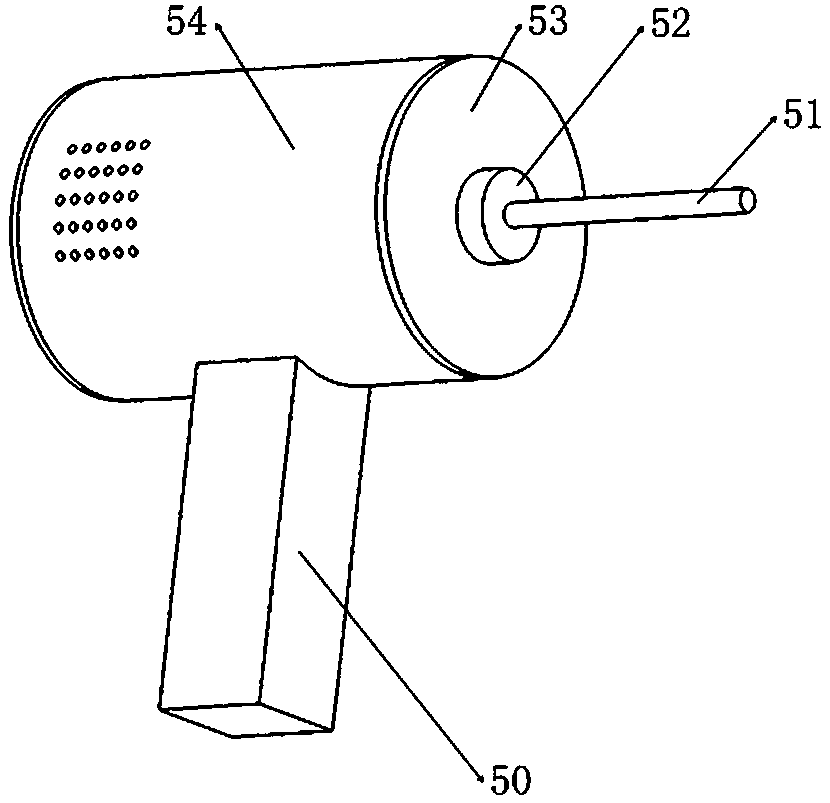

Dustproof electric drill

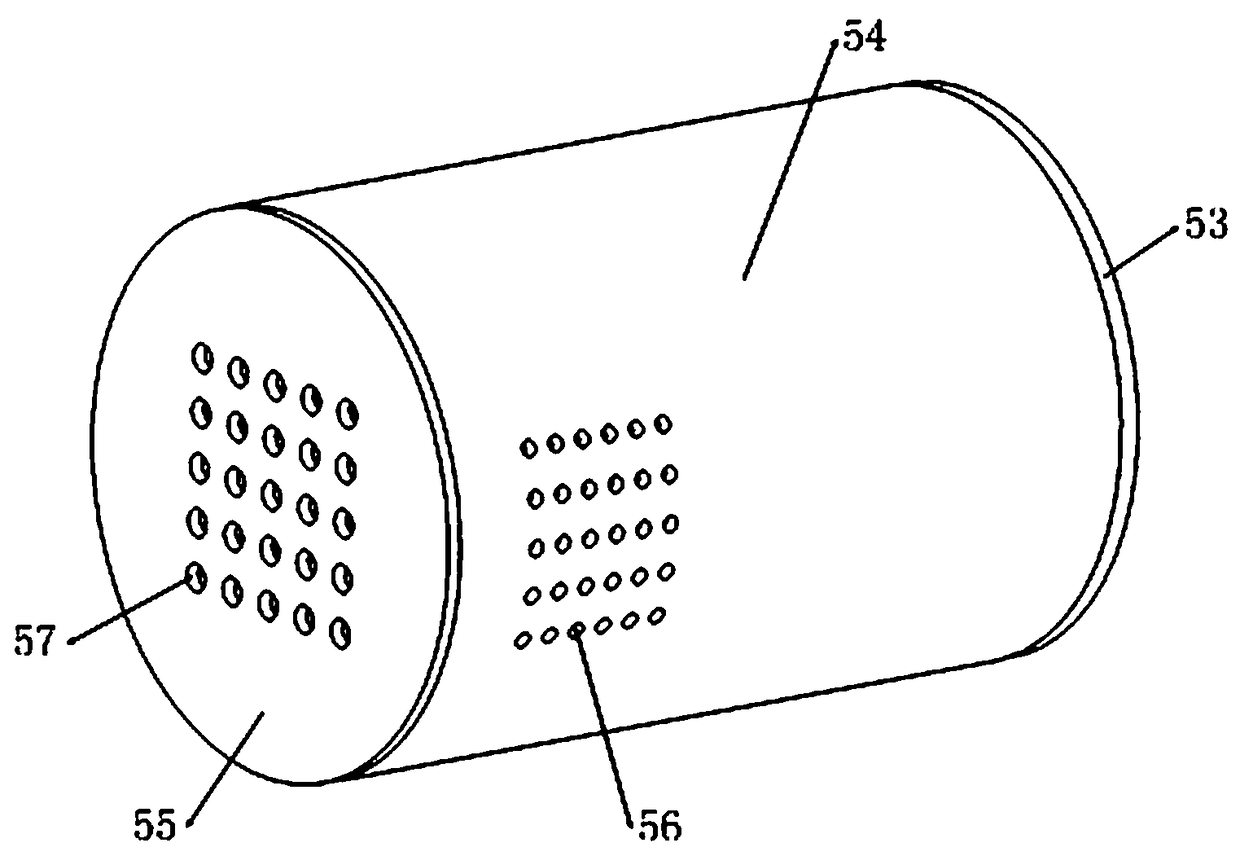

A dust-proof, electric drill technology, used in portable drilling rigs, drilling/drilling equipment, components of boring machines/drilling machines, etc., can solve the problems of heat dissipation and retention of electric drills, and achieve the effect of avoiding mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

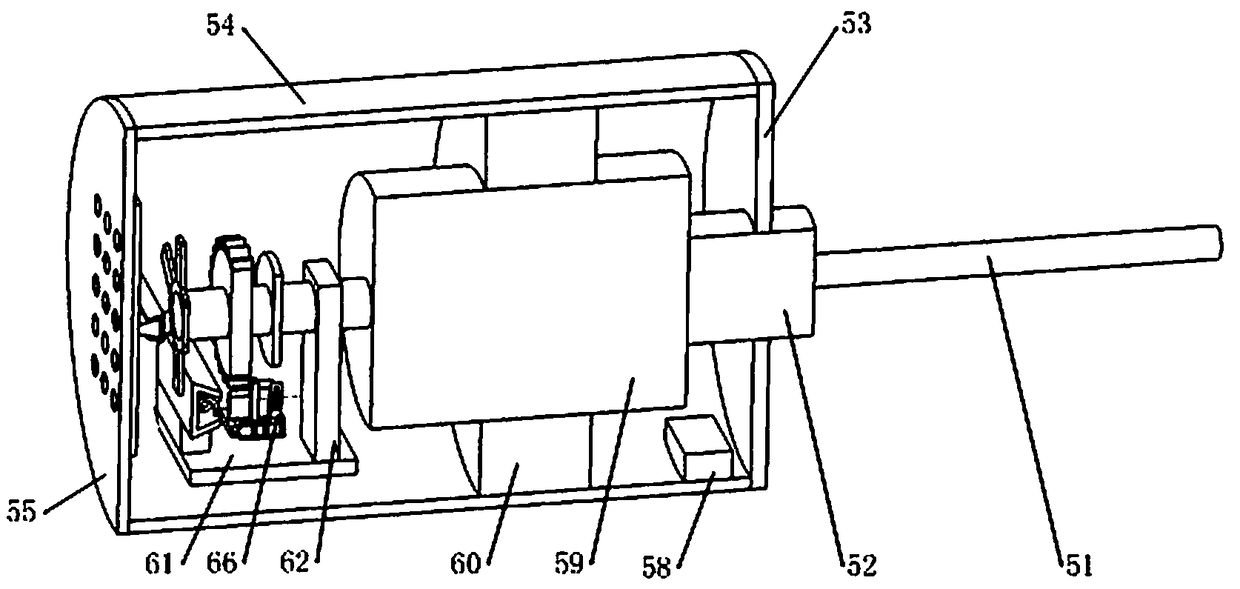

specific Embodiment approach

[0042] Specific embodiments: when the electric drill of the present invention needs to be stopped, the control switch on the handle 50 is turned off, and the control module 58 receives the signal of closing the reduction motor 59. At this time, the control module 58 controls the reduction motor 59 to reverse several times, and then completely Stop reduction motor 59. When the reduction motor 59 reverses, the drive shaft 1 drives the friction wheel 2 and the drive gear 3 to reverse, and the drive gear 3 and the friction wheel 2 are set to rotate counterclockwise. Such as Figure 12 As shown, when the rotation direction of the friction wheel 2 is counterclockwise, driven by the friction of the friction wheel 2, the arc-shaped friction plate 35 will slide on the outer circular surface of the friction wheel 2 along the counterclockwise rotation direction of the friction wheel 2 The arc-shaped friction plate 35 will make the sliding plate 29 swing around the center of the pin 37, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com