Patents

Literature

130results about How to "Reduce plating cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

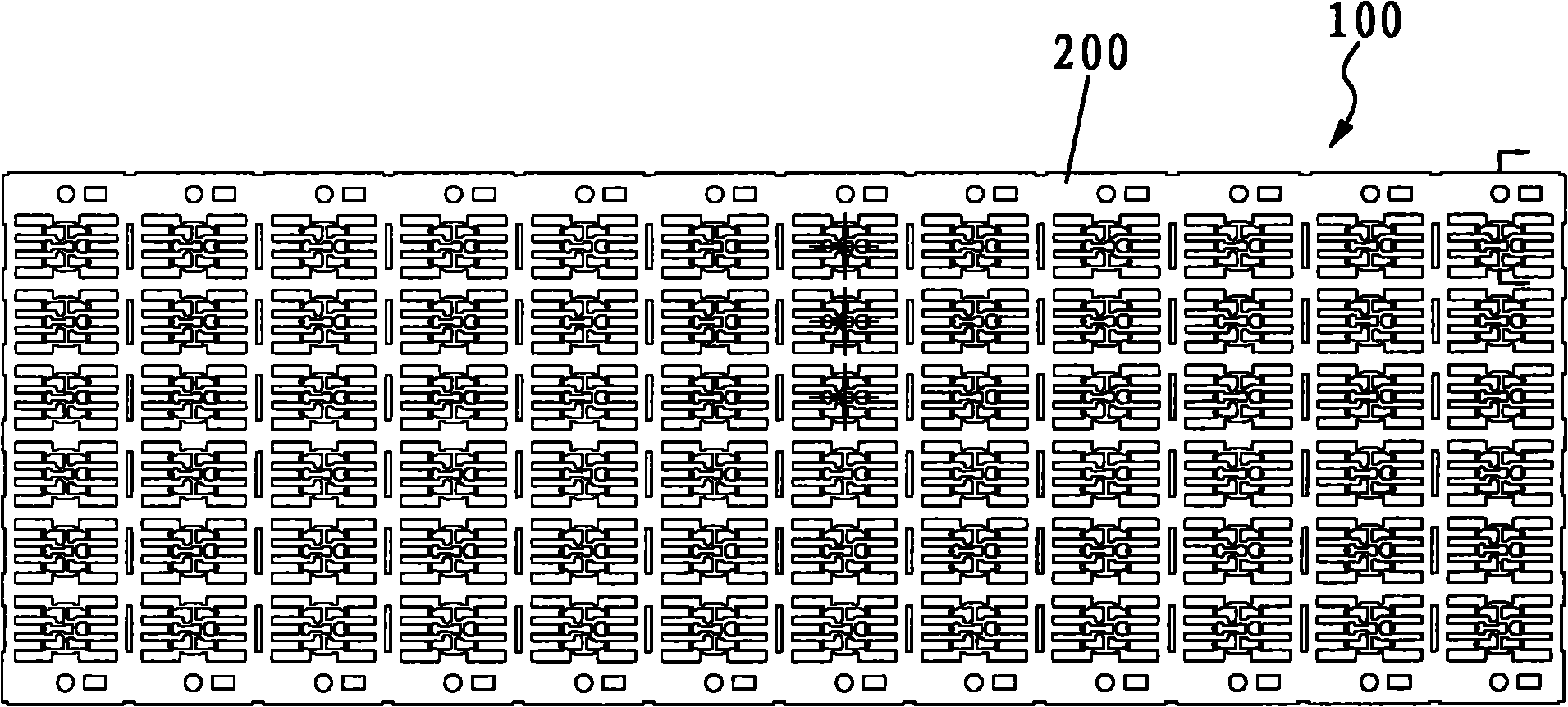

LED lead frame and electroplating method and electroplating equipment thereof

InactiveCN101867009AReduce manufacturing costIncrease production costSemiconductor devicesCopper platingSilver plate

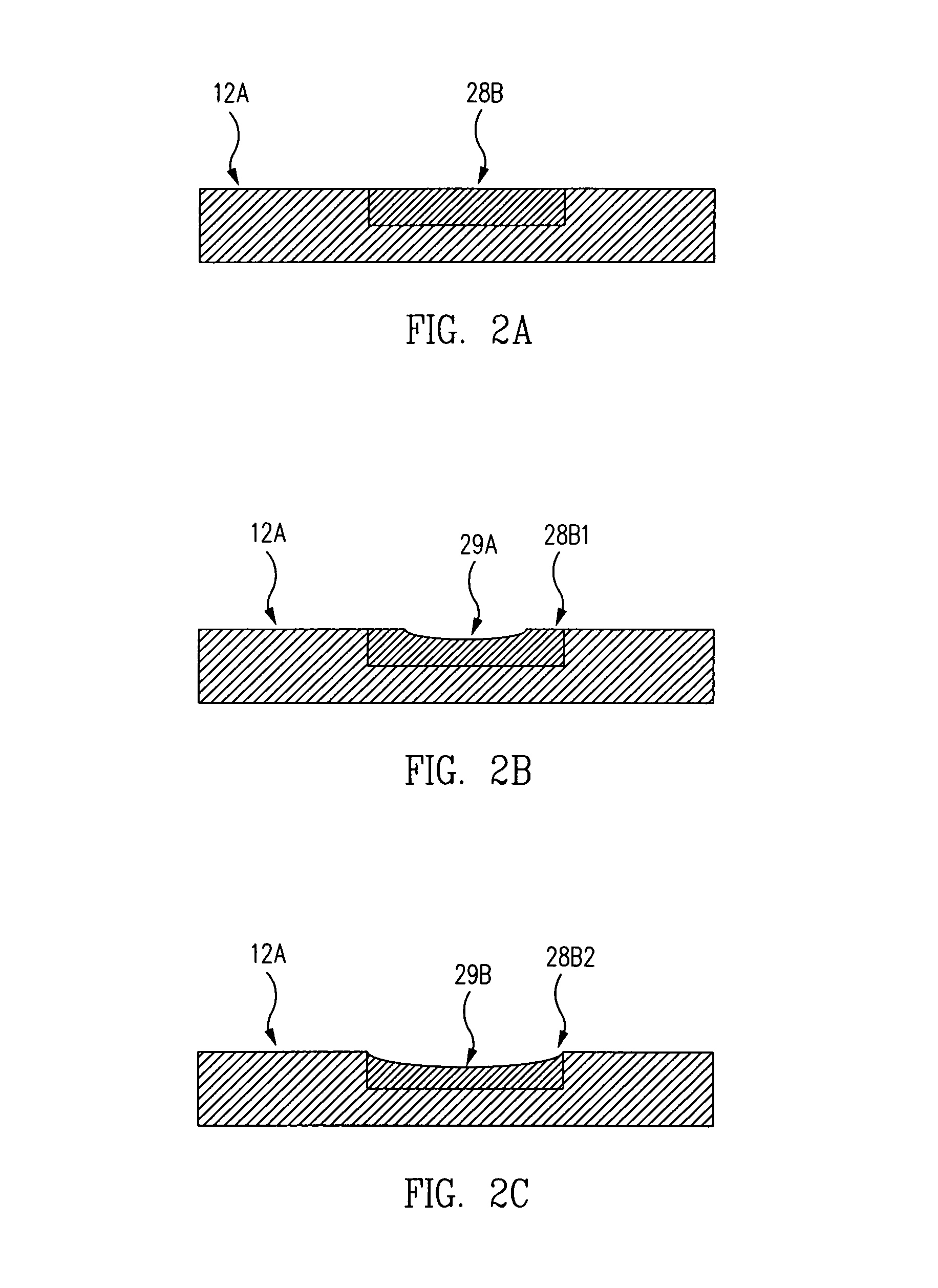

The invention discloses an LED lead frame which is divided into three parts, i.e. a side frame, a functional area and a chip placing area; an anti-replacement protective film is formed on the whole lead frame; a primary silver plated layer is formed on the whole functional area by selecting electroplating silver, and a secondary silver plated layer is formed on the chip placing area by local silver electroplating, so that the silver plated layer of the chip placing area is thicker than the silver plated layer of the functional area around; and an anti-copper oxidation organic protective film is formed on the side frame. The electroplating method comprises the following steps: chemical deoiling->electrolytic deoiling->water washing->acid washing->water washing->copper plating->water washing->anti-replacement treatment->water washing->electroplating silver selection for functional areas on the back side and on the front side->local silver electroplating of chip placing area->silver recovery->water washing->deplating->water washing->neutralization->water washing->anti-copper oxidization treatment->water washing->hot water washing->drying. The invention also discloses electroplating equipment. The invention can effectively use metal silver, reduces the cost, improves the bonding force between plastics and the lead frame, and achieves the purpose of anti-layering.

Owner:XIAMEN YONGHONG TECH

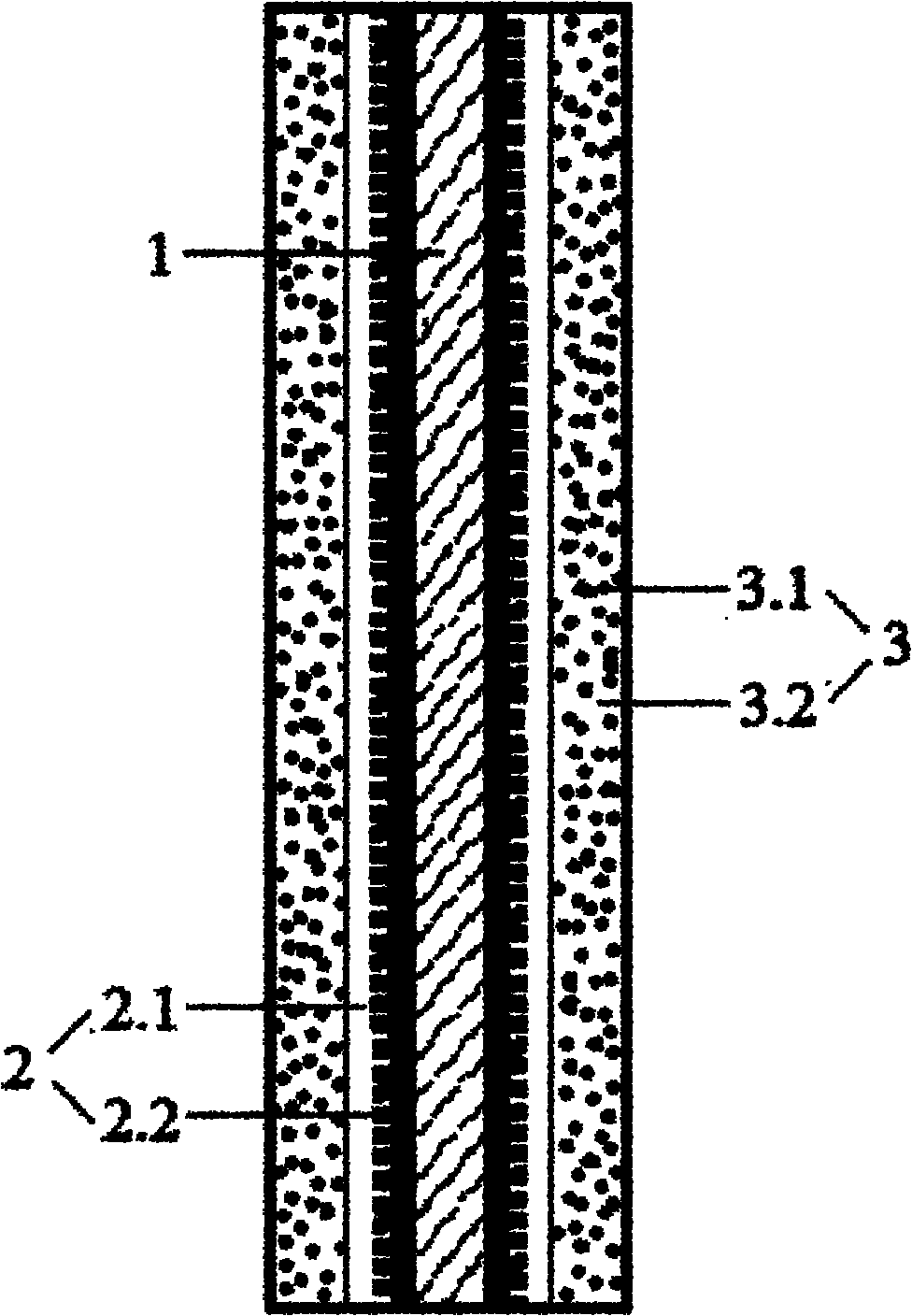

Light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition and preparation method thereof

The invention relates to a light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition, which is composed of a metal substrate, an interlayer and a composite electro-catalysis superficial layer in sequence from inside to outside, wherein the metal substrate is Al or Al base alloy (Al-M1), the interlayer is a composite layer Al2O3-(Pb-M2) composed of Al2O3 or Pb base alloy, and the composite electro-catalysis superficial layer is a composite deposite (Pb-M2)-M3Ox composed of Pb or Pb base alloy and oxide catalyst or a composite deposite PbO2-M3Ox composed of PbO2 and oxide catalyst. The preparation method of the anode comprises the following steps: preparation of the metal substrate: carrying out anodic oxidation on the metal substrate surface and prefabricating a multihole Al2O3 layer; then performing an electro-deposition Pb or Pb base alloy layer on the multihole Al2O3 layer; and plating a (Pb-M2)-M3Ox or PbO2-M3Ox composite superficial layer on the surface of the Pb or Pb base alloy layer. The anode prepared by the invention can effectively reduce production energy consumption, improve cathode product quality, lower labor intensity, is suitable for industrialized production and can replace the Pb base alloy anode applied in the existing industry.

Owner:KUNMING HENDERA SCI & TECH

Jetting electroplating method directly of nozzle

The invention opens a plating method of the semiautomatic vertical jet. The process is to install the Ti skep that is set the effuser between the space and the PCB in the plating vat. The horizontal pendulum is used to transfer the liquid uniformly. The inflating pipe that is changed from two into one is used in the active carbon or reverse tank treatment.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

