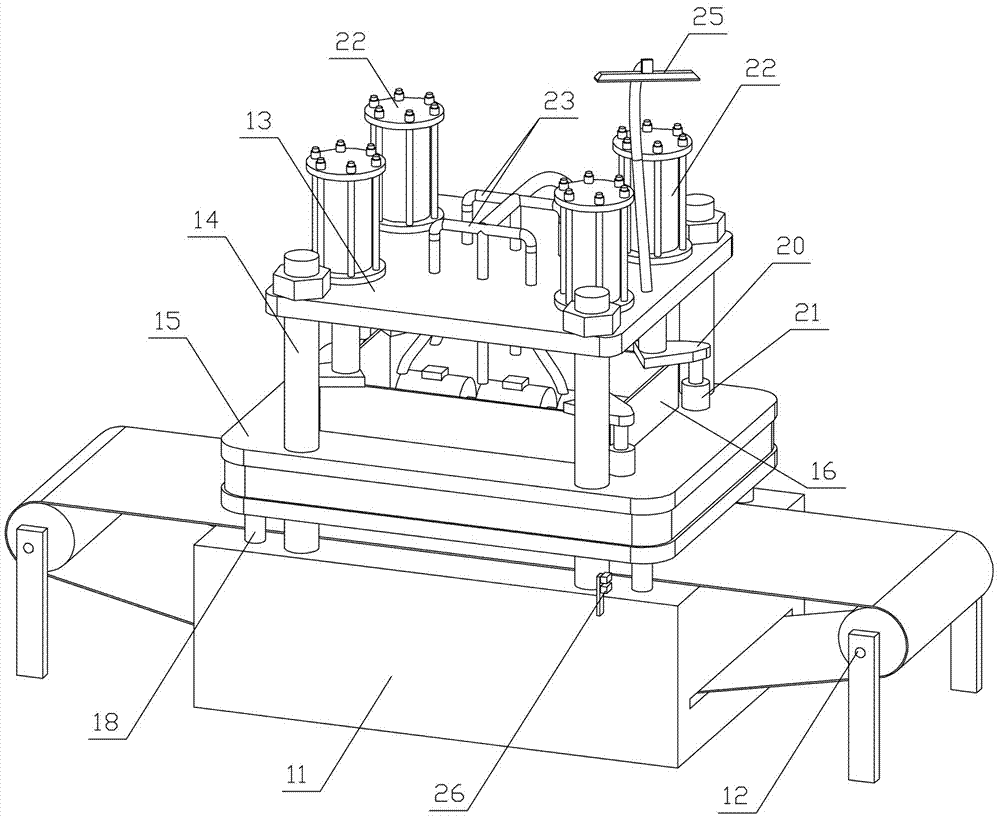

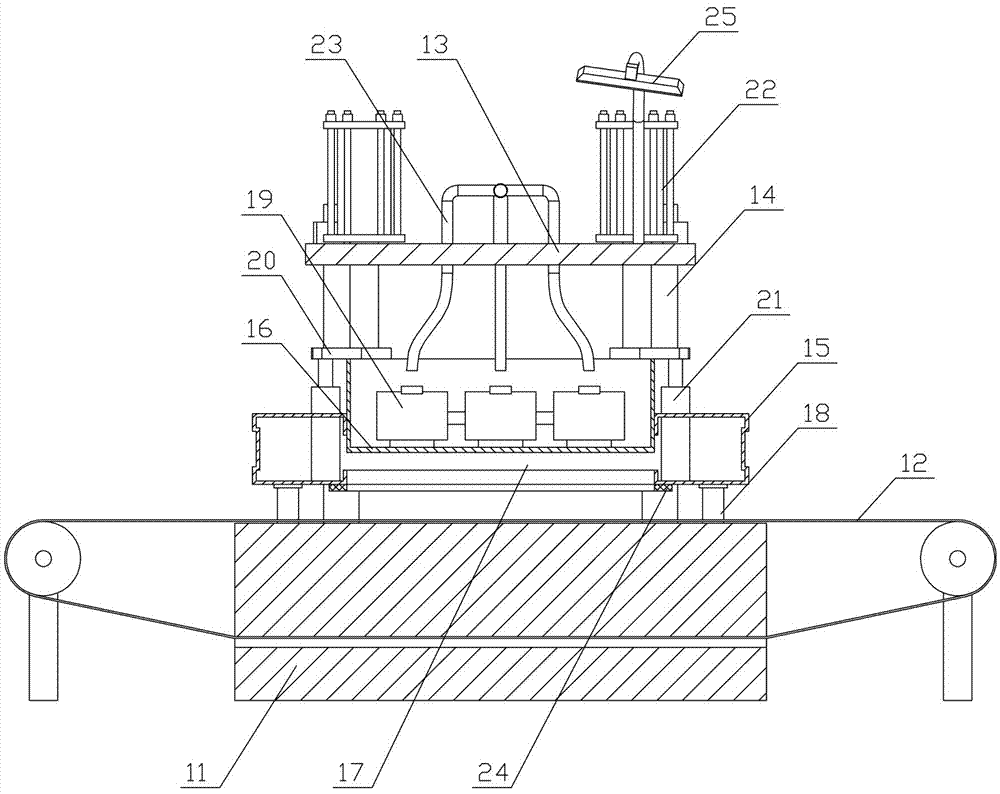

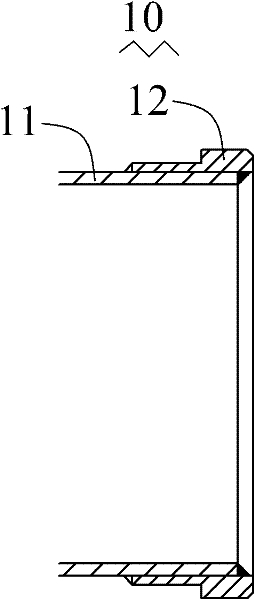

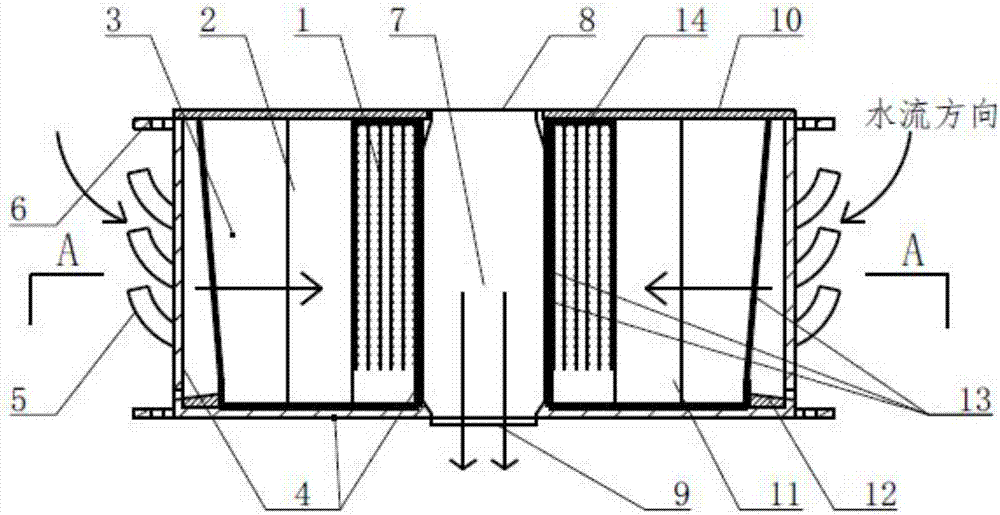

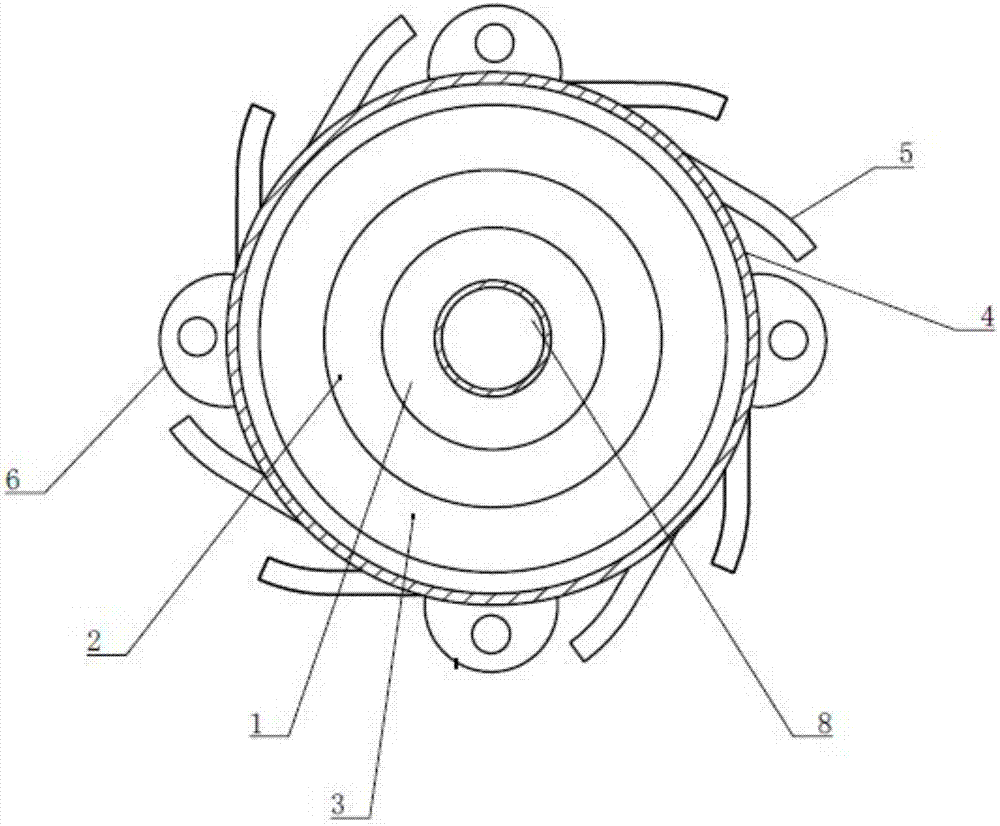

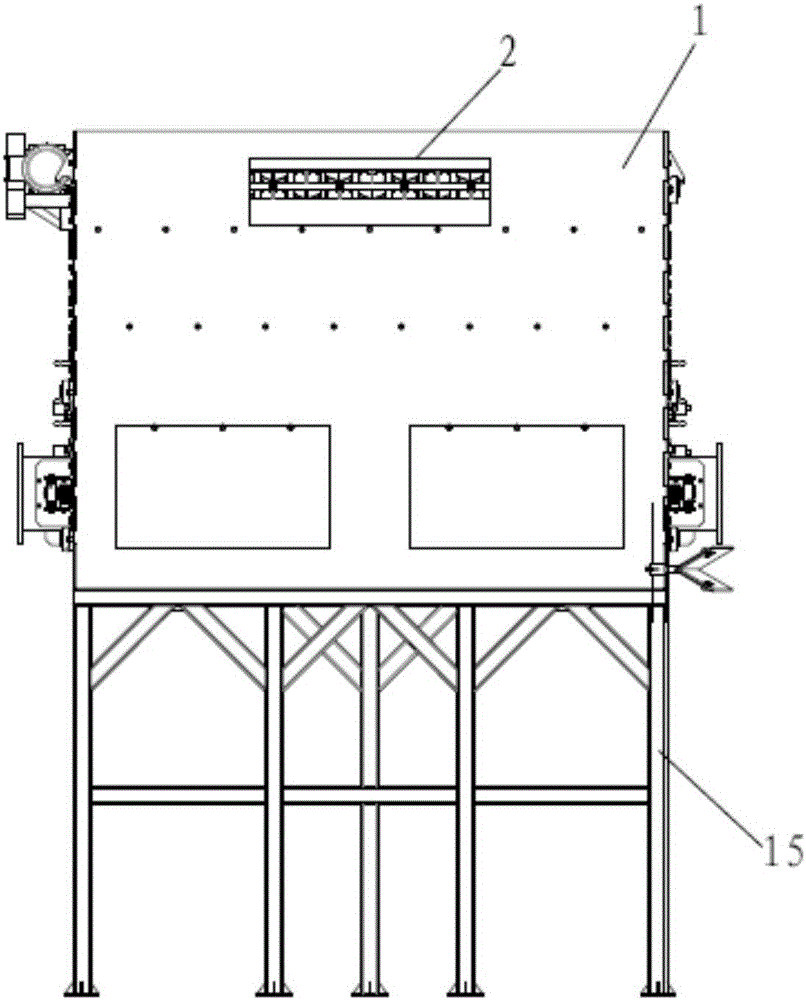

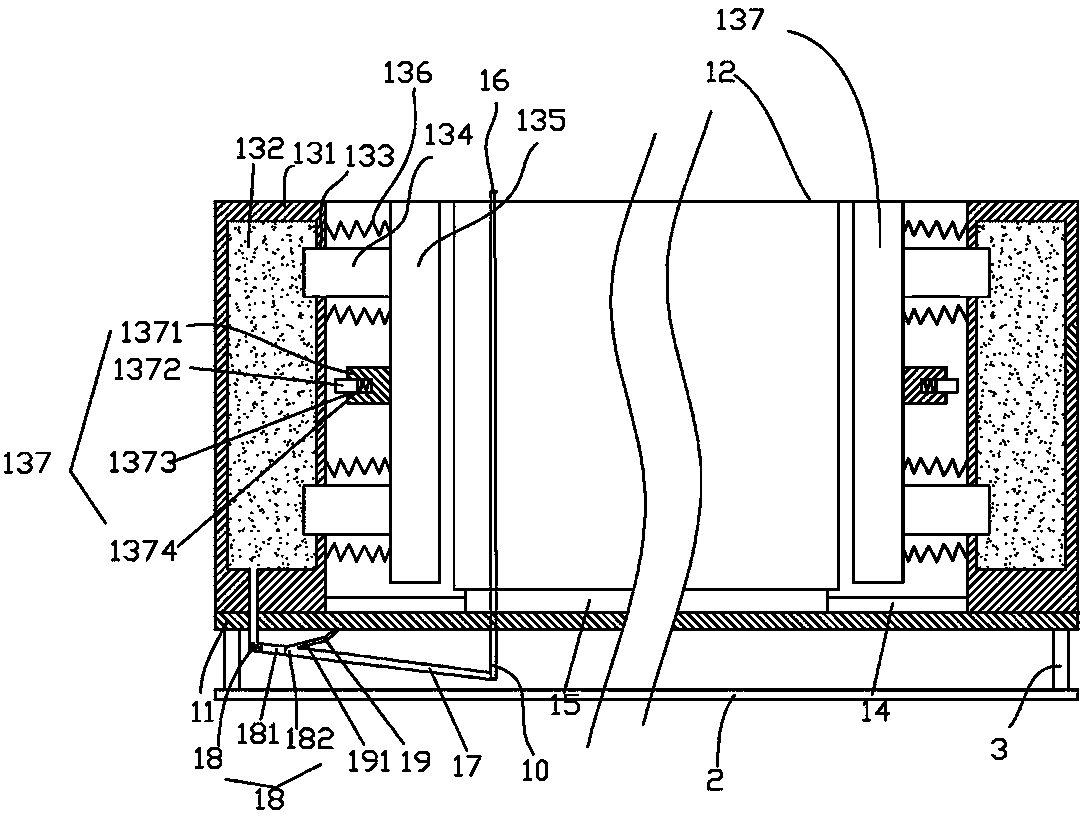

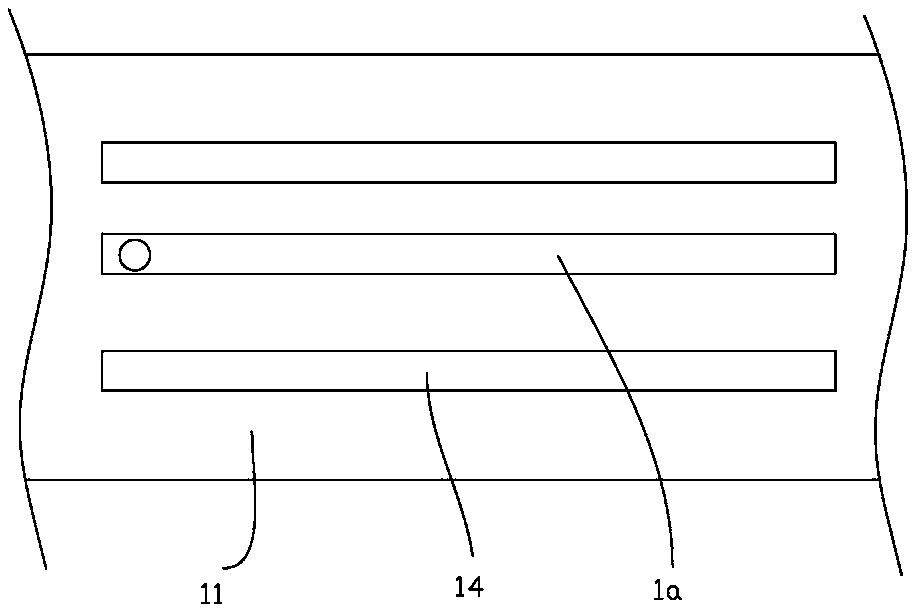

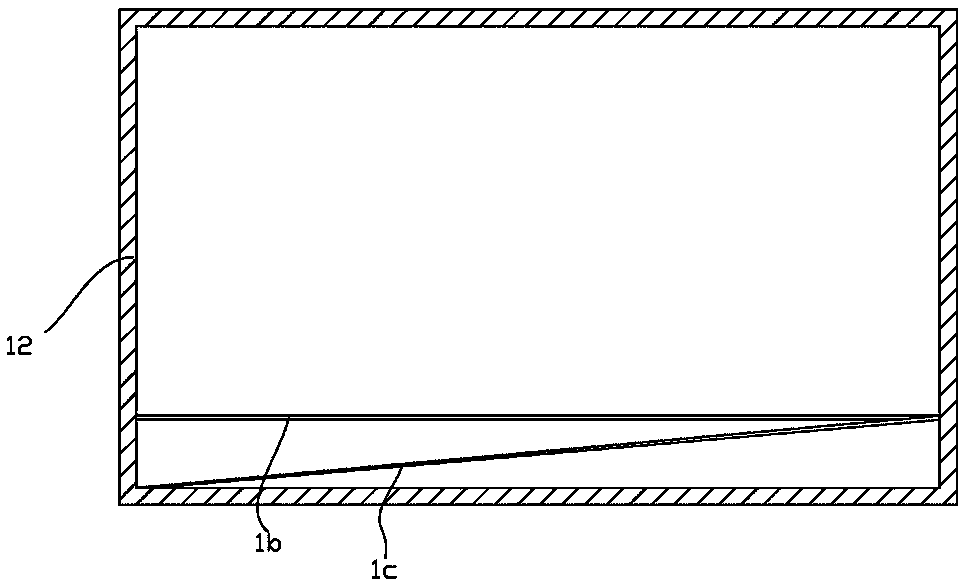

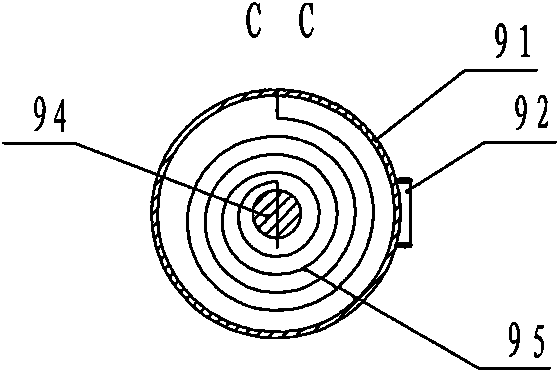

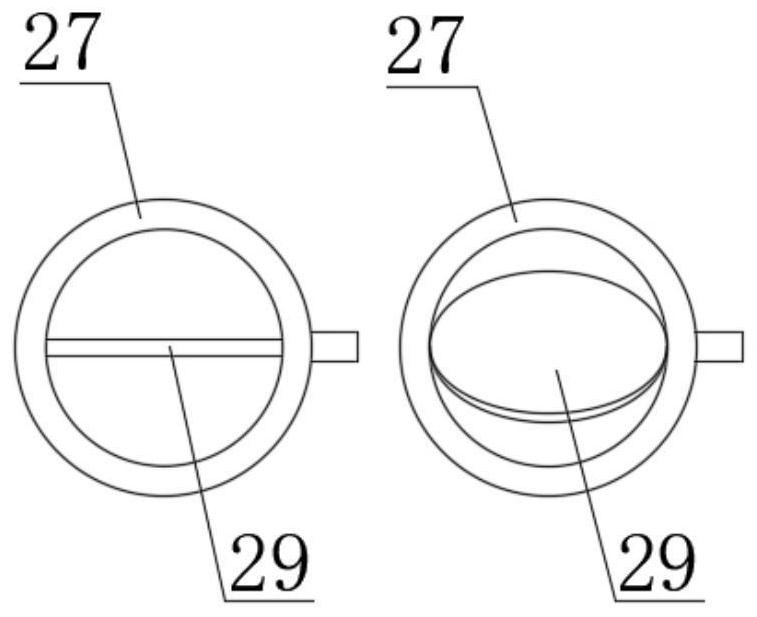

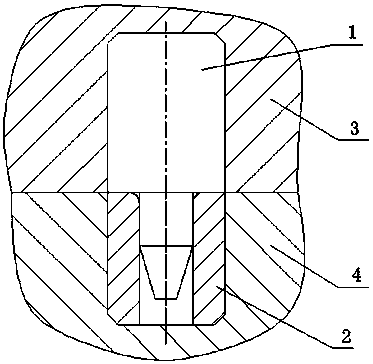

Differential-pressure swirl-type backwashing filtration system

InactiveCN102107100ANot easy to bruiseExtend your lifeStationary filtering element filtersFiltrationDrive shaft

