Tray-free stacking machine

A palletizer and pallet-less technology, applied in the field of palletizers, can solve problems such as a large number of pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

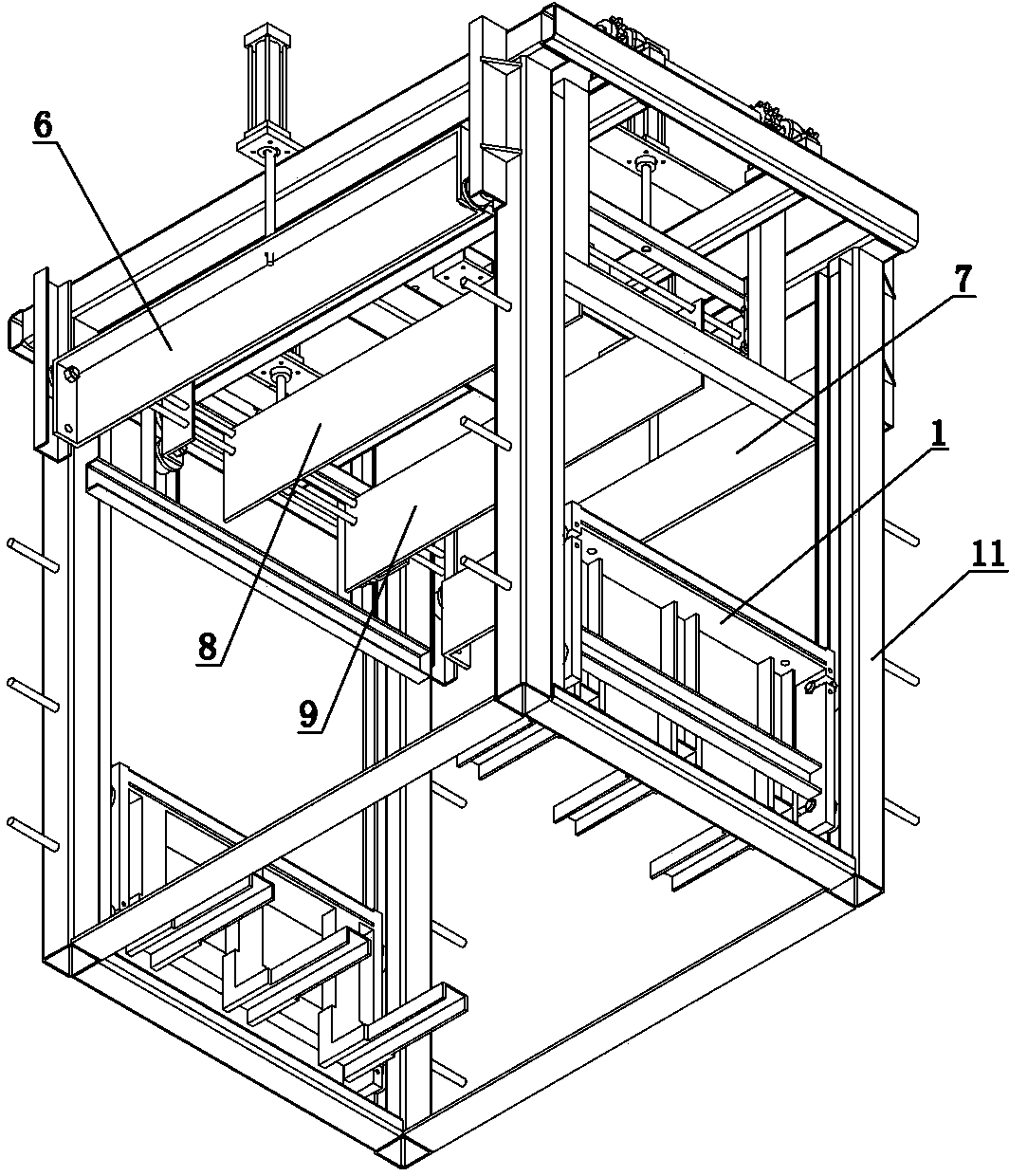

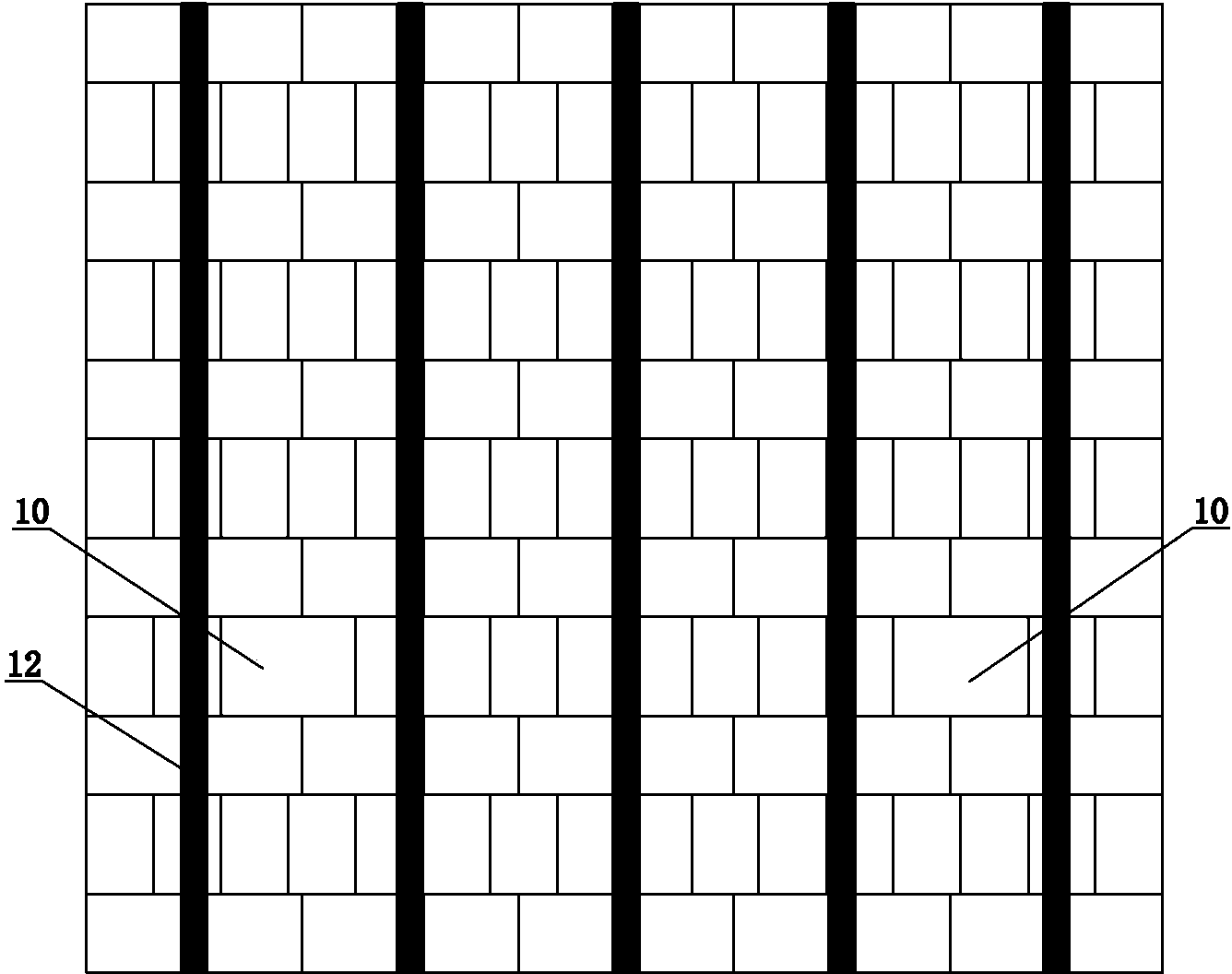

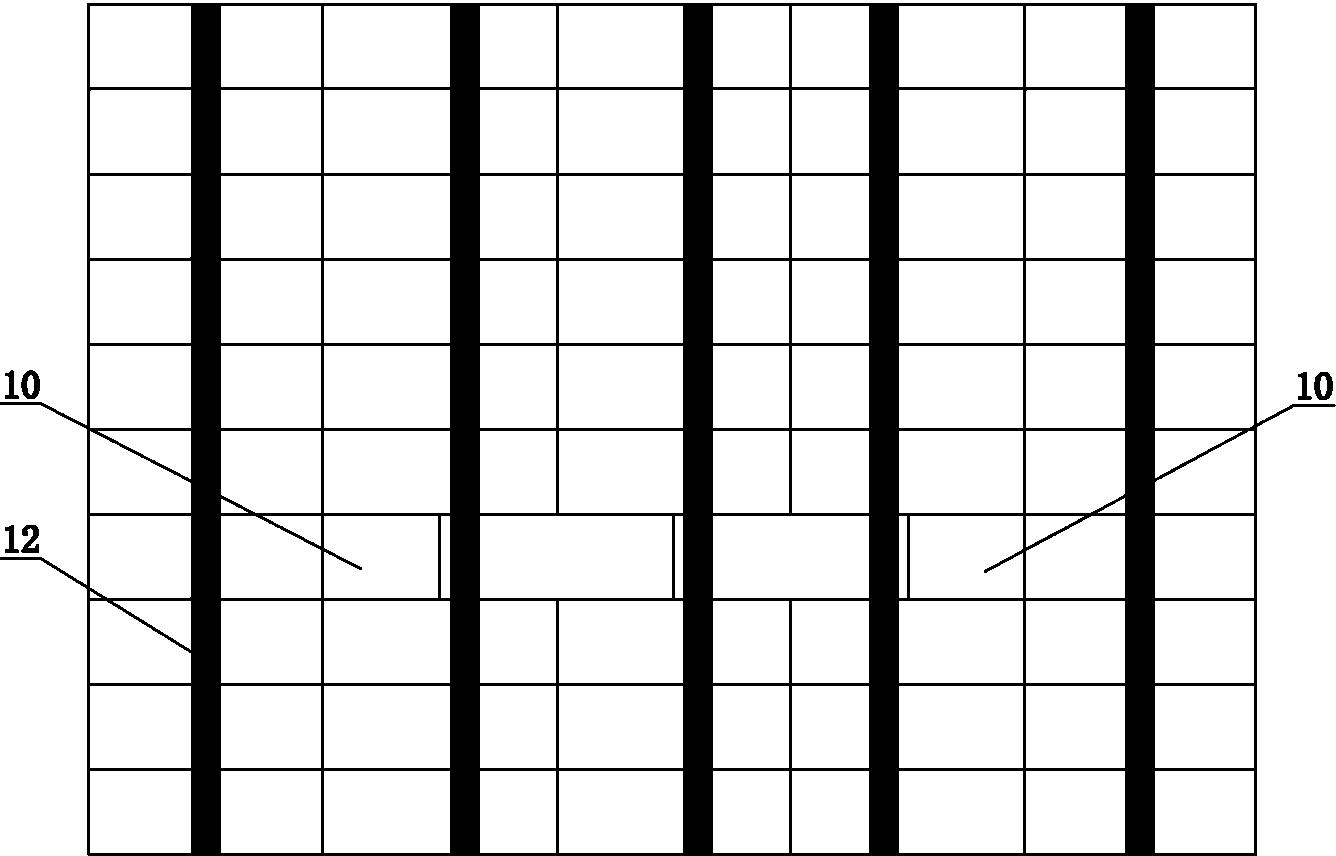

[0020] refer to figure 1 and figure 2 . A pallet-less palletizer, including a carrier board that can move left and right, a brick feeding device that sends each layer of bricks to the carrier board one by one, and a brick receiving device 1 that is located on one side of the carrier board and can be lifted , a liftable baffle is provided above one side of the carrier. There are two carrier plates, and the two carrier plates are the first carrier plate 2 located on the left side of the brick receiving device 1 and the second carrier plate 3 located on the right side of the brick receiving device 1 . There are two brick feeding devices, the two brick feeding devices are respectively located at the front side of the first carrier board 2 and send the horizontally placed bricks to the first carrier board 2 column by column and the first brick feeding device 4 and The second brick feeding device 5 which is located at the front side of the second carrier 3 and sends the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com