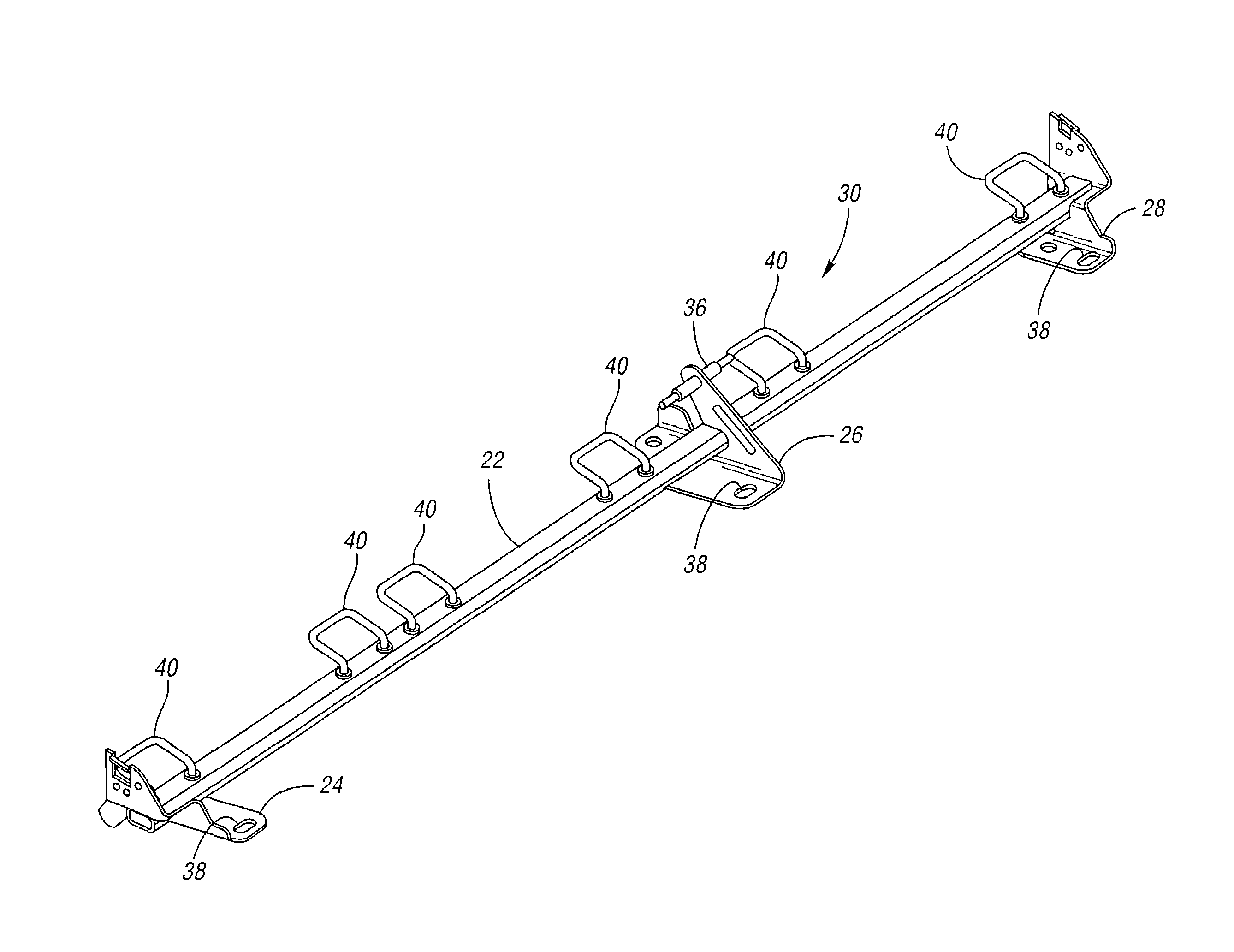

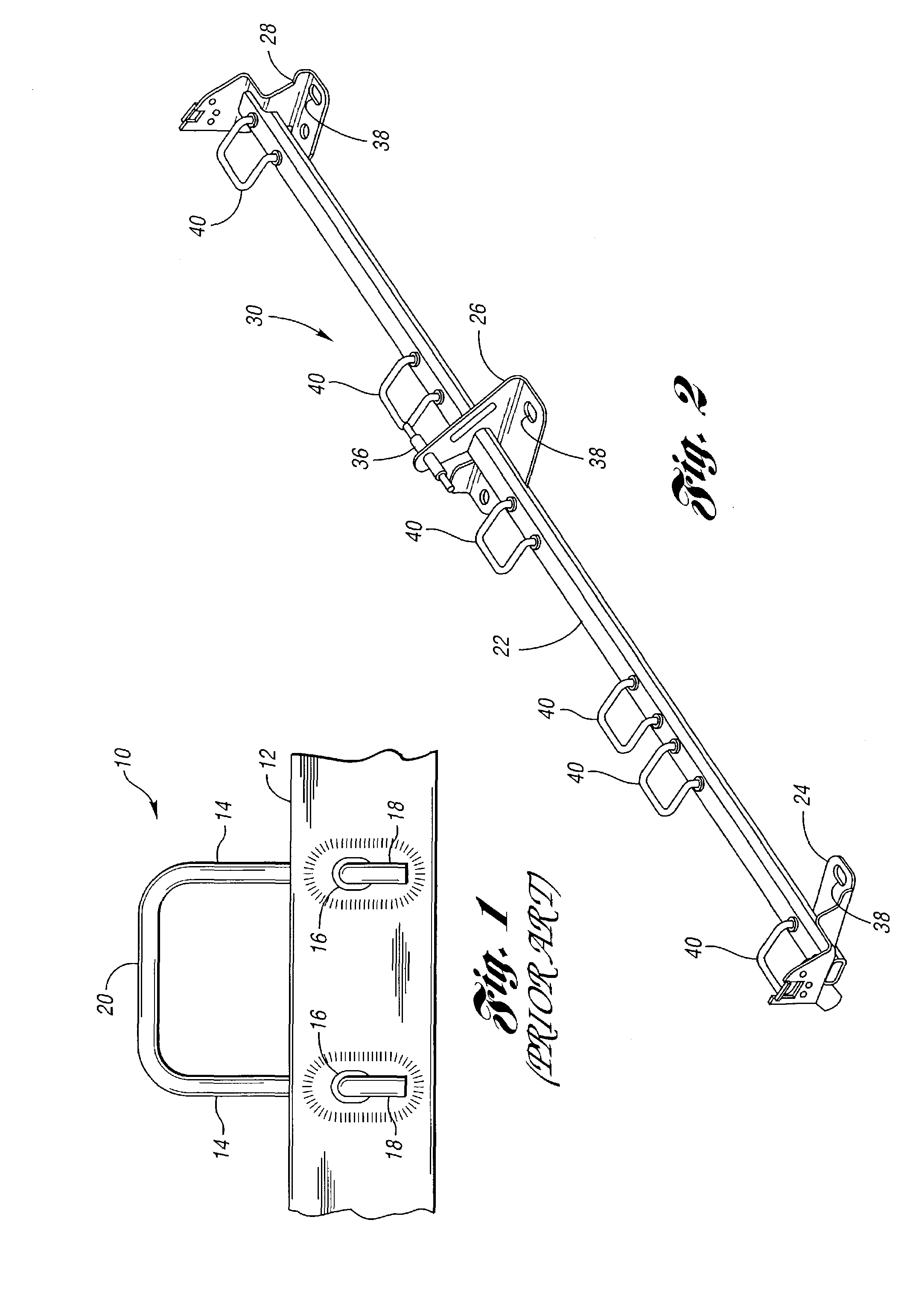

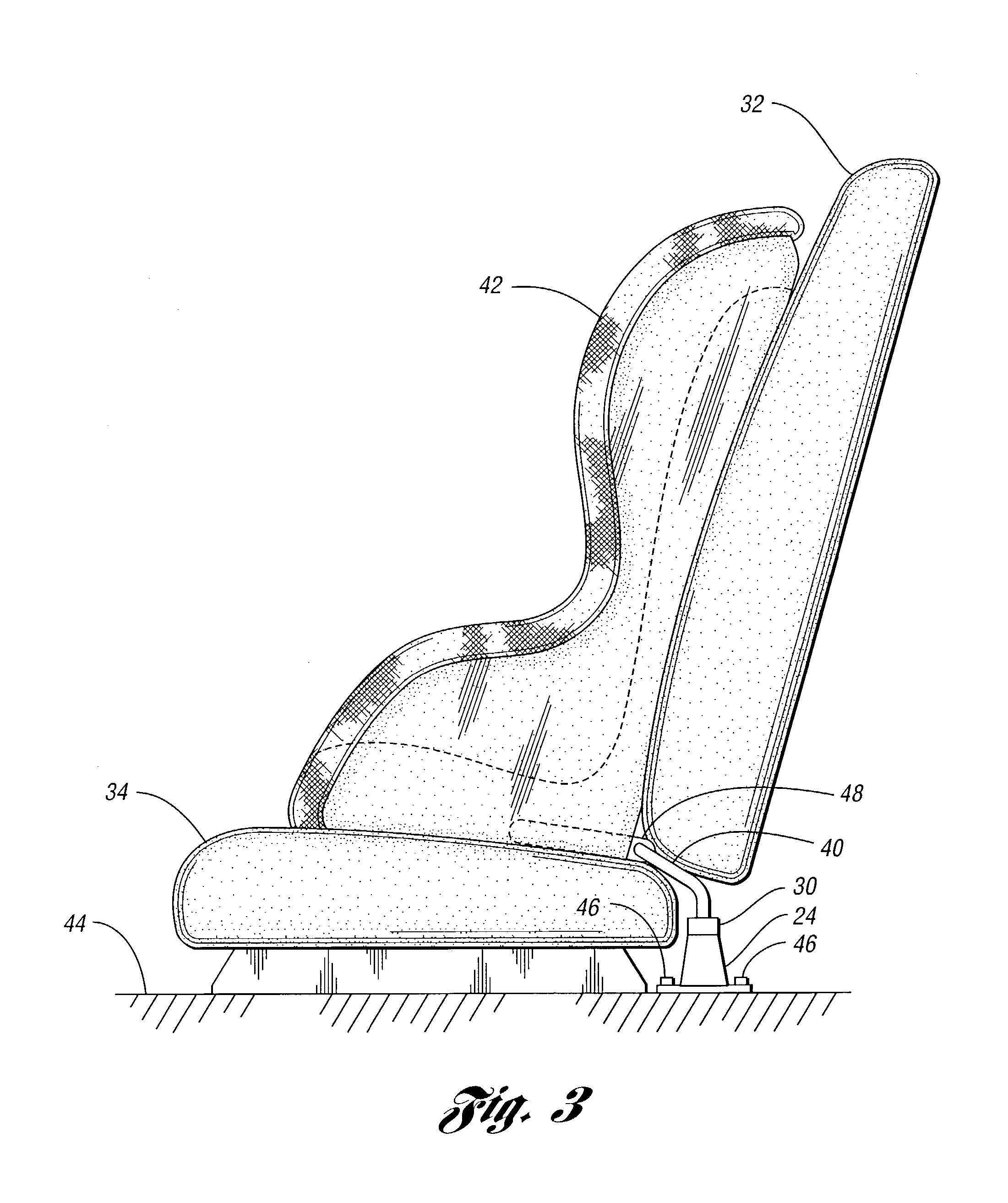

Restraint anchorage for a child restraint system

InactiveUS7131693B2Eliminate weldsImprove quality controlKids chairsStowing appliancesMobile vehicleChild restraint

A restraint anchorage for a child safety seat for an automotive vehicle having a cross member disposed behind the vehicle's seat. U-shaped latch wires are attached to the cross member. Collars are provided on the legs of the latch wires which engage one side of the cross members. The ends of the legs which protrude through holes provided in the cross member are peened over to form enlarged heads locking the latch wire to the cross member.

Owner:MAGNA CLOSURES INC

Nickel-nanodiamond composite plating solution and preparation thereof

InactiveCN101280452ASoluble in waterGood dispersionElectrolytic coatingsSurface-active agentsSize ratio

The invention discloses a nickel-nano-diamond composite plating solution, which is in blend composition with the size ratio 0.1-2:22 through the modified nano-diamond water or dilute sulfuric acid solution and the water solution of nickel sulfate, nickel chloride, boric acid, saccharin and butynediol. The invention also discloses the preparation method of the composite plating solution. The composite plating solution of the invention has a high degree of stability, in which the key issues existed in the composite plating technique of nano-diamond that the nano-diamond is easy to be in agglomeration and settlement and the plating solution is unstable are resolved. Moreover the composite plating solution is in favor of the stable control of the structure and properties of the composite coating. During the preparation process, the ultrasound technology and the organic surface-active agent are not required to use, which is not only help reduce the plating cost, but also the environmental problems resulted from the adoption of the organic surface-active agents comprising sulfur, phosphorous and other elements are avoided. The composite coating obtained from the plating solution through a simple plating process is bright and smooth. Compared with the coating that the nano-diamond is not comprised and obtained under the same conditions, the micro-hardness of the composite coating can be increased at most by 38%, and the coefficient of friction can be reduced by 29%.

