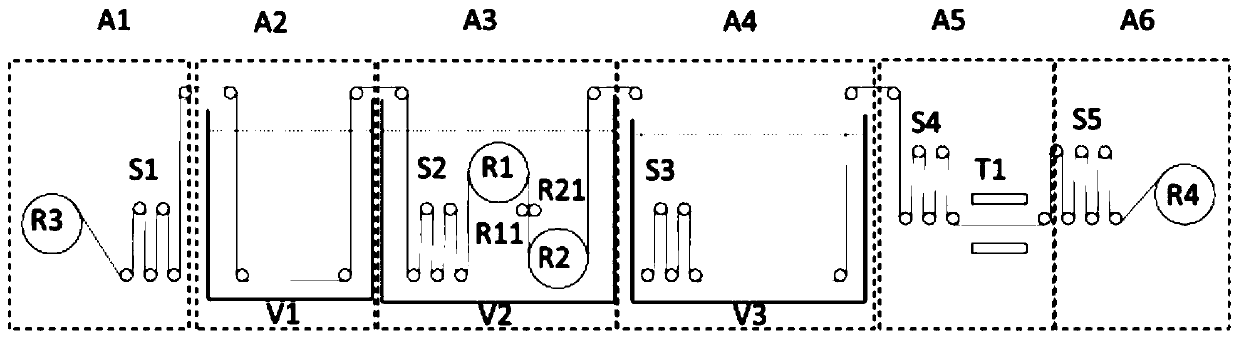

Lithium-ion battery pole piece pre-lithiating device

A lithium-ion battery, pre-lithiation technology, applied in the direction of battery electrodes, electrochemical treatment of electrodes, electrode manufacturing, etc., can solve the problems of uneven pre-lithiation, easy bending, damage and powder drop, etc., to achieve specific energy and cycle Improved performance, high production reliability, and high first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Preparation of the positive electrode sheet: the weight ratio of lithium cobaltate (LCO), PVDF, and Super-P is 96:2:2, stirring and pulping, coating the positive electrode slurry on both sides of the positive electrode current collector, and drying , compaction, slitting, and cutting into pieces to obtain the positive pole piece.

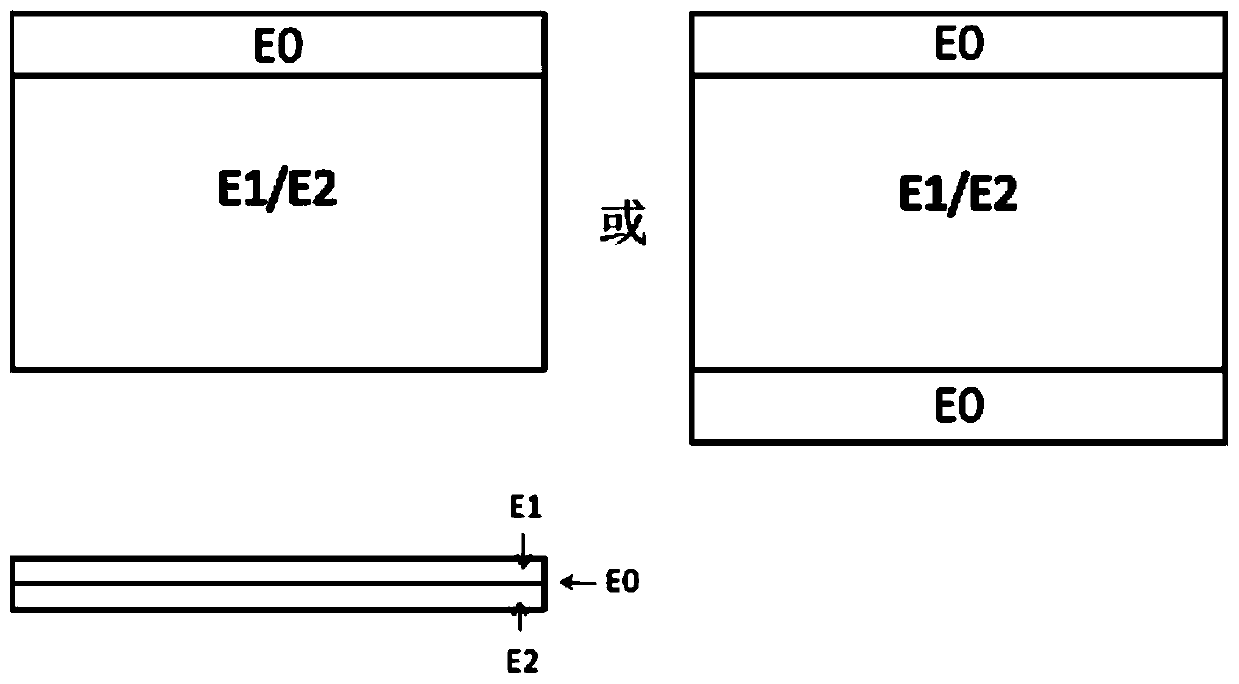

[0063] Preparation of negative electrode sheet: negative active material artificial graphite (or containing silicon, silicon alloy, silicon carbon composite, silicon oxide, or tin, tin alloy, tin oxide), styrene-butadiene rubber (SBR), carboxymethyl fiber Sodium plain (CMC), according to the required weight such as 96:2:2, add deionized water to stir and homogenate to make negative electrode slurry; the negative electrode slurry is double-sided coated on the negative electrode current collector, and coated into figure 2 Structure, with empty foil on one or both sides, the design capacity per unit area is 25Ah / m 2 , after drying, compacting, ...

