An aluminum tube dual-purpose hanger

A dual-purpose, aluminum tube technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of inapplicable aluminum tube galvanizing treatment, affecting the effect of electroplating, increasing the number of hangers, etc., to achieve the promotion of electroplating Quality, ensuring the quality of electroplating, reducing the effect of the quantity used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

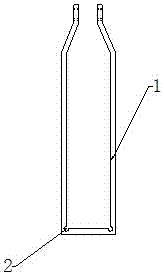

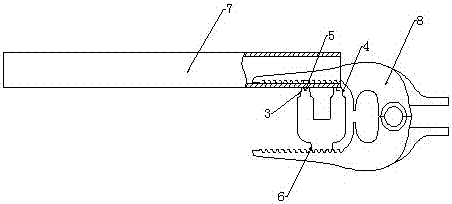

[0019] The aluminum tube dual-purpose hanger of the present embodiment comprises a cross bar and the hanger 1 that is arranged on the two ends of the cross bar, such as figure 1 As shown, the hanger 1 is bent to form a U-shape by an aluminum profile, and a circular through hole 2 is symmetrically opened at the bend of the hanger 1;

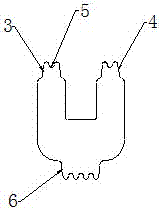

[0020] Such as figure 2 As shown, the cross-section of the aluminum profile is U-shaped, and the two top ends of the U-shape are respectively provided with an isosceles trapezoidal first protrusion 3 and a second protrusion 4, and the top of the first protrusion 3 and the second protrusion 4 The bottom width is 1 / 2 of the U-shaped width on one side, the bottom width of the first protrusion 3 and the second protrusion 4 are 2 / 3 of the U-shaped width on one side, and the first protrusion 3 and the second protrusion The protrusion 4 transitions smoothly at the junction with the U-shape, and on the upper surfaces of the first protrusion 3 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com