Owner:浣石

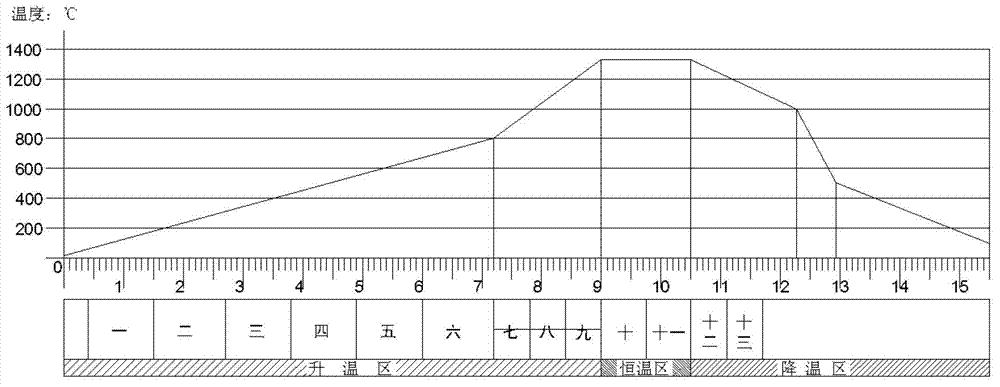

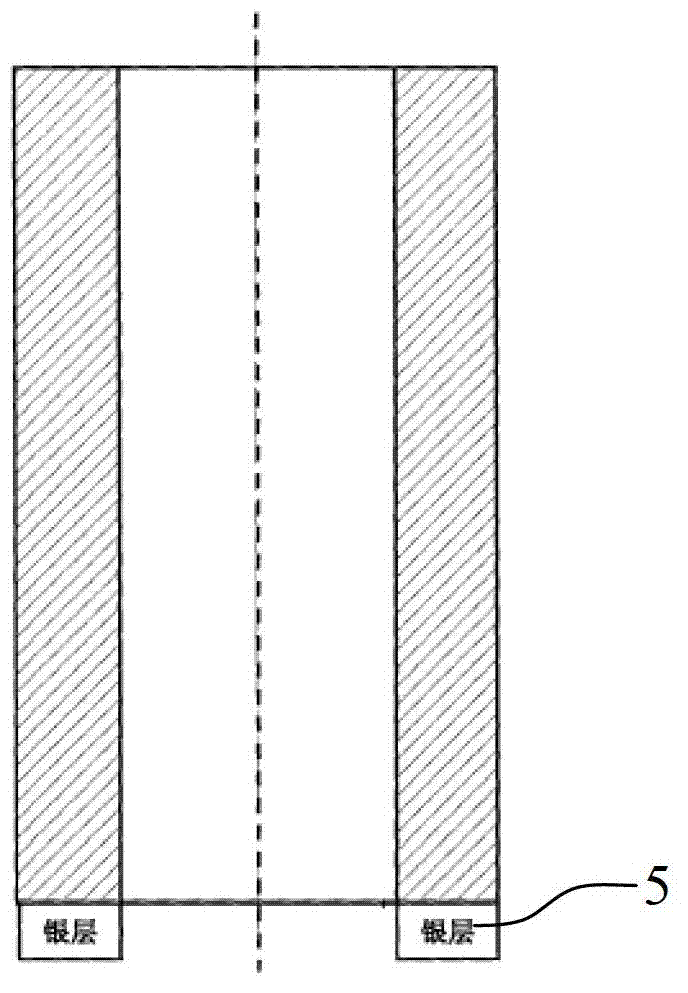

Novel medium cavity filter with cavity

ActiveCN102969549AReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

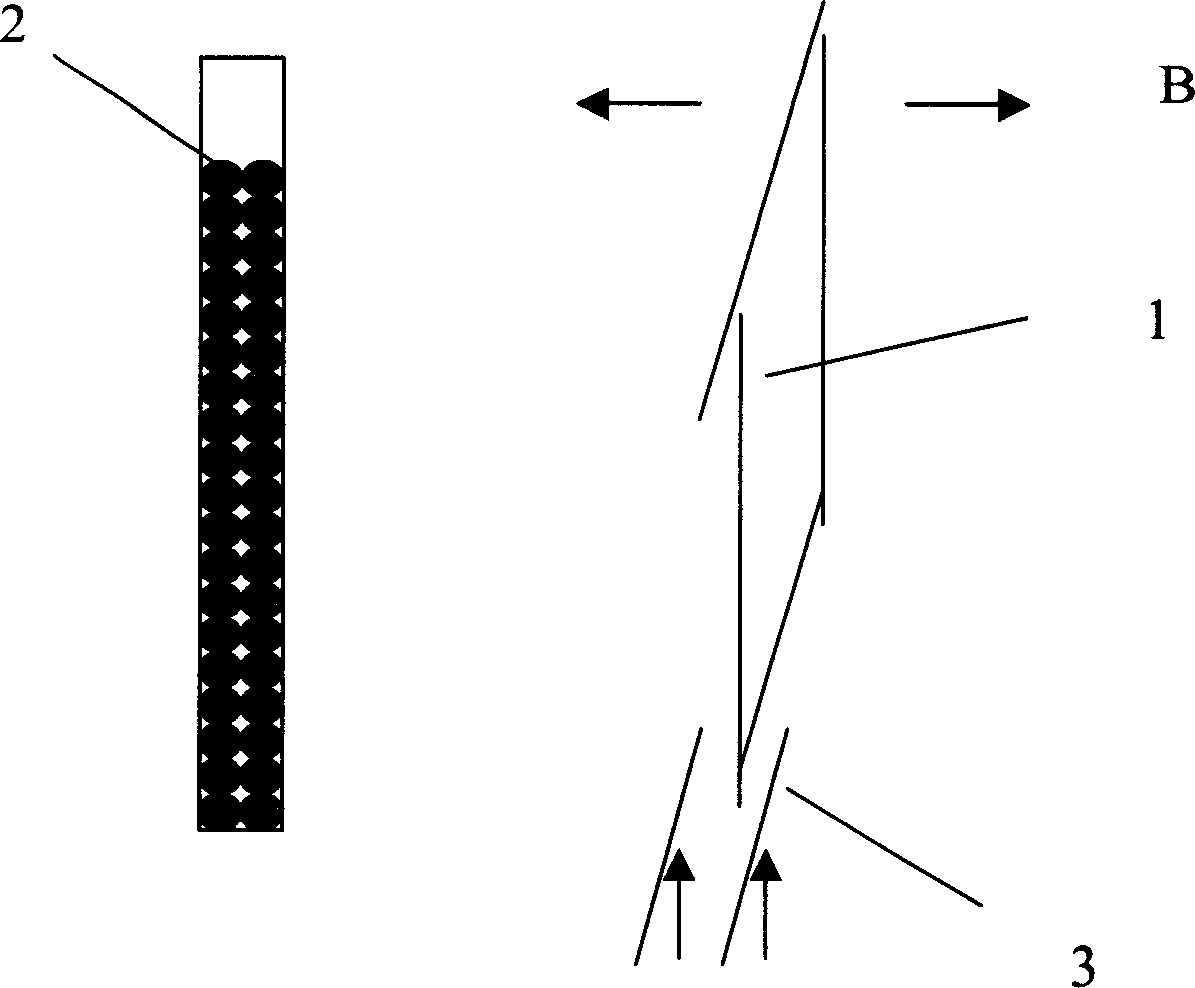

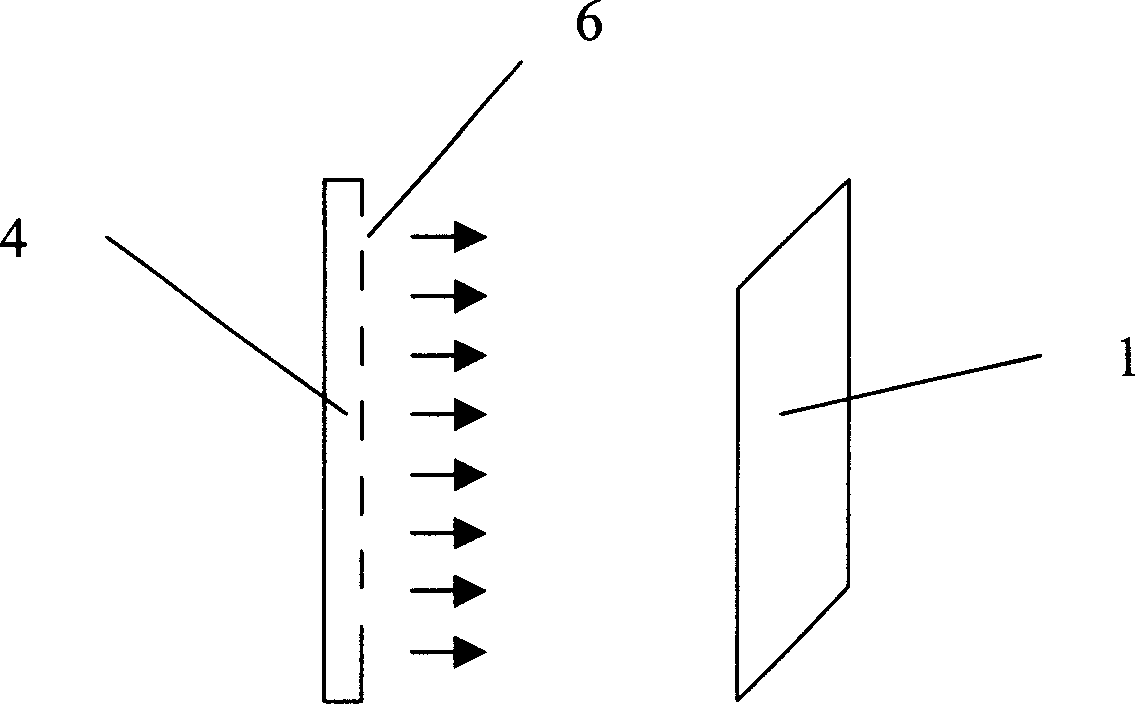

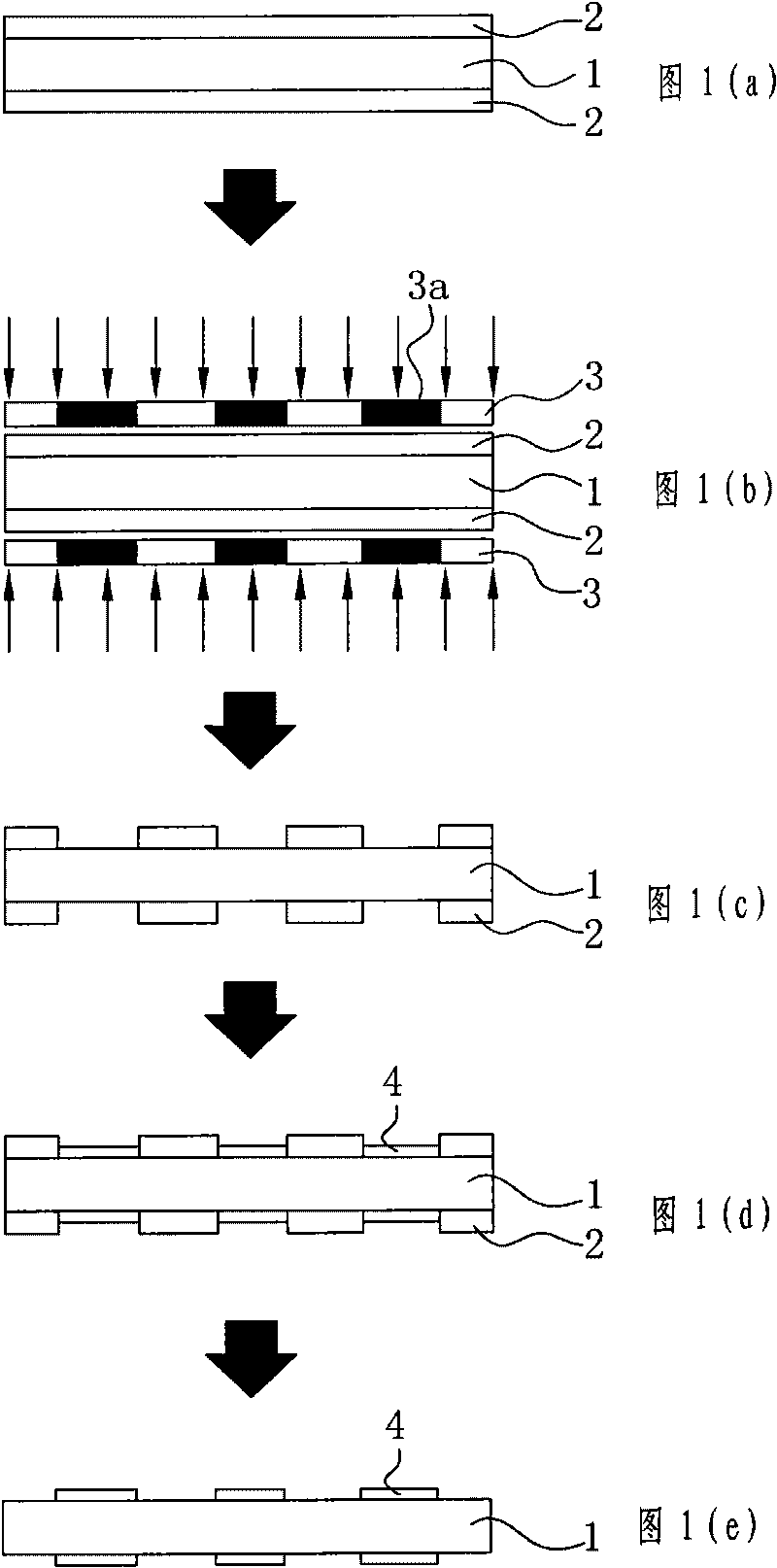

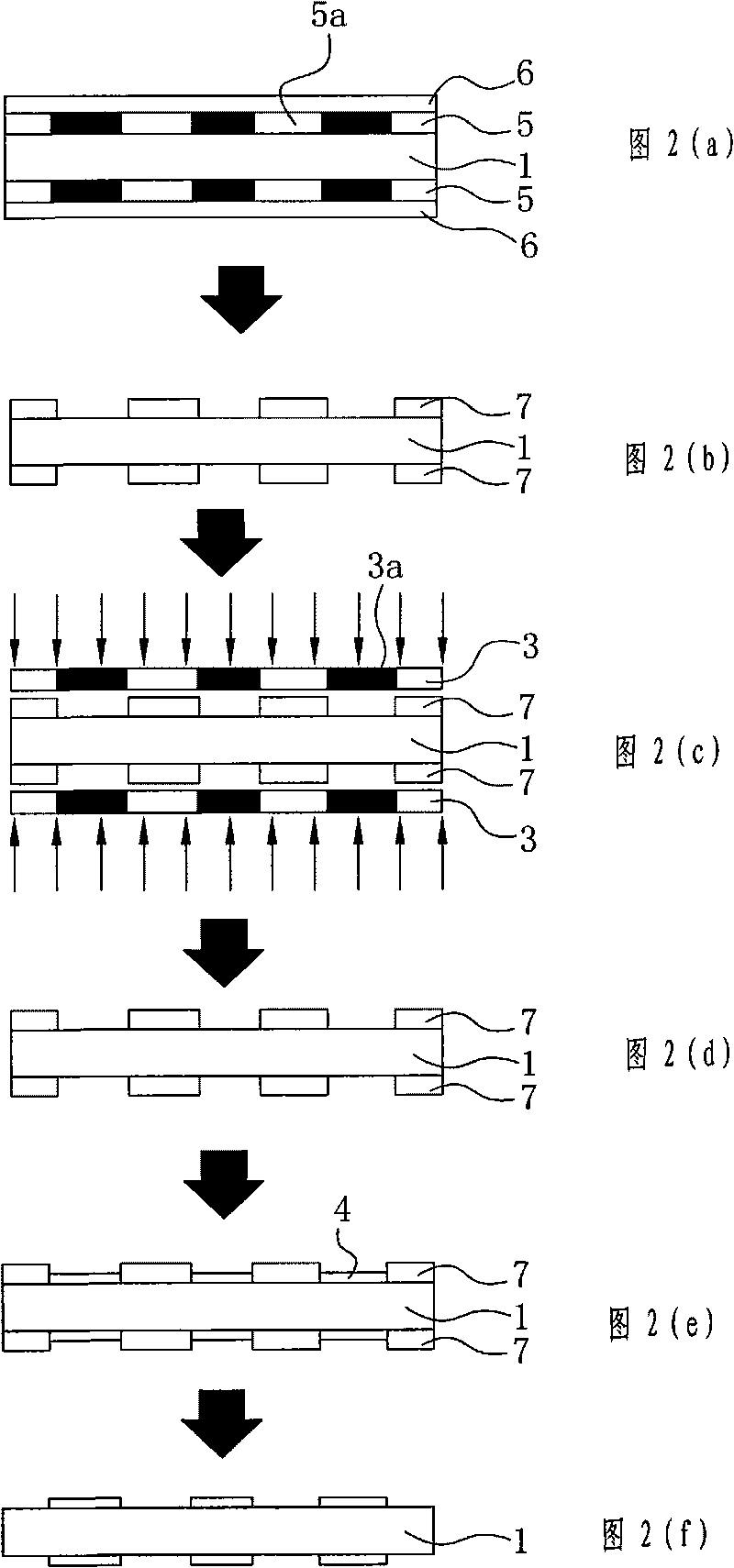

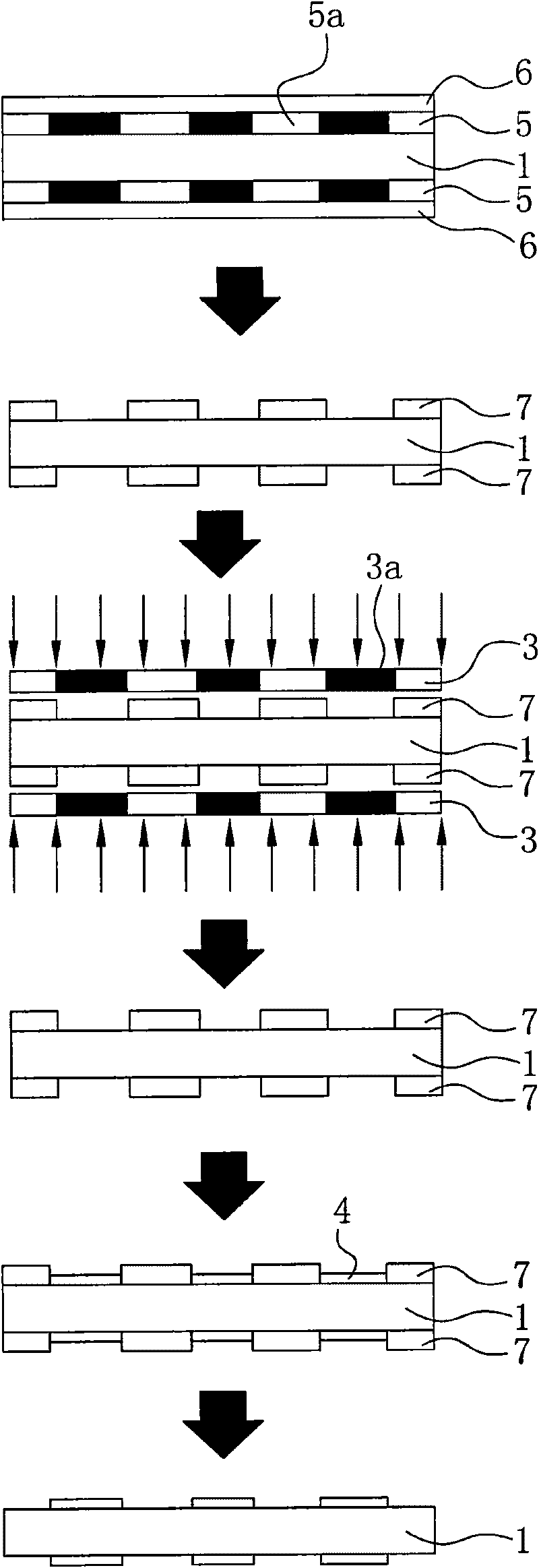

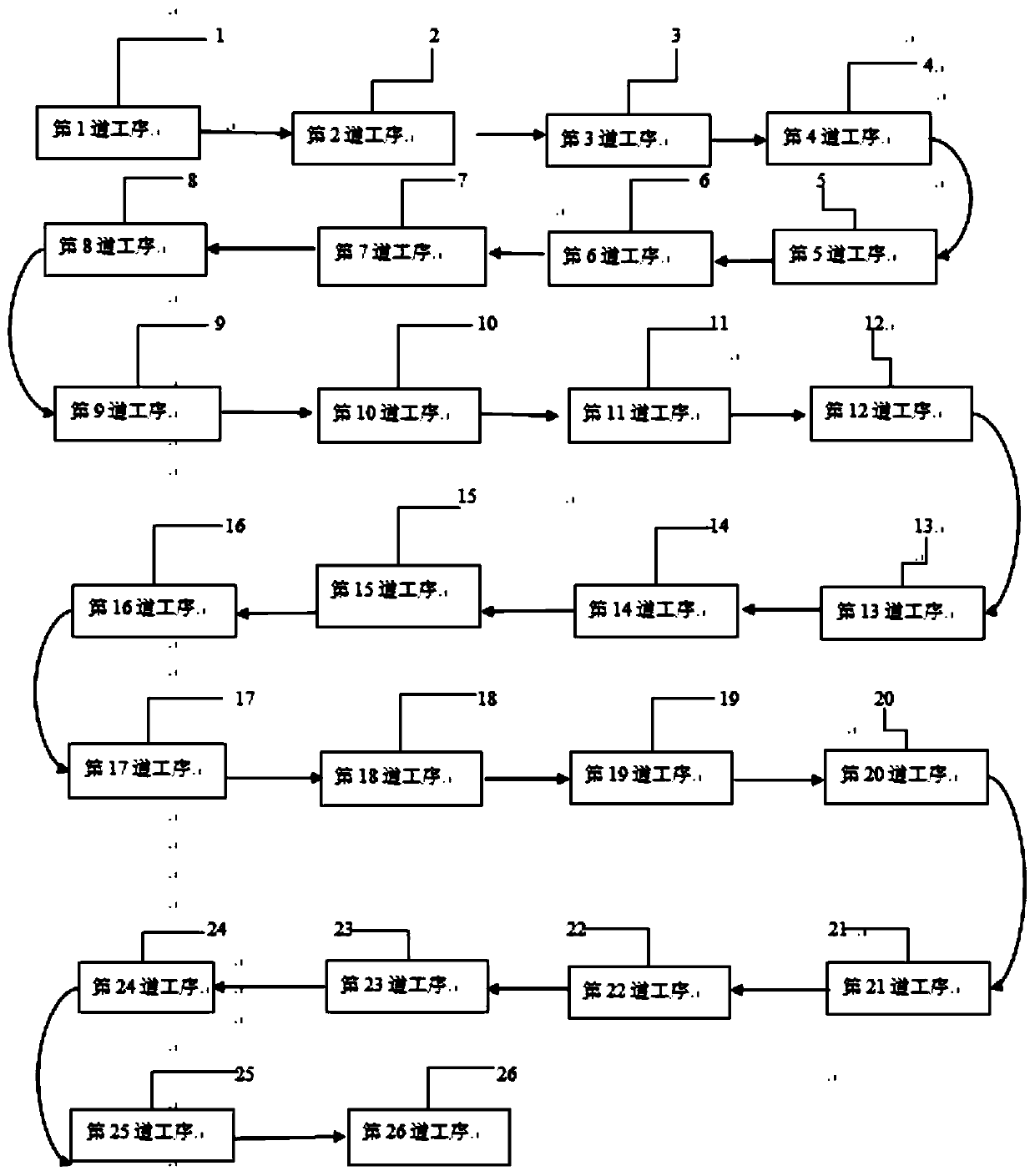

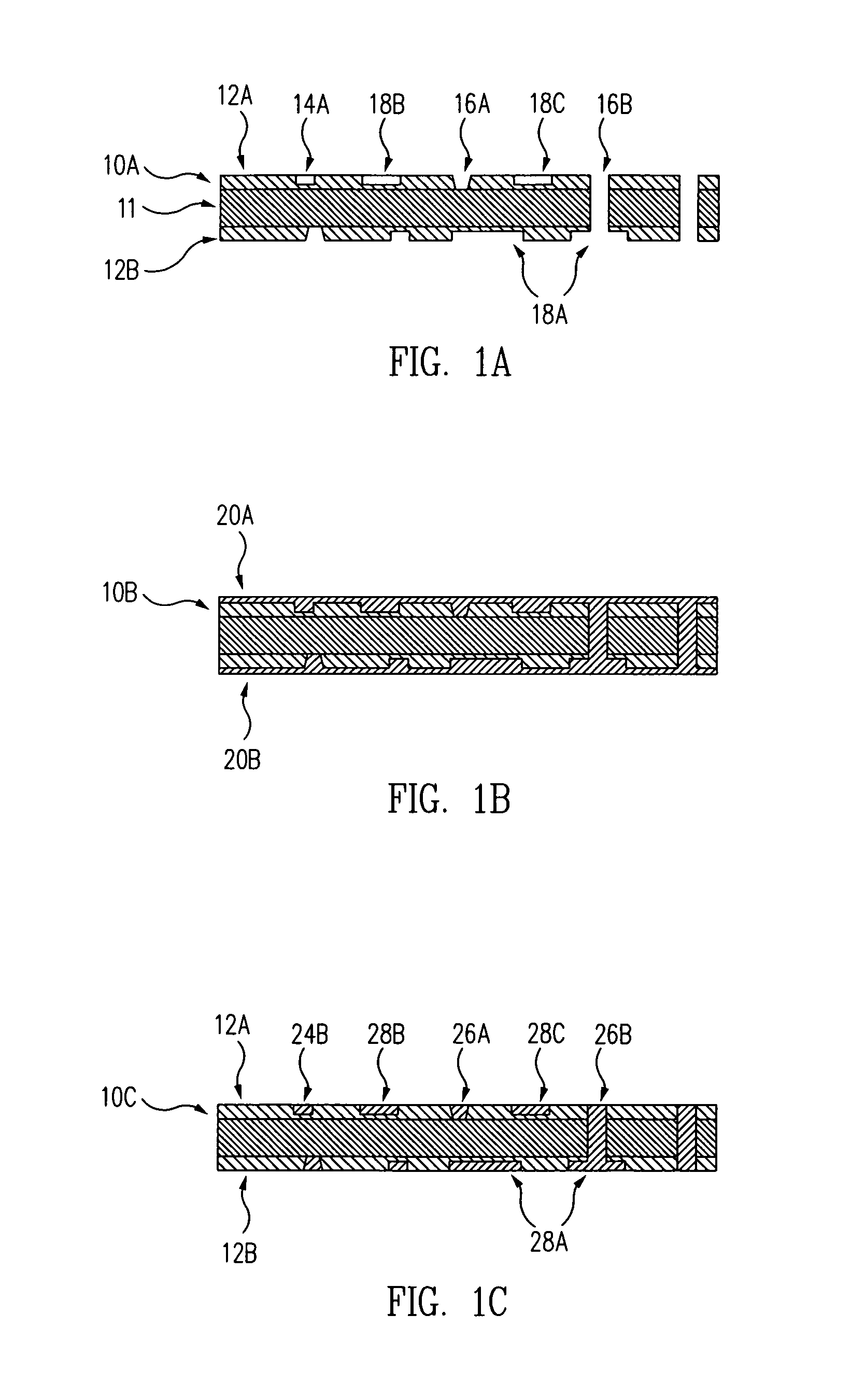

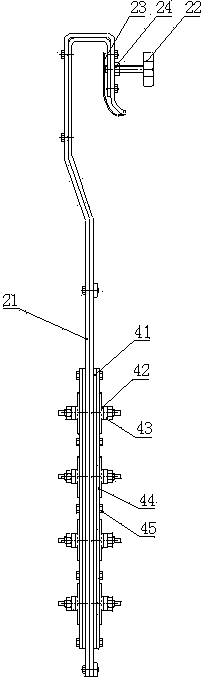

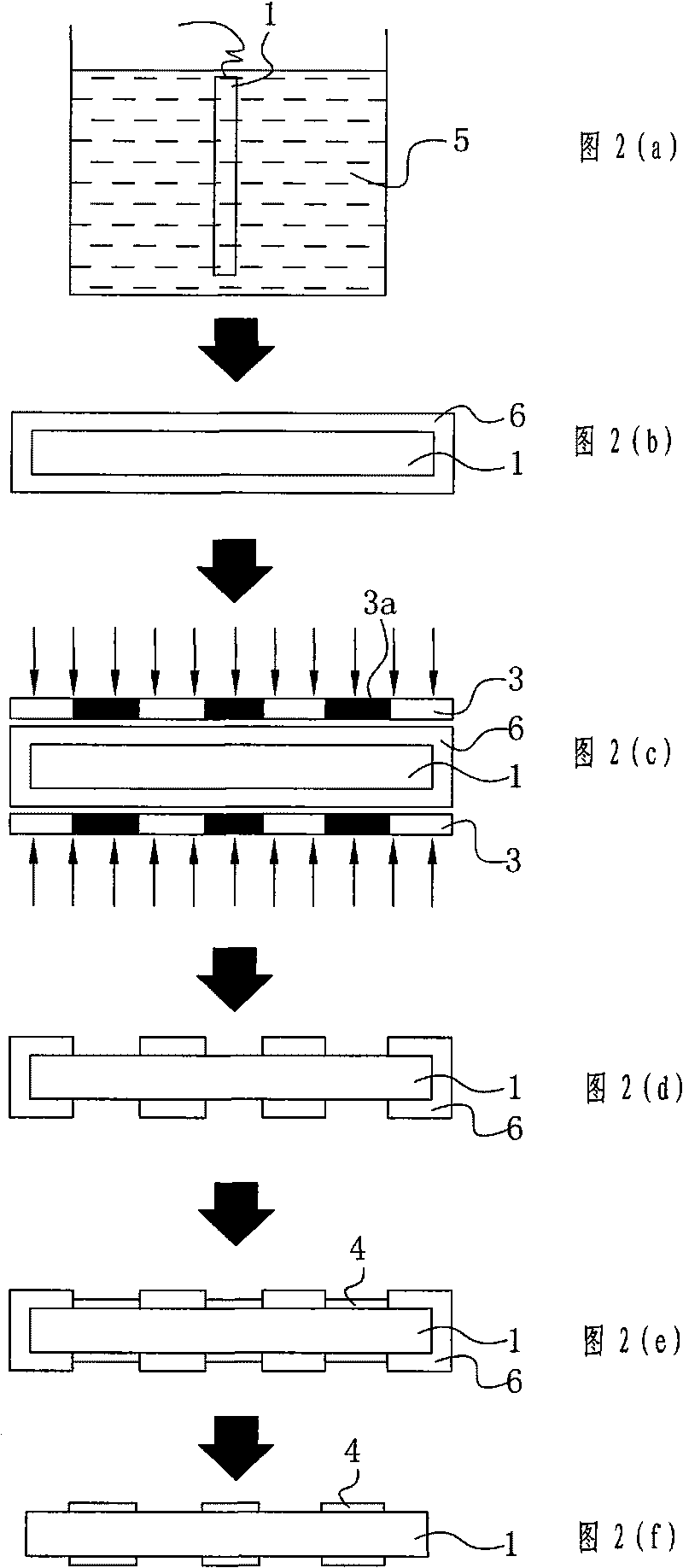

Electroplating method of integrated circuit lead frame

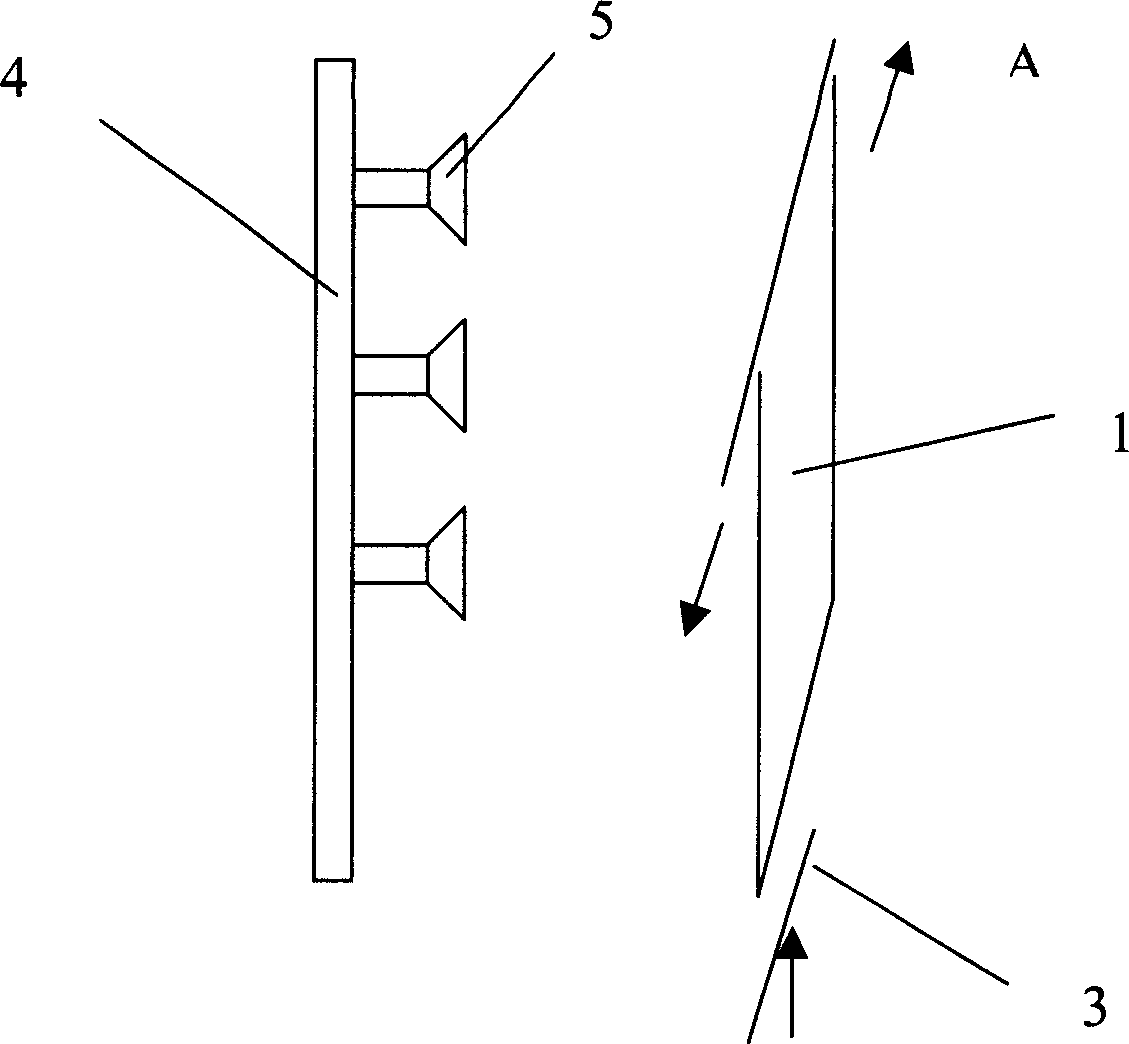

The invention discloses an electroplating method of an integrated circuit lead frame, which is characterized by comprising the following steps of: firstly, manufacturing a screen plate (5); secondly, diluting light sensing ink (6); thirdly, carrying out printing on a lead frame (1); fourthly, drying; fifthly; exposing; sixthly, developing; seventhly, electroplating a metal layer; eighthly, removing a film; and ninthly, cleaning and sunning. Compared with the prior art, the invention has the advantages that because steps that the light sensing ink and a screen plate technology are firstly used to carry out film coating on the lead frame and then exposing, developing and electroplating are carried out are adopted, the screen plate is printed only aiming to a special region so as to efficiently save the use level of the light sensing ink, the use level of the light sensing ink is obviously less than the that of dry film, and in addition, the price of the light sensing ink is obviously lower than the that of the dry film, therefore, the invention has low electroplating cost and is beneficial to batch production.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Method for improving excessive circuit etching of circuit board

InactiveCN104411105AExpanding the scope of improvement in etchingPrevent over etchingConductive material chemical/electrolytical removalEtchingCopper

The invention discloses a method for improving excessive circuit etching of a circuit board, belonging to the field of outer circuit etching of printed circuit boards. The method for improving excessive circuit etching of the circuit board disclosed by the invention comprises the following steps of: micro-electroplating a copper layer with the thickness of 5-6 mu m on a complete board; transferring an outer pattern onto the outer layer of the circuit board to form a circuit pattern, wherein the width of a copper circuit is 0.03-0.04 mm more than that of a copper circuit required practically; thickening a pattern electroplated copper layer till the thickness is 11-13 mu m, and then, electrotinning with the thickness of 5-6 mu m; and vacuumizing and etching after demoulding. According to the invention, the processes before and after etching are improved in an unified manner; therefore, the improvement range of outer circuit etching is enlarged; the effect of preventing excessive circuit etching can be achieved better; the production efficiency of outer circuit etching is effectively increased; scraps due to the fact that circuits are too thin are reduced; and the electroplating quality is increased.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Quick zinc sulfate electroplating process

A quick zinc sulfate electroplating process comprises the following steps: firstly, removing oil on a work piece, washing the workpiece by water, acid and water respectively, then soaking the workpiece into electroplating liquid in a galvanizing bath, taking out the work piece, washing the workpiece by water, then passivating the workpiece, washing the workpiece by water again, and drying the workpiece with hot wind. Content of chemical materials in each liter of the electroplating liquid is as follows: 80 to 150 grams of zinc sulfate, 120 to 180 grams of potassium chloride, 25 to 30 grams of buffer, 1 to 2 grams of additive and 20 to 25 grams of lustre-coating agent. The workpiece is soaked in the electroplating liquid for 10 to 15 minutes at a temperature of between 5 and 60 DEG C, and the pH value of the electroplating liquid is 4 to 5. The technical conditions of soaking the workpiece in the electroplating liquid in order to galvanize are as follows: the current density is 2 to 5A / dm; the cathode motion speed is 15 to 20 times per minute. By using the process to galvanize the workpiece, the deposition velocity is quick; dispersive power is good; corrosion resistance is strong; electroplating time is reduced by 60 percent; processing cost is reduced by 30 percent; production efficiency is high; and economic benefit is good.

