Protective rack mechanism used for small-load machinery

A small load, tooth protection technology, applied in the direction of mechanical equipment, belts/chains/gears, transmission parts, etc., can solve the problems that the gears cannot be continuously moved, the end teeth are broken, and the head end of the rack cannot be maintained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

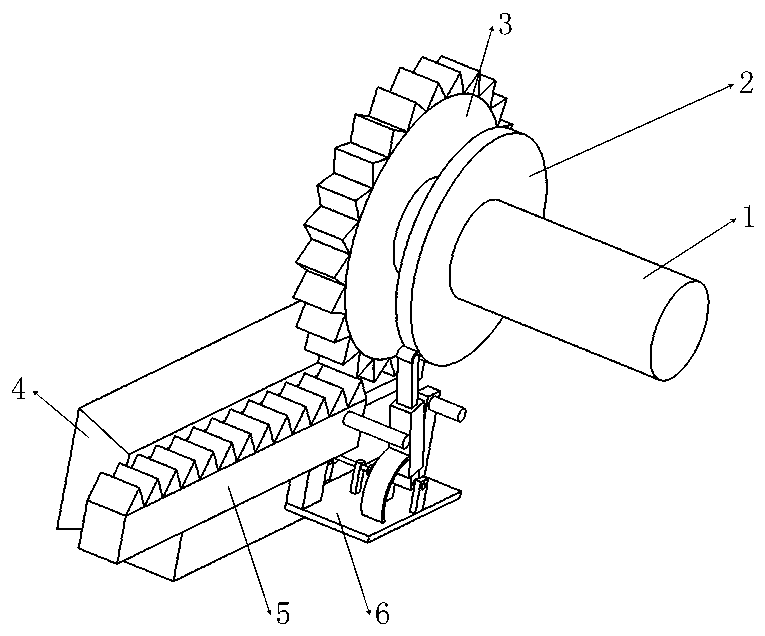

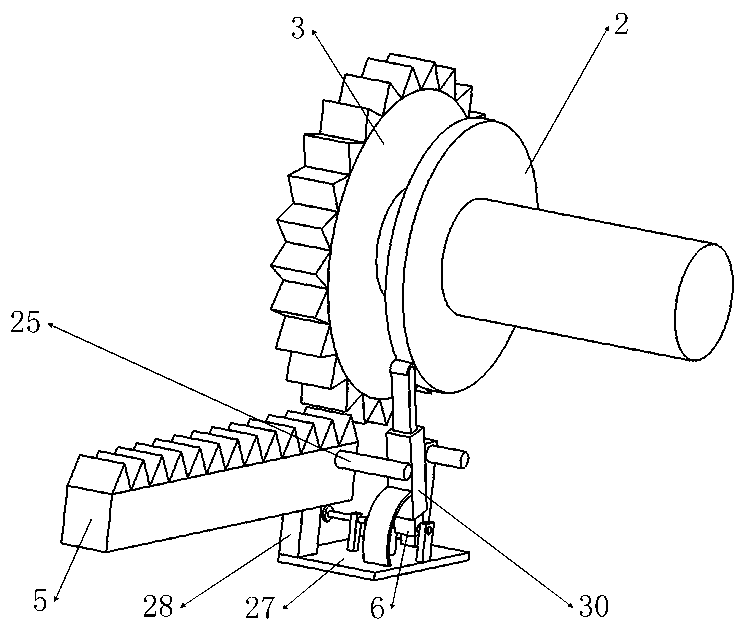

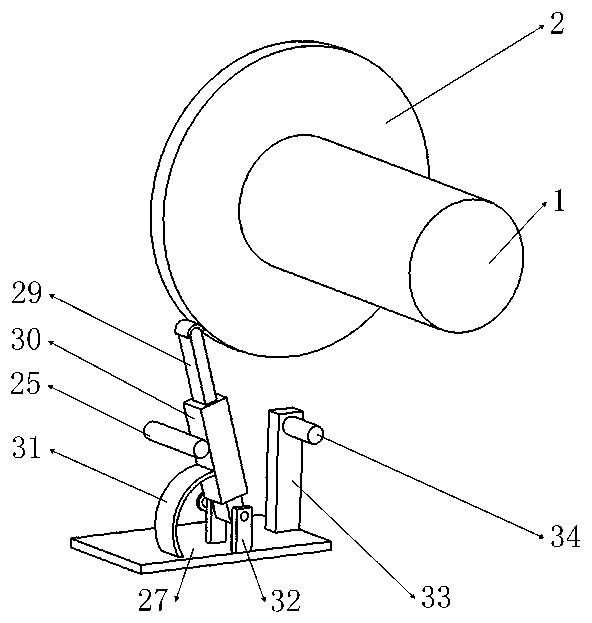

[0054] Specific embodiments: when the power unit in the small-load mechanical mechanism does not drive the drive shaft 1 to rotate, the friction wheel 2 and the drive gear 3 do not rotate. The first spring 12 is in the natural state, the limit plate 48 on the drive rack 5 is not limited by the limit block 13, the third gear 46 does not mesh with the first rack 16, and the leaf spring 31 is in the natural state. The drive gear 3 is in mesh with the drive rack 5 .

[0055]When the power unit in the small-load mechanical mechanism drives the drive shaft 1 to rotate forward, the drive shaft 1 drives the drive gear 3 and the friction wheel 2 to rotate forward, as Figure 4 , 19 As shown, the rotation direction of the friction wheel 2 and the drive gear 3 is set to be clockwise at this time. The forward-rotating driving gear 3 drives the driving rack 5 to move, the first trapezoidal slider 10 moves following the driving rack 5, and the first spring 12 is stretched; the limiting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com