A differential-pressure swirl-type backwashing filtration system. An indexing mechanism and a transmission mechanism are disposed on the top of a filter cylinder body; the internal cylinder body is divided into a water-inlet chamber and a water-outlet chamber by a clapboard; eight filter cores are disposed in the water-outlet chamber and are distributed uniformly and circumferentially; a water inlet is disposed along a tangent of the cylinder wall of the water-outlet chamber; a sewage draining exit and a dirt discharging exit are disposed in the water-inlet chamber; a sucking disc is disposed between the dirt discharging exit and the clapboard, and is driven to rotate by a transmission shaft of the transmission mechanism. The device adopts eight groups of filter core structures, and by using the hydrodynamics principle, the device has the advantages of less no-load pressure loss, less backwashing water consumption, good filtering effect, compact structure, and reliable operation, and can perform backwashing under low differential pressure.

Owner:天津富斯特环保设备有限公司

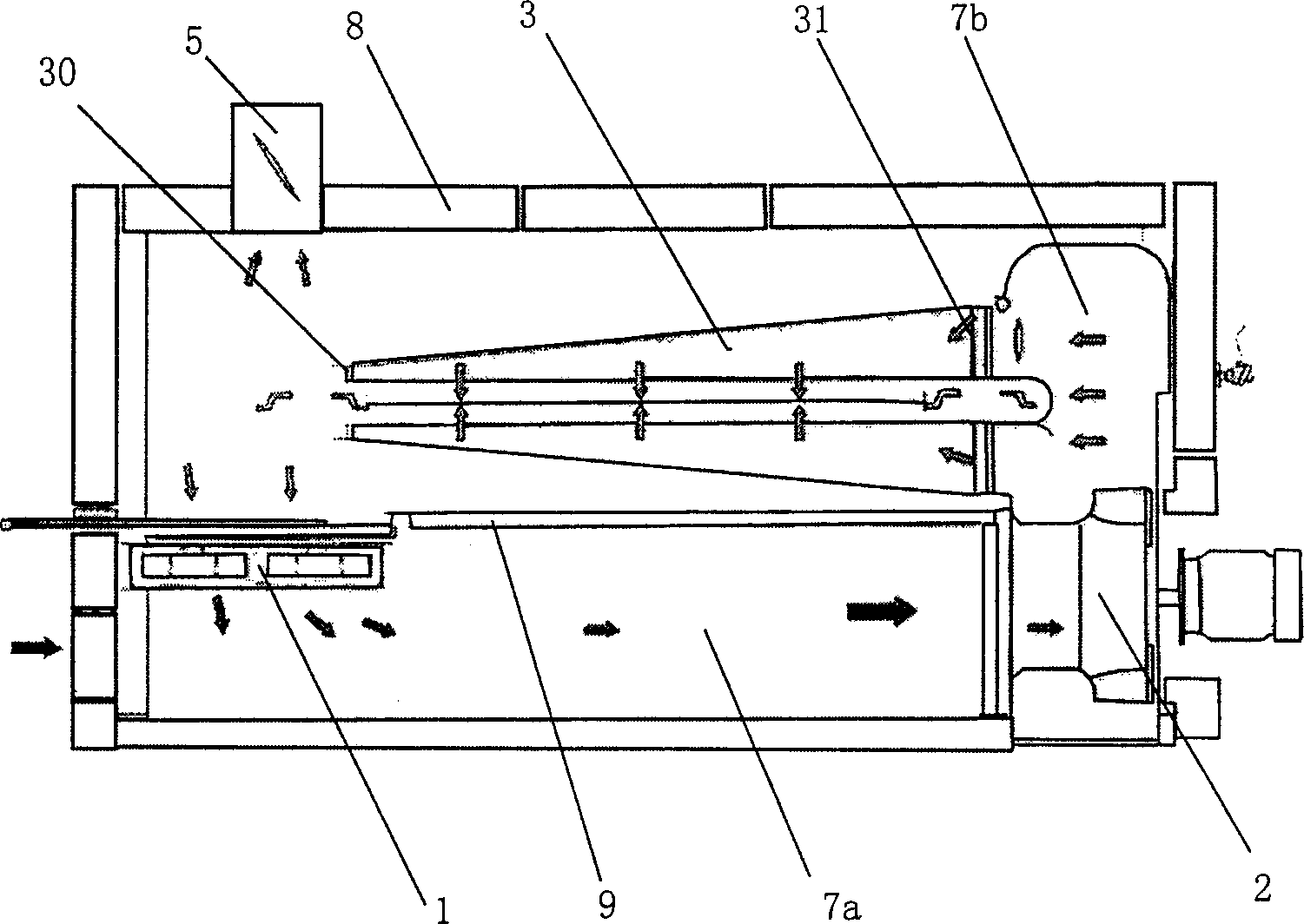

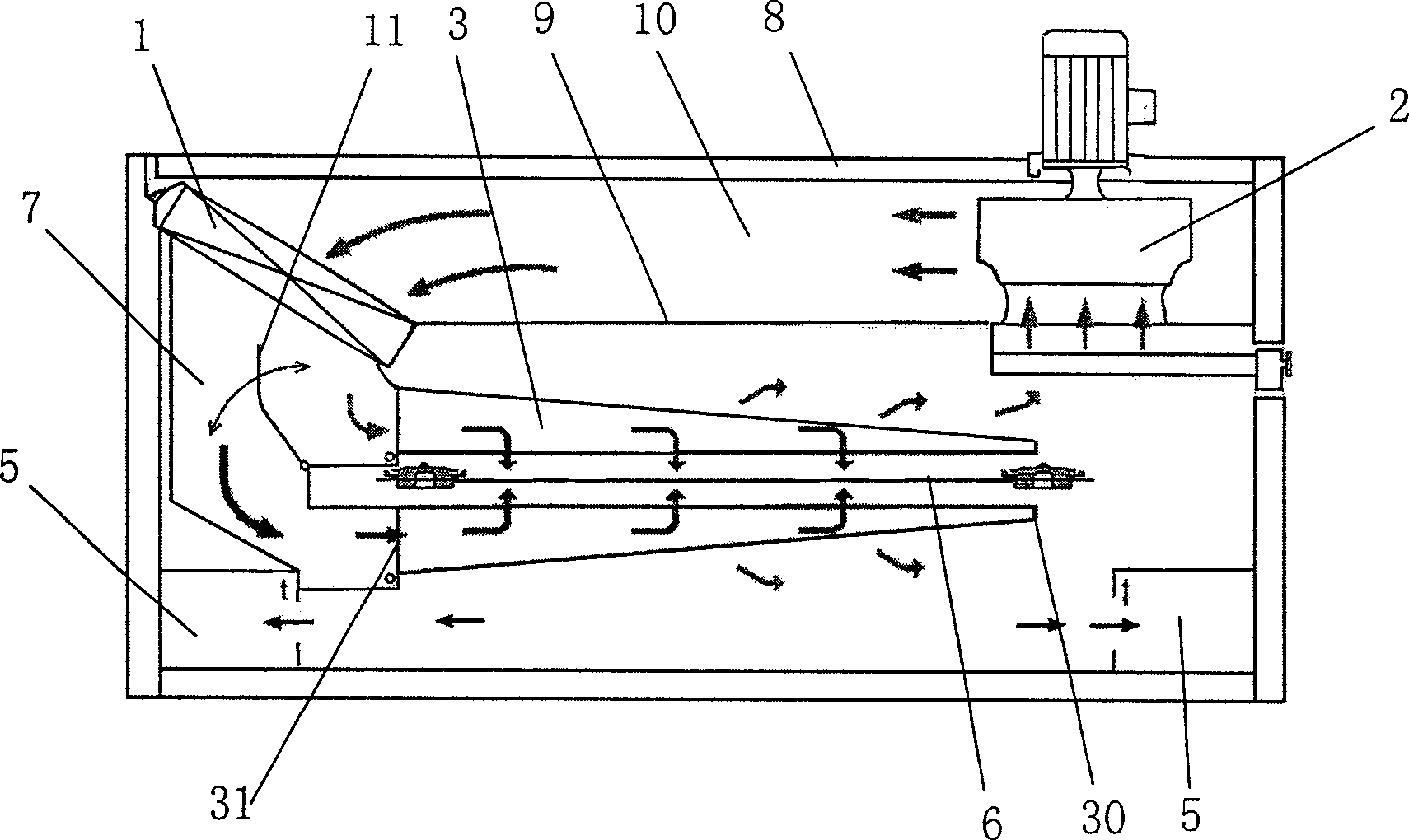

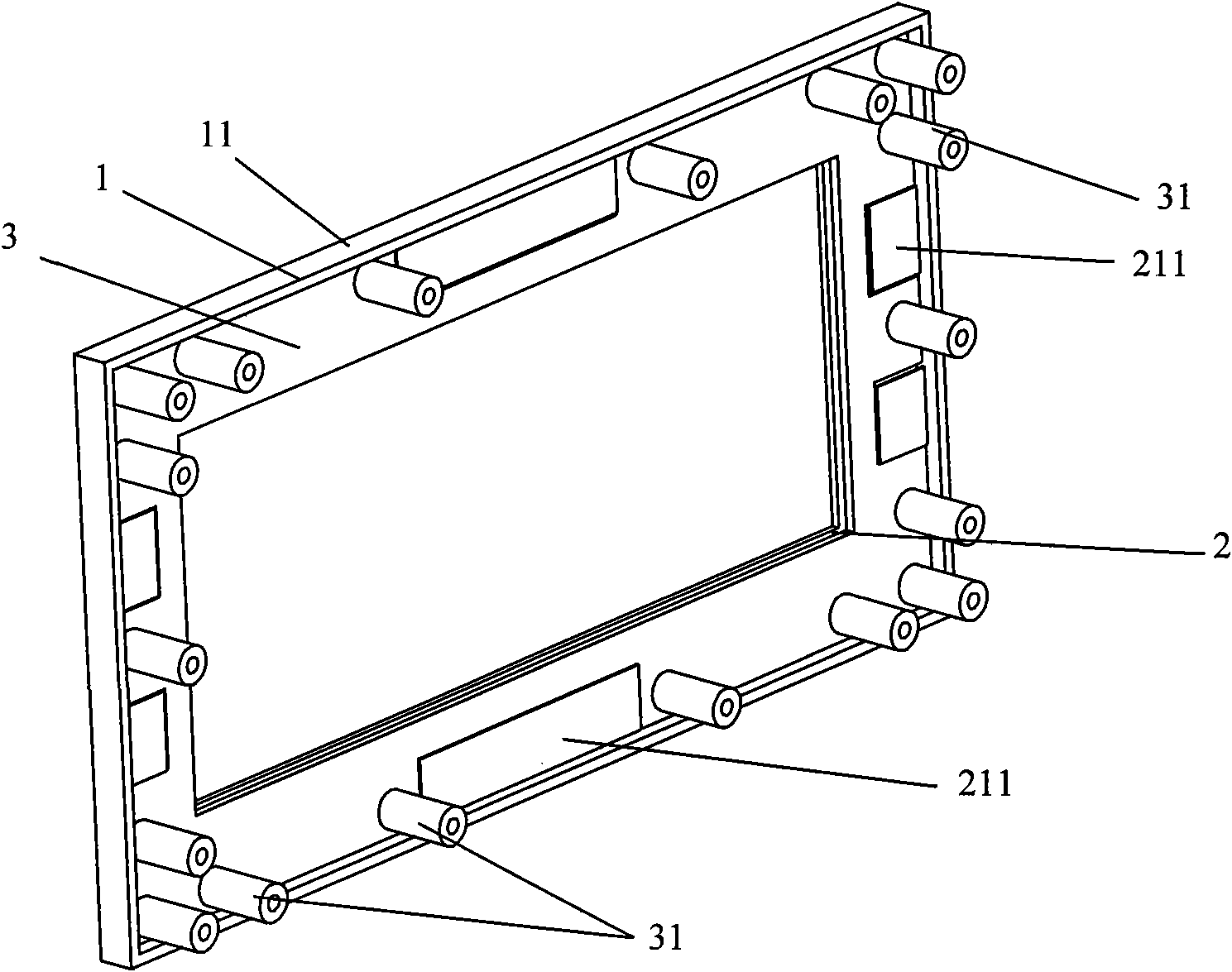

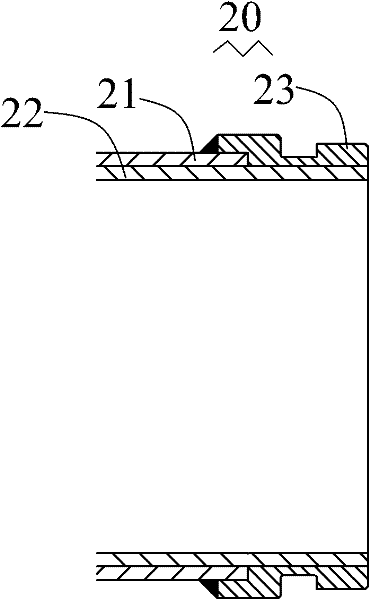

Drying oven of stenter setting machine

ActiveCN1804186ALower requirementExtended service lifeDrying solid materials with heatHeating/cooling textile fabricsCold airEngineering

The oven of a setting stenter comprises a machine case (8) arranged a build-in nozzle (3) with a fresh-air end (31) and a return-air end (30), a fan (2) on side of end (30) to draw cold air, and a heat exchanger (1) on side of end (31); wherein, arranging an air channel (10) between one end of the (1) and exhaustion port of fan (2) and an air-collector (7) between another side of (1) and the end (31). This invention has low request to fan to prolong service time, and reduces heat energy loss and consumption and the cost.

Owner:洪正凯

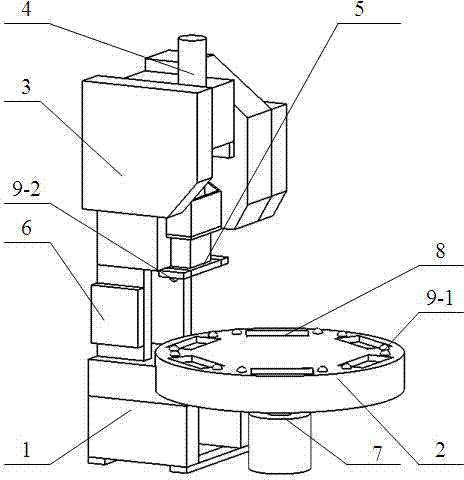

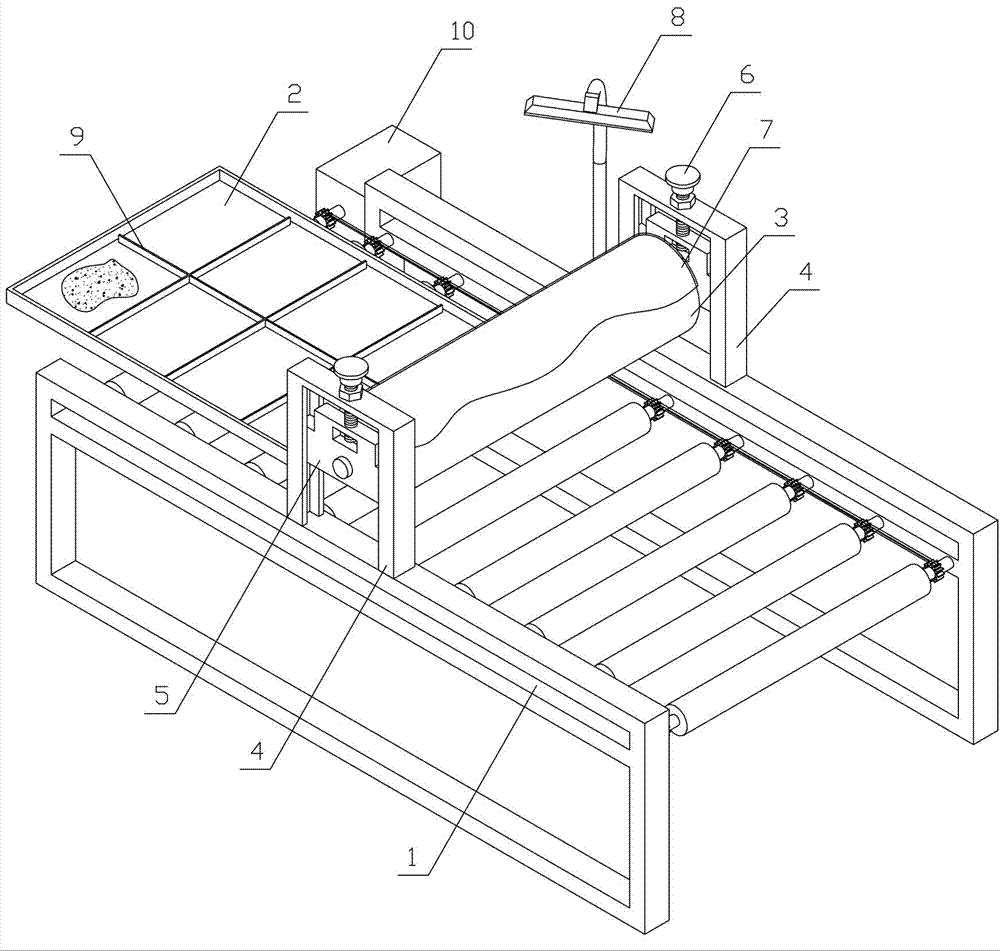

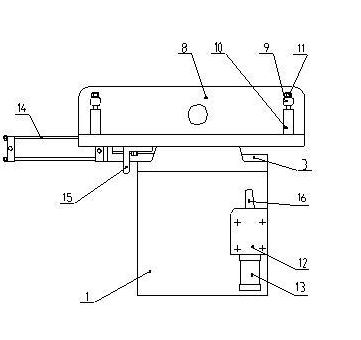

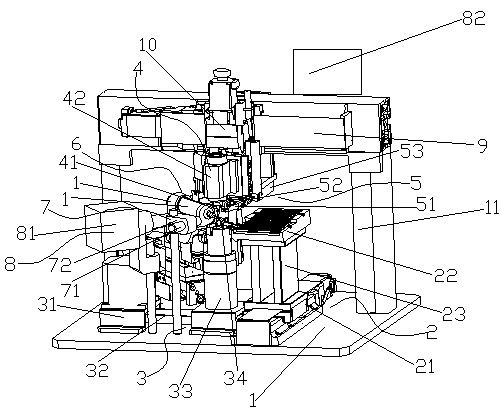

Punching machine for processing multiple workpieces

InactiveCN102886410ANot easy to bruiseImprove work efficiencyMetal-working feeding devicesPositioning devicesPunchingElectric machinery

The invention provides a punching machine for processing multiple workpieces. The punching machine comprises a base frame, a rotary workbench, a bracket, a working rod, a punching head, an electric control box and a control motor, wherein the bracket is arranged on the base frame; the working rod is arranged on the bracket; the punching head is arranged at the bottom of the working rod; the electric control box is arranged on one side of the bracket; the control motor is arranged on one side of the base frame; the rotary workbench is arranged on the control motor; a slot is formed in the base frame; the rotary workbench is clamped in the slot of the base frame and can move along the slot of the base frame; and a die slot is formed into a circle in the rotary workbench. By the punching machine for processing multiple workpieces, a transmission mechanism is arranged in the bottom of the punching machine, so that the working efficiency can be greatly improved; and during operation, hands of a worker are difficult to injure.