Owner:梁新中

Round terminal and method of making the same

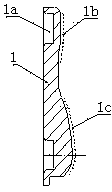

InactiveCN102290661AReduce plating costContact member manufacturingCoupling contact membersEngineeringMechanical engineering

The invention discloses a rolling terminal and a making method thereof. The rolling terminal comprises a rolling bar; insertion bars vertically extended with the bar are uniformly arranged on the bar; tail ends of the insertion bars are outwards lapped over; and only one surface of the insertion bars is coated with a clad layer. On the premise of no influence on product function and a final terminal structure, a plate is formed by stamping, electroplated and formed by secondary stamping, so an electroplating process of the terminal is changed from immersion plating to brush plating, and the terminal provided with the insertion bars of which only one surface is coated with the clad layer is finally formed, and the electroplating cost is greatly reduced.

Owner:苏州海创电子有限公司

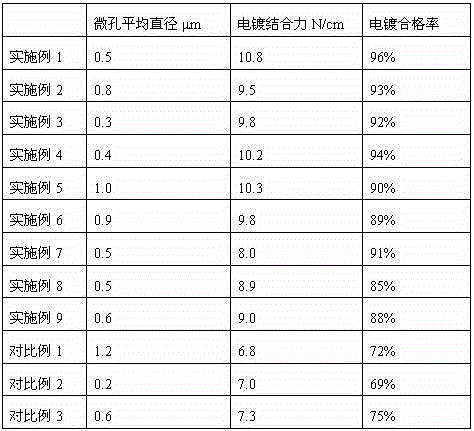

Resin composition directly used in electroplating

The invention relates to a resin composition capable of being directly electroplated. The resin composition comprises the following components in parts by weight: 75 to 95 parts of thermoplastic resin, 2 to 5 parts of a microcapsule foaming agent and 3 to 20 parts of conductive powder, wherein the thermoplastic resin is selected from ABS (Acrylonitrile Butadiene Styrene), PC (Poly Carbonate), PP (Propene Polymer), PE (Poly Ethylene), PA (Poly Amide), PBT (Poly Butylene Terephthalate), PET (Poly Ethylene Terephthalate), PMMA (Poly Methyl Methacrylate), ASA (Acrylonitrile Styrene Acrylate), AES (Acrylonitrile Ethylene Styrene) or is an alloy resin of the ABS, the PC, the PP, the PE, the PA, the PBT, the PET, the PMMA, the ASA and the AES; the conductive powder is antimony-doped stannic oxide powder. The resin composition contains the microcapsule foaming agent and the conductive powder, so that fine and even holes can be formed in a product after the resin composition is molded in an injection molding manner; meanwhile, the product has the certain conductivity, so that a metal layer can be directly electroplated on the surface of the product. Thus, the working procedures of coarsening and palladium soaking in an electroplating process are omitted. Therefore, the complicated electroplating process is simplified, the working efficiency is improved and the electroplating cost is lowered. More importantly, a concentrated sulfuric acid and a dichromic acid do not need to serve as a coarsening liquid during the electroplating process, so that the pollution is greatly reduced, i.e., the environmental friendliness is realized.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

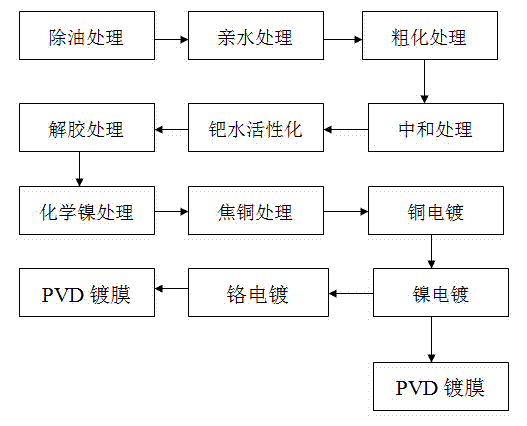

Plastic substrate electroplating method

InactiveCN104328432AReduce processing timeReduce usageLiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingHeat resistance

The invention discloses a plastic substrate electroplating method. According to the plastic substrate electroplating method, the treatment time of such processes as roughing, copper plating and nickel plating is reduced, a semi-bright nickel plating process in a traditional electroplating process is directly cancelled, the production capacity is greatly improved, the electroplating cost and the usage amount of chromium are reduced so that the pollution on the natural environment is reduced, and the time taken by the traditional process and the thickness of a copper plated layer as well as the thickness of a nickel plated layer are reduced; the plastic substrate electroplated surface finally treated by use of a PVD coating method is more environment-friendly in contrast with the traditional electroplating process, and is better in heat resistance, corrosion resistance, scratch resistance and oxidation resistance; and in addition, a temperature and a gas content adopted in the PVD coating technology are adjusted so that the PVD films of various bright colors with strong metal texture and third dimension can be formed to overcome the shortcoming of thin colors that can be plated by use of the traditional plastic electroplating process.

