Punching machine for processing multiple workpieces

A multi-workpiece, punching technology, used in metal processing equipment, manufacturing tools, feeding devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention designs a punching machine for multi-workpiece processing. The bottom of the punching machine is equipped with a transmission mechanism, thereby greatly improving work efficiency and making it difficult for workers to injure their hands during operation.

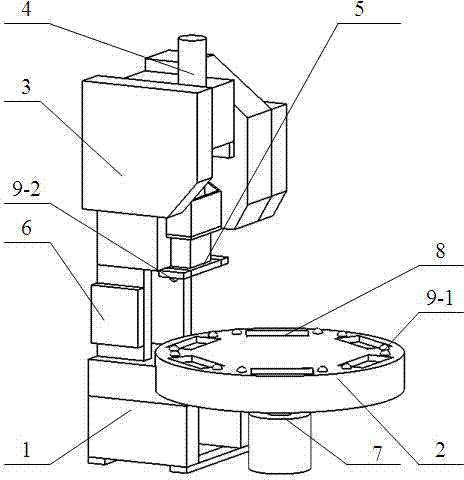

[0018] As an embodiment of the present invention, the present invention provides a structural schematic diagram such as figure 1 A punch press for multi-workpiece processing shown includes a base frame 1, a rotary table 2, a support 3, a working rod 4, a stamping head 5, an electric control box 6 and a control motor 7, and the support 3 is arranged on the base frame 1 On the support 3, there is a working rod 4, the bottom of the working rod 4 has a stamping head 5, the electric control box 6 is arranged on one side of the support 3, and a control motor 7 is arranged on one side of the bottom frame 1. There is a rotary table 2 on the control motor 7, the bottom frame 1 has a groove, the rotary ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com