Method for electroplating lead frame

A lead frame and frame technology, which is applied in the direction of electrolytic organic material plating, circuits, electrical components, etc., can solve the problems of large amount of dry film, easy to be plated, unfavorable mass production of lead frames, etc., to ensure the quality of electroplating, electroplating low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

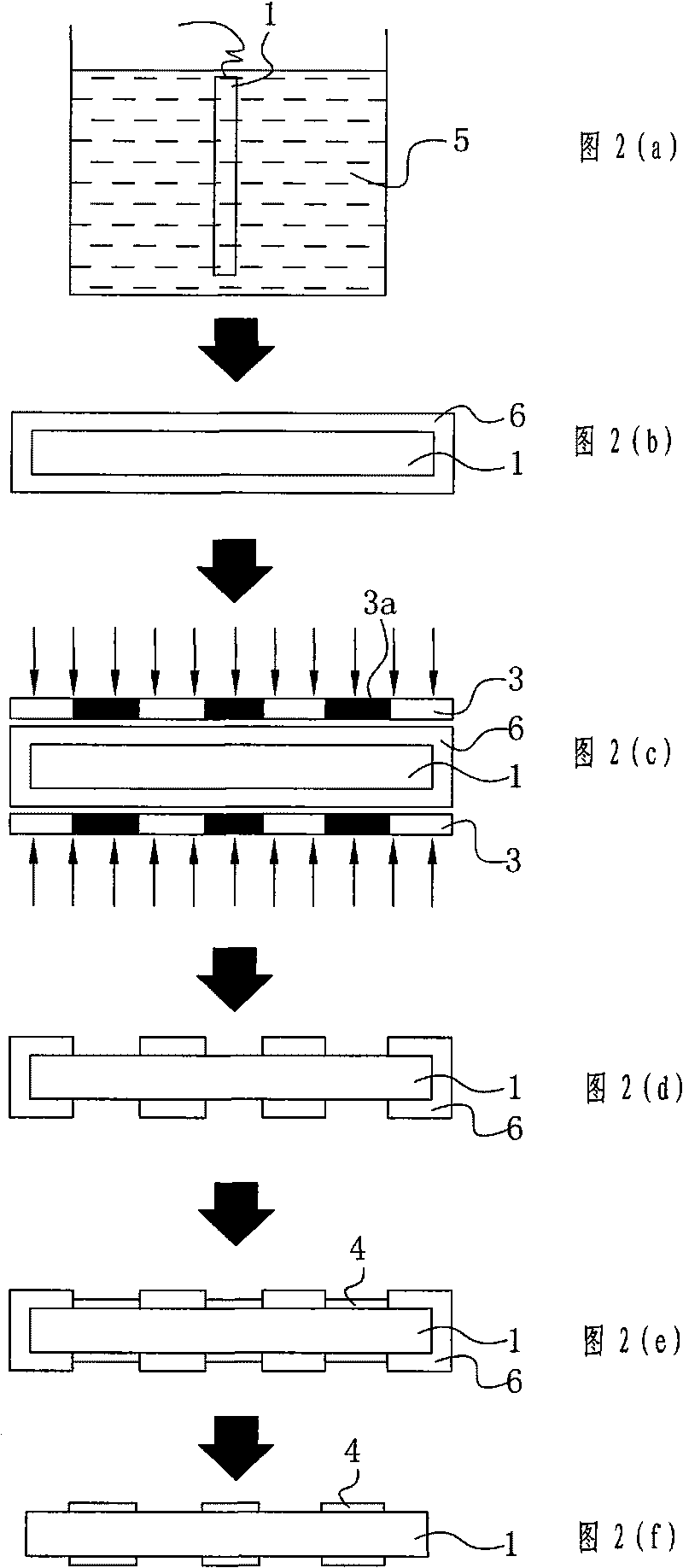

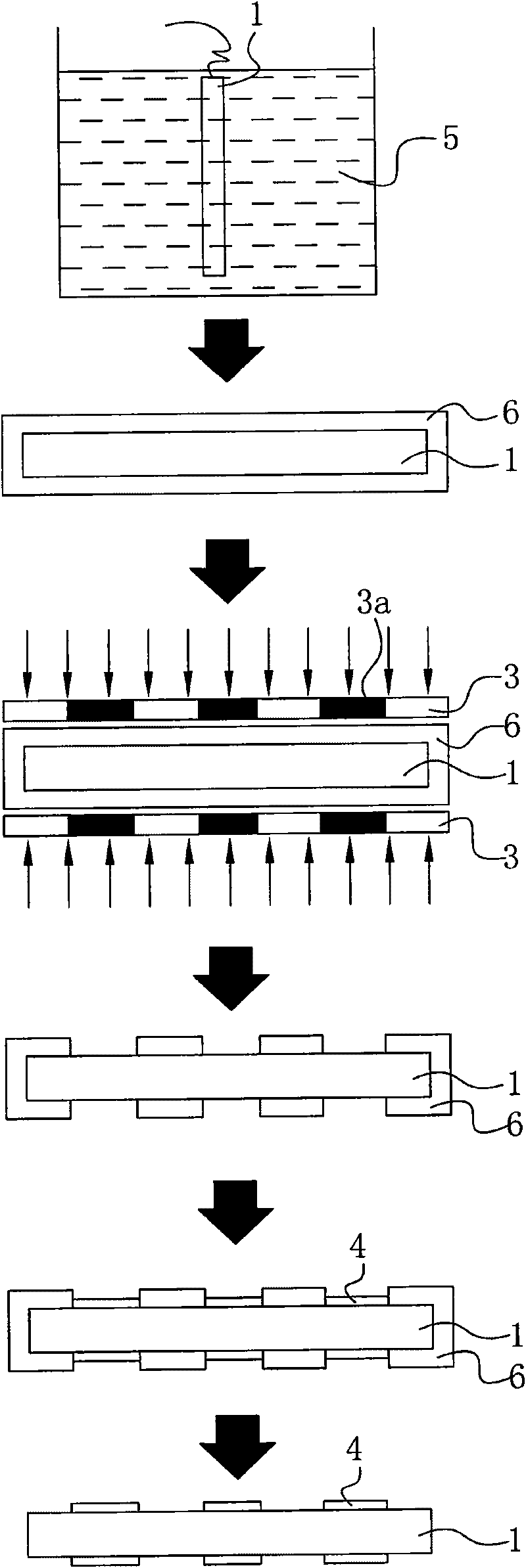

[0025] 1. prepare wet film solution 5, the concentration of described wet film solution 5 is 55%, film is the model that American Rohm and Haas Company produces is EAGLE TM 2100 ED PHOTORESIST;

[0026] ②. After the lead frame 1 is connected to the wire, put it into the wet film solution 5 as shown in Figure 2(a) for electroplating, the electroplating time is 10-12 seconds, and the temperature is 40°C-50°C, as shown in Figure 2(b ) shows that after electroplating, the surrounding surfaces of the lead frame 1 are coated with a film layer 6;

[0027] ③. Wash the electroplated lead frame 1 with clean water, and dry it in a conventional sawing furnace, the drying temperature is 90°C-100°C, and the drying time is 80-90 seconds;

[0028] ④. Expose the dried lead frame 1. The exposure is required to be carried out in a dust-free environment. When exposing as shown in FIG. 2(c), put a glass mask 3 on the upper and lower surfaces of the lead frame 1. 3 is provided with a light-shiel...

Embodiment 2

[0034] 1. prepare wet film solution 5, the concentration of described wet film solution 5 is 65%, film is the model that American Rohm and Haas Company produces is EAGLE TM 2100 ED PHOTORESIST;