Owner:曹德天

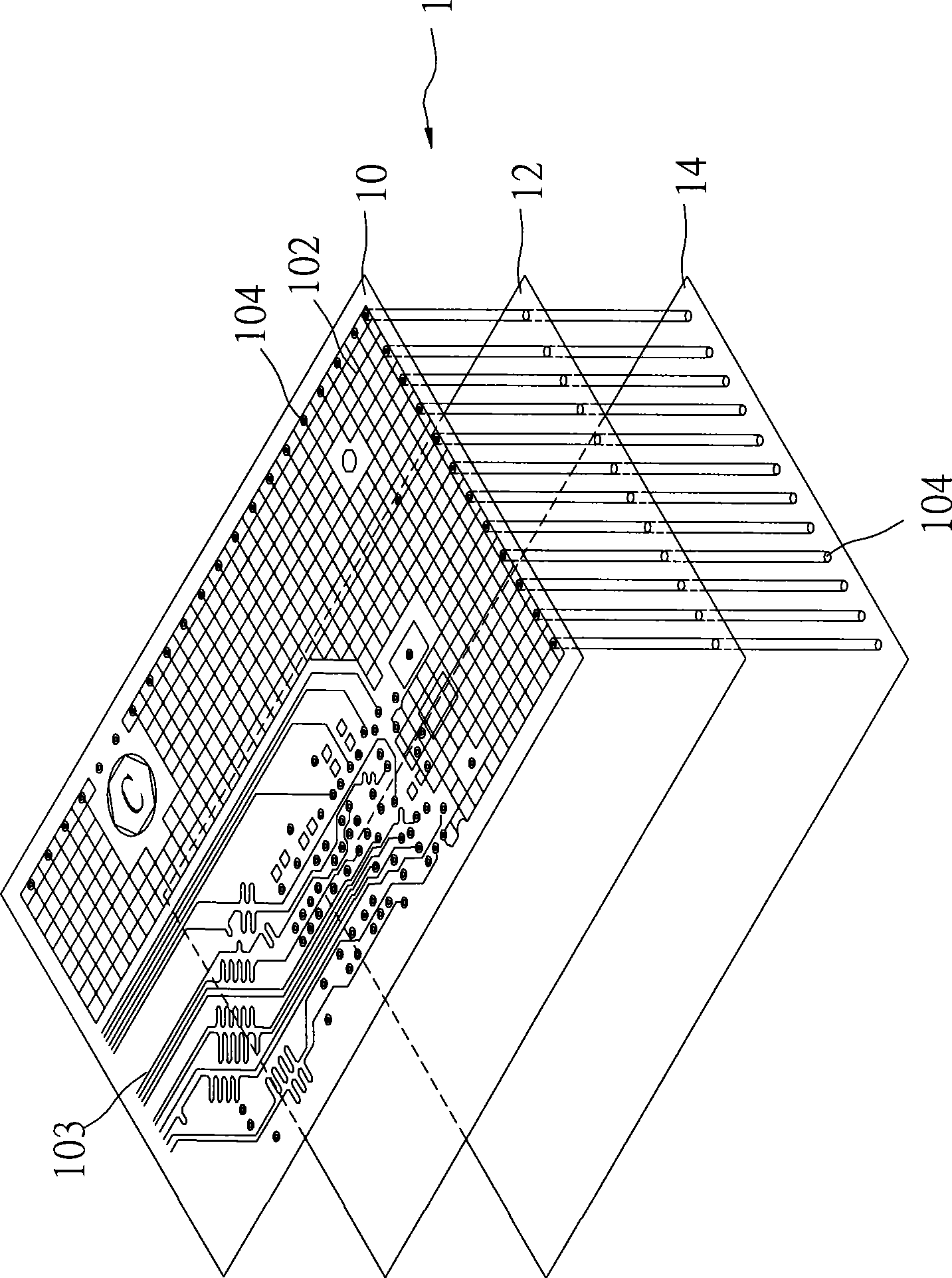

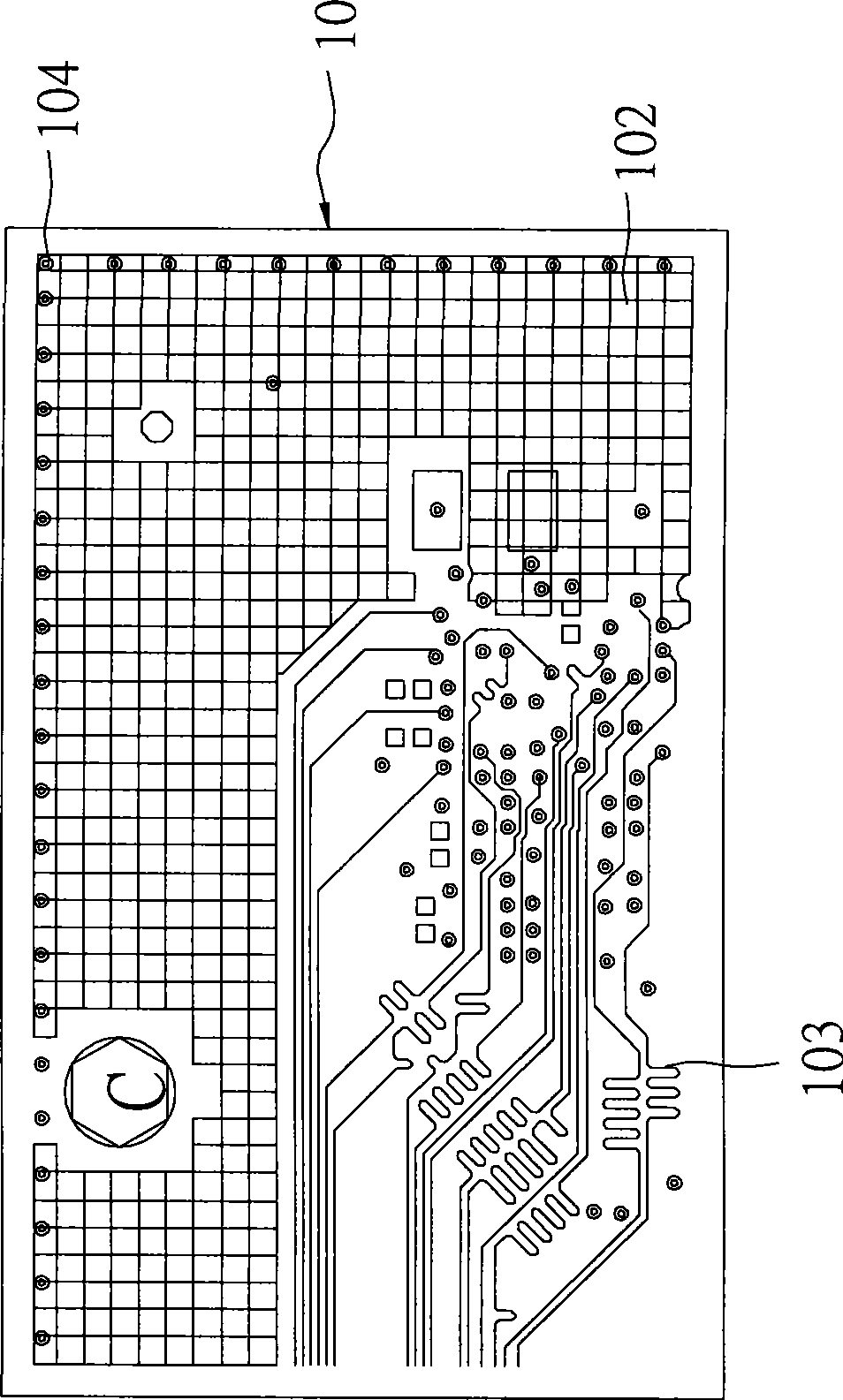

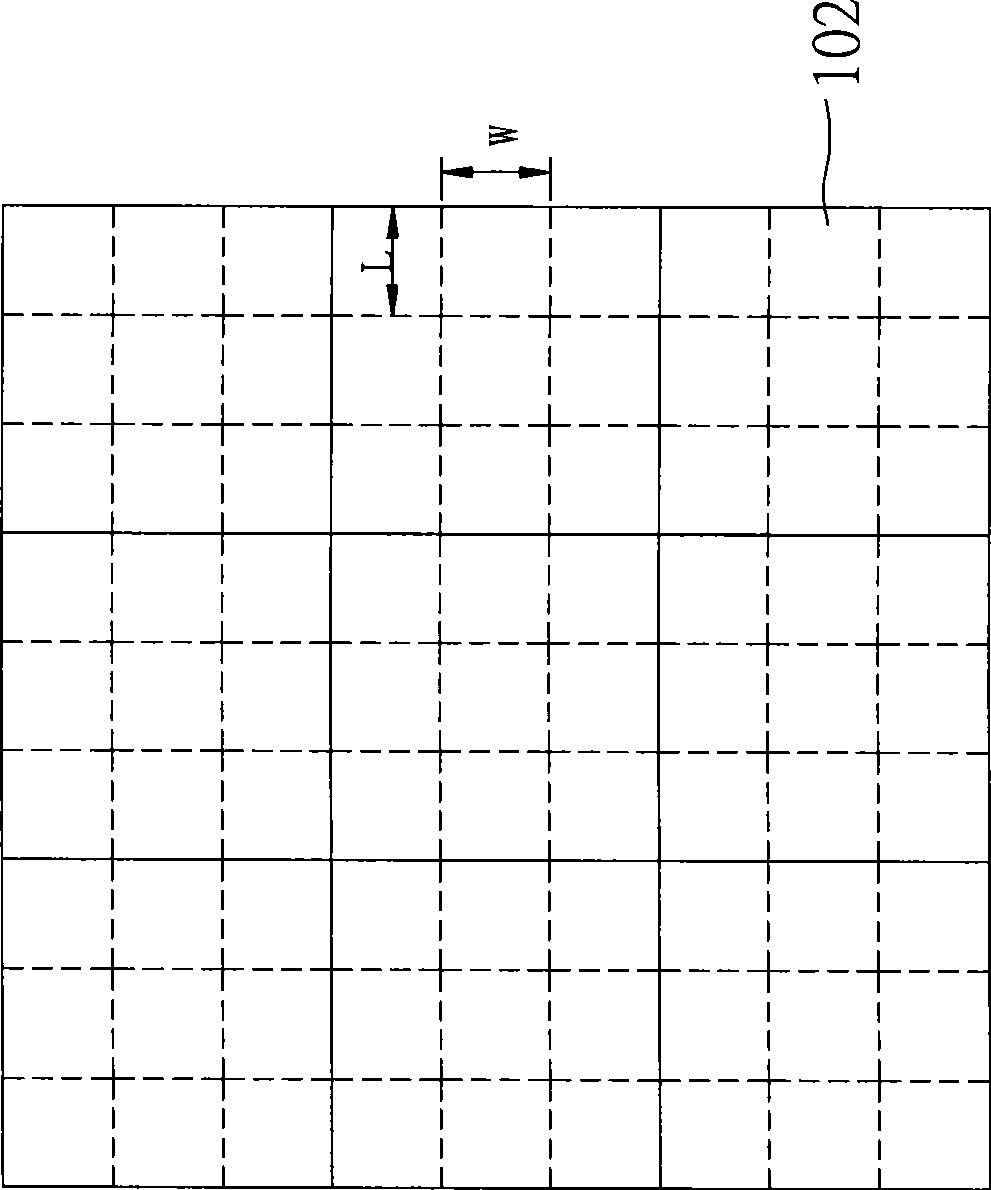

Circuit board layout structure and method for preventing electromagnetic interference

ActiveCN101472454AShorten the lengthReduce mutual interferencePrinted circuit detailsMagnetic/electric field screeningElectromagnetic interferenceEngineering

The invention relates to a circuit board layout structure and a method for preventing electromagnetic interference, wherein, the circuit board layout structure comprises a multilayer printed circuit board, a plurality of conduction grids and a plurality of conduction perforations. The multilayer printed circuit board is provided with a plurality of signal layers and a grounding layer; a plurality of signal circuits are arranged on each signal layer; the conduction grids wrapping the signal circuits on each signal layer are distributed on each signal layer; and the conduction perforations are formed among the layers of the multilayer printed circuit board, and electrically connected to the grounding layer and conduction grids on each signal layer. Therefore, according to the design of the size of the conduction grids, the purpose of blocking the frequency of a specialized electromagnetic wave can be achieved. The invention can reduce the length distributed by a field of interference sources, so as to weaken noise radiation degree, further reduce the mutual interference degree of signals, reduce the number of the conduction perforations by about 30 to 50 percent, and avoid the intensity reduction of the circuit board. In addition, the invention adopts a mode of conduction grid layout, thereby reducing the electroplating cost by about 25 to 30 percent.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

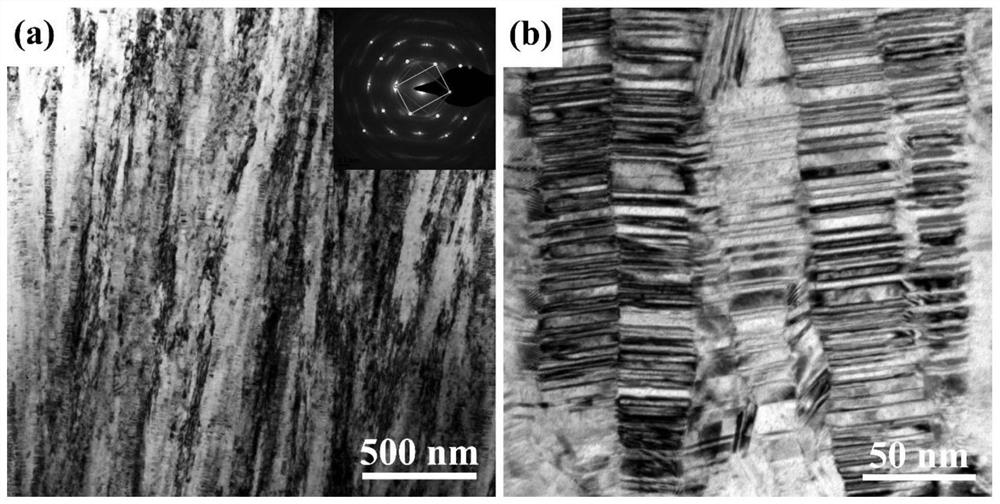

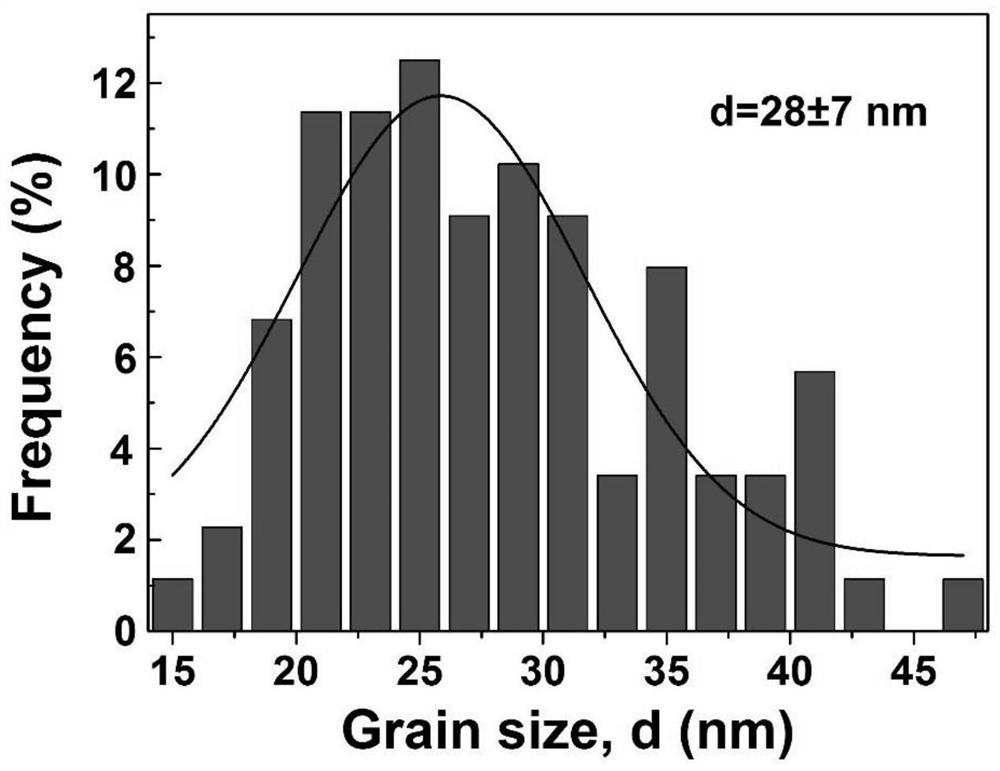

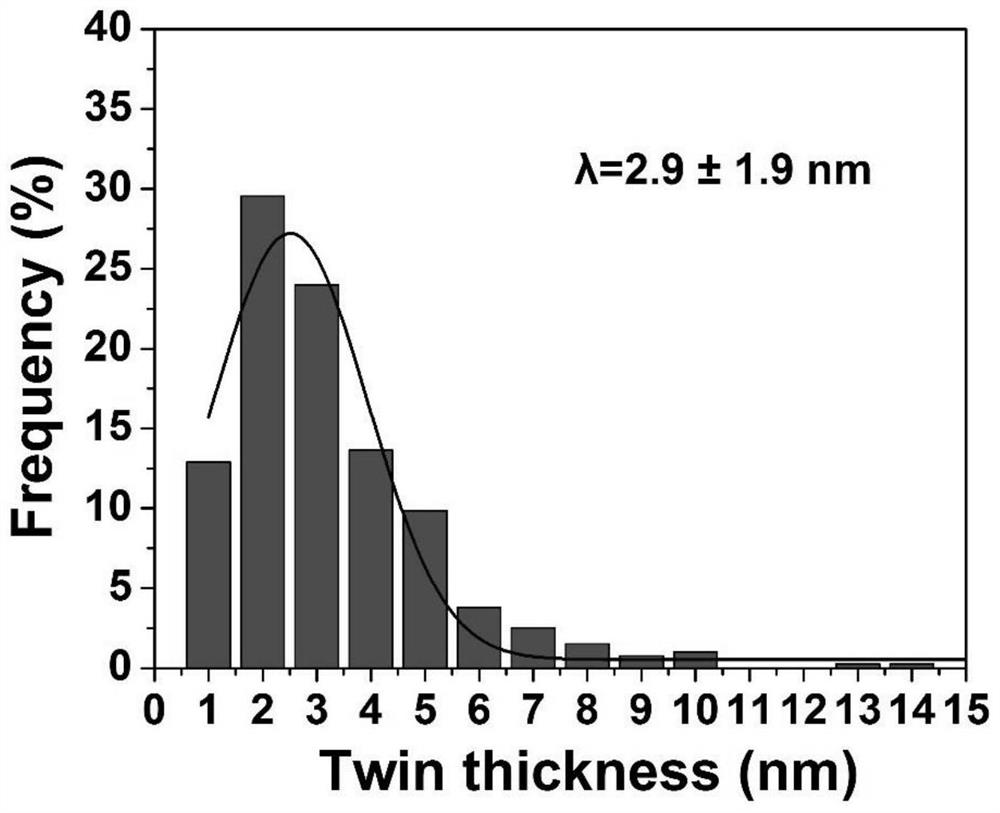

Nano twin-crystal nickel with extremely small twin-crystal lamella thickness and ultrahigh strength and preparation thereof

