Panel shell of television and preparation method thereof

A manufacturing method and TV technology, which are applied to TVs, color TVs, parts of color TVs, etc., can solve problems such as bruises on the edges and corners of TV panels, lack of metal texture, deformation, etc., and achieve reduction in matching processes and saving Material cost, effect of beautifying metal texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

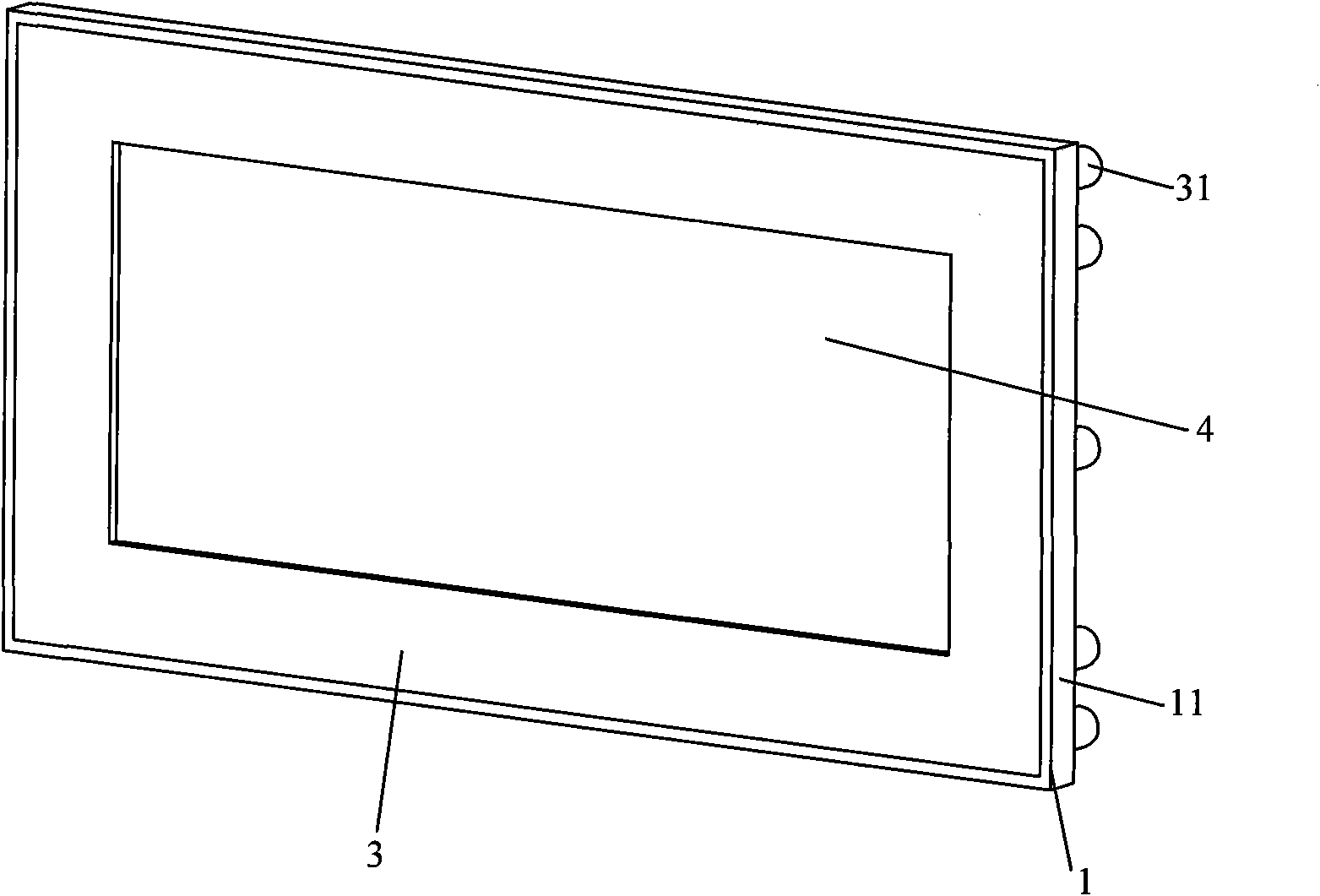

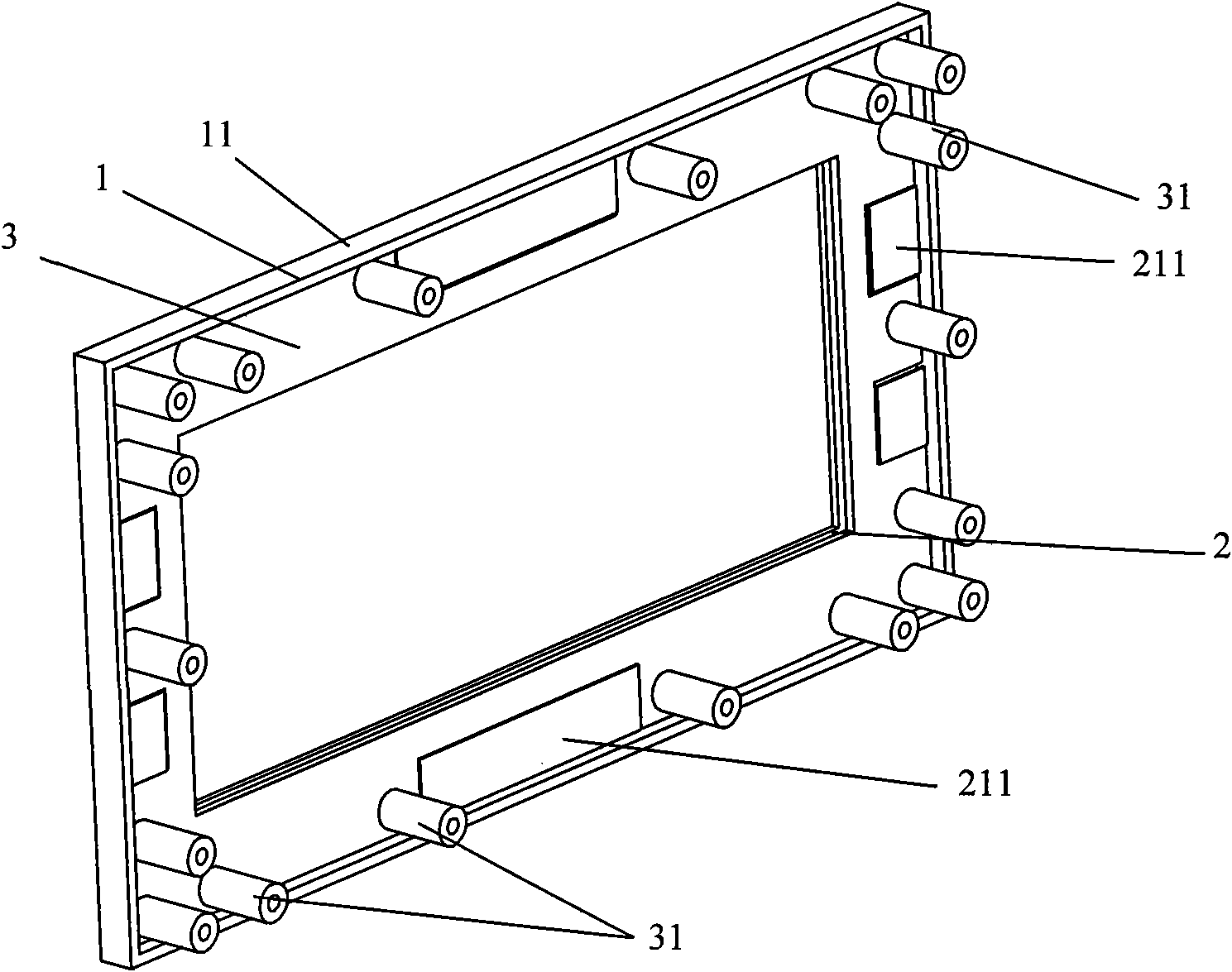

