Automatic laminating machine for optical filter

A laminating machine, automatic technology, applied in optics, optical components, installation and other directions, can solve the problems of low lamination accuracy, high labor cost, high labor intensity, etc., to achieve no health hazards, high lamination accuracy, artificial low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

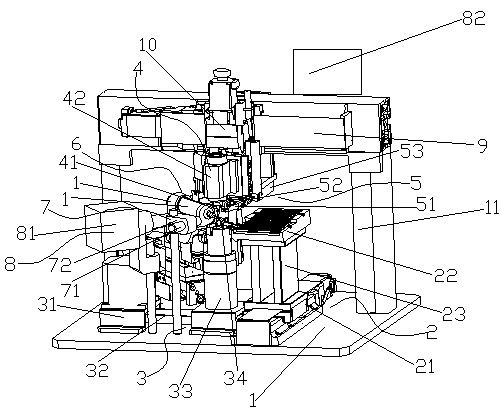

[0016] see figure 1 , an automatic bonding machine for filter wave plates, including a base 1, a feeding mechanism 2, a rotating mechanism 3, a suction nozzle feeding mechanism 4, a correction mechanism 5, an automatic dispensing mechanism 6, a UV curing mechanism 7, and a CCD vision mechanism 8 , X-axis linear module 9 and Z-axis linear module 10, the jig rotation mechanism 3 is located in the center of the base, the feeding mechanism 2, the correction mechanism 5, the automatic dispensing mechanism 6, the UV curing mechanism 7, The CCD visual mechanism 8 is distributed and arranged on the outside of the rotating mechanism 3 in the counterclockwise direction and is spaced from each other at a certain distance without interference. The X-axis linear module 9 is arranged on one side of the base 1 through the mounting frame 11. The Z-axis line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com