The invention relates to a superhard nanocrystal metal material, in particular to nano twin-crystal nickel with extremely small twin-crystal lamella thickness and ultrahigh strength and a preparationmethod thereof. The nano twin-crystal nickel with a thickness of hundreds of microns to millimeters is prepared by utilizing an electrolytic deposition technology, wherein a microstructure of the nanotwin-crystal nickel is composed of columnar crystal particles with lengths of 200-3000 nm and widths of about 10-50 nm, twin-crystal lamella structures with high density and consistent orientation are contained in columnar crystals, a thickness of each twin-crystal lamella structure is 0.5-10 nm, the crystal particles with the twin-crystal structures can account for 100% of the crystal particlesof a whole sample, a room-temperature microhardness of a material can reach 8.5 GPa or above and is 1.5-2 times or above that of common electroplating nano nickel, and after annealing is carried out at 250 DEG C for half an hour, the hardness is increased to 9.6 GPa and a structure roughening temperature can reach 350 DEG C or above and is 150 DEG C or above higher than a structure roughening temperature of common nanocrystal nickel. A prepared nanocrystal coating can be applied to wear-resistant protection of metal materials such as copper, nickel, alloys of the copper and nickel, and stainless steel, and can also be applied to the fields of micromechanical systems (MEMS) and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Imitation gold electroplating method

InactiveCN104451792AImprove bindingBright colorSuperimposed coating processMegasonic cleaningElectrochemistry

The invention discloses an imitation gold electroplating method. The imitation gold electroplating method is characterized by comprising the operation steps of part installing and suspending, oil removing and rust removing treatment, hot water washing, corrosion treatment, cold water washing, bright nickel plating, cold water washing, imitation gold plating treatment for 50-80 seconds, cold water washing, passivation treatment, cold water washing, drying, varnishing, spin-drying, baking, workpiece mounting and dismounting, and inspecting and packaging. Ultrasonic degreasing and the electrochemical method are combined to remove oil for the oil removing treatment; an ultrasonic wave cleaning mode is adopted for the hot water washing and cold water washing; the imitation gold plating is performed at the temperature of 20-25 DEG C and with the pH of 8.0-9.0 and the current density of 5-10A / dm<3>. The imitation gold electroplating method is simple and convenient to operate, and a plating layer is high in bonding force; a treated workpiece is bright in color, and has long service life; the plating cost is low.

Owner:HENGYANG FENGSHUN AXLE CO LTD

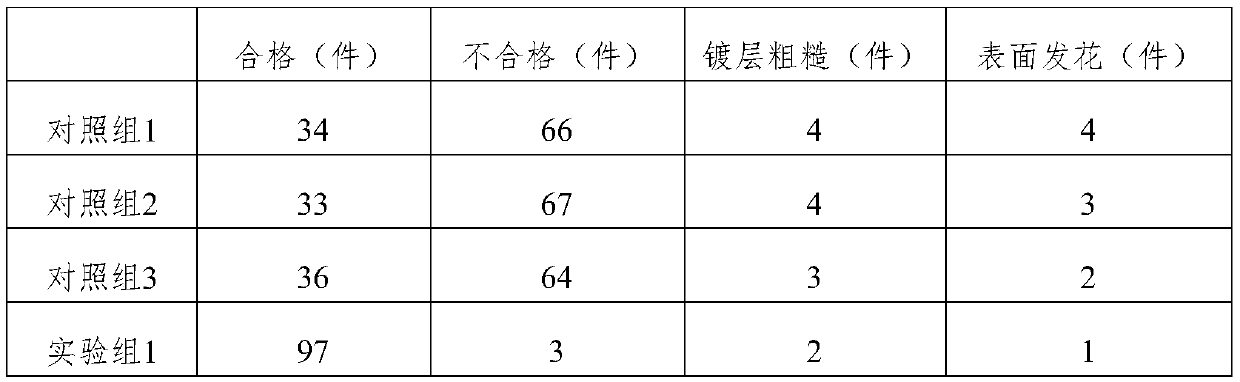

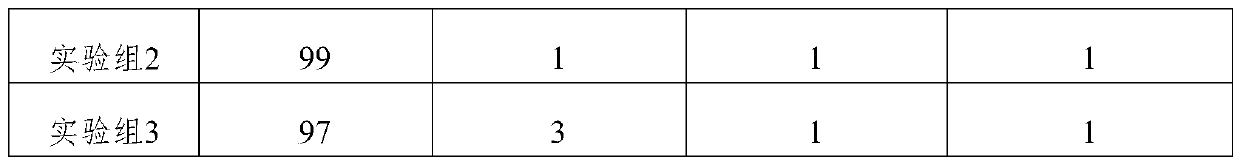

Method for improving nickel electroplating quality of aluminum-silicon alloy

ActiveCN110670098AImprove bindingAvoid technical problems such as blistering, peeling, rough coating, etc.AnodisationAnodizingSilicon alloy

The invention relates to the field of aluminum-silicon alloy electroplating, in particular to a method for improving the nickel electroplating quality of aluminum-silicon alloy. The method comprises the steps of organic oil removal, cleaning, electrolytic degreasing, drying, sand blasting, cleaning, oil removal, cleaning, descaling, cleaning, racking, cleaning, activation, cleaning, hard sulfuricacid anodizing, cleaning, copper pre-plating, cleaning, activation, cleaning, nickel pre-plating, nickel plating, cleaning, cleaning with hot water, cleaning and drying. According to the method, through adding of the steps of activation and hard sulfuric acid anodizing, the bonding between a substratum and copper plating is promoted, and generation of watermarks after plating is avoided; the qualified rate reaches 97%, and rework is reduced after the plating quality is qualified; the plating cost is reduced, so that the overall manufacturing cost is further reduced; meanwhile, the delivery cycle is shortened; and the method is high in adaptation to operators, and benefits scale promotion.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

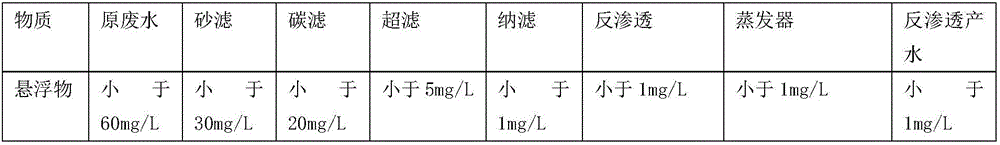

Electroplating nickel-containing wastewater resource utilization technology

The invention discloses an electroplating nickel-containing wastewater resource utilization technology which comprises the steps of firstly collecting and storing electroplating nickel-containing wastewater, removing suspended solids in wastewater, filtering part of organism and auxiliaries out through activated carbon, then sequentially performing ultrafiltration, nanofiltration and reverse-osmosis operation on the purified electroplating nickel-containing wastewater to obtain concentrated solution and finally evaporating the concentrated solution in environment with temperature of 160 DEG C and steam pressure larger than 0.6Mpa to obtain nickel crystal. According to the electroplating nickel-containing wastewater resource utilization technology, the wastewater is sand filtered to remove particles, part of organic pollutant and part of heavy metal are filtered out by the activated carbon, finally wastewater can reach a standard to be reused through ultrafiltration, nanofiltration and reverse osmosis; furthermore, percolate can be reused to a plating tank after crystallization, and plating cost is reduced.

Owner:CHINA SEWAGE TREATMENT GENERAL HOSPITAL HUBEI CHAIN CO LTD

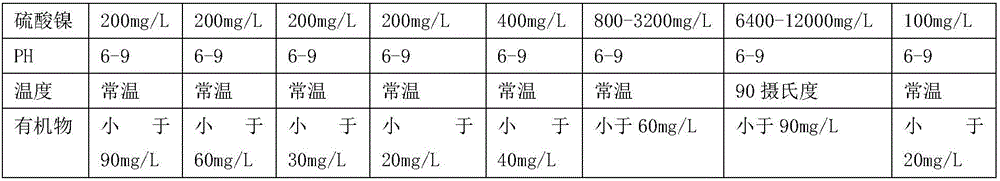

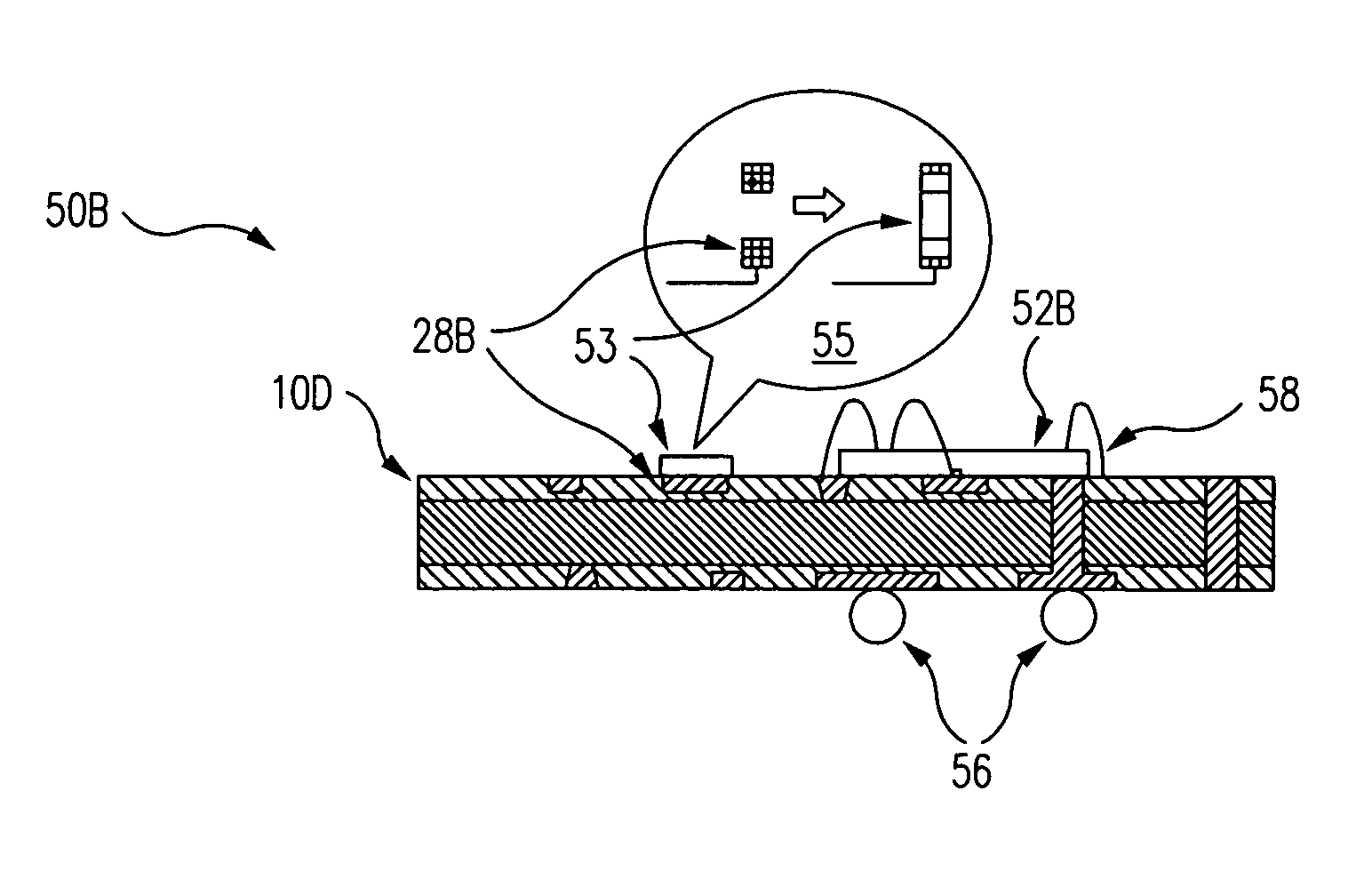

Semiconductor package substrate fabrication method

InactiveUS7501338B1Reduce contiguous conductive area of landReduce amountInsulating substrate metal adhesion improvementPrinted circuit aspectsHigh densityLine width

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

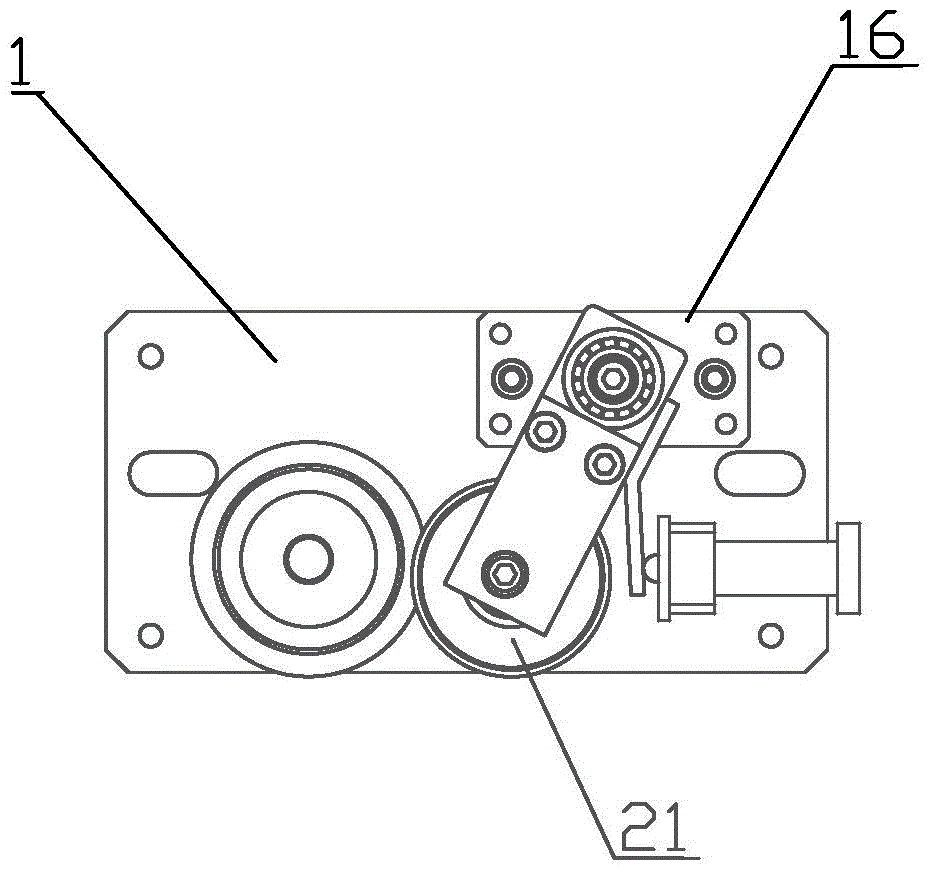

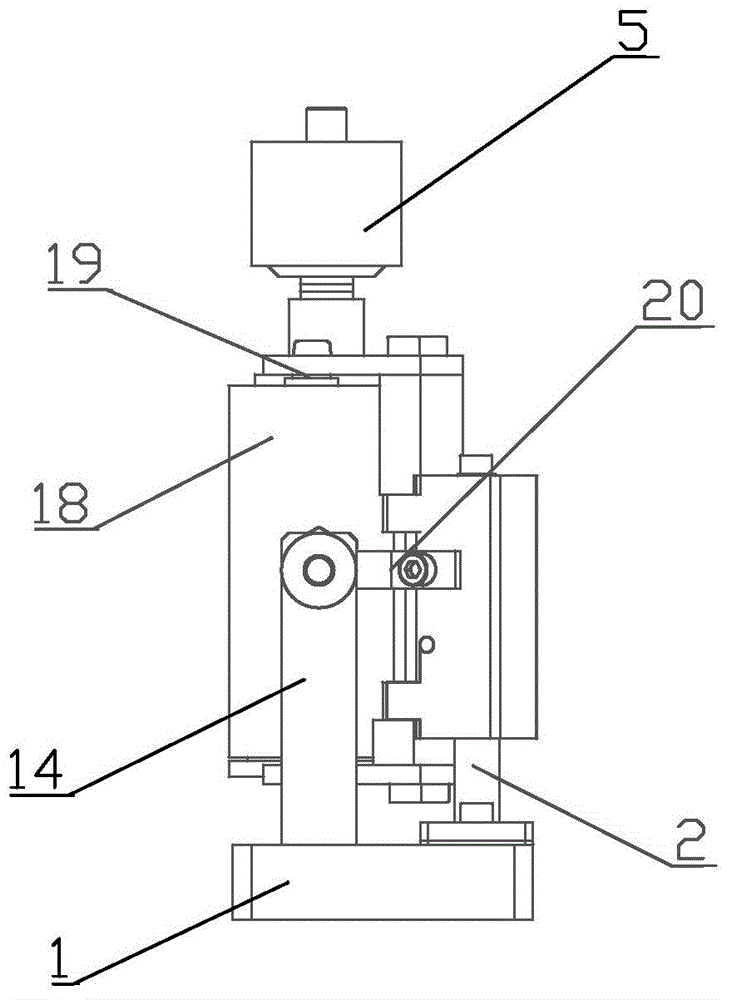

Hydrargyrum vertical type conductive seat

PendingCN104911678AUniform coatingSmall amount of deformationElectrolysis componentsSilica gelRejection rate

The invention discloses a hydrargyrum vertical type conductive seat which comprises a bottom plate, a guide wheel, a hydrargyrum head, a fixing block, supporting blocks, a regulating screw, a fixing seat, a rubber coating wheel and a spring sheet, wherein the bottom plate is connected with a guide wheel shaft A and the guide wheel, the guide wheel is provided with a connecting seat and a hydrargyrum head with a shield, and the side of the guide wheel is provided with the rubber coating wheel in a pressure connecting mode. The rubber coating wheel comprises a PP wheel and a silica gel wheel and is connected with the fixing block through a guide wheel B. The supporting blocks A, B and C are axially connected with the fixing seat through a fixed shaft, the fixing seat is fixedly connected with the bottom plate, the side surface of the supporting block B is provided with the spring sheet and the regulating screw, and the regulating screw is provided with a limiting nut and a PP pressing block. Since the spring sheet is controlled through the regulating screw, the rubber coating wheel can compress the material belt on the guide wheel, the electric conduction of the conductive seat is even, the tension of the material belt is stable, the quality of the electroplated product is high, the rejection rate is low, the medicine solution loss is reduced, the cost is saved and the working efficiency is improved.

