Efficient laser marking method and device for multi-style small-batch articles

A laser marking method and laser marking technology are applied in the field of high-efficiency laser marking methods and laser marking devices for various styles and small batches of items, and can solve the problems of low efficiency, troublesome focusing operation and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

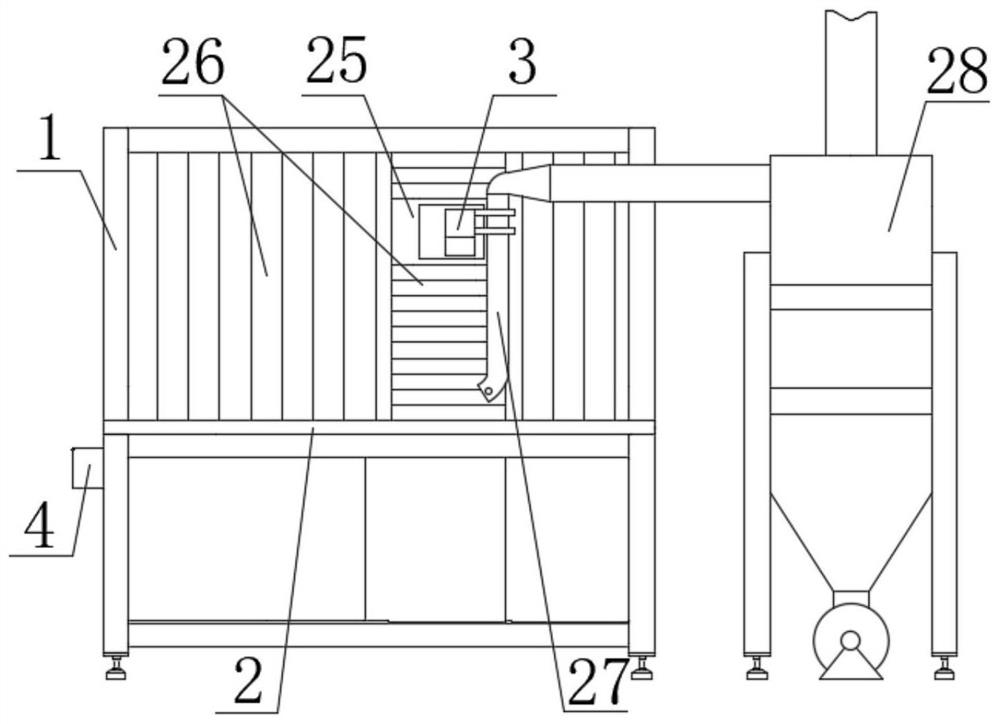

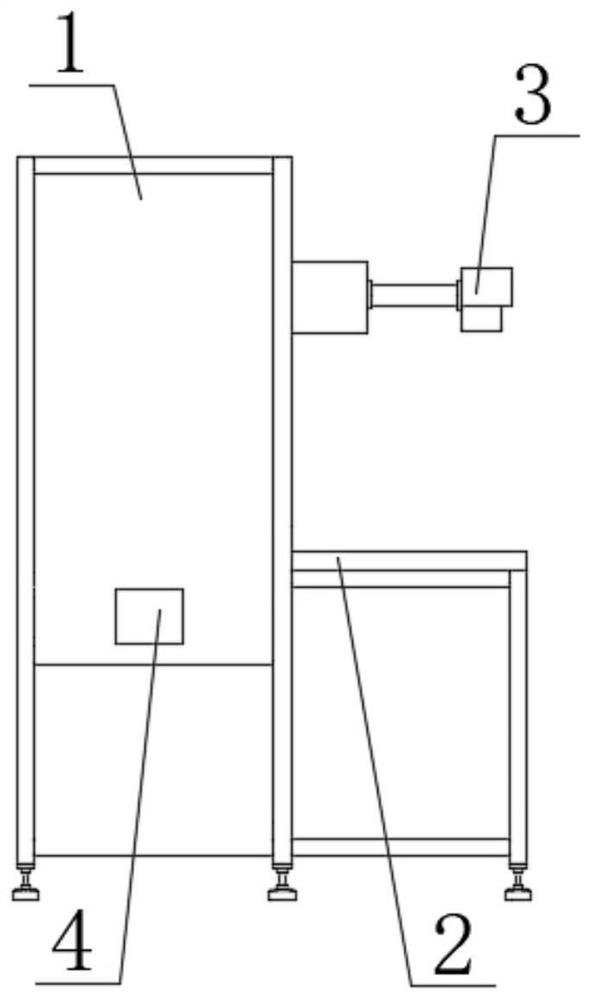

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

[0033] Example. A high-efficiency laser marking method for multi-style and small-batch items, comprising the following steps,

[0034] a. For each style of the item to be marked, draw the plane drawing separately; and then set the logo on the specific position on the plane drawing of the corresponding style according to the customer's needs, and obtain the finished drawings of different styles of the marked item;

[0035] b. Import all the finished drawings into the computer, and typesetting the finished drawings in the area corresponding to the working platform in the computer desktop;

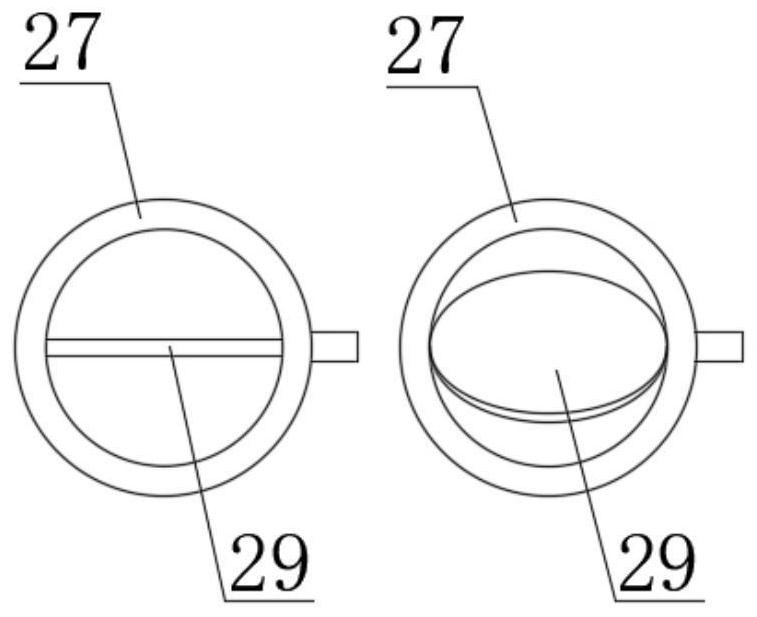

[0036] c. The staff manually measure the thickness data of each style of marked item, and input the thickness data into the computer, and match the thickness data of each style of marked item with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com