Owner:WUJIANG HUAPENG CAN FACTORY

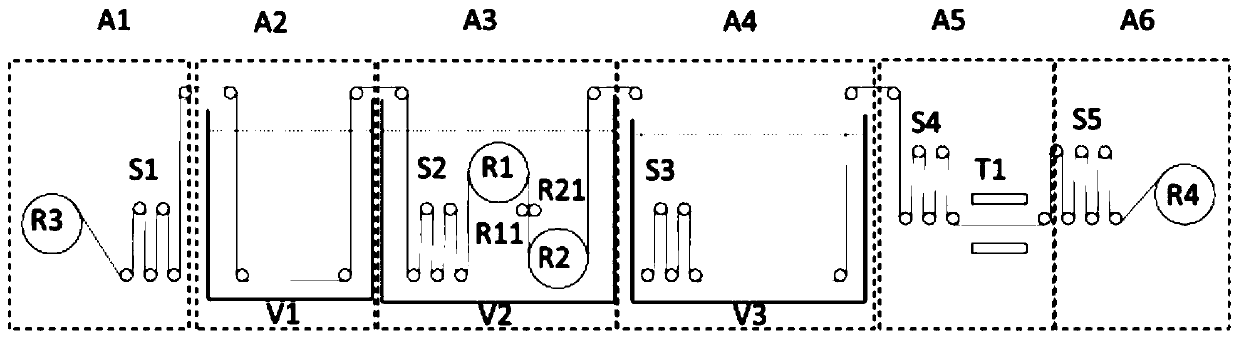

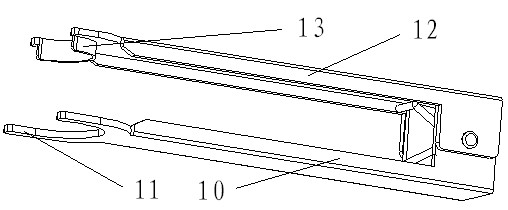

Lithium-ion battery pole piece pre-lithiating device

PendingCN110335992AImprove first-time efficiencyIncrease capacityElectrochemical processing of electrodesSecondary cellsPower flowElectrical battery

The invention discloses a lithium-ion battery pole piece pre-lithiating device, comprising an unwinding module, a pre-soaking module, a pre-lithiating module, a cleaning module, a drying module and awinding module which are connected in turn. By employing a wet electrochemistry method, the device can complete roll-to-roll continuous pre-supplement of lithium to lithium-ion battery pole pieces. The device has high production efficiency and high production reliability, and pole pieces are not easy to be damaged by touch. The amount of lithium supplemented can be precisely controlled and adjusted according to the current and the movement speed of pole pieces, and the device is suitable for large-scale production. The lithium supplement device is suitable for pole pieces made of all kinds ofmaterials, and is compatible with many lithium-ion battery preparation processes, such as multi-tab winding, full-tad winding and laminating. A lithium-ion battery prepared from pole pieces pre-lithiated by the device has higher first efficiency and significantly improved capacity, specific energy and cycle performance.

Owner:安普瑞斯(无锡)有限公司

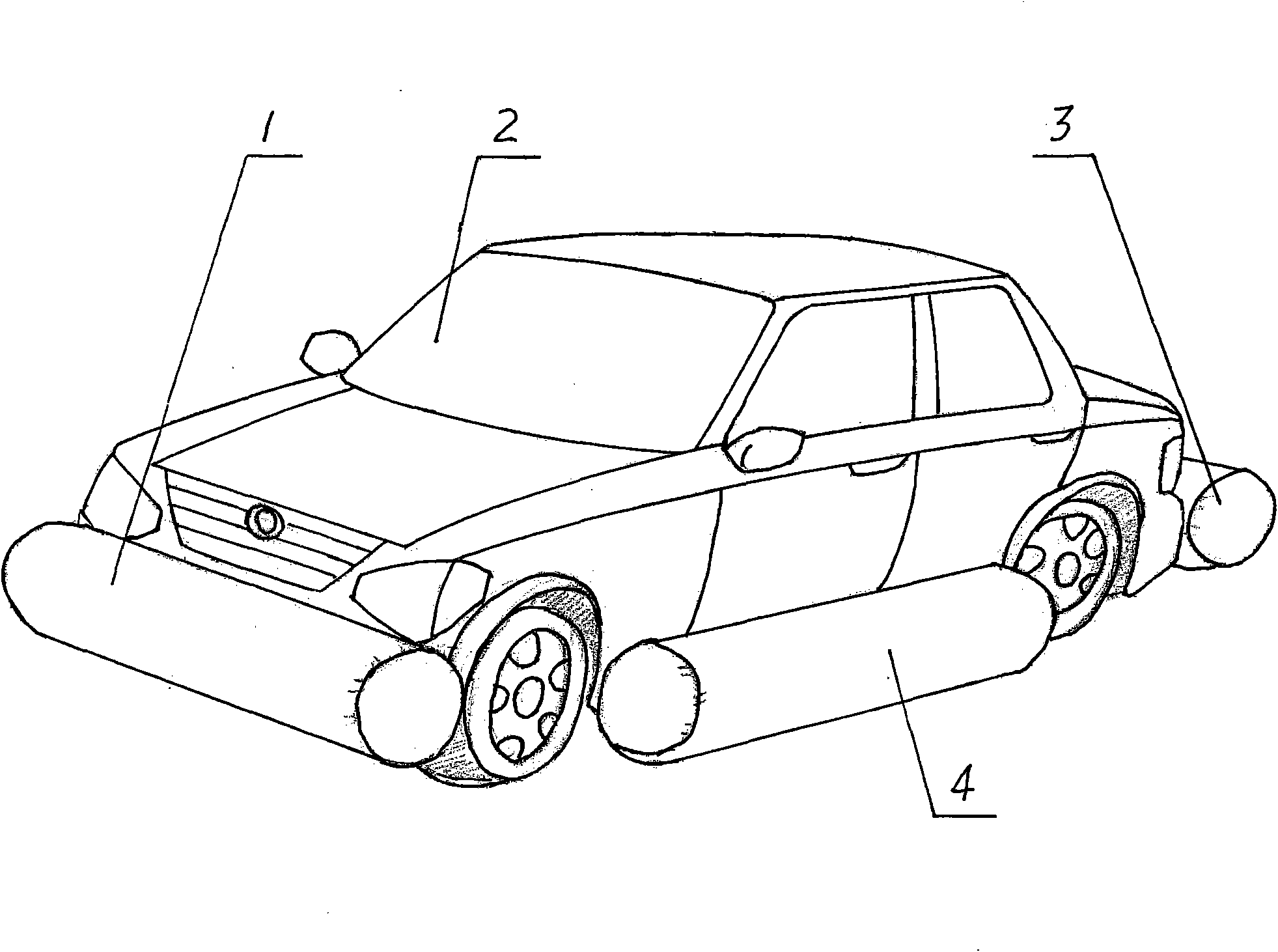

Anti-flood and anti-collision safety airbag for cars

InactiveCN101670819AAvoid rear-end collisionsReduce damagePedestrian/occupant safety arrangementBumpersFront airbagEngineering

The invention discloses an anti-flood and anti-collision safety airbag for cars, which comprises a safety airbag, wherein the safety airbag is arranged in a car body, a front airbag is arranged in a front bumper of the car body, a rear airbag is arranged in a rear bumper, and lateral airbags are arranged at the lower parts on both sides of the vehicle body. When a collision accident of a vehicle occurs, the safety airbags rapidly expand and spring to form a buffering air cushion, absorb impact energy, protect a vehicle body, control the side tipping of the vehicle body, avoid rear-end collision and perform a buffering function for a collided object, so that the vehicle is not easily damaged and can not easily hit others. The invention greatly lightens the injured degree of the vehicle bodyas well as drivers and passengers, reduces severe traffic accidents, and lowers economic losses and casualties to the most point. The safety airbags can also be opened when people encounter a flood,and the car can float in water, thereby avoiding the car from being submerged and encountering accidents.

Owner:邢涵瑞

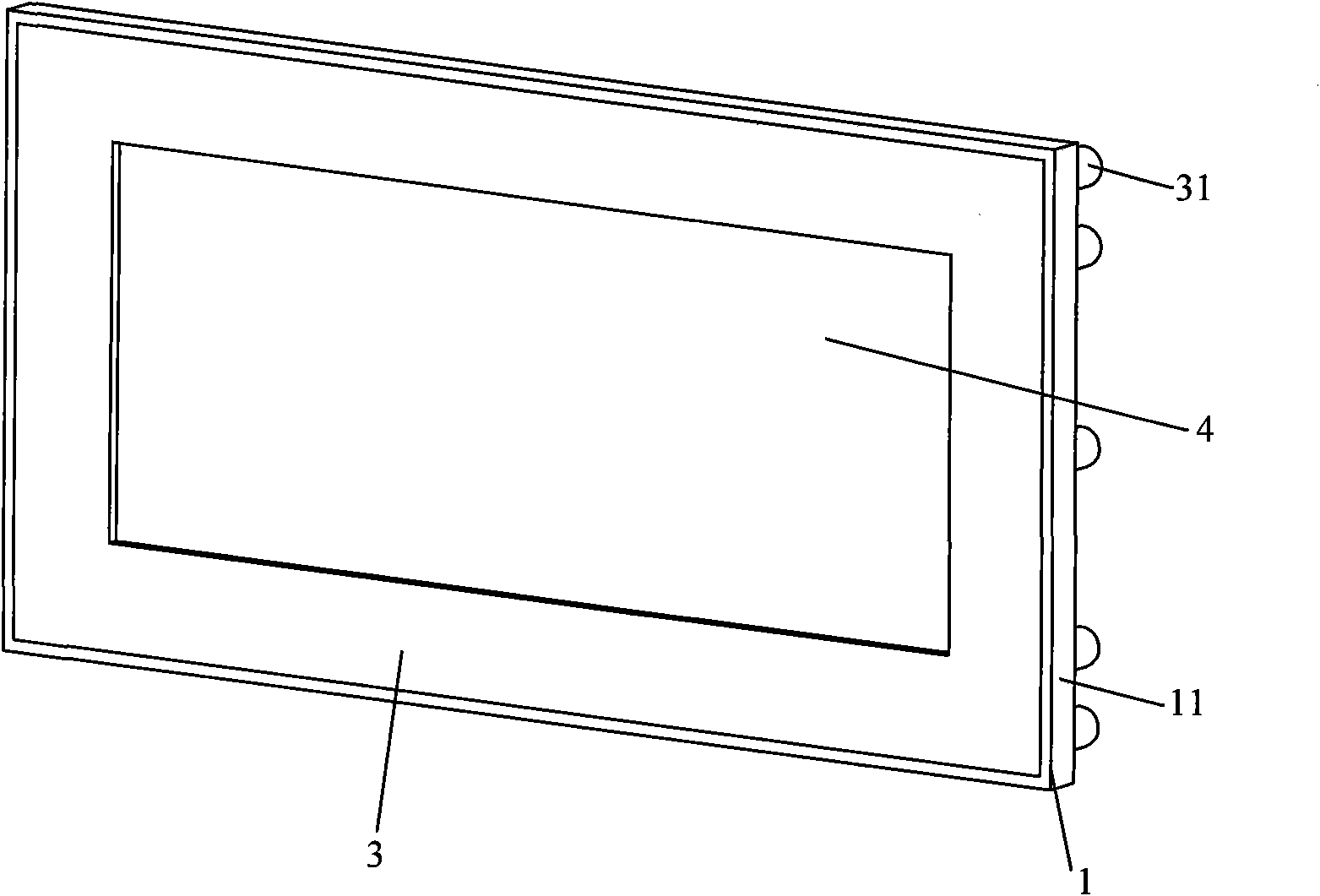

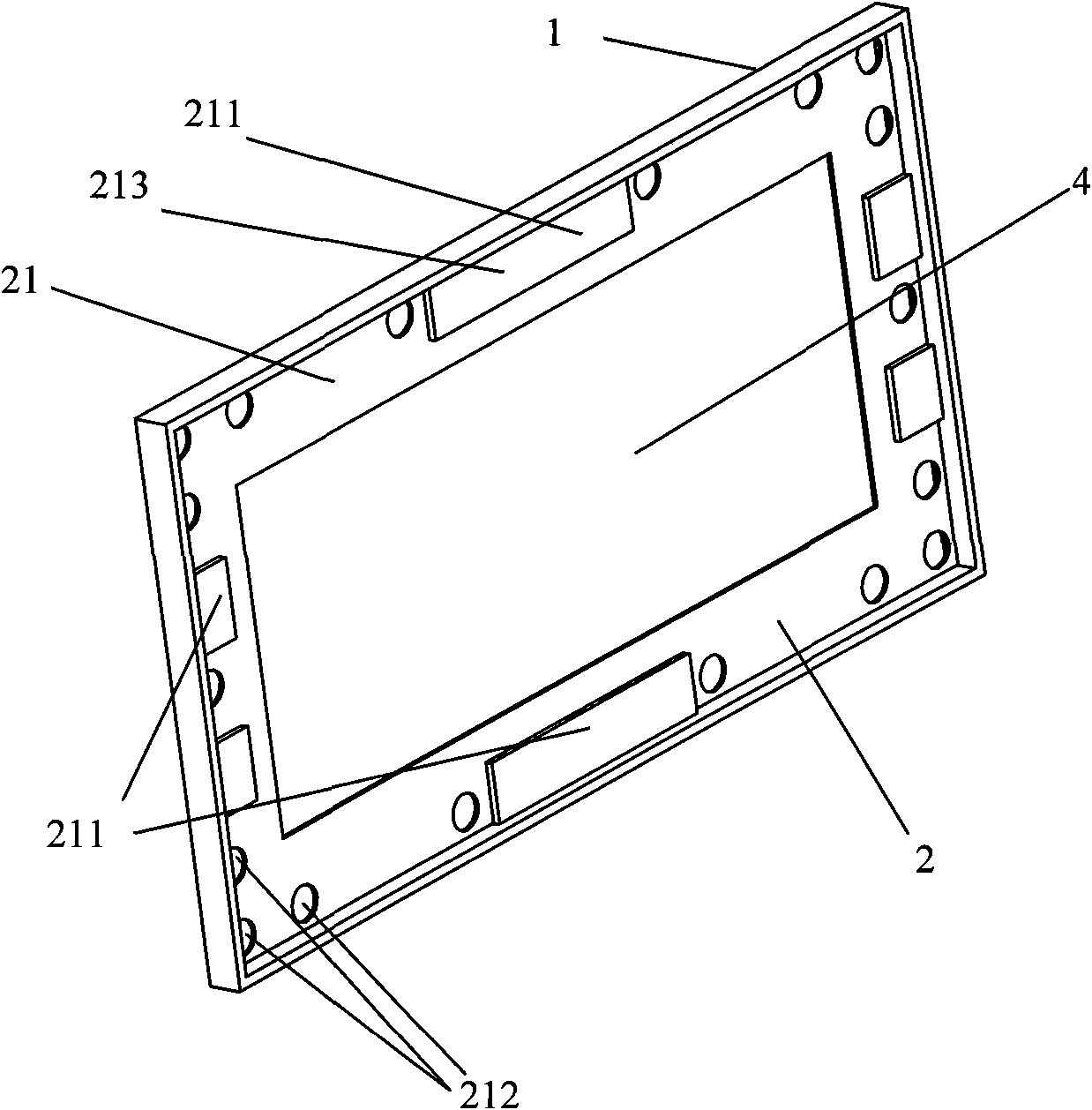

Panel shell of television and preparation method thereof

InactiveCN101895710ABeautify the metal texture effectAvoid deformationTelevision system detailsColor television detailsEngineeringMetal

The invention discloses a panel shell of a television which comprises a lateral metal frame, an internal metal frame and a plastic panel; wherein the internal metal frame is arranged at the central part of the inner side of the lateral metal frame and is connected with the lateral metal frame; the plastic panel is arranged in the inner side of the lateral metal frame and is used for cladding the front and rear surfaces of the internal metal frame; and the lateral metal panel, the internal metal panel and the plastic panel are connected by an injection molding and the external surface of the lateral metal frame is not cladded by the plastic panel. The panel shell of the television of the invention can be directly used as a panel shell cladding an LED screen and the panel shell of the television, thus not only improving metal texture on appearance of the television, but also reducing working procedures of coordinating and assembling components of the LED screen and the panel shell of the television as well as clearance, saving materials cost thereof, and reaching the further ultrathin development for the television.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