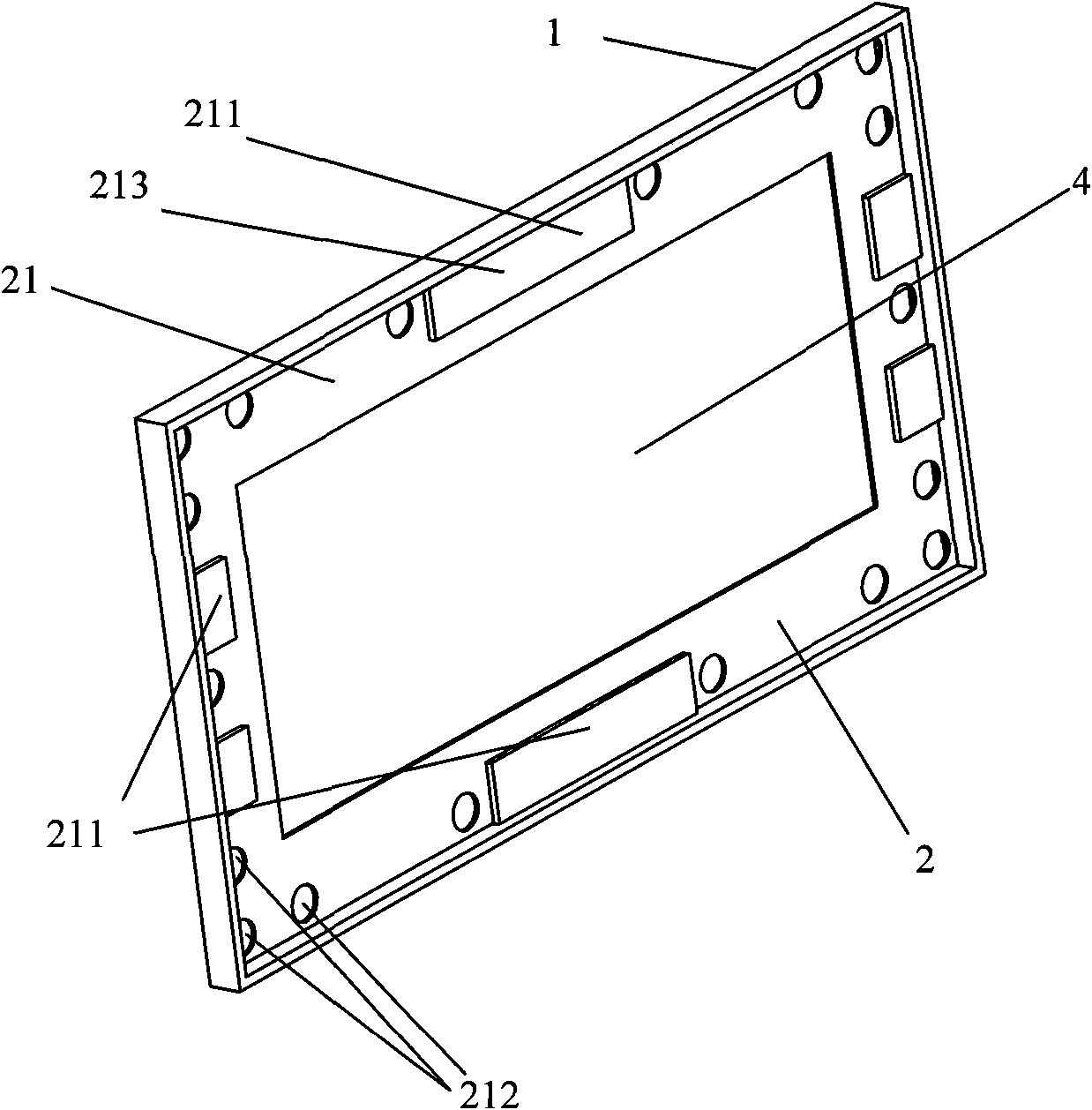

[0023] See figure 1 , figure 2 with image 3 . Embodiment 1 of the present invention includes a TV panel including a metal outer frame 1 , a metal inner frame 2 and a plastic panel 3 . Wherein, the metal outer frame and the metal inner frame form a metal frame. The inner metal frame is made of metal material, located inside the outer metal frame 1 and connected to the outer metal frame. The metal inner frame may be a plurality of ribs connecting two opposite sides of the metal outer frame, or may be a hollow plane plate connected with the metal outer frame. In this specific embodiment, the metal inner frame 2 is a flat plate with a hollow center. The metal outer frame and the metal inner frame can be integrally formed, or can be a metal frame formed by fixing the metal inner frame on the inner side of the middle part of the metal outer frame by welding or other methods. The present invention does not limit the metal outer frame. The molding method of the frame and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com