Grinding device with quick-disassembly structure

A grinding and grinding head technology, which is applied to the device for fixing the grinding wheel, the parts of the grinding machine, and the grinding/polishing equipment, etc. The loading and unloading process is simple and practical, the maintenance and replacement are convenient, and the effect of quick and safe removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

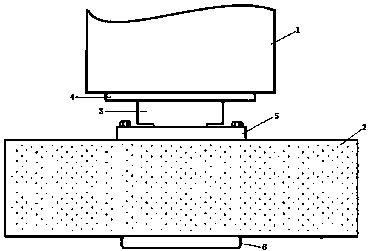

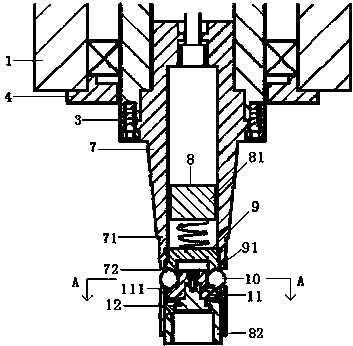

[0027] see Figure 1-4 , shows the grinding device with quick release structure of the present invention.

[0028] Described grinding device comprises the grinding head 1 that is arranged on the front end of grinding machine tool and the grinding cutter 2 that is installed on the grinding head 1 detachably, and described grinding cutter 2 can be diamond grinding head, and described grinding A driving rod 3 is arranged in the grinding head 1, and the driving rod 3 is rotatably placed inside the grinding head 1 and driven to rotate by a driving device (not shown). Between the driving rod 3 and the grinding head 1 Be provided with bearing and locating ring 4, refer to figure 2 , the positioning ring 4 positions the bearing between the driving rod 3 and the grinding head 1 .

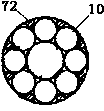

[0029] see figure 2 , showing the specific structure of the drive rod 3, the drive rod has a hollow through hole, a knife rod 7 is fixed in the hollow through hole, and the knife rod 7 is fixed by a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com