Owner:KUNSHAN YIDING IND TECH CO LTD

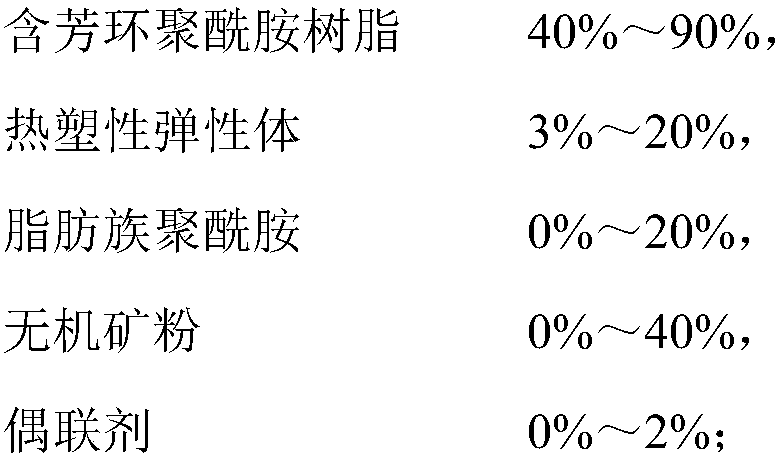

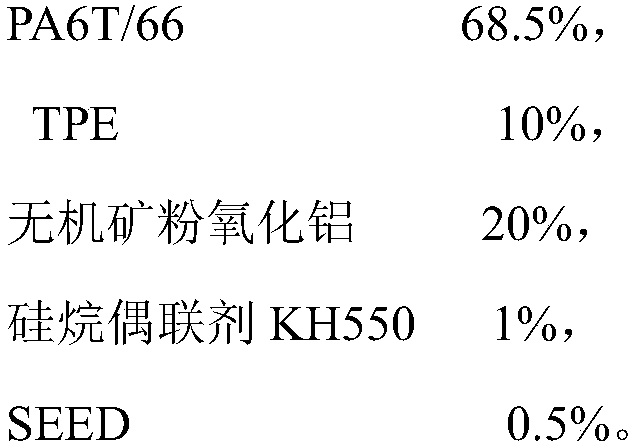

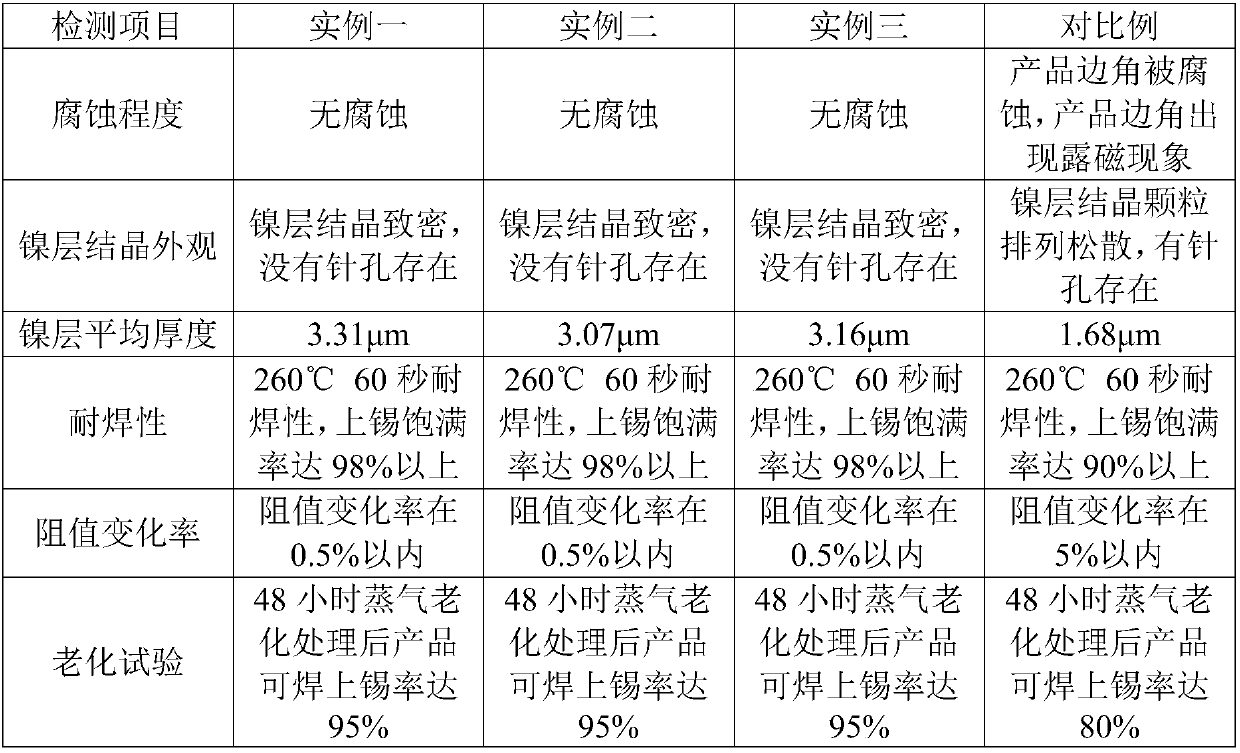

Aliphatic polyamide compound for environment-friendly electroplating and preparation method thereof

The invention provides an aliphatic polyamide compound for environment-friendly electroplating. The polyamide compound is prepared from the following raw materials in percentage by weight: 40 percentto 90 percent of aliphatic polyamide resin, 3 percent to 20 percent of a thermoplastic elastomer, 0 percent to 2 percent of a coupling agent and 0 percent to 40 percent of inorganic ore powder, wherein the melt index of the thermoplastic elastomer is higher than that of the aliphatic polyamide resin. The invention further provides a preparation method of the aliphatic polyamide compound for the environment-friendly electroplating; the aliphatic polyamide compound provided by the invention can be treated by utilizing an environment-friendly potassium permanganate roughening solution, so that the aliphatic polyamide compound is suitable for the development of the environment-friendly electroplating; after the electroplating is carried out, the electroplating binding force between the polyamide compound and the surface of an electroplating cladded layer can reach 10N or more; the utilization safety is ensured.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Zinc-nickel alloy electroplating process for metal surface

InactiveCN111058067AThe plating process is simpleImprove uniformityCellsElectrogalvanizationWater flow

The invention discloses a zinc-nickel alloy electroplating process for a metal surface, and relates to the technical field of electroplating, wherein the zinc-nickel alloy electroplating process comprises the steps of raw material inspection, chemical oil removal, primary water washing, electrochemical oil removal, secondary water washing, polishing, pickling, hanging, zinc-nickel alloy electroplating, quaternary water washing, drying and detection packaging. The chemical oil removal comprises the steps of treating grease on the surface of a metal component by alkali liquor with saponificationeffect to remove saponifiable grease; primary water washing comprises the steps of washing the metal component subjected to oil removal in the step S2 by flowing hot water flow. According to the zinc-nickel alloy electroplating process, based on the original process, the stirring device is additionally arranged, on one hand, the uniformity and speed of mass transfer in electroplating can be improved, on the other hand, the problem that the thickness of a plating layer is easily increased in a high-current area can be prevented; in addition, the electroplating process of the zinc-nickel alloyelectroplating process is simple, the electroplating effect of the metal surface is improved, and the electroplating cost is effectively reduced.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

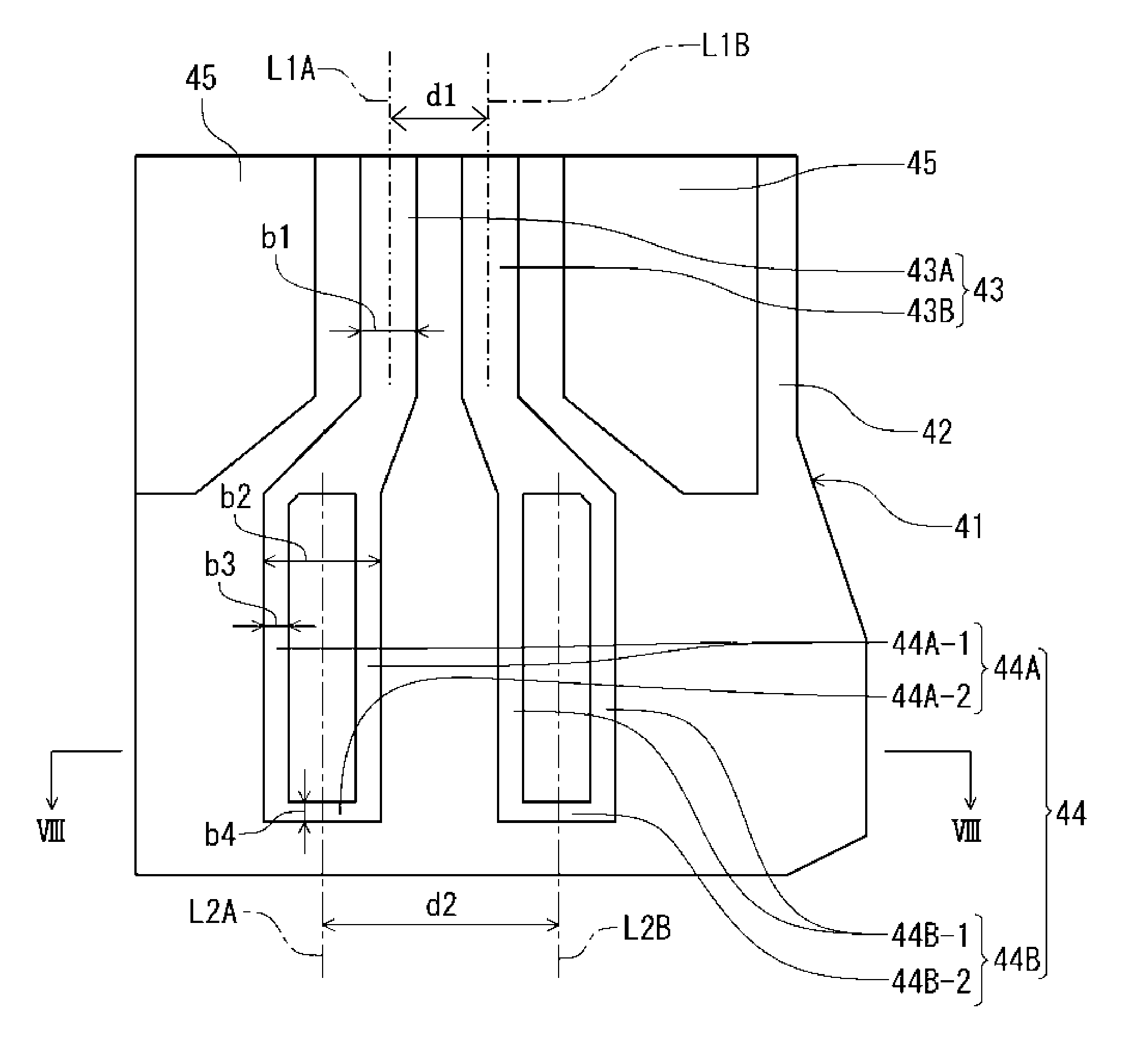

Electrical connector

ActiveUS9444160B2Reduce areaIncrease displacementCoupling device connectionsCross-talk/noise/interference reductionMating connectionElectrical connector

An electrical connector is to be connected to a mating connector. The electrical connector includes a circuit board member formed of an insulation plate member; and a holding member for holding the circuit board member. The circuit board member includes a connecting portion to be connected with a mating connector of the mating connector. The connecting portion includes a pair of conductive band portions and a first insulation region disposed between the conductive band portions.

Owner:HIROSE ELECTRIC GROUP

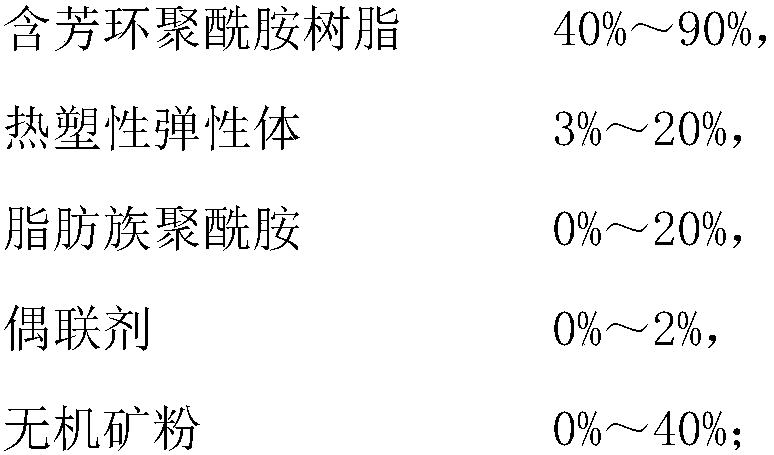

Polyamide compound for environment-friendly electroplating and preparation method thereof

ActiveCN107663372AImprove the plating effectImprove mechanical propertiesThermoplastic elastomerPolyamide

The invention provides a polyamide compound for environment-friendly electroplating. The polyamide compound is prepared from the following raw materials in percentage by weight: 40 percent to 90 percent of aromatic-ring-containing polyamide resin, 3 percent to 20 percent of a thermoplastic elastomer, 0 percent to 20 percent of aliphatic polyamide, 0 percent to 2 percent of a coupling agent and 0 percent to 40 percent of inorganic ore powder, wherein the melt index of the thermoplastic elastomer is higher than that of the aromatic-ring-containing polyamide resin and the aliphatic polyamide. Theinvention further provides a preparation method of the polyamide compound for the environment-friendly electroplating; the polyamide compound provided by the invention has better electroplating performance and mechanical property and can be treated by utilizing an environment-friendly potassium permanganate roughening solution, so that the polyamide compound is suitable for the development of theenvironment-friendly electroplating; after the electroplating is carried out, the electroplating binding force between the polyamide compound and the surface of an electroplating cladded layer can reach 10N or more; the utilization safety is ensured.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Nickel electroplating solution and application thereof

InactiveCN107587173ANot corrosiveImprove plating efficiencyJewellerySodium acetateSodium acetrizoate

The invention relates to a nickel electroplating solution. The nickel electroplating solution is prepared from the following components by mass concentration: 10 to 20 g / L of main salt, 40 to 50 g / L of a buffer agent, 300 to 500 g / L of conductive salt, 0.01 to 0.1 g / L of a stress relieving agent and 2 to 20 g / L of a stabilizing agent, wherein the main salt is one or more of nickel aminosulfonate,nickel sulfate, nickel chloride and nickel oxalate; the conductive salt is one or more of sodium sulfamate, sodium sulfate, sodium chloride and sodium acetate. The pH value of the nickel electroplating solution is 6.5 to 7.5. The nickel electroplating solution disclosed by the invention has the advantages of no corrosiveness, high electroplating efficiency and environment-friendly formula; a nickel layer obtained by electroplating of the nickel electroplating solution is uniform, compact, high in hardness and anti-corrosion; the nickel electroplating solution is particularly suitable for nickel electroplating for sheet elements.

Owner:广东羚光新材料股份有限公司

Preparation method of alkaline zincate zinc-plating brightener

The invention discloses a preparation method of an alkaline zincate zinc-plating brightener and relates to a preparation method of a brightener, and the preparation method is used for solving the problems that the existing zincate zinc-plating brightener is narrow in bright current density range, dark in plating layer and rough in surface. The preparation method comprises the following steps of: adding 12-15g of 33wt% dimethylamine into a four-neck bottle; then heating to 23 DEG C, completely dropwise adding 12-15g of epichlorohydrin into the four-neck bottle at the speed of 3-4s / drop; after dropwise adding is finished, heating to 25 DEG C-30 DEG C, reacting for 1.5-2.5 hours, and completely dropwise adding 0.1-1g of tetraethylenepentamine into the four-neck bottle; and after dropwise adding is finished, heating to 65 DEG C-75 DEG C, and reacting for 4-5 hours, so as to obtain the alkaline zincate zinc-plating brightener. The current density of the alkaline zincate zinc-plating brightener disclosed by the invention is 0.5-10.73A / dm<2>. The alkaline zincate zinc-plating brightener disclosed by the invention is applied to the field of zinc electroplating.