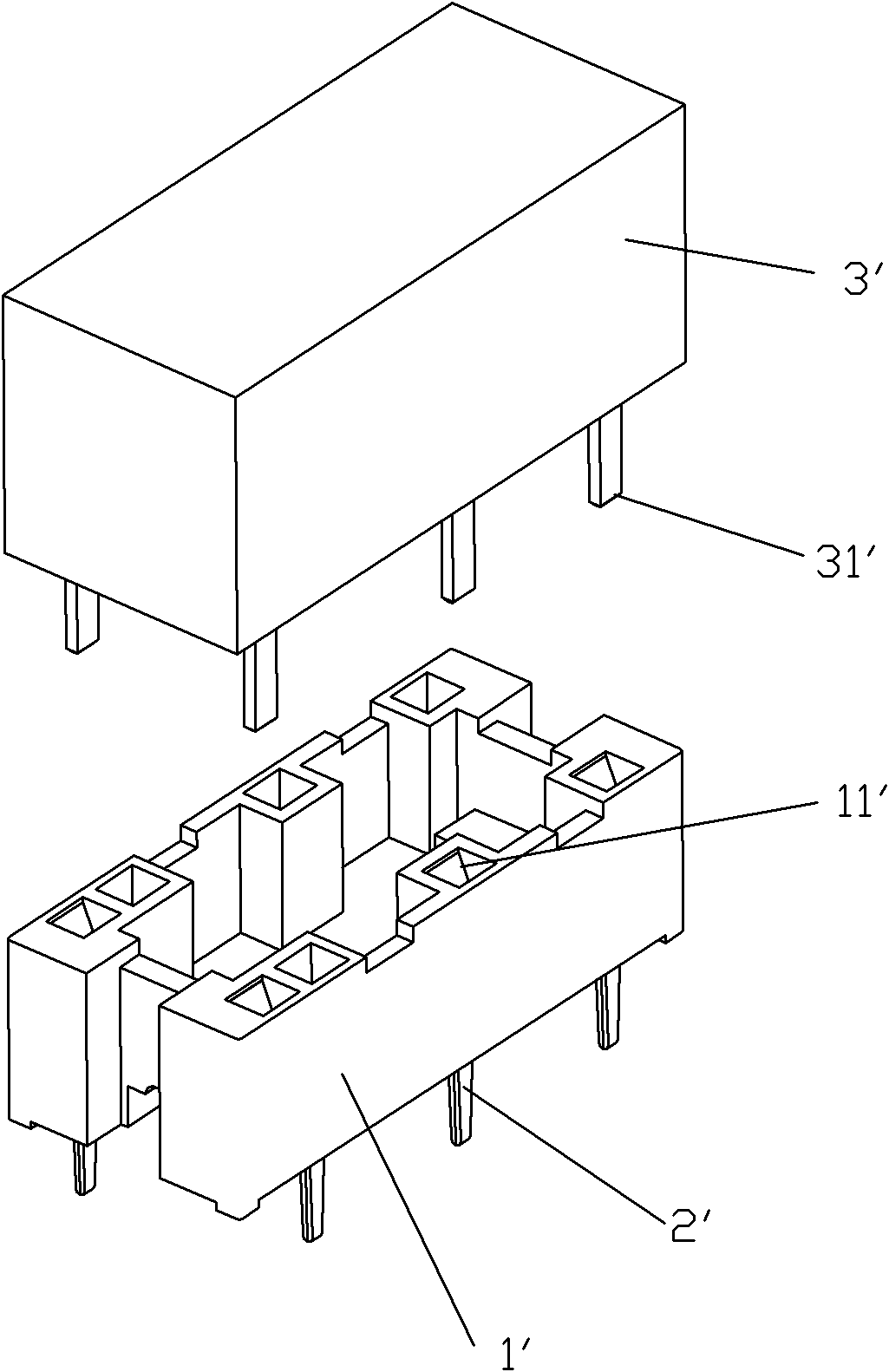

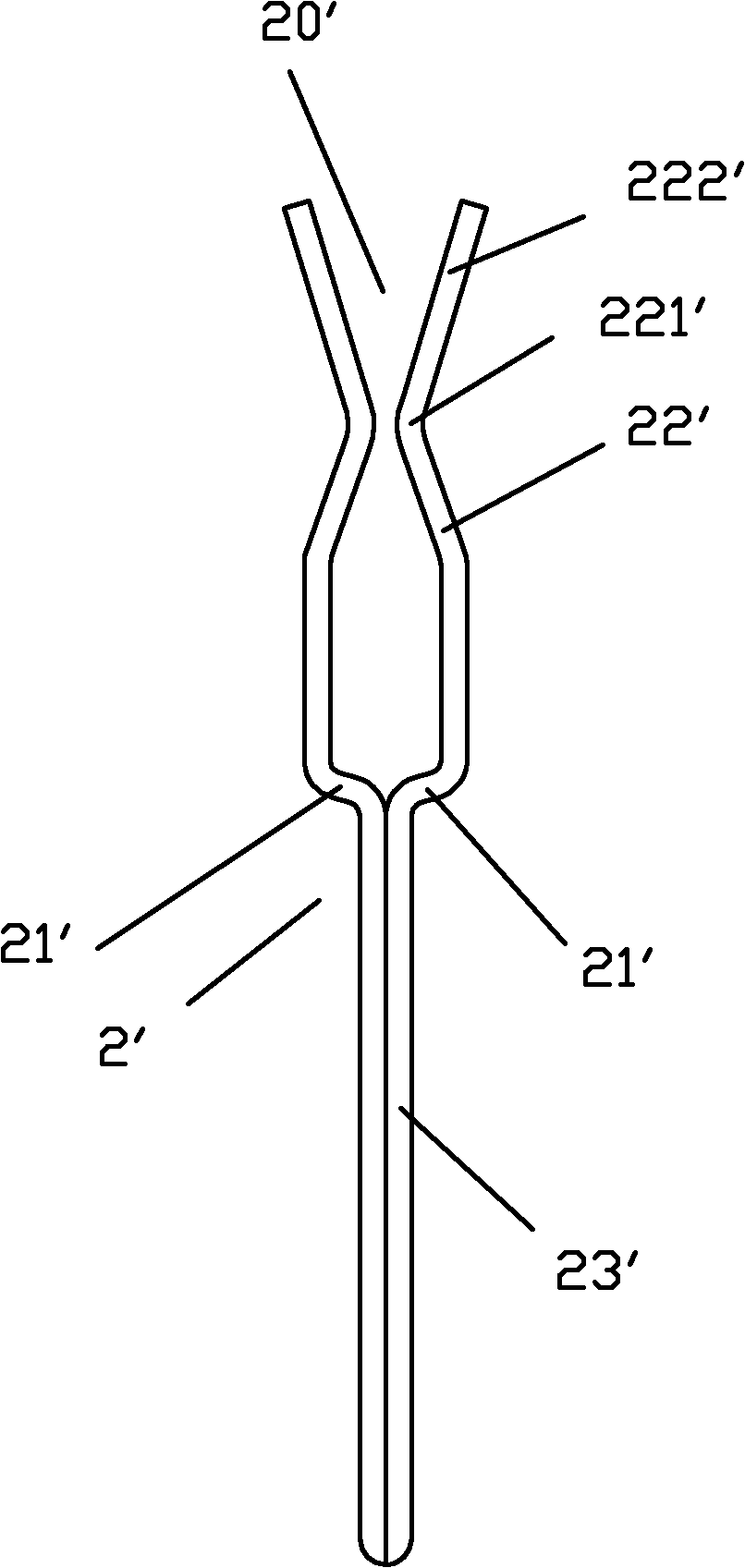

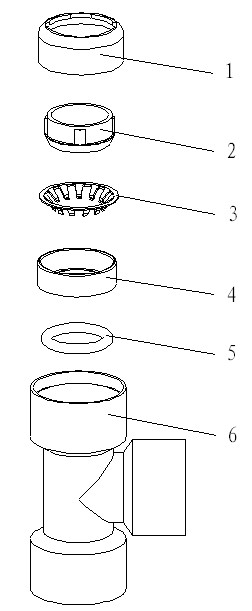

Clamping spring structure of relay socket

InactiveCN102163783AIncrease widthEasy to useElectric discharge tubesCoupling device detailsVoltageBand shape

The invention discloses a clamping spring structure of a relay socket. The clamping spring structure consists of two reeds made of banded cooper alloy; one end of each reed is a free end and the other ends of the two reeds are connected together to form opposite fixed ends; the middle parts of the free ends of the two reeds are respectively provided with a bending part; a V shape serving as an input port is formed by tail ends of the free ends of the two reeds through the bending parts; and end heads of the tail ends of the free ends of the two reeds are respectively provided with a chamfering surface arranged vertically. By improvement on the input port of the clamping spring structure, the width of the input port of a clamping spring is increased so as to facilitate the insertion of leading feet of a relay into the input port of the clamping spring; a line-to-surface contact between the tail ends of the free ends of the reeds and the surface of a plastic partition wall is changed into a surface-to-surface contact to make the application of the relay socket more convenient; and the insulating wall is difficult to damage so that the performance of voltage withstand and insulation of the relay socket are improved and the service life of the relay socket is prolonged.

Owner:XIAMEN HONGYUANDA ELECTRIC APPLIANCE

Preparation method of artificial quartz stone composite color plate

The invention provides a preparation method of an artificial quartz stone composite color plate. The quartz stone composite color plate is prepared from quartz sand with different meshes, quartz powder, unsaturated polyester resin, a coupling agent, a curing agent, and an accelerant through the steps of batching, mixing, dyeing, distributing materials, performing vacuum vibration forming, curing by a drying oven as well as grinding and molding. During preparation of the quartz stone composite color plate, the treatment method of the raw materials is unique and the used equipment is improved by an inventor, so that the prepared quartz stone composite color plate has higher quality, the problems that flowing and blooming phenomena are liable to occur in the preparation process of the quartz stone composite color plate are solved, and outstanding contribution is made for the artificial quartz stone industry.

Owner:湖北赛典新材料科技有限公司

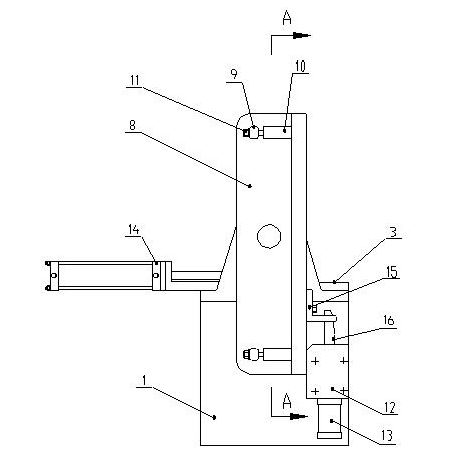

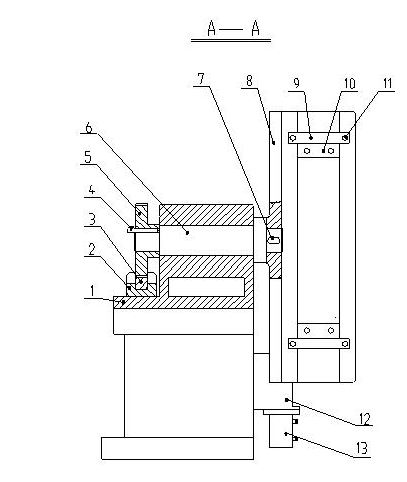

Rotary clamping apparatus for drilling crankshaft large disk flange hole

InactiveCN101966656ANot easy to bruiseSimple structurePositioning apparatusMetal-working holdersGear wheelEngineering

The invention relates to a rotary clamping apparatus for drilling a crankshaft large disk flange hole. The rotary clamping apparatus comprises a support seat, a rack slideway, a drive cylinder, a rack, a gears, a rotating shaft and a clamping apparatus body supporting plate, wherein the rotating shaft is arranged in a round hole of the support seat; one end of the rotating shaft is provided with the gears, while the other end is connected and fixed with the clamping apparatus body supporting plate; the rack slideway is arranged on a flat plate on the lower part of the support seat; the rack is arranged in the rack slideway and is connected with a cylinder rod of the drive cylinder; the rack and the gears are occluded to drive the rotating shaft to rotate and thus drive the clamping apparatus body supporting plate to roll over so as to ensure that the clamping apparatus body supporting plate is in two position states, namely a horizontal position and a vertical position. The rotary clamping apparatus has a simple structure; a crankshaft is difficult to damage when horizontally clamped; and after being clamped, the crankshaft can rotate to the vertical position to be reliably fixed and locked and is conveniently drilled. The rotary clamping apparatus is an ideal rotary clamping apparatus for drilling the crankshaft large disk flange hole.

