Forklift work device with steel pipe clamp

A technology of working devices and steel pipe clamps, applied in the direction of lifting devices, etc., can solve the problems that the functions of forklifts cannot meet the needs of various working conditions, and achieve the effects of reducing repeated purchases, convenient operation and maintenance, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

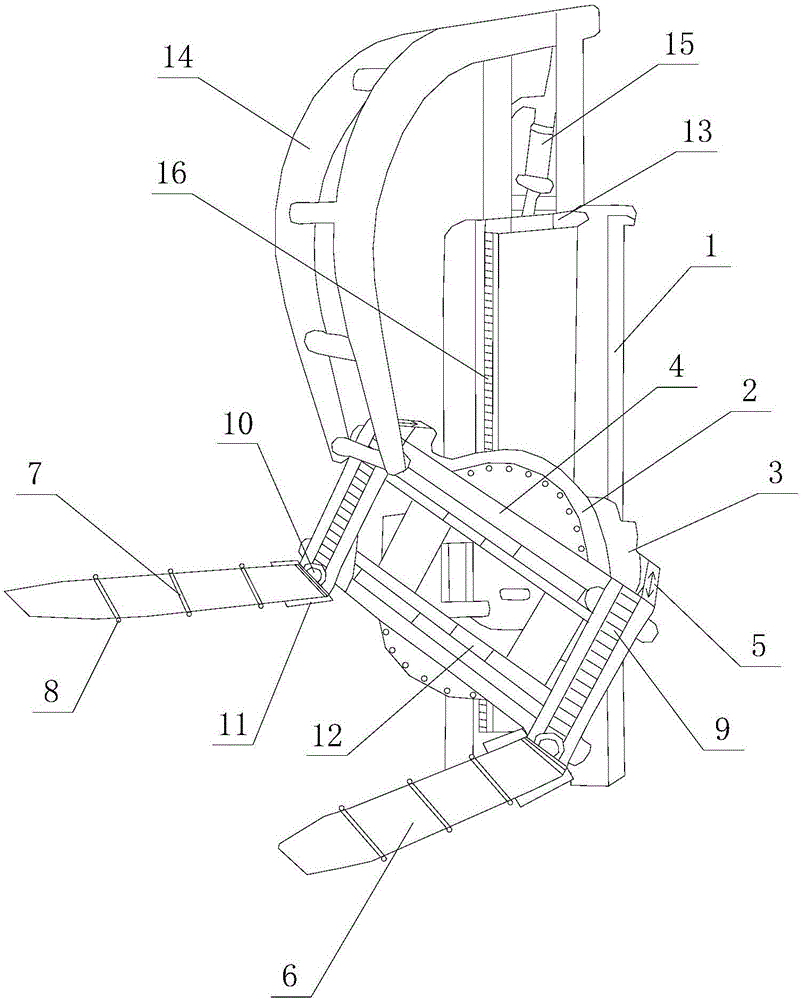

[0016] Such as figure 1 As shown, a forklift working device with steel pipe clamps includes a mast 1, and a rotator 2 is arranged on the mast 1, and the rotator 2 is arranged on the mast 1 by sliding up and down through the sliding parts 3 on both sides, and the rotator 2 There is a fork frame 4 on it, the fork frame 4 is rotated on the door frame 1 through the rotator 2, the lower end of the fork frame 4 is connected with the rotator 2, and a push-pull cylinder 5 is arranged between the upper end of the fork frame 4 and the rotator 2, and the fork frame 4 is provided with two slide guides, and a distance adjusting device is arranged between the two slide guides. Each slide guide is connected with a fork 6, and the fork 6 is provided with a plurality of fork shapes. The two ends of the curved joint 7 are provided with fastening bolts 8, the inner sides of the door frame 1 are provided with slide rails 16, and a rotating shaft 13 is provided between the two sliding rails 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com