Cooling apparatus for wine making

A cooler and cooling pipe technology, applied in the field of wine coolers, can solve problems such as poor cooling effect and inability of water to flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

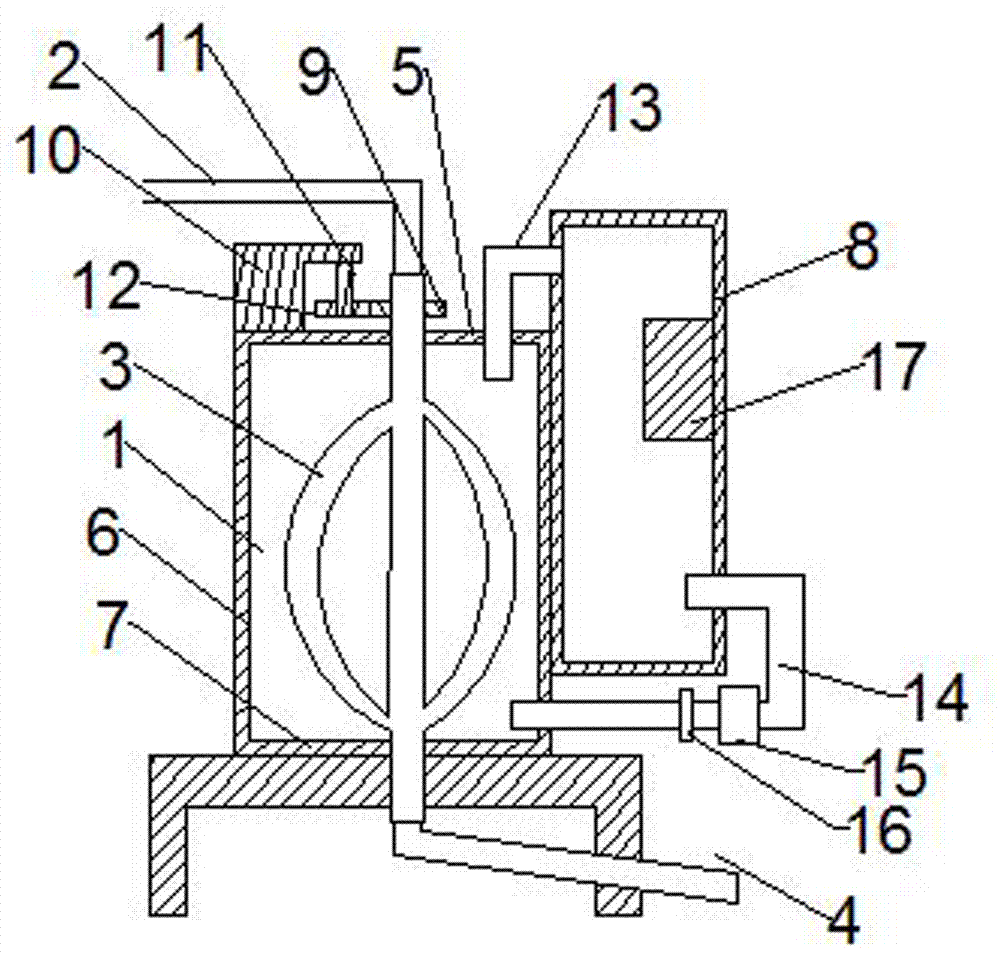

[0017] The reference signs in the drawings of the description include: cooling barrel 1, steam inlet pipe 2, cooling pipe 3, wine outlet pipe 4, top cover 5, annular side wall 6, bottom plate 7, water storage tank 8, driven gear 9, Motor 10, rotating shaft 11, rotating gear 12, water inlet pipe 13, water outlet pipe 14, water pump 15, control valve 16, refrigerator 17.

[0018] Such as figure 1 Shown: a brewing cooler, including a cooling barrel 1, a steam inlet pipe 2, a cooling pipe 3 and a wine outlet pipe 4, the cooling barrel 1 includes a top cover 5, an annular side wall 6 and a bottom plate 7, and the cooling pipe 3 is located in the cooling barrel 1, the steam inlet pipe 2 and the wine outlet pipe 4 are located outside the cooling barrel 1, the cooling pipes 3 are at least four, the cooling pipes 3 are arranged circularly around the vertical direction, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com