Owner:TIANRUN IND TECH CO LTD

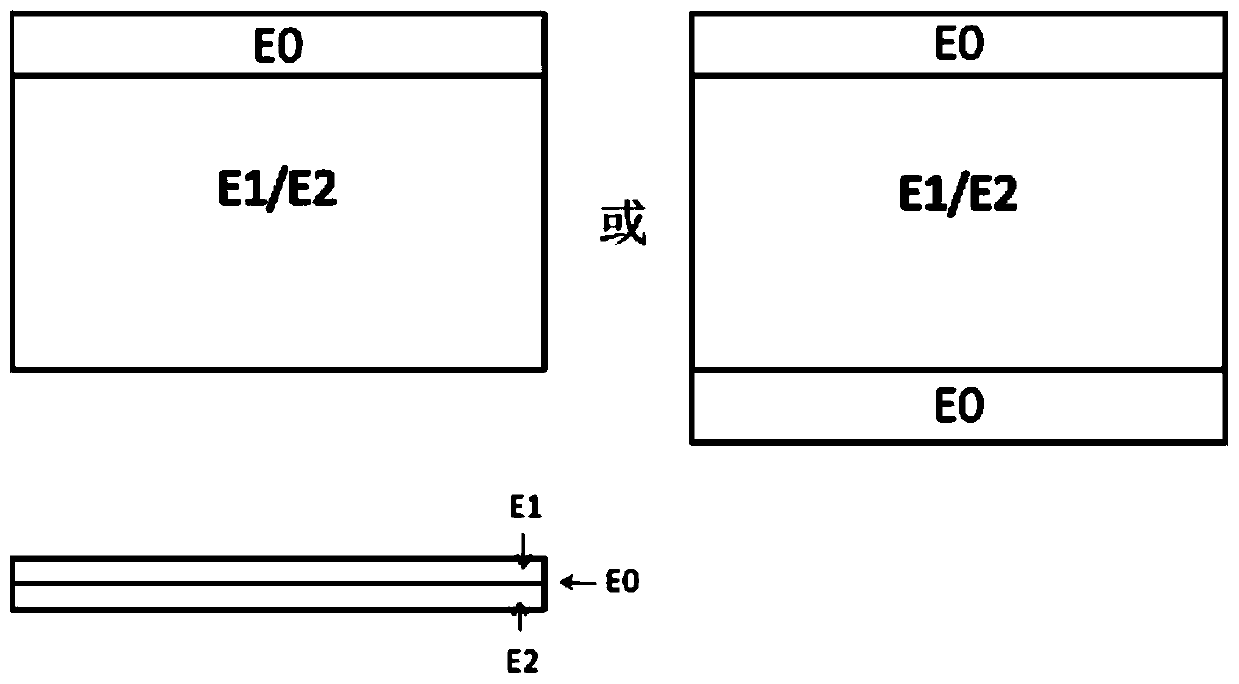

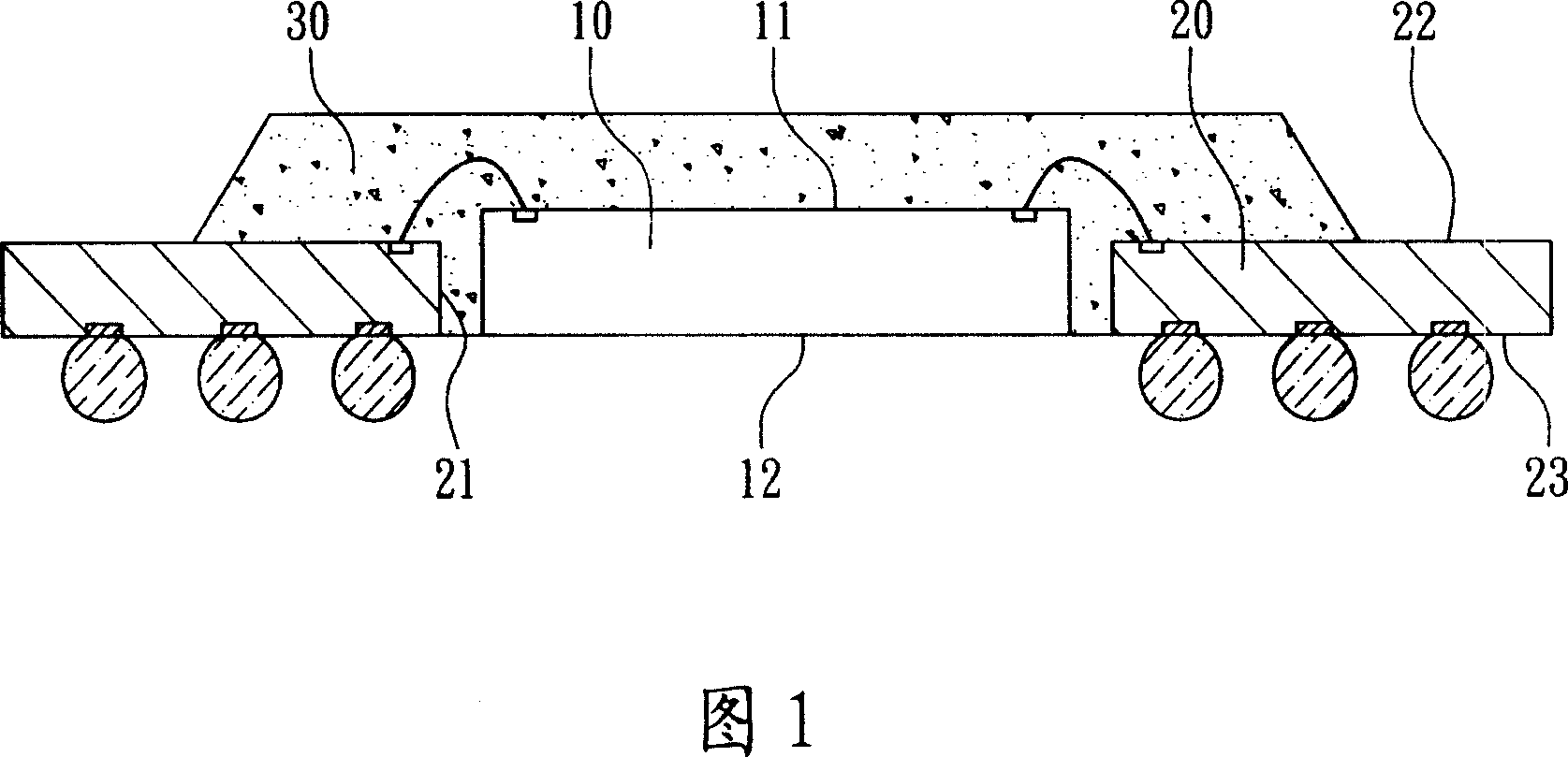

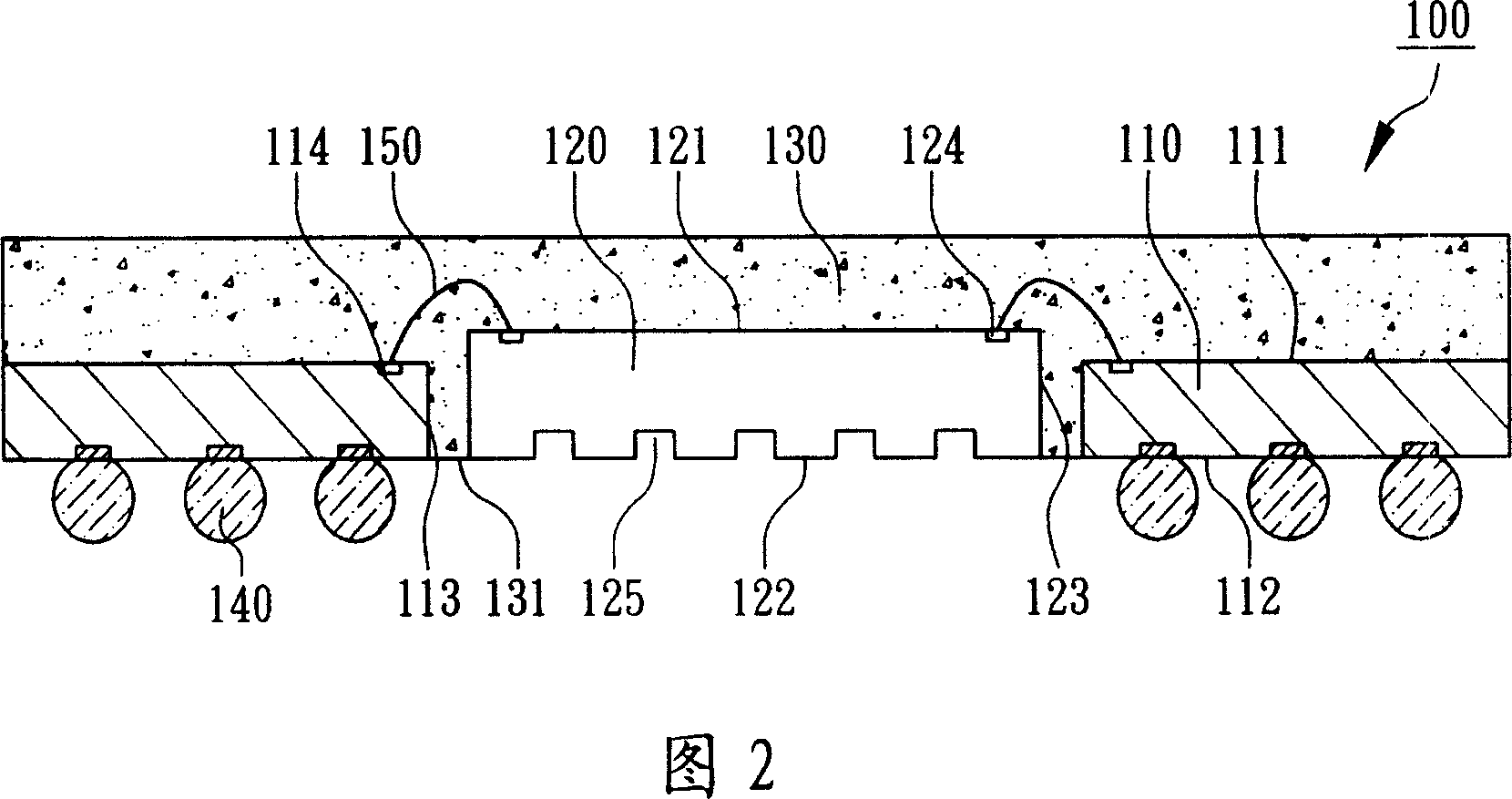

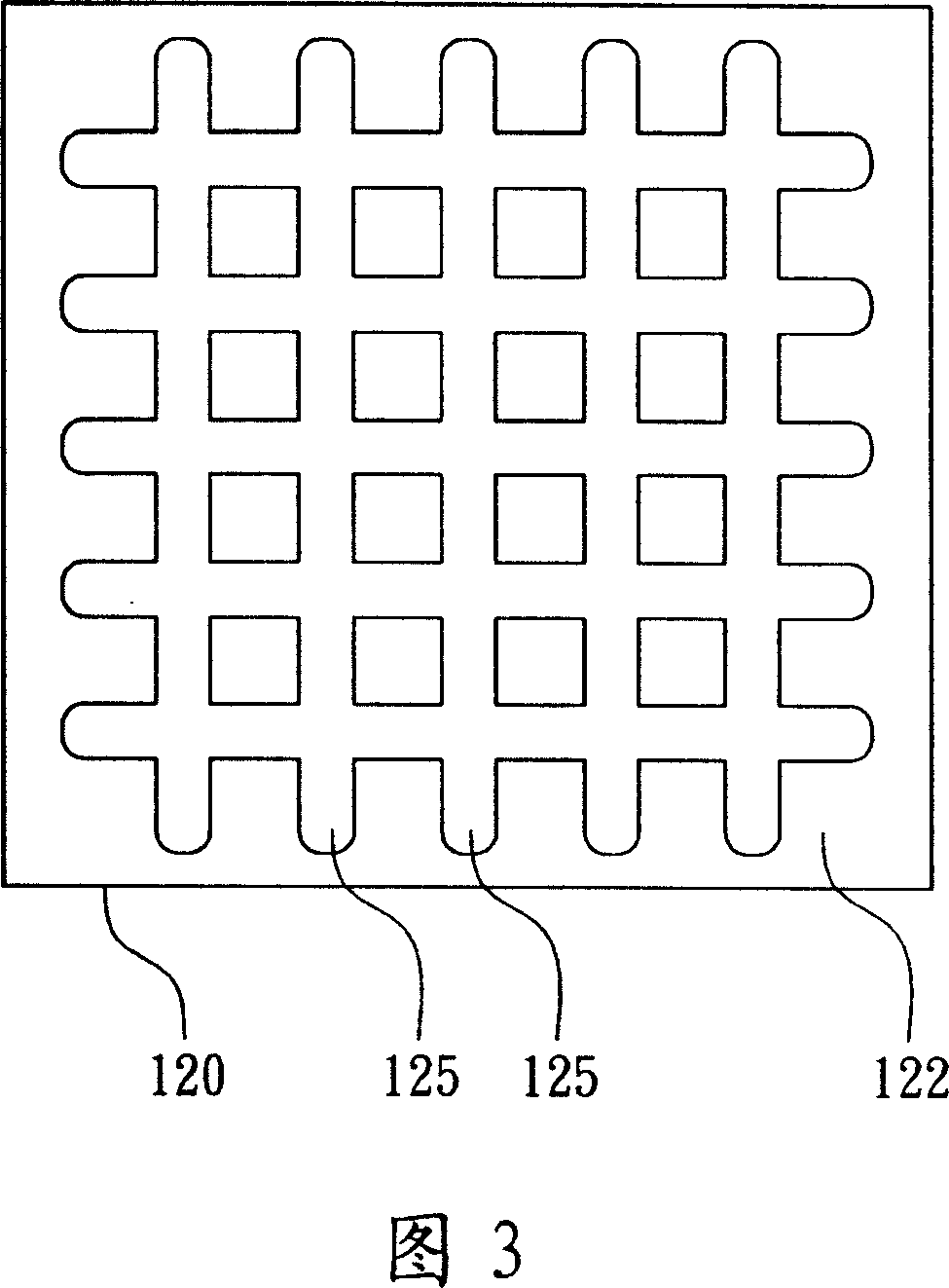

Thin packing structure for enhancing crystal fin radiation

InactiveCN1941336AImprove structural strengthIncreased exposed surface areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention is concerned with the thin sealing structure for enhancing the radiation of the wafer back, including: the base panel, the wafer, and the sealing colloid; the base panel is with the upper surface, the under surface, and the transfixing geode; the wafer is contained at the geode of the base panel and with the initiative surface and the back surface, the initiative surface forms plural number of welding underlay and electric connects with the base panel, the back surface of the wafer forms plural number of the grooves; the sealing colloid forms on the upper surface of the base panel, covers the initiative surface of the wafer, and show the back surface and the grooves of the wafer, therefore the grooves is with the effects to enhance the radiation of the wafer back and intensity of the wafer.

Owner:CHIPMOS TECH INC

Tomato storing method

InactiveCN106615043AKeep bright colorsAvoid damageNatural extract food ingredientsVegetable peelingFlavorComputer science

The invention mainly relates to the technical field of planting, and discloses a tomato storing method. The tomato storing method comprises the following steps of cleaning tomatoes for removing dirt, performing high-temperature dehydration, performing fresh keeping, performing sterilization, performing packaging, and performing storage. The tomato storing method is simple, the tomato storing time can be as long as 90-100 days, after 110 days, the intact preservation rate of the stored tomatoes is 91.2%, the water content is 81.7%, and economic returns are increased by 11.4%. After the tomatoes are picked, the picked tomatoes are cleaned with a dietary alkali solution, so that sundries can be removed, bright color of the tomatoes can be maintained, skins are hardened, the damage of the tomatoes is reduced, and the storage period of the tomatoes is prolonged; the tomatoes are subjected to high-temperature short-time treatment, so that the water content of the skins is reduced, the tomatoes are not liable to damage due to collision, the respiration effect of the skins is weakened, the contents of moisture and nutrients in the tomatoes are maintained, and the storage period of the tomatoes is prolonged; a fresh-keeping agent solution is sprayed onto the tomatoes, so that the respiration of the tomatoes is restrained, the effects of resisting bacteria and killing insects are achieved, the tomatoes are kept complete, and the tomatoes are not decomposed; the fresh keeping agent solution is extracted from pure plants, so that the fresh keeping agent solution is safe and healthy, the flavor of the tomatoes is maintained, and the disease resistance of human bodies can be enhanced.

Owner:蚌埠市宗洼草鸡养殖农民专业合作社

Double-sided coated aluminum alloy wheels

InactiveCN102259557ABright surfaceImprove wear resistanceHubsPolyester coatingsPolyesterSurface layer

The invention relates to an automobile wheel hub, in particular to an aluminum alloy wheel hub with coating on both sides, which is provided with an aluminum alloy wheel hub base body, and is characterized in that the two sides of the hub base body are respectively provided with high-temperature-resistant insulating primers and wear-resistant decorations in turn. The surface layer, the high temperature resistant insulating primer layer is generally composed of epoxy polyester powder coating, methyl methacrylate-acrylate copolymer coating and polybutadiene, and the wear-resistant finishing layer is polyurethane acrylic light-cured layer. The invention has the advantages of environmental protection, energy saving, cost reduction, bright surface, good wear resistance, not easy to be damaged, and the like.

Owner:WEIHAI WANFENG AUTO WHEELS

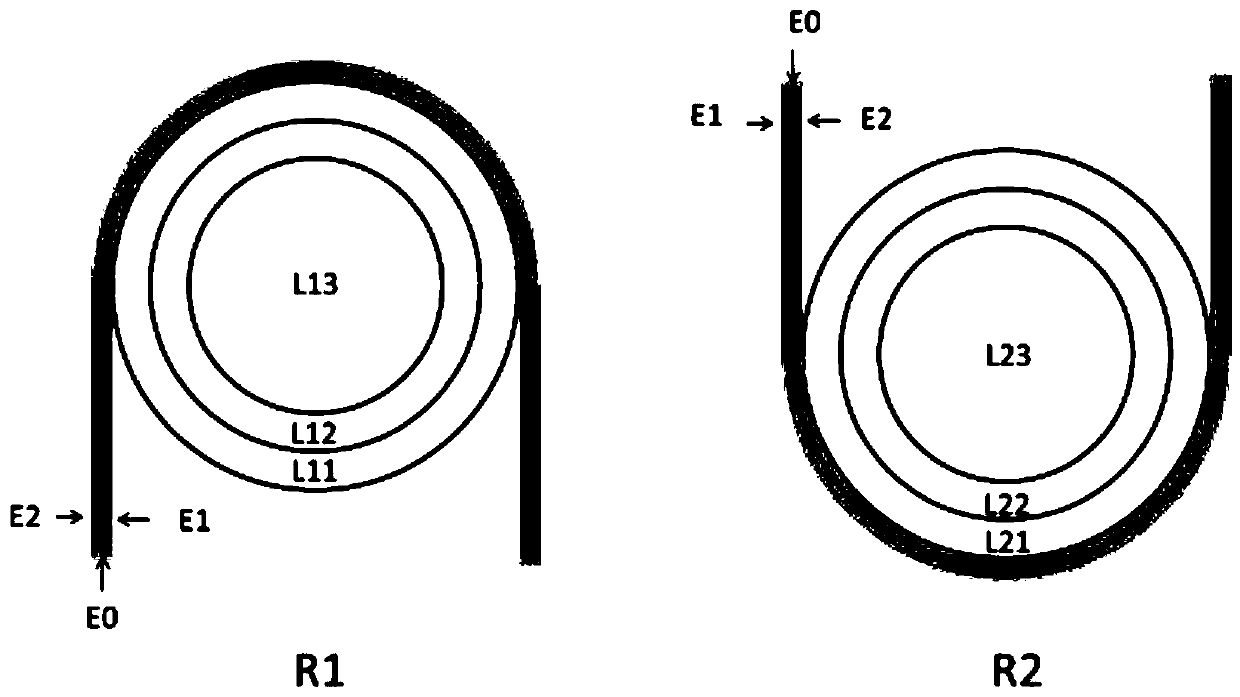

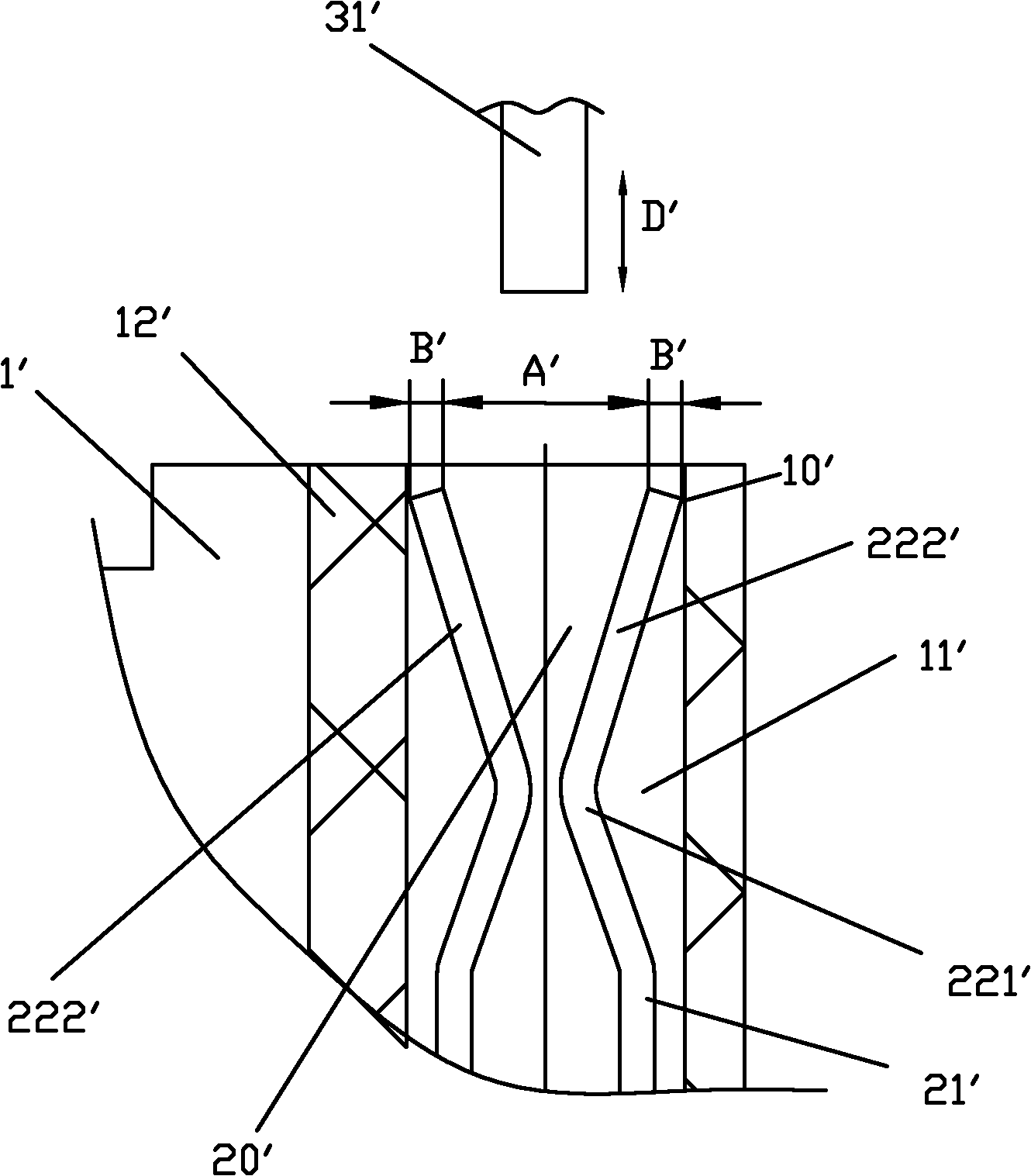

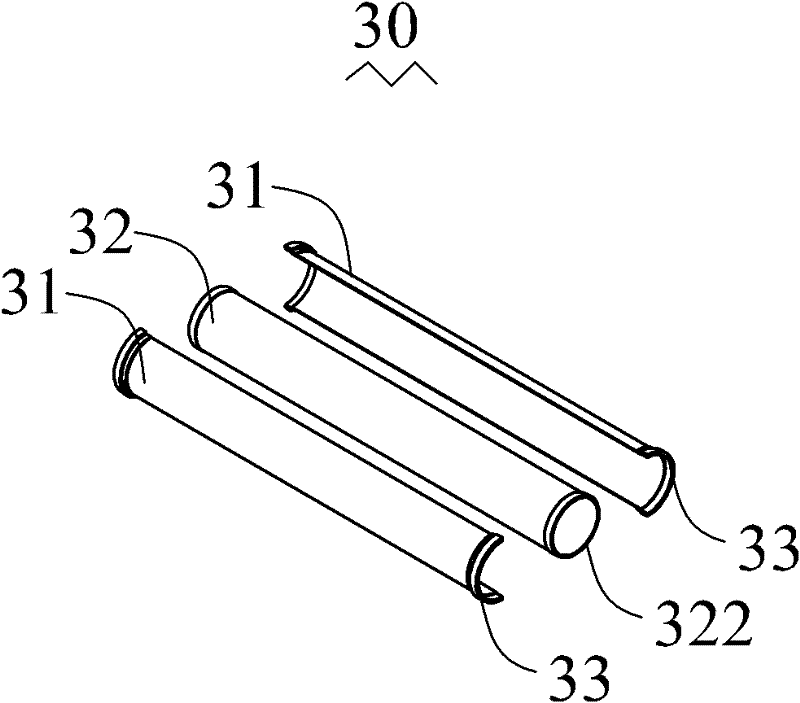

Material conveying machine, composite structure conveying pipe and manufacture method thereof

ActiveCN102537533AHigh strengthReduce toughnessFlanged jointsBulk conveyorsWear resistantShear capacity

The invention discloses a composite structure conveying pipe and a manufacture method of the conveying pipe. The composite structure conveying pipe comprises an outer pipe and an inner pipe, wherein the outer pipe is made of a light alloy material; the inner pipe is made of a light wear-resistant material; and the inner pipe is arranged in the outer pipe. In addition, the invention also discloses a material conveying machine including the composite structure conveying pipe. According to the invention, the outer pipe of the composite structure conveying pipe made of the low-density, high-strength and high-toughness material can provide enough strength and toughness at a lighter weight so as to prevent deformation and burst of the conveying pipe, and has higher shear resistance, less possibility of damages caused by bumping or dropping and lower cost in comparison with the composite material; and the inner pipe made of the light wear-resistant material can provided enough wear resistance at a lighter weight. Therefore, the overall weight of the product is reduced by more than 50% in comparison with that of a steel conveying pipe so as to facilitate assembly and disassembly, greatly improve efficiency and safety and simplify the process, and subsequent heat treatment for the inner layer is obviated.