[0035] ②. After the lead frame 1 is connected to the wire, put it into the wet film solution 5 for electroplating as shown in Figure 2(a). ) shows that after electroplating, the surrounding surfaces of the lead frame 1 are coated with a film layer 6;

[0036] ③. Clean the lead frame 1 after electroplating with clean water, and dry it in a conventional sawing furnace, the drying temperature is 95°C-105°C, and the drying time is 60-80 seconds;

[0037] ④. Expose the dried lead frame 1. The exposure is required to be carried out in a dust-free environment. When exposing as shown in FIG. 2(c), put a glass mask 3 on the upper and lower surfaces of the lead frame 1. 3 is provided with a light-shielding part 3a, the light-shielding part 3a prevents the corresponding film layer 6 from bein...

Embodiment 3

[0043] 1. prepare wet film solution 5, the concentration of described wet film solution 5 is 75%, film is the model that American Rohm and Haas Company produces is EAGLE TM 2100 ED PHOTORESIST;

[0044] ②. After the lead frame 1 is connected to the wire, put it into the wet film solution 5 for electroplating as shown in Figure 2(a). ) shows that after electroplating, the surrounding surfaces of the lead frame 1 are coated with a film layer 6;

[0045] ③. Clean the lead frame 1 after electroplating with clean water, and dry it in a conventional sawing furnace, the drying temperature is 100°C-110°C, and the drying time is 30-60 seconds;

[0046]④. Expose the dried lead frame 1. The exposure is required to be carried out in a dust-free environment. When exposing as shown in FIG. 2(c), put a glass mask 3 on the upper and lower surfaces of the lead frame 1. 3 is provided with a light-shielding part 3a, and the light-shielding part 3a prevents the corresponding film layer 6 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com