Coating modification method for improving performance of rich-lithium manganese-base positive electrode material

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of capacity fading, low initial Coulombic efficiency, poor rate performance, etc., and achieve small voltage drop and low cost , good stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

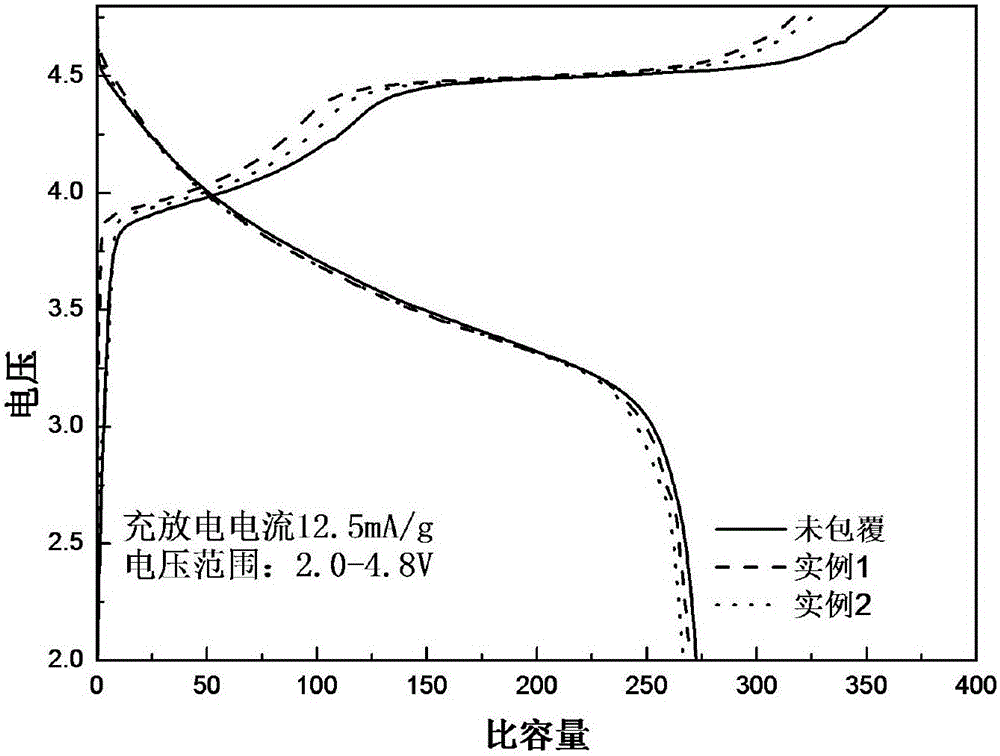

[0037] The lithium-rich manganese-based positive electrode material containing the praseodymium phosphate coating layer of this embodiment has the chemical formula Li[Li 0.2 Mn 0.54 Ni 0.13 Co 0.13 ]O 2 The outer surface of the layered structure of lithium-rich manganese-based cathode material is coated with praseodymium phosphate; in the example, the coating amount is PrPO 4 / Li[Li 0.2 Mn 0.54 Ni0 .13 Co 0.13 ]O 2 The mass ratio is 3%.

[0038] The preparation method is:

[0039] (1) Prepare the mixture: According to the molecular formula Li[Li 0.2 Mn 0.54 Ni 0.13 Co0 .13 ]O 2 The molar ratio of Mn:Ni:Co=54:13:13 to 5g of the hydroxide precursor and 3.65g of analytical grade LiOH·H 2 O, added to the mixing tank of the ball mill, after grinding and mixing uniformly, the element composition is Li[Li 0.2 Mn 0.54 Ni 0.13 Co 0.13 ]O 2 mixture;

[0040] (2) Sintering and grinding: The element composition obtained in step (1) is Li[Li 0.2 Mn 0.54 Ni 0.13 Co0 .13 ]O 2 The mixture was kept at...

example 2

[0044] In Example 2, divide by PrPO in step (2) 4 / Li[Li 0.2 Mn 0.54 Ni 0.13 Co 0.13 ]O 2 Except for the different mass ratios, the other experimental steps are the same as in Example 1, where PrPO in Example 2 4 / Li[Li 0.2 Mn 0.54 Ni 0.13 Co 0.13 ]O 2 = 5%,

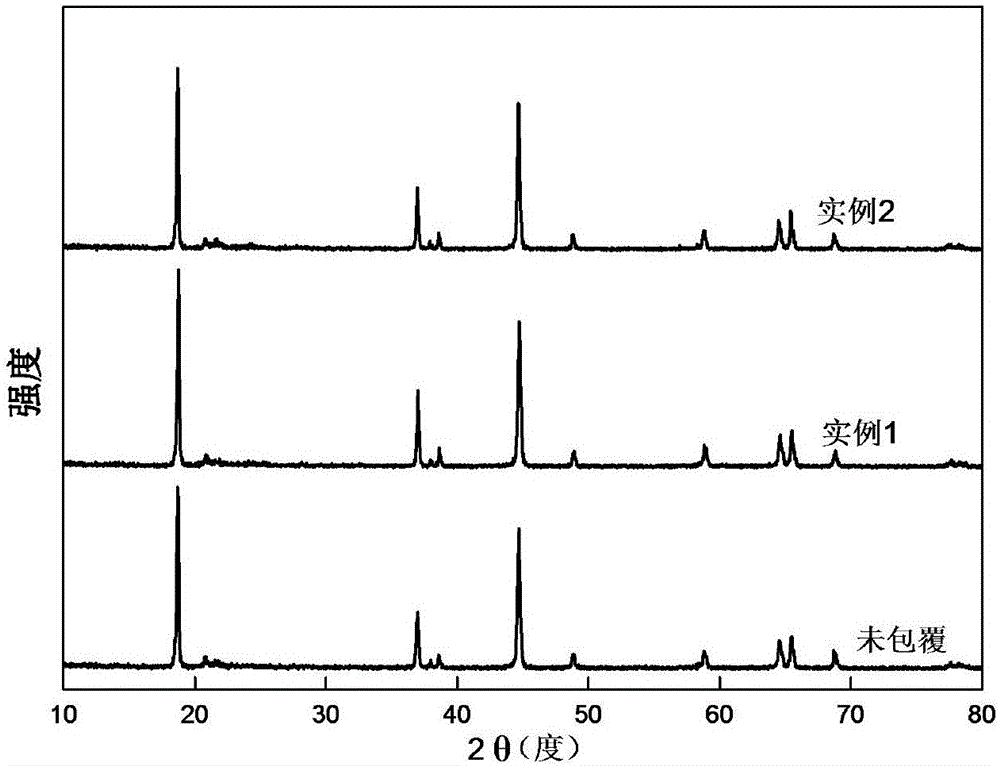

[0045] XRD pattern analysis

[0046] XRD pattern analysis was performed on the lithium-rich manganese-based cathode material containing the praseodymium phosphate coating layer and the manganese-based layered cathode material obtained in step (2), and the results are as follows figure 1 As shown, the lithium-rich manganese-based positive electrode material containing the praseodymium phosphate coating layer obtained in the embodiment and the lithium-rich manganese-based positive electrode material obtained in step (2) have a pure-phase layered structure with complete crystals. After coating, there is no Affect the crystal form of the material, see figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com