Owner:ZOOMLION HEAVY IND CO LTD

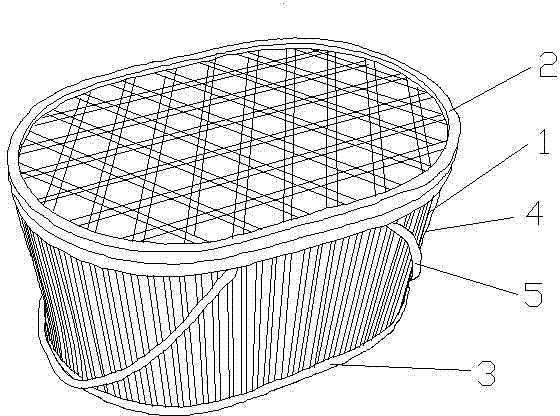

Method for producing and culturing edible fungi with bamboo container

InactiveCN104737774AEasy to transportIncrease productionCultivating equipmentsMushroom cultivationFertilizerPlastic bag

The invention discloses a method for producing and culturing edible fungi with a bamboo container. The method for producing and culturing the edible fungi with the bamboo container comprises the steps that the bamboo container is elected to be used for producing and culturing the edible fungi; plant leftovers and the like are used as raw materials; even stirring is conducted after water is added, pile-turning fermentation is conducted, and sterilization is conducted; strains are sowed, and spore germination is conducted; the fruiting times of different varieties are different, and fruiting is conducted again. The method for producing and culturing the edible fungi with the bamboo container has the advantages that after the edible fungi are produced and cultured with the bamboo container by one cycle, waste culture medium can be broken in a centralized mode, the waste culture medium can serve as fertilizer for planting flowers, vegetables, fruits and the like after the waste culture medium is piled and fermented, the advantages of reutilization can be achieved, and environment pollution is avoided; the container can be transferred and placed on any places, transportation is convenient, damage, caused by squeezing, between the fungi is unlike to occur, static culture of the edible fungi is converted into dynamic culture of the edible fungi, and the container can be conveniently hung on indoor places to be used for fungus culture; landscape type edible fungus culture is designed, and the container containing the edible fungi can be made into a potted landscape to be appreciated and can also be used for purifying air, for example, the container containing the edible fungi can serve as a lucid ganoderma landscape; more edible fungi can be contained compared with a plastic bag, the yield is high, and management is convenient.

Owner:张泽军

Thermoplastic non-metal integral bathroom and preparation method for same

InactiveCN105133865AIncrease production capacitySave energyCovering/liningsDomestic plumbingMicro nanoPolymer science

The invention discloses a thermoplastic non-metal integral bathroom and a preparation method for the same. The integral bathroom comprises a suspended ceiling, a wall surface, a ground, a sanitary appliance, a storage cabinet, a door frame and a window frame. Kunlun spar composite material is employed to be base bodies and modified polyurethane is secondarily injection-molded to form each component of the integral bathroom; the modified polyurethane comprises polyurethane composite material having 2 to 40% of modifier; the modifier is made either from aramid fibers, carbon material, micro-nano modeled material, fluorine-containing material, inorganic fibers or crystal whiskers. The integral bathroom can be integrally designed according to consumer's needs; integral bathrooms with uniformed styles, harmony appearance, rich colors and shapes can be achieved; user individual demands can be met; each component of the integral bathroom is secondarily injection-modeled; coating spraying can be avoided; rejection rate can be greatly reduced; more energy can be conserved and environment can be protected; each component surface of the integral bathroom is dirty-resistant, scratch-resistant, impact-resistant and temperature resistant; and the integral bathroom has performance better than paint and coatings.

Owner:SHANGHAI HUDA INVESTMENT & DEV +1

Swirl filter and sewage purification method therefor

PendingCN107098488AExtend your lifeFor automatic dischargeWater/sewage treatment by centrifugal separationWater contaminantsPurification methodsConical forms

The invention discloses a swirl filter, which comprises a water inlet pipe, a filter drum, a filling barrel, a filter net, a central water outlet pipe, a cover plate and a sludge diversion plate, wherein the water inlet pipe is of a helical structure and is arranged to communicate with an inner cavity of the filter drum along the tangential direction of the filter drum; the whole filling barrel is an annular barrel with an opening in the top and the outer wall is a cone; the filling barrel is located in the inner cavity of the filter drum and an annular space is formed between the outer wall of the filling barrel and the outer wall of the filter drum. The invention further provides a sewage purification method. Sewage enters a barrel in a tangential form and forms swirling flow, heavy particles naturally fall off and the filter net is not easily bruised or blocked, so that the life of the filter is prolonged and the filter effect is improved. In addition, the filter drum is in a conical form, and is capable of assisting the heavy particles in naturally falling off, and the sludge diversion plate is also arranged at the lower part of the filter, so that the falling heavy particles can be automatically discharged out of the filter, and the filter has the advantages of adaptive capacity and a high treatment effect.

Owner:JIANGSU LONG LEAPING ENG DESIGN

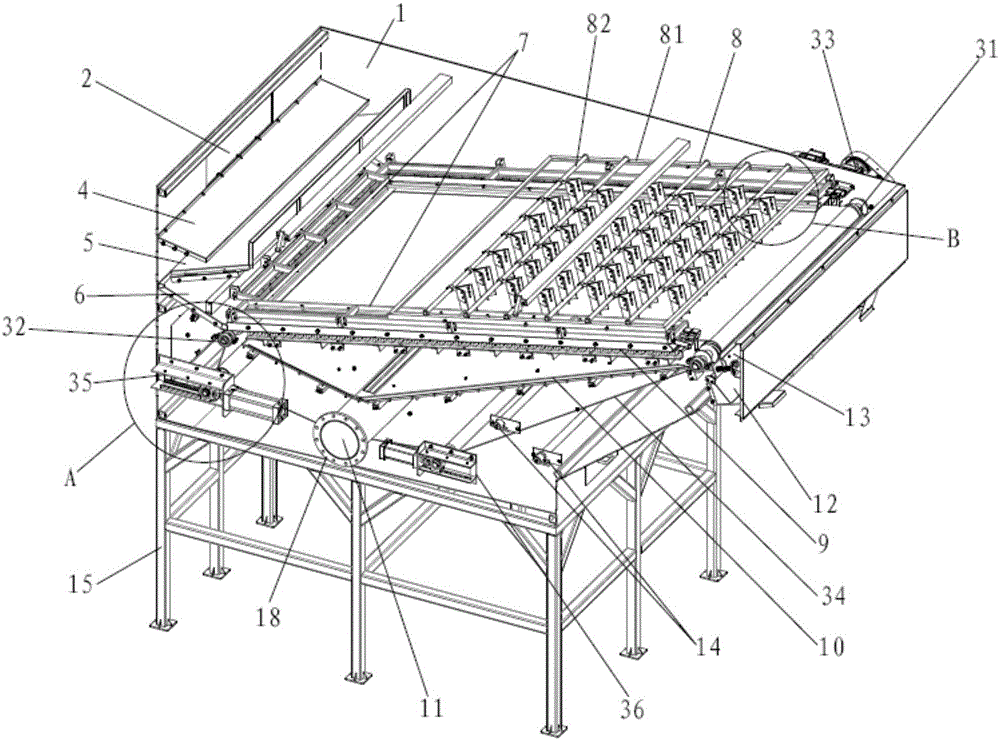

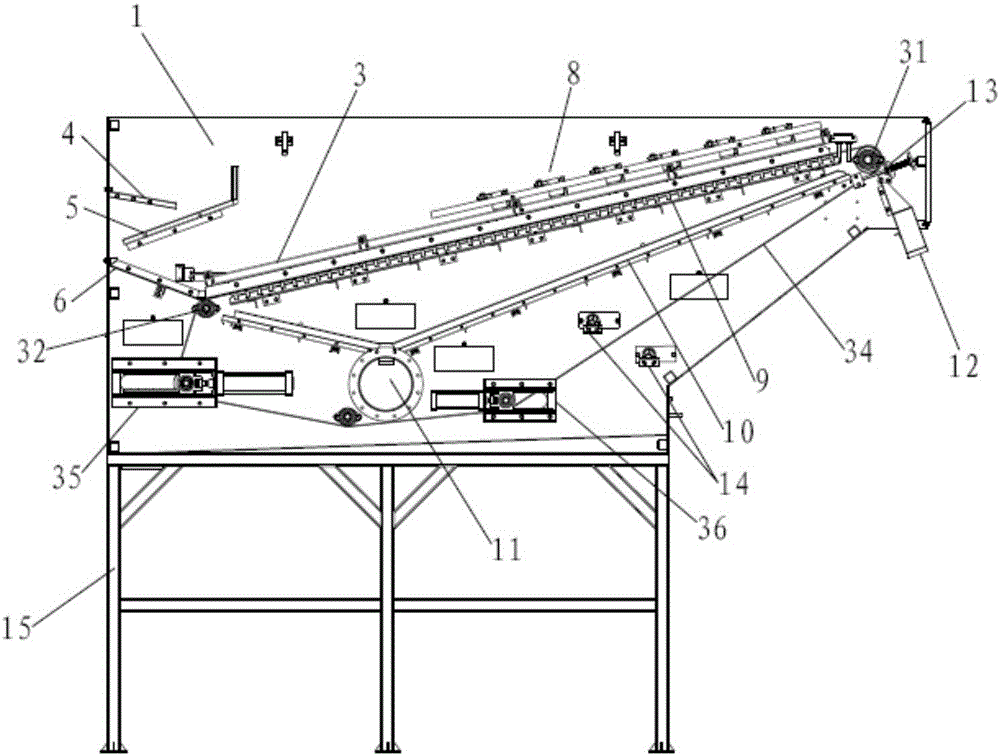

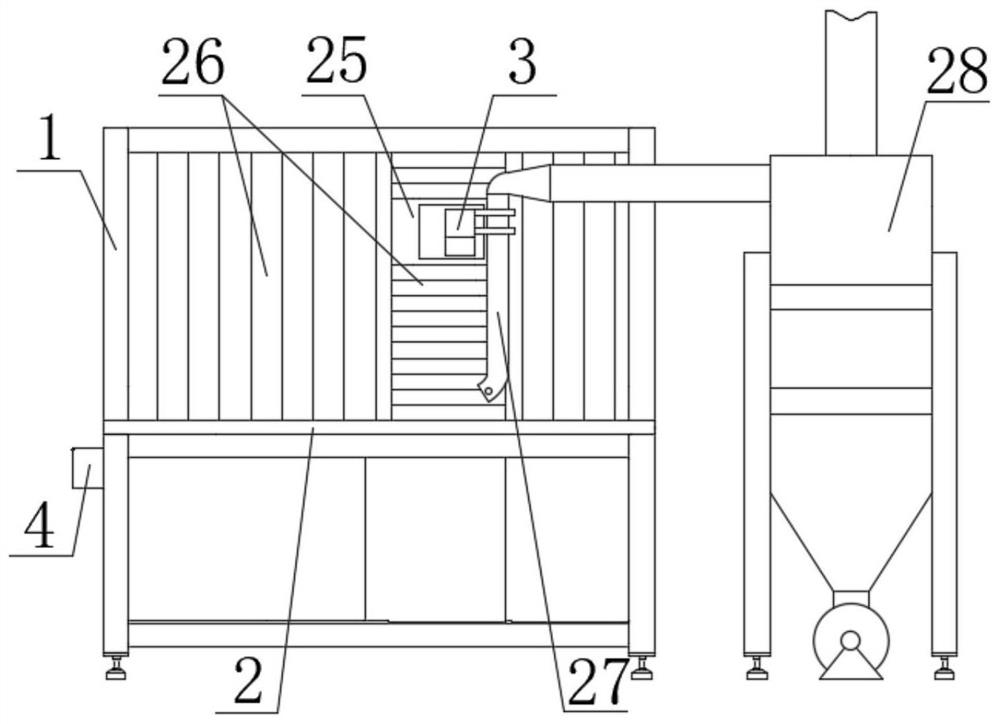

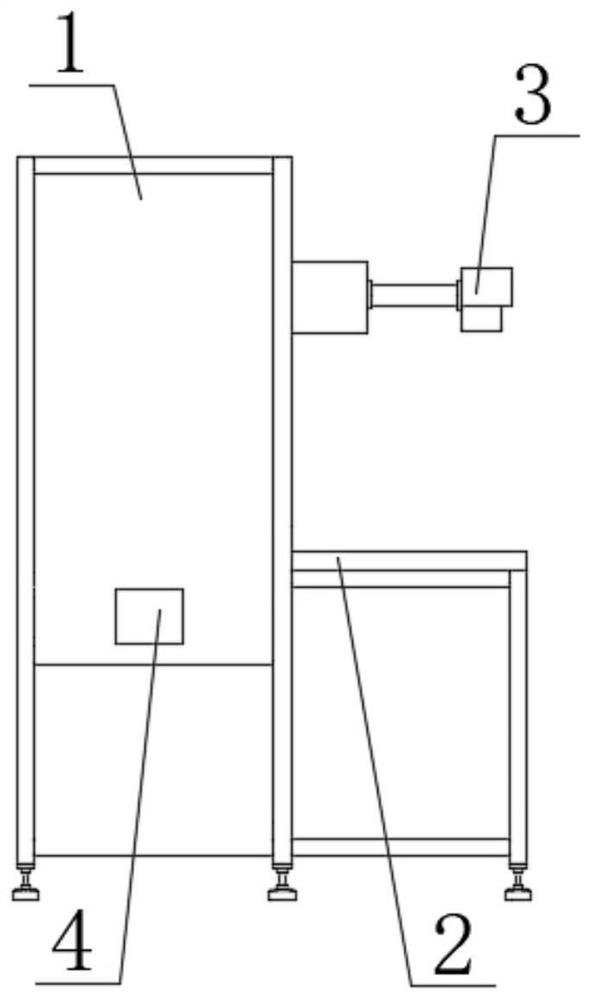

High-precision large-flux belt-type filtration and concentration equipment based on filter cloth

ActiveCN106045266AEasy to insertWear-resistantSludge treatment by de-watering/drying/thickeningFiltrationMechanical equipment

The invention relates to high-precision large-flux belt-type filtration and concentration equipment based on filter cloth, and relates to the technical field of concentrated mechanical equipment. The belt-type filtration and concentration equipment comprises a frame, a mud inlet, a filter device, a splash guard, a regulating plate and a bottom plate, wherein the filter device comprises a driving roller and a driven roller; the driving roller is connected with the driven roller through the filter cloth; a filter cloth tensioning mechanism and a filter cloth offset adjusting mechanism are also connected to the filter cloth; side-leakage-proof hold-down mechanisms are arranged on the left and right sides of the filter cloth; a mud turning mechanism is arranged above the filter cloth; a filter cloth support rack is arranged under the filter cloth; drainage openings are formed in the filter cloth support rack; a water receiving plate is arranged under the filter cloth support rack; a mud outlet is formed near the driving roller; a scraper plate is arranged above the mud outlet. The belt-type filtration and concentration equipment has the advantages of small size, good treating capability and high precision, and the operation method is easy to grasp.

