Test device for simulating lubricating oil quality faults on line and using method thereof

A test device and fault technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of permanent damage to unit components, complicated operation, additional installation, etc., achieve high reliability, ensure authenticity, and prevent major accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

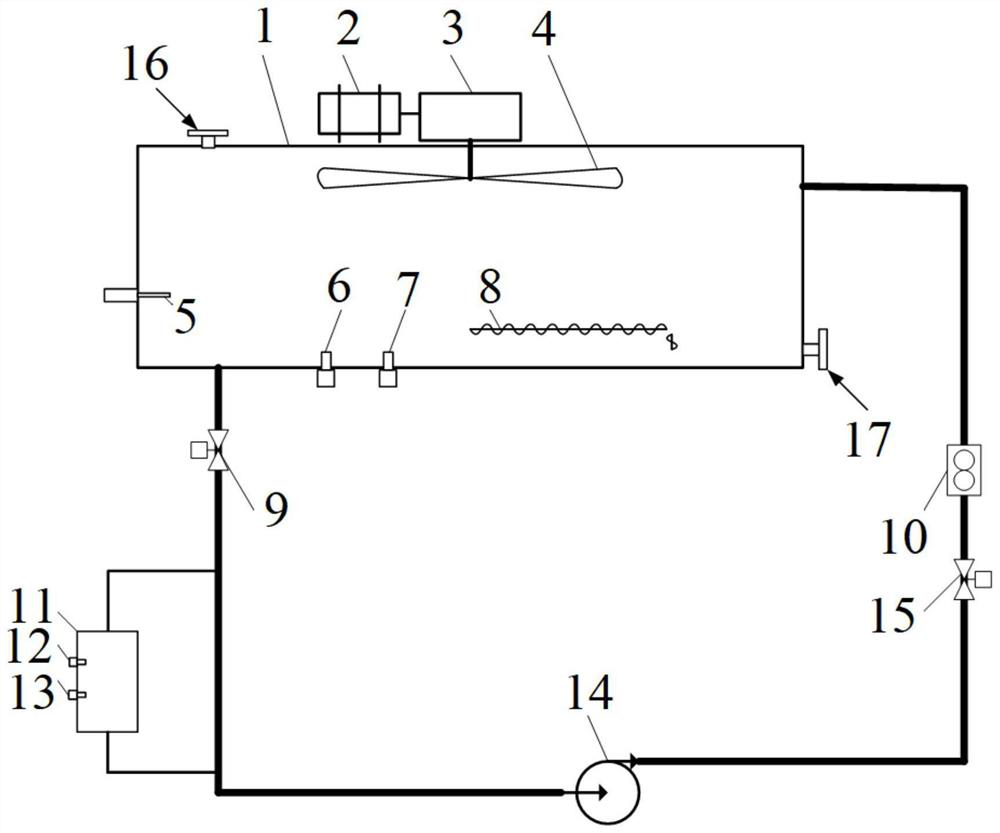

[0049] The invention provides a test device for online simulation of lubricating oil quality faults, such as figure 1As shown, it includes an oil tank 1, the top of the oil tank 1 is provided with an oil filling port 16, the bottom of the oil tank 1 is provided with an oil discharge port 17, and one end of the oil tank 1 is connected to the first adjustable electric valve 9 through the pipeline in turn, particle size detection. The unit 11 , the oil pump 14 , the second adjustable electric valve 15 , the flow meter 10 , and the other end of the oil tank 1 .

[0050] The lubricating oil viscosity sensor 6 and the water content sensor 7 are both installed at the bottom of the oil tank 1, and the optical particle size sensor 12 and the metal particle size sensor 13 are both installed on the particle size detection unit 11. The particle size sensor requires that the measured lubricating oil must flow, and There are strict requirements on the flow and pressure of the lubricating oi...

Embodiment 2

[0062] In this embodiment, in each case, the heating oil temperature is 38°C.

[0063] Others are the same as in Example 1.

Embodiment 3

[0065] In this embodiment, in each case, the heating oil temperature is 42°C.

[0066] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com