Owner:HARBIN UNIV OF SCI & TECH

Surface palladium-free environment-friendly low-cost activated electroplating process

InactiveCN111349957AEasy to useLong storage timeLiquid/solution decomposition chemical coatingCopper platingEconomic benefits

The invention provides a surface palladium-free environment-friendly low-cost activated electroplating process. The process comprises the following steps of S1 pretreatment; S2 degumming; S3 copper replacement; S4 acid copper plating; S5 chromium plating; and S6 drying. The electroplating process is good in degreasing and activating effects, short in copper-plating and chromium-plating time, stable in copper-plating and chromium-plating effects, high in electroplating efficiency, simple and convenient to operate, stable in process performance, low in electroplating cost, good in economic benefit, nontoxic and environment-friendly in raw materials used in the electroplating process and environment-friendly.

Owner:太仓市金鹿电镀有限公司

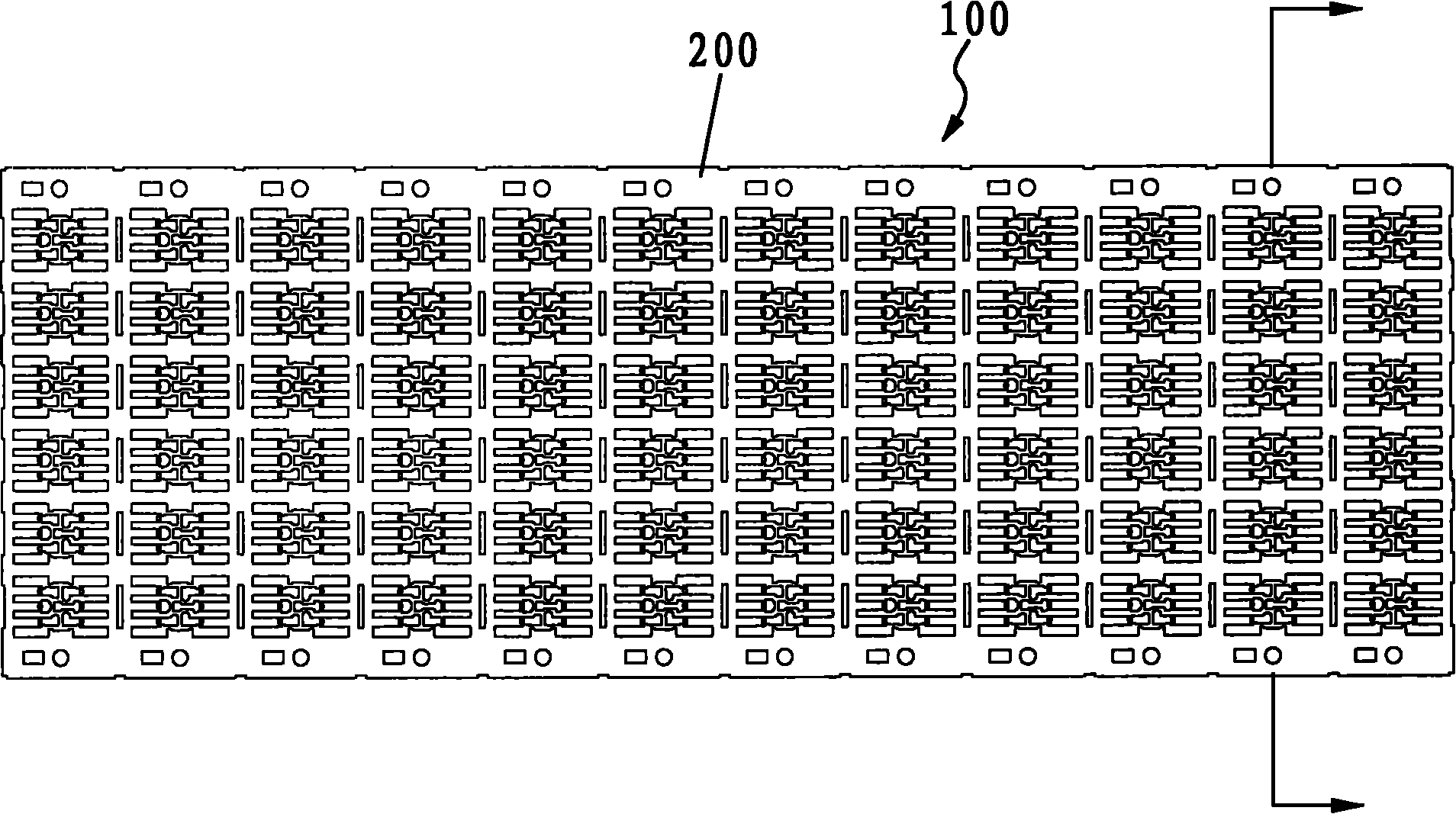

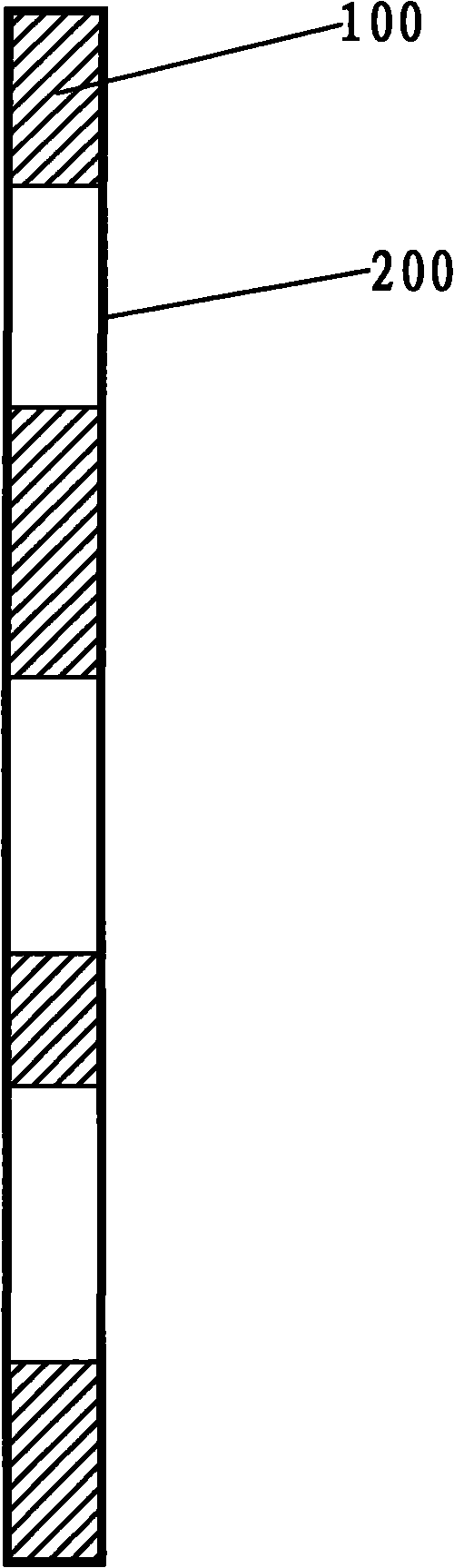

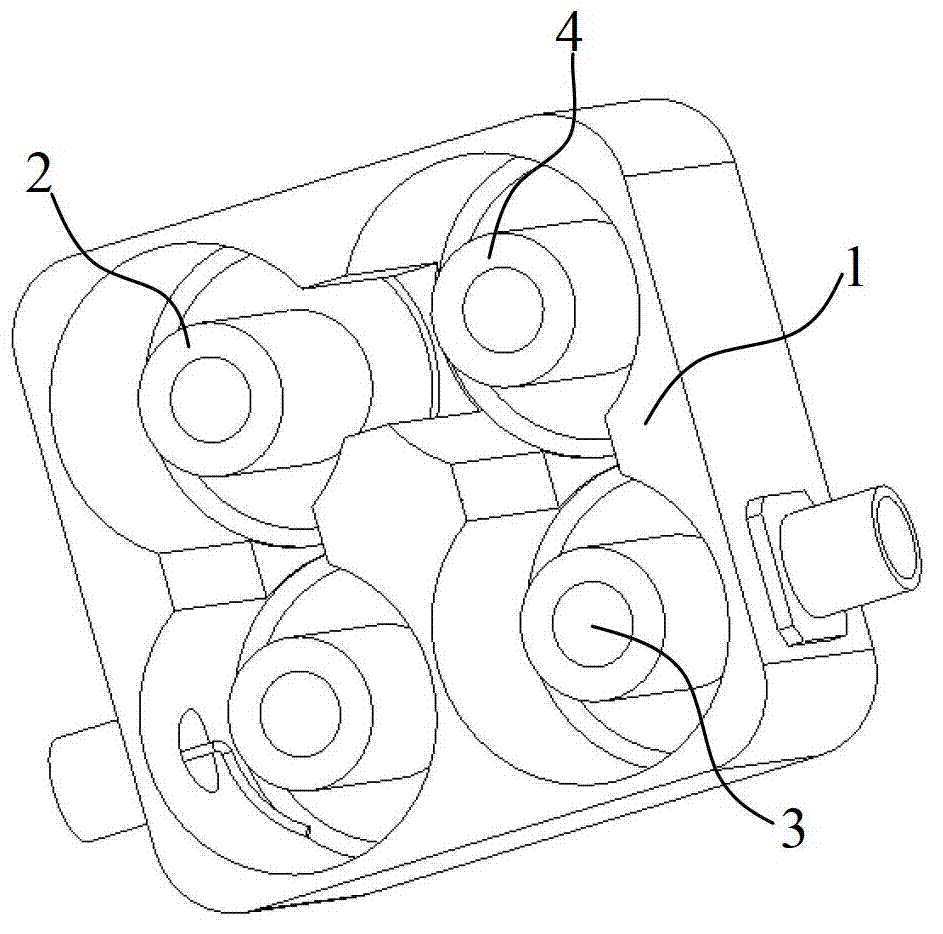

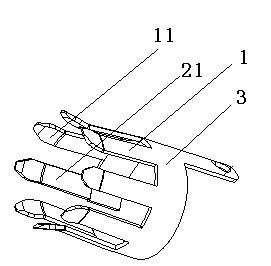

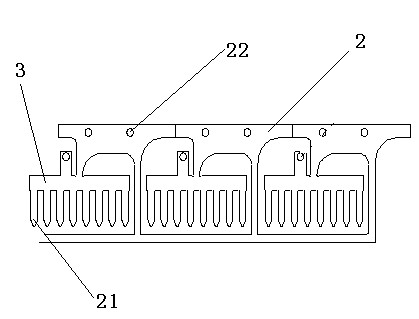

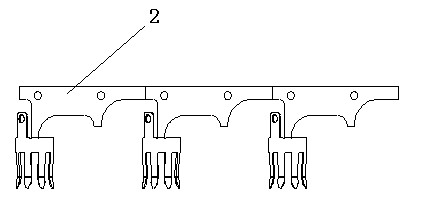

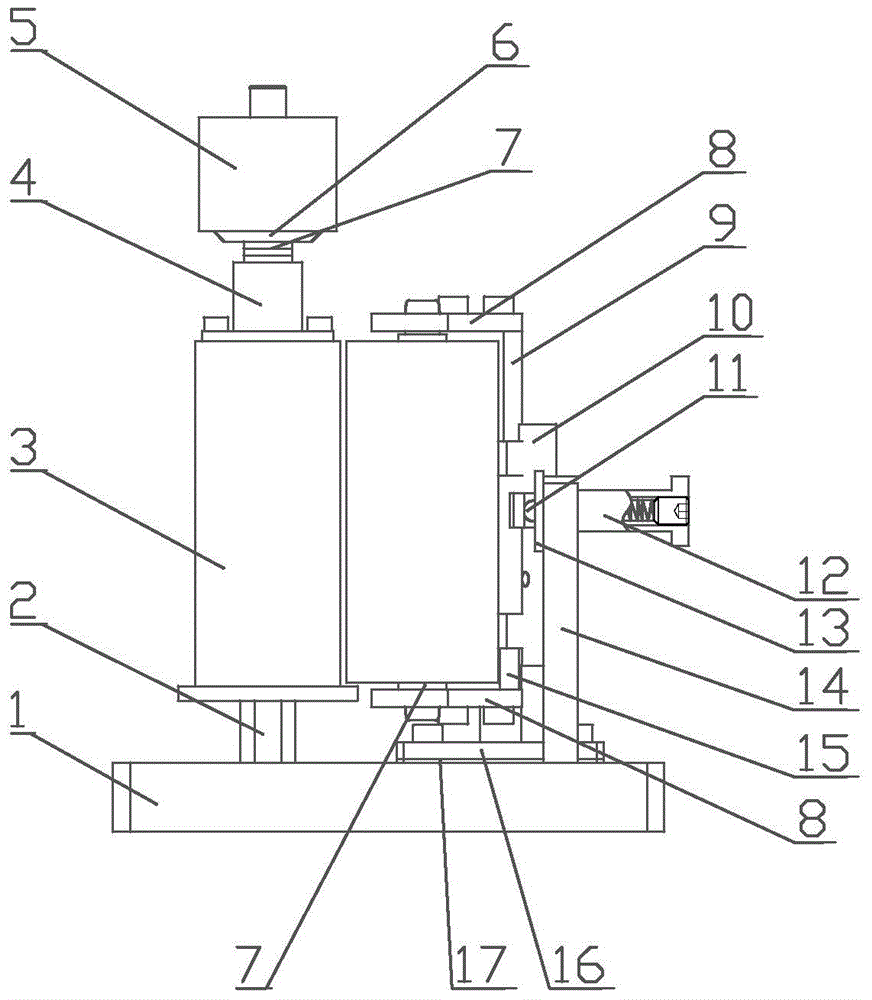

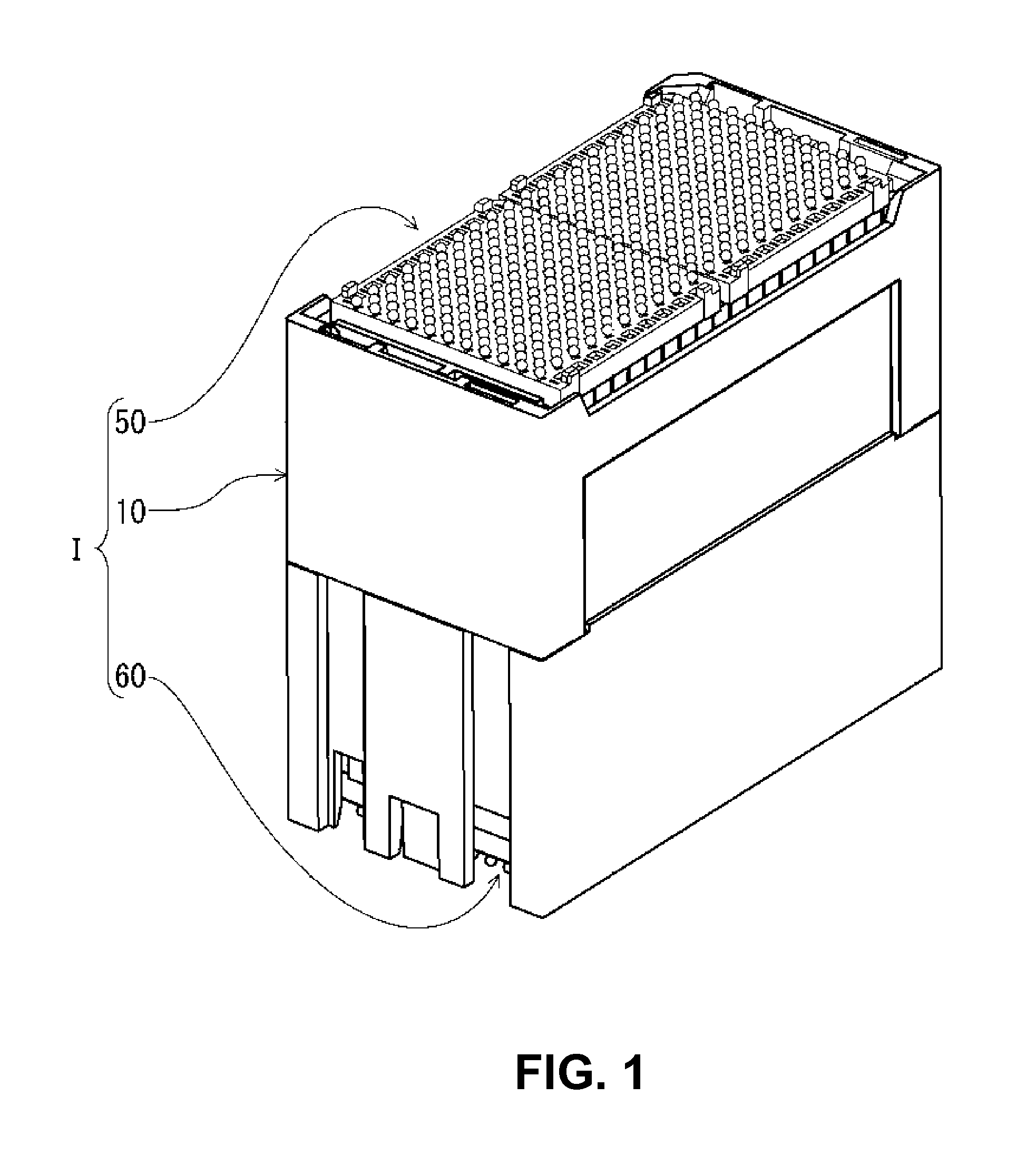