Owner:FOSHAN UNIVERSITY

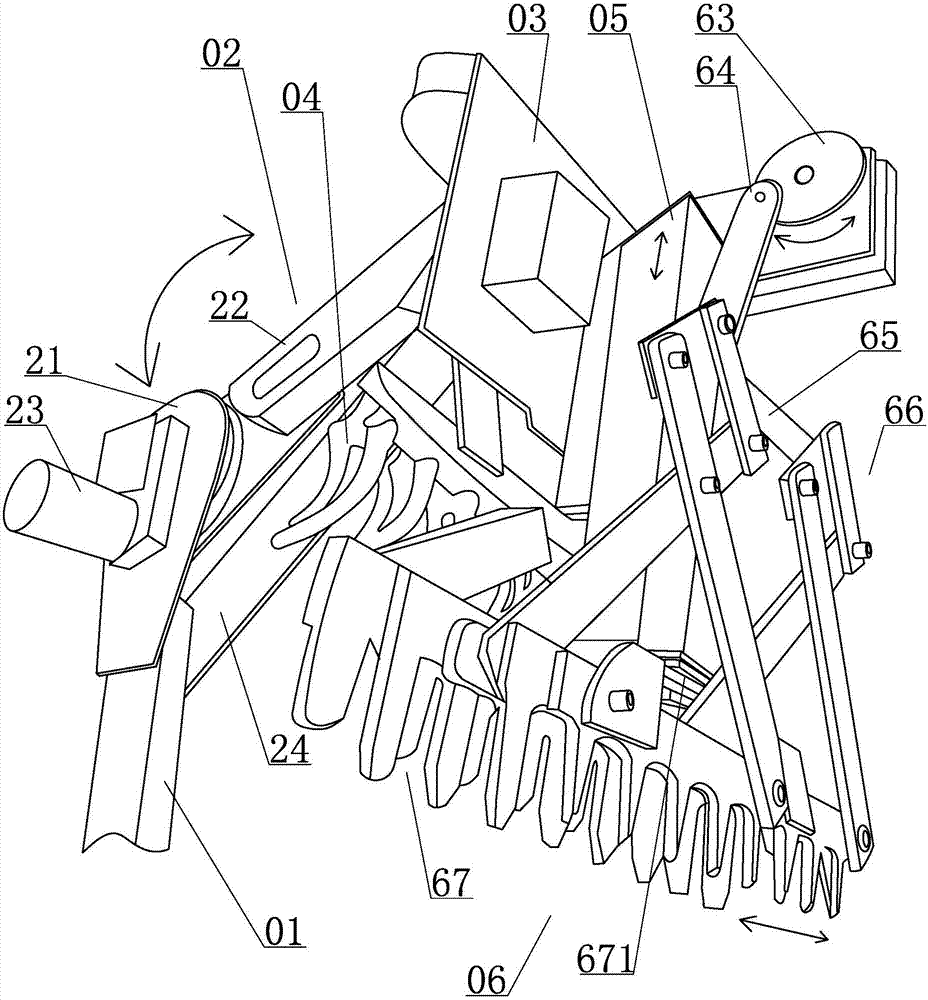

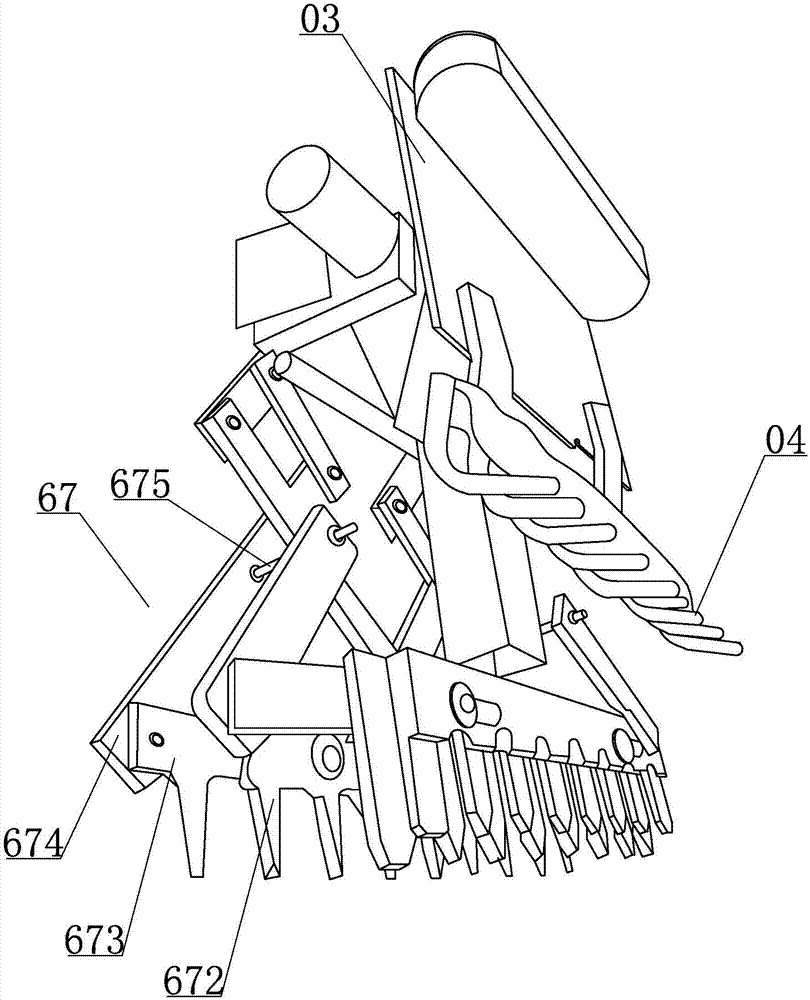

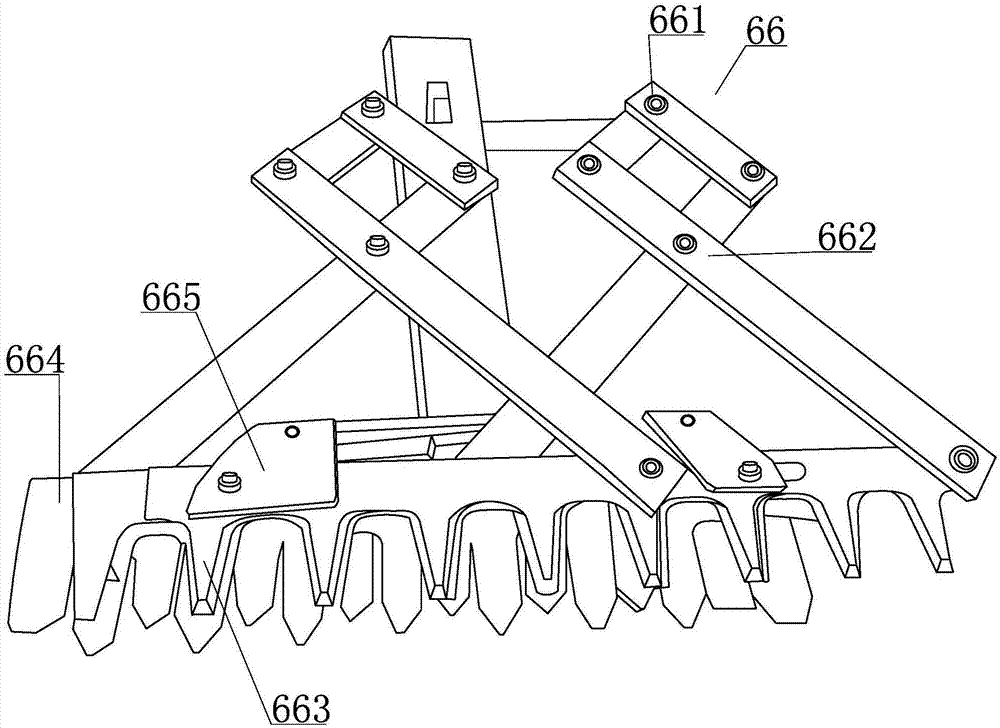

Litchi picking mechanical arm

The invention discloses a litchi picking mechanical arm. The litchi picking mechanical arm comprises a support, a vertical-rotating device arranged at the end of the support, a translation table arranged on the vertical-rotating device, a comb arranged on the translation table, a fixing base which is arranged on the surface of the translation table and extends downwards and a scissor device which is arranged on the fixing base and moves up and down. The vertical-rotating device comprises a rotating disc arranged at the end of the support, a swinging arm arranged on the rotating disc and a first motor for driving the swinging arm to move up and down, and a supporting rod for supporting the swinging arm and being matched with the swinging arm to move is arranged between the swinging arm and the support. The translation table is fixed on the swinging arm. The litchi picking mechanical arm has the automatic and intelligent functions, and has the effects that operation is easy and convenient, the efficiency is high, litchi trees are better protected, and popularization is convenient.

Owner:黄健明

Buffer moisturizing fruit box for transportation

ActiveCN108423273ANot easy to bruiseGood moisturizing effectPackaging under vacuum/special atmosphereContainers to prevent mechanical damageEngineeringNozzle

The invention discloses a buffer moisturizing fruit box for transportation. The buffer moisturizing fruit box comprises an outer box body, an inner box body which is arranged in the outer box body andcan move, buffer devices which are arranged on a moving path of the inner box body, are positioned on the two sides of the inner box body, and are used for buffering the inner box body, a water nozzle arranged above the inner box body, a water storage cavity which is arranged under the outer box body and communicates with the bottom of the inner box body, and a water pressing mechanism which is driven by the buffer devices and is used for pressing water in the water storage cavity so that the water can be sprayed out of the water nozzle, wherein the water storage cavity is connected with thebottom of the inner box body through a water inlet channel; the water storage cavity communicates with the water nozzle through a water outlet channel; a bottom plate is arranged under the water storage cavity; and the bottom plate is connected with the bottom of the outer box body through a plurality of connecting pillars. According to the buffer moisturizing fruit box, fruits can be effectivelybuffered, fruits are prevented from being damaged due to collision with the box wall, water can be sprayed through the buffer function, moisturizing and fresh keeping are achieved on fruits, and themoisturizing effect is good.

Owner:长汀县木易电子商务有限公司

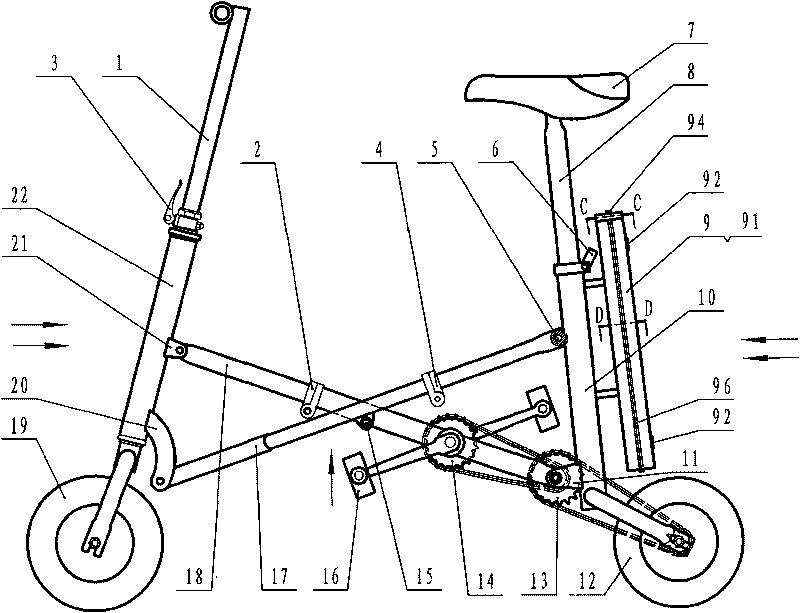

Half-packaging folding bicycle

InactiveCN101758882AEasy to foldFast folding methodFoldable cyclesCycle containersVertical tubeVehicle frame

The invention relates to a half-packaging folding bicycle. The bicycle comprises a frame head pipe, a frame riser pipe, handle bars, folding pedals, a cradle and the like, wherein an X-shaped frame main pipe is arranged between the frame head pipe and the frame riser pipe, and the X-shaped frame main pipe comprises a pipe A and a pipe B; four ends of the pipe A and the pipe B are respectively provided with an end hinge, the four end hinges are all movably connected with the pipe A and the pipe B, wherein two end hinges are fixedly connected with the frame head pipe, and the other two end hinges are fixedly connected with the frame riser pipe; the pipe A and the pipe B are respectively provided with a middle hinge; the pipe A is in a Y shape and comprises a large pipe and two small pipes; a rotation shaft is arranged at the intersection of the pipe A and the pipe B; the pipe A is provided with a secondary transmission and acceleration chain wheel; and the frame riser pipe is fixedly provided with a half-packaging device. The invention has the advantage that the folding method is simple, fast and easy. After being half folded, the bicycle can be pushed like the bicycle which is not folded; and after being half folded or fully folded, the bicycle can be packaged partially, thereby ensuring the convenient carrying.

Owner:詹富生

Efficient laser marking method and device for multi-style small-batch articles

The invention discloses an efficient laser marking method and device for multi-style small-batch articles. The laser marking method comprises the steps that a drawing is prepared and typeset on a computer, the thickness of marks in the drawing is set, a contour is marked on a working platform according to the drawing, the marked articles are placed on the contour, the focusing height is set according to the thickness, and then laser marking is carried out. The laser marking device comprises a rack, and the working platform and a three-axis linkage mechanism which are distributed front and back are connected to the rack. The three-axis linkage mechanism is connected with a laser marking head located above the working platform, the three-axis linkage mechanism is electrically connected with a control box, and the laser marking head is also electrically connected with the control box. The efficient laser marking method and device for the multi-style small-batch articles can be suitable for laser marking operation of multiple types of small-batch articles, and further has the advantages of being high in machining efficiency, convenient to operate, high in safety, capable of conveniently removing pollutants, high in machining precision, stable in control and good in dust removal and environmental protection performance.

Owner:张振宇

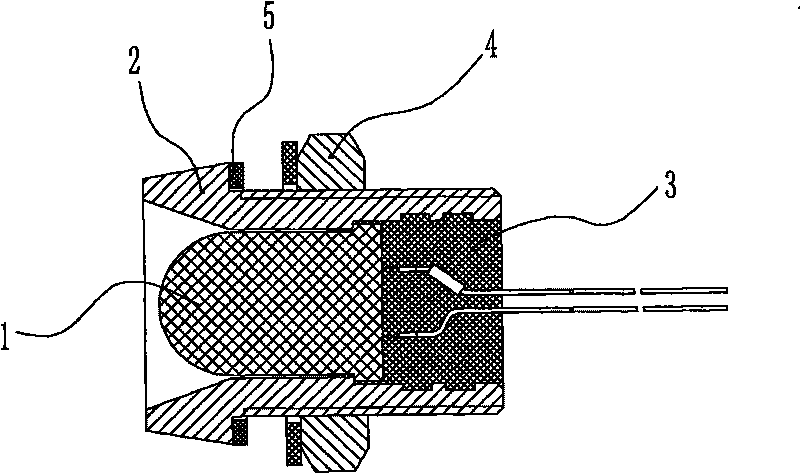

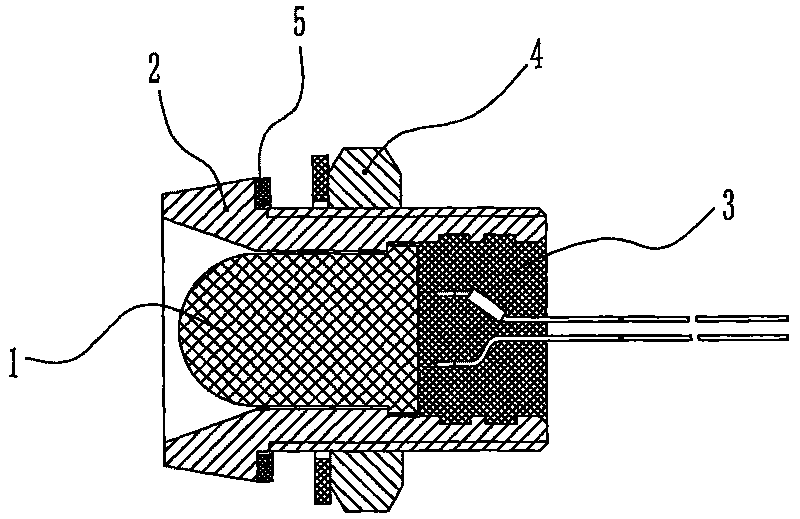

Mining signal lamp

InactiveCN101706051AImprove warning effectImprove the protective effectLighting applicationsPoint-like light sourceEngineeringSealant

The invention discloses a mining signal lamp comprising a light-emitting diode, the light-emitting diode is arranged in a cylindrical shell, pouring sealant is placed in the cavity at the wire inlet end of the light-emitting diode in the cylindrical shell, the pouring sealant connect the light-emitting diode and the cylindrical shell fixedly; the external surface of the cylindrical shell is connected with a fastening nut in threads. The invention has the advantages of simple structure and low cost; when in use, not only the brightness is high, but also the properties of anti-explosion and anti-collision required by operation in the pit under the protection of cylindrical shell and pouring sealant.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

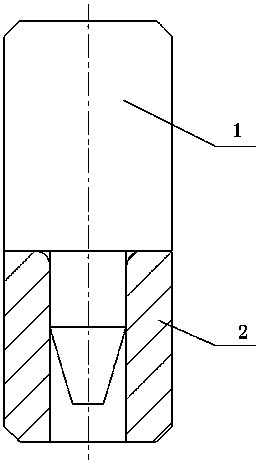

Wood die positioning device for high-precision sand mould casting

The invention provides a wooden mold positioning device for high-precision sand casting, which includes a convex side part and a concave side part, the convex side part is a steel positioning pin, and the concave side part is a steel positioning sleeve. The steel positioning pin is small The cylindrical surface matches the inner cylindrical surface of the steel positioning sleeve. The large cylindrical surface of the steel positioning pin has knurling, and the upper end has chamfers, which play a guiding role during assembly, and the lower end of the small cylinder has chamfers. The outer cylindrical surface of the steel positioning sleeve is knurled, the outer side of the lower end is chamfered, and the upper end of the inner hole is chamfered. The positioning pin and the positioning sleeve of the present invention are made of steel with high hardness and strength, and are not easy to be worn and damaged when friction and collision occur during use; the positioning pin and the positioning sleeve are processed by precision machine tools with high precision ; The positioning device is low in cost and has good promotion and application value.

Owner:QINGDAO RUNCHENG VEHICLE FITTINGS CO LTD

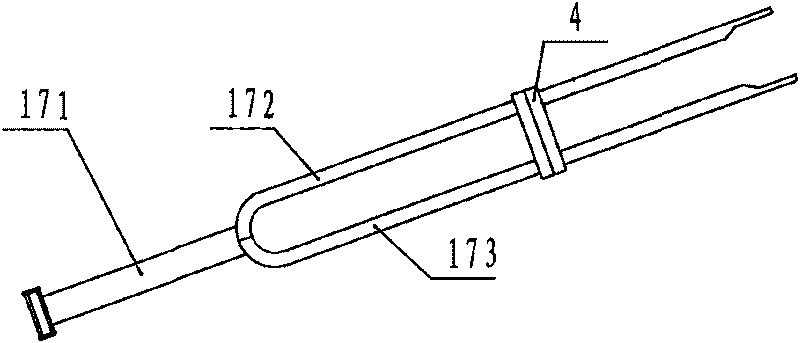

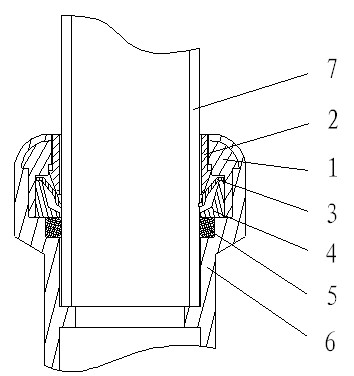

Fluid pipe connection device and supporting pipe demolition tool thereof

InactiveCN102635747ASimple and fast operationNot easy to wearCouplingsBranching pipesEngineeringMechanical engineering

The invention provides a fluid pipe connection device, aiming to solve the problems that the pipe demolition is troublesome and the top part of the pushing gear ring can be easily worn and damaged. The fluid pipe connection device comprises a pipe connector, and an inner gear clamping ring and a pushing gear ring are arranged in the pipe connector and a plug sleeve via the plug sleeve arranged fixedly on the pipe connector. When a pipe is butted, the pipe penetrates through the plug sleeve, the pushing gear ring and the inner gear clamping ring, and the wall of the pipe is tightly clamped by the inner gear clamping ring; and when the pipe is removed, and an inner gear is pushed by the pushing gear ring along the pipe insertion direction so that the wall of the pipe is not clamped by the inner gear clamping ring. The fluid pipe connection device is characterized in that the pushing gear ring and the plug sleeve are contacted in a sliding way; and the top end of the pushing gear ring is basically flush with the plug sleeve or is contracted into the plug sleeve when the pipe is butted. The invention also provides a supporting pipe demolition tool, which comprises a handle, the handle is connected with an ejection block, and the ejection block can extend into a clearance between the plug sleeve and the wall of the pipe to push the pushing gear ring.

Owner:MUCH RISE INVESTMENT

Automatic laminating machine for optical filter

The invention discloses an automatic laminating machine for an optical filter. The machine comprises a base, a feeding mechanism, a rotating mechanism, a suction nozzle material taking mechanism, a correcting mechanism, an automatic dispensing mechanism, a UV curing mechanism, a CCD visual mechanism, an X-axis linear module and a Z-axis linear module. A jig rotating mechanism is arranged in the center of the base, and the feeding mechanism, the correcting mechanism, the automatic dispensing mechanism, the UV curing mechanism and the CCD visual mechanism are arranged on the outer side of the rotating mechanism. The X-axis linear module is arranged on the upper portion of one side of the base, the Z-axis linear module is movably arranged on the X-axis linear module, and the suction nozzle material taking mechanism is arranged on the Z-axis linear module and located above the rotating mechanism. Products are automatically clamped and fixed to a clamping jaw, corrected and subjected to rotary dispensing and curing in sequence, manual operation is not needed, the operation efficiency is high, the labor intensity is low, the labor cost is low, the dispensing effect is good, the fitting precision is high, the yield is high, frequent reworking is not needed, the products are not easily damaged, glue solution product waste is small, the material cost is low, no harm is caused to eyes, and hidden health hazards are avoided.

Owner:厦门贝莱信息科技有限公司

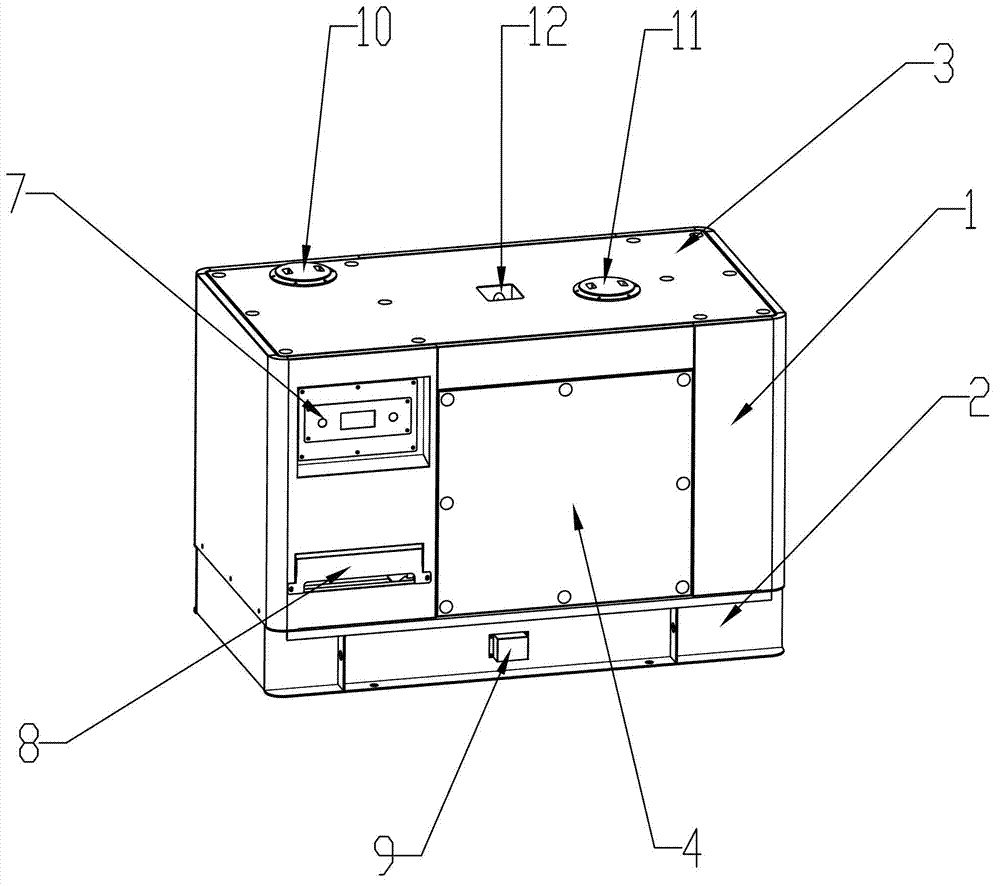

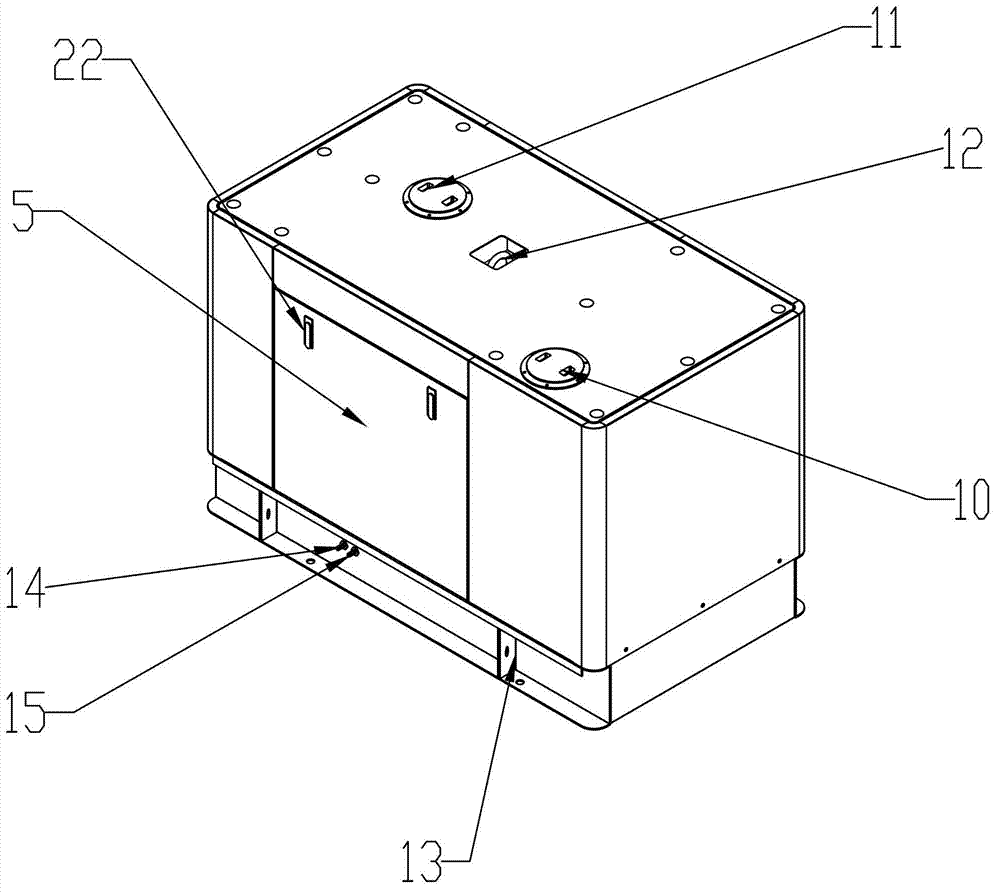

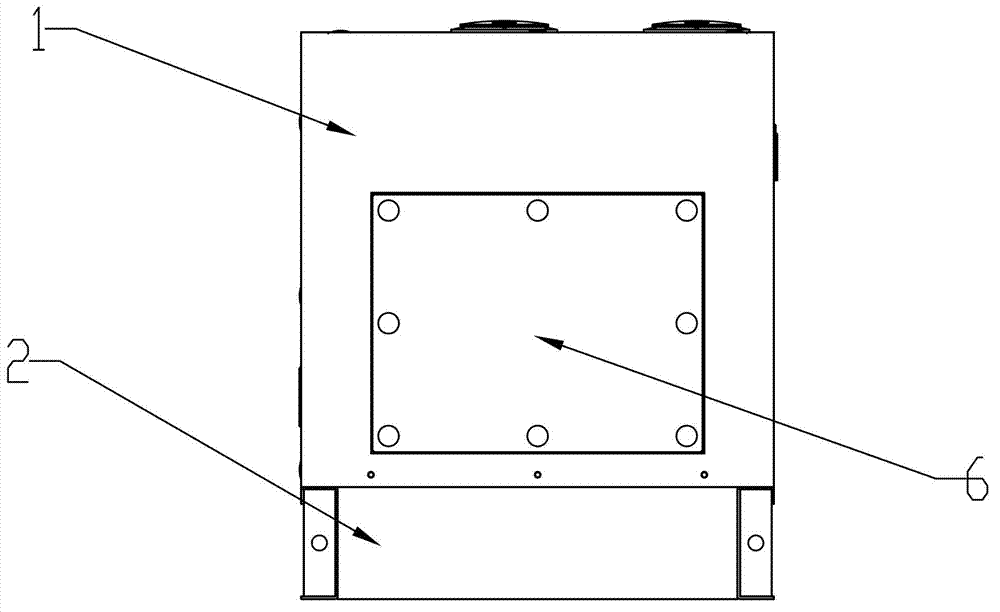

Vehicle-mounted generating set box body

InactiveCN102818096AEasy to carryImprove cooling effectMachine framesMachines/enginesCooling effectEngineering

The invention relates to a vehicle-mounted generating set box body and belongs to the technical field of vehicle-mounted generators. The vehicle-mounted generating set box body comprises a water box, a partition plate, a centrifugal fan and air guide plates, wherein the bottom of a chassis is provided with an air inlet, and the water box is arranged in the air inlet; the chassis is internally provided with a partition plate, and one side of the partition plate is provided with the centrifugal fan; and an outer ring of the centrifugal fan is provided with multiple cambered air guide plates, and the lower end of the centrifugal fan is provided with an air outlet. The vehicle-mounted generating set box body provided by the invention has the advantages that the structure is simple, compact and reasonable; through adoption of a four-corner circular arc design, the appearance is beautiful, collision can be avoided, a access door which is easy to assemble is arranged and is convenient to maintain; and upper rings and lower rings are more convenient to transport, the heat dissipation effect of the water box is good, the ventilation is reliable, and a cooling effect of a vehicle-mounted generating set is good.

Owner:WUXI OUMA MACHINERY MFG

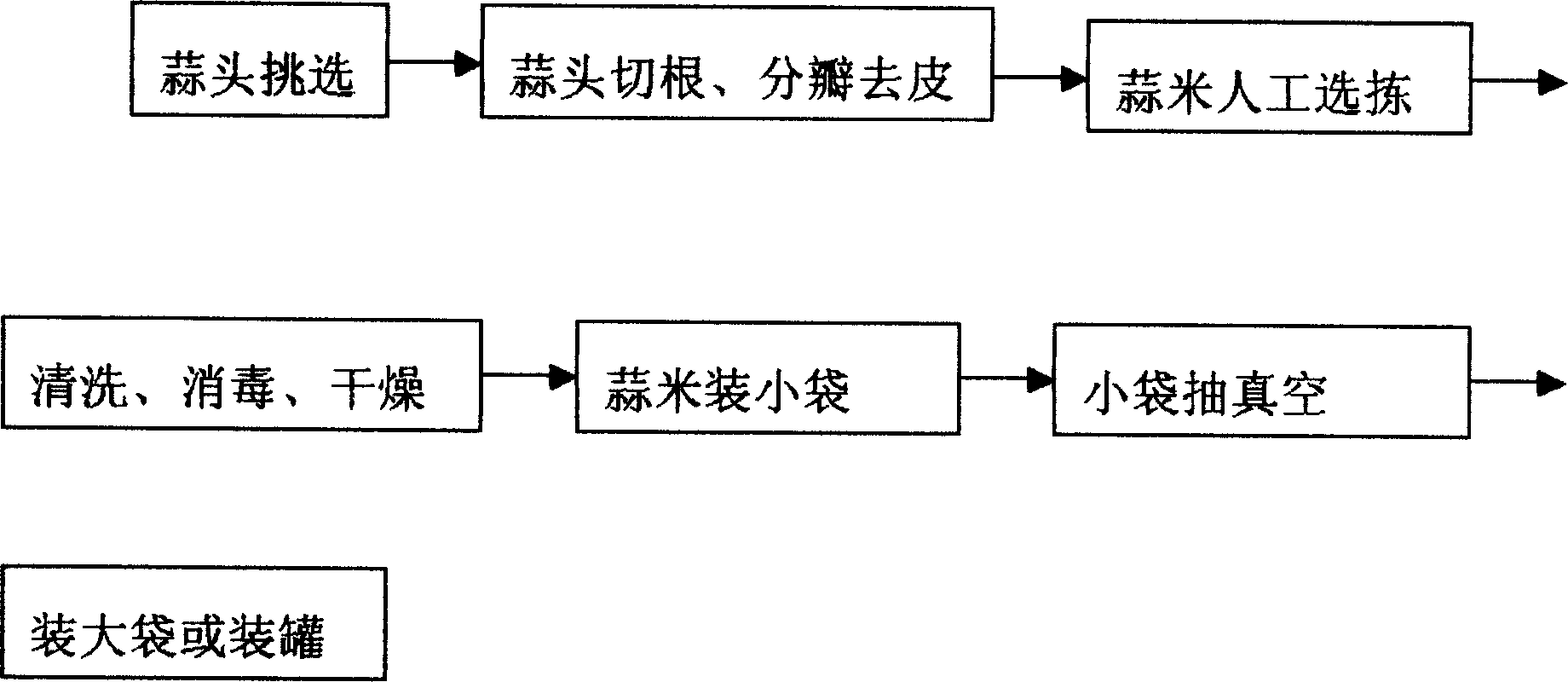

Vacuumizing, fractional packaging fresh-keeping method for garlic millet

InactiveCN1732787AAvoid breedingAvoid pollutionFruit and vegetables preservationPackaging under vacuum/special atmosphereVacuum pumpingBiology

Owner:周晓宏

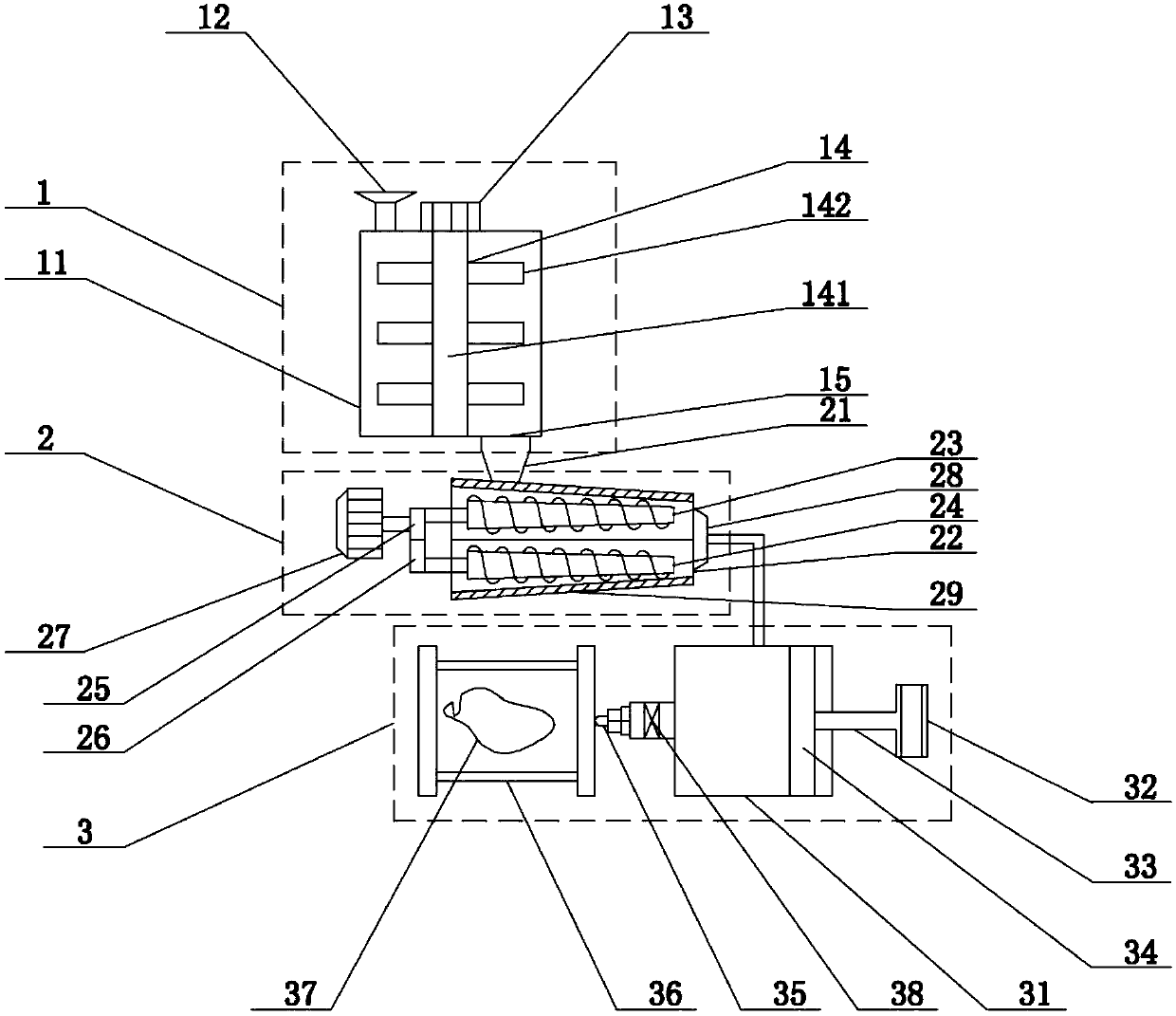

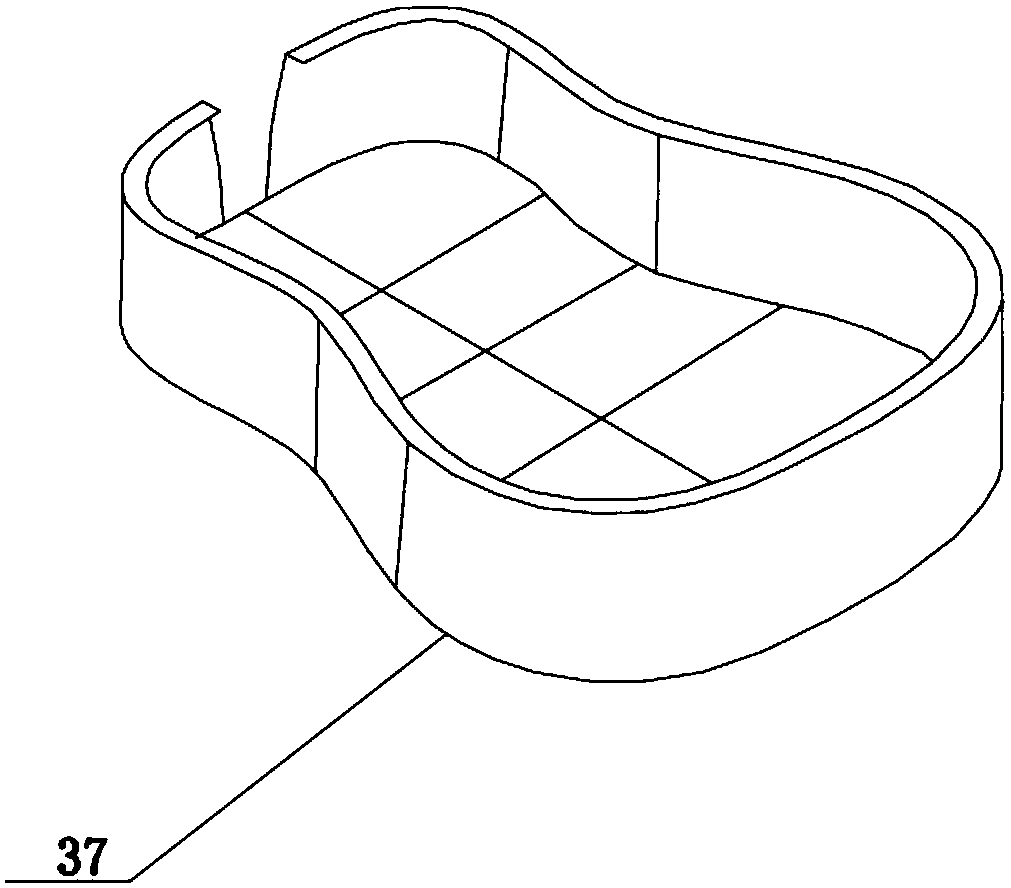

Novel guitar bag production device and preparation method thereof

The invention relates to the field of mold machines, and in particular to a novel guitar bag production device and a preparation method thereof. The novel guitar bag production device comprises a material mixing device, a double-screw extrusion device and a plastic injection device; the material mixing device comprises a material mixing barrel, a material inlet, a stirring motor, a stirring assembly and a discharging port, wherein the stirring assembly comprises a rotating shaft and stirring blades; the double-screw extrusion device comprises a feeding hopper, a screw cylinder, a main screw rod, a slave screw rod, a main gear, a slave gear, an extrusion motor and a material extrusion port; and the plastic injection device comprises a material barrel, a hydraulic cylinder, a piston rod, a material pushing plate, a rotating spray head, a mold fixing device and a guitar bag mold, wherein and the material barrel is connected with the material extrusion port through a pipeline. According tothe adopted technical scheme, the novel guitar bag production device and the preparation method thereof have the advantages that the structure is simple, the design is reasonable, the quality of a finished product is good, a guitar can be effectively protected from collision damage and fall damage, the novel appearance is kept for a long time, the guitar is not prone to cracking, and the servicelife of the guitar is greatly prolonged.

Owner:唐凡

Method for producing anti-deformation edge-covered door

InactiveCN107803911ALarge emissionsShorten the production cycleWood working apparatusSanderFace sheet

The invention relates to a method for producing an anti-deformation edge-covered door. The method comprises the following steps: firstly, selecting a qualified raw material plate, utilizing a sander to sand the surface of the raw material plate, evening the raw material plate, and making the evened raw material plate into a door core plate according to the size of a door opening of a user; then, utilizing a press to perform veneer gluing, pressing and shaping on the front side surface and the rear side surface of the door core plate, wherein a veneer gluing plate for veneer gluing is a standard part which is subjected to paint treatment, and the veneer gluing plate has the length larger than that of the door core plate and the width larger than that of the door core plate; after that, utilizing a cutter to cut the veneer gluing plate to ensure that the left side surface, the right side surface, the upper side surface and the lower side surface of the veneer gluing plate are respectively flush with the four side surfaces of the door core plate to obtain a door panel; selecting a U-shaped groove, and performing coating and veneer gluing on the U-shaped groove; and at last, performingedge covering and sealing on the left side surface, the right side surface, the upper side surface and the lower side surface of the door panel, and punching a locking hole and hinge holes to obtainan end product. The method is short in production period and lower in manual cost; and as the four side surfaces of the door are edge-covered by the U-shaped groove, the door is prevented from moisture-absorbing deformation.

Owner:浙江安丰居家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com