Embodiment 1

[0080] Preparation of negative electrode sheet: Negative active materials artificial graphite, styrene-butadiene rubber (SBR), sodium carboxymethyl cellulose (CMC), according to the required weight, such as 96:2:2, add deionized water and stir to make negative electrode slurry material; the negative electrode slurry is coated on both sides on the negative electrode current collector, and the design capacity per unit area of one side is 25Ah / m 2 , after drying, compacting, and slitting, the width of the active material after slitting is 71mm, and the pre-lithiation is performed, and the negative electrode sheet is obtained after the pre-lithiation and cutting into pieces.

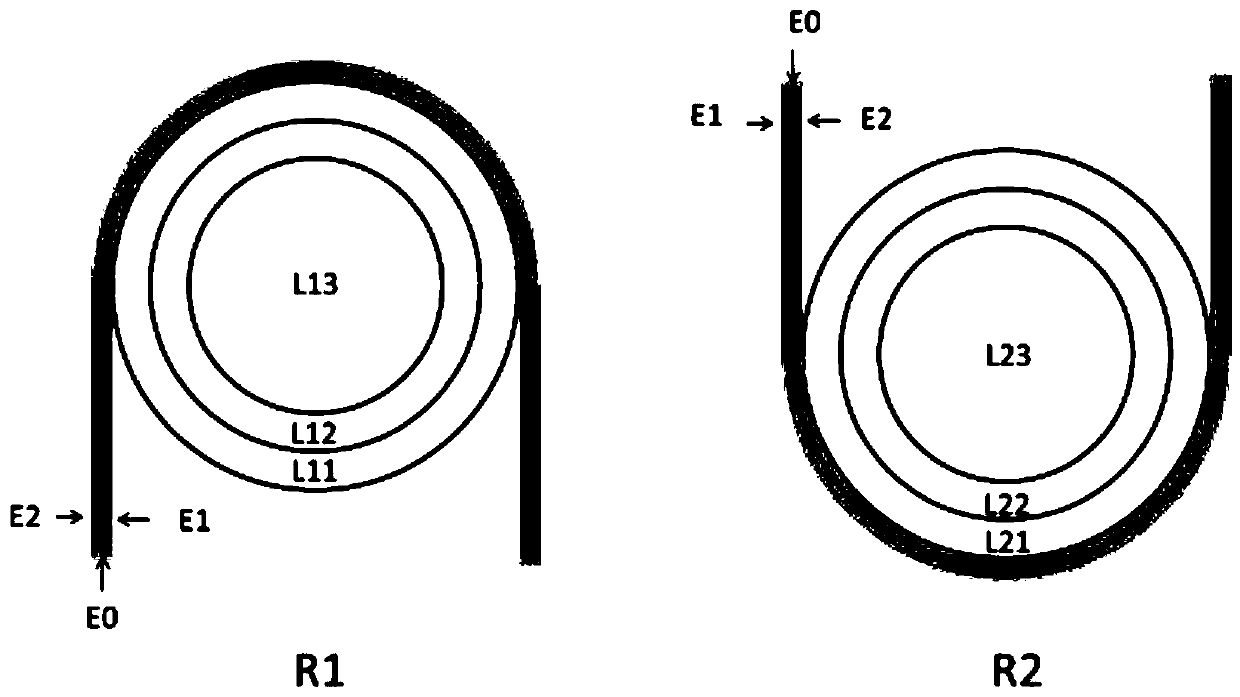

[0081] Pre-lithiation process: the current through the first current and voltage control device C1 and the second current and voltage control device C2 is 6A, the width of the active material of the electrode pole piece is 71mm, and the operating linear speed of the electrode pole piece in the A3 module is ...

Embodiment 2

[0084] Preparation of negative electrode sheet: Negative active material artificial graphite, silicon oxide negative material, styrene-butadiene rubber (SBR), sodium carboxymethyl cellulose (CMC), add deionized water according to the required weight such as 40:56:2:2 Stir and homogenize to make negative electrode slurry; apply the negative electrode slurry on the negative electrode current collector on both sides, and the design capacity per unit area of one side is 25Ah / m 2 , after drying, compacting, and slitting, the width of the active material after slitting is 71mm, and the pre-lithiation is performed, and the negative electrode sheet is obtained after the pre-lithiation and cutting into pieces.

[0085] Pre-lithiation process: the current through the first current and voltage control device C1 and the second current and voltage control device C2 is 6A, the width of the active material of the electrode pole piece is 71mm, and the operating linear speed of the control el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com