Differential-pressure swirl-type backwashing filtration system

A technology of backwash filtration and swirling flow, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., which can solve the problem of reducing the service life of sewage pipes, failing to ensure smooth water flow, and heavy particles are easy to bruise and discharge sewage Pipe and other problems, to achieve the effect of saving space, simple installation, and avoiding mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

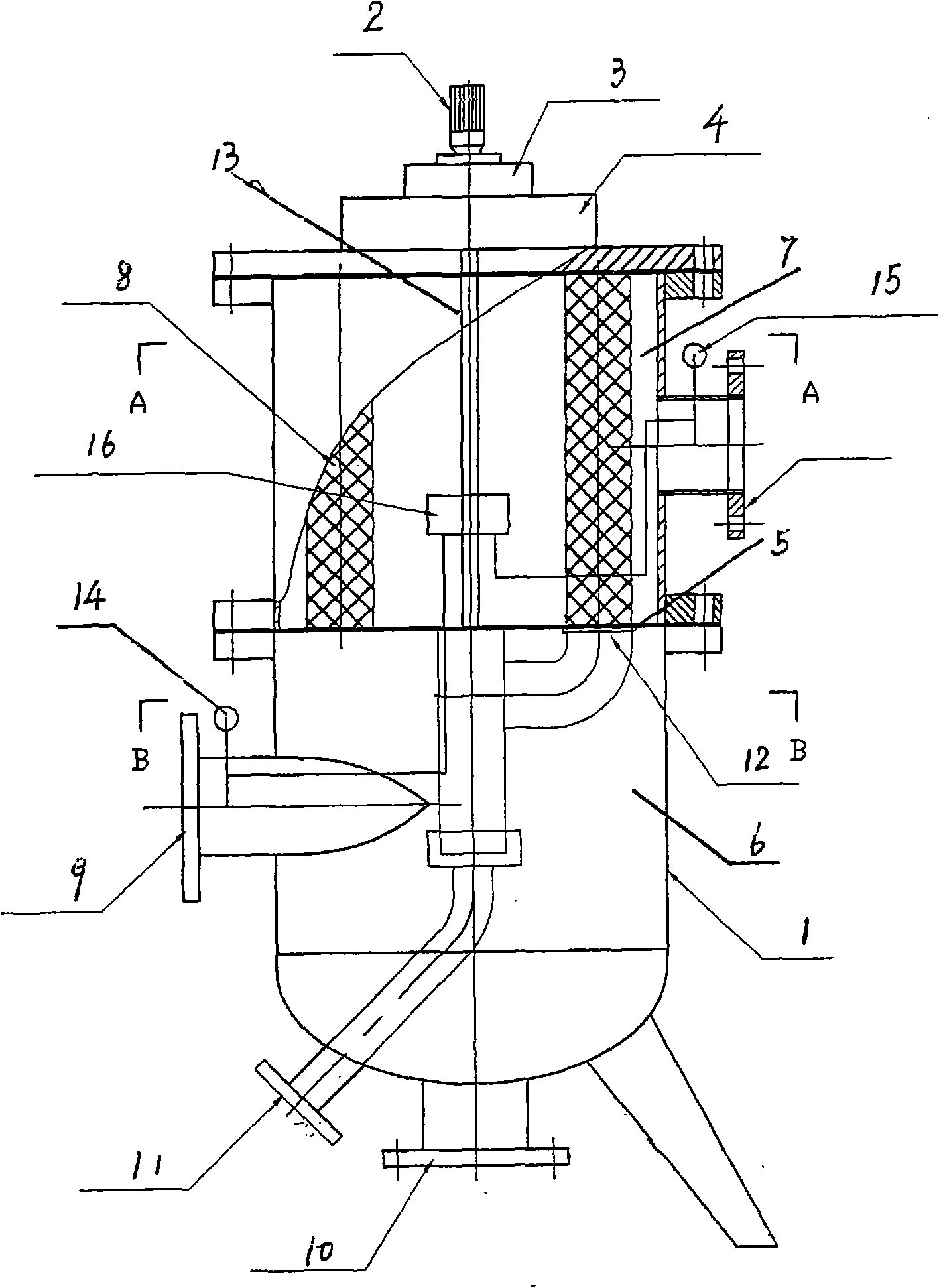

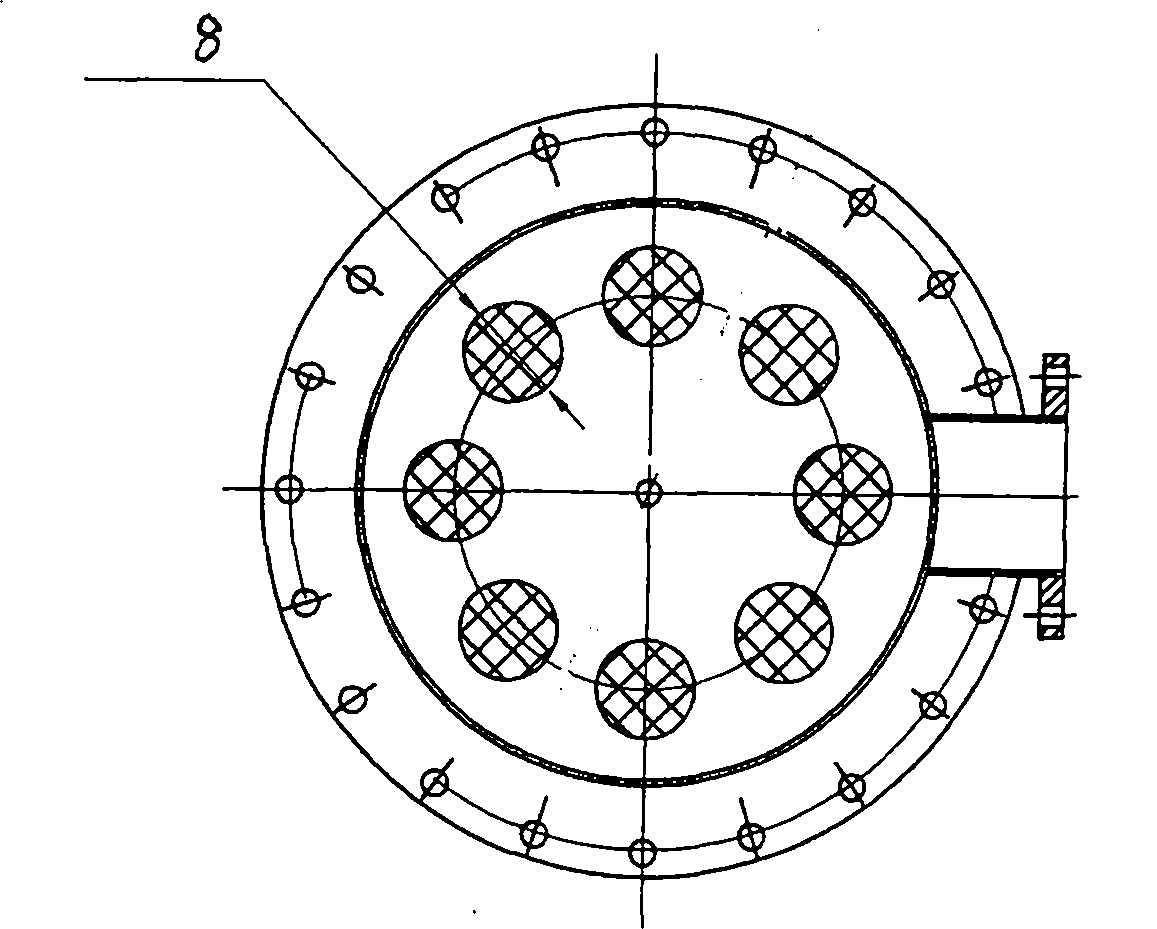

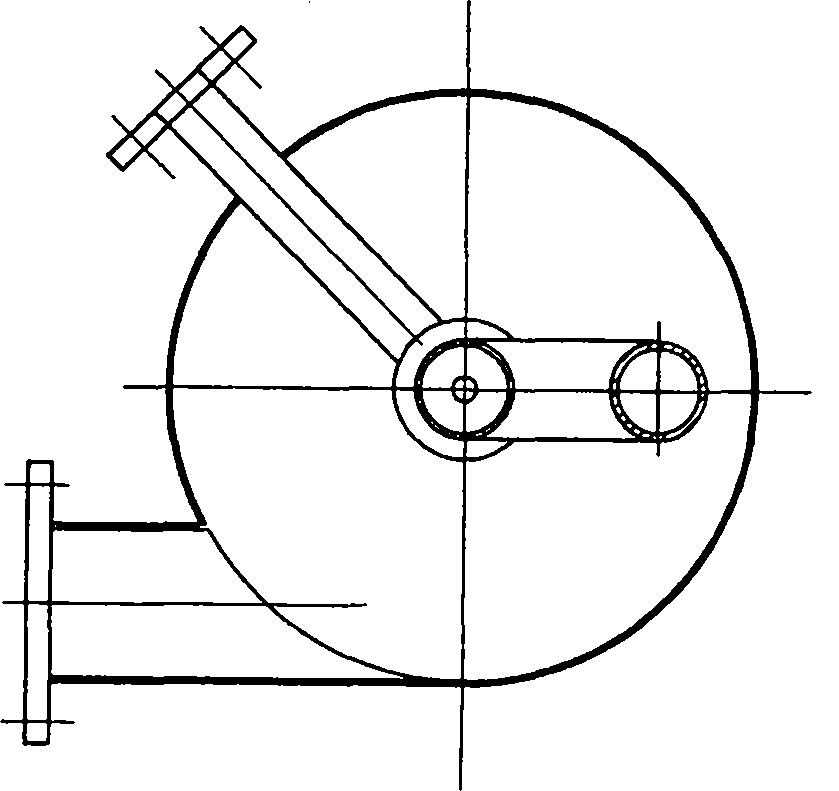

[0020] As shown in the figure: a pressure difference, swirl type backwashing filter system, a motor 2, a reducer 3 and an indexing mechanism 4 are installed on the top of the filter cylinder 1. The separator 5 divides the inner part of the filter cylinder into a water inlet chamber 6 and a water outlet chamber 7. The water outlet chamber is equipped with eight filter elements 8 evenly distributed according to the circumference. There is a sewage discharge port 10 and a scale discharge port 11 inside; the suction cup 12 is installed between the scale discharge port and the partition, and is driven to rotate by the drive shaft 13 of the motor and the reducer. An inlet pressure gauge 14 is installed at the above-mentioned water inlet. An outlet pressure gauge 15 is installed at the above-mentioned water outlet, and the pressure gauge is connected with a pressure controller 16 .

[0021] The working principle of the invention is: when the sewage containing solid particles and sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com