Rotary clamping apparatus for drilling crankshaft large disk flange hole

A technology of rotating fixture and crankshaft, applied in boring/drilling, drilling/drilling equipment, clamping and other directions, can solve the problem of easily bumping the crankshaft, achieve reliable fixation and locking, easy drilling processing, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

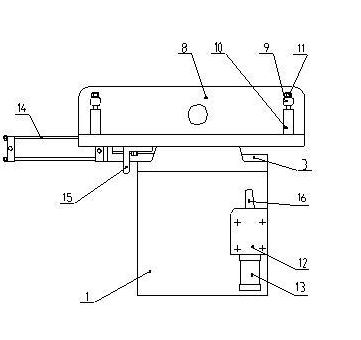

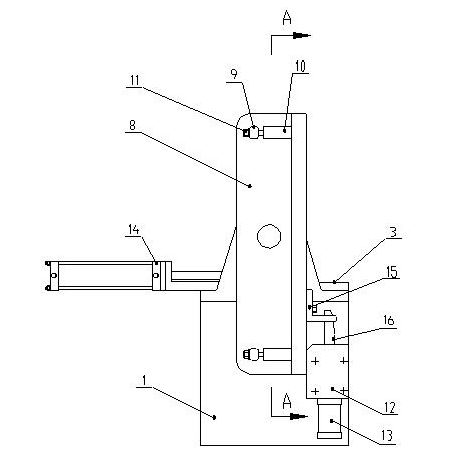

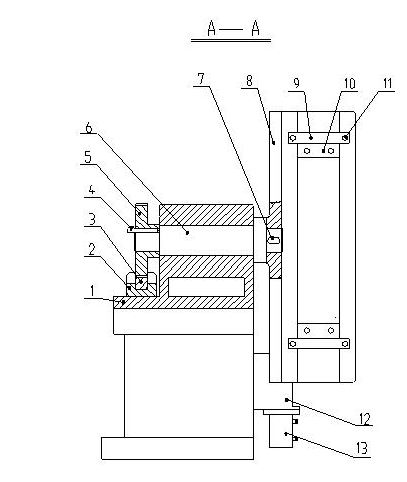

[0015] from figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen in the figure that a rotary jig for drilling the flange hole of the crankshaft plate includes a support 1, a rack slide rail 2, a driving cylinder 14, a rack 3, a gear 5, a rotating shaft 6, and a clamp body supporting plate 8. A horizontal circular hole is arranged on the upper part of the support 1, and the rotating shaft 6 is installed in the circular hole of the support 1, and the rotating shaft 6 can rotate in the circular hole. One end of rotating shaft 6 is equipped with gear 5, and the other end is connected and fixed with clamp body supporting plate 8, specifically gear 5 and clamping body supporting plate 8 are fixed on the two ends of rotating shaft 6 by wedge key 4 and flat key 7 respectively. The rack slide rail 2 is fixed on the flat plate at the bottom of the support 1. There is a plane at one end of the rack slide rail 2, and the driving cylinder 14 is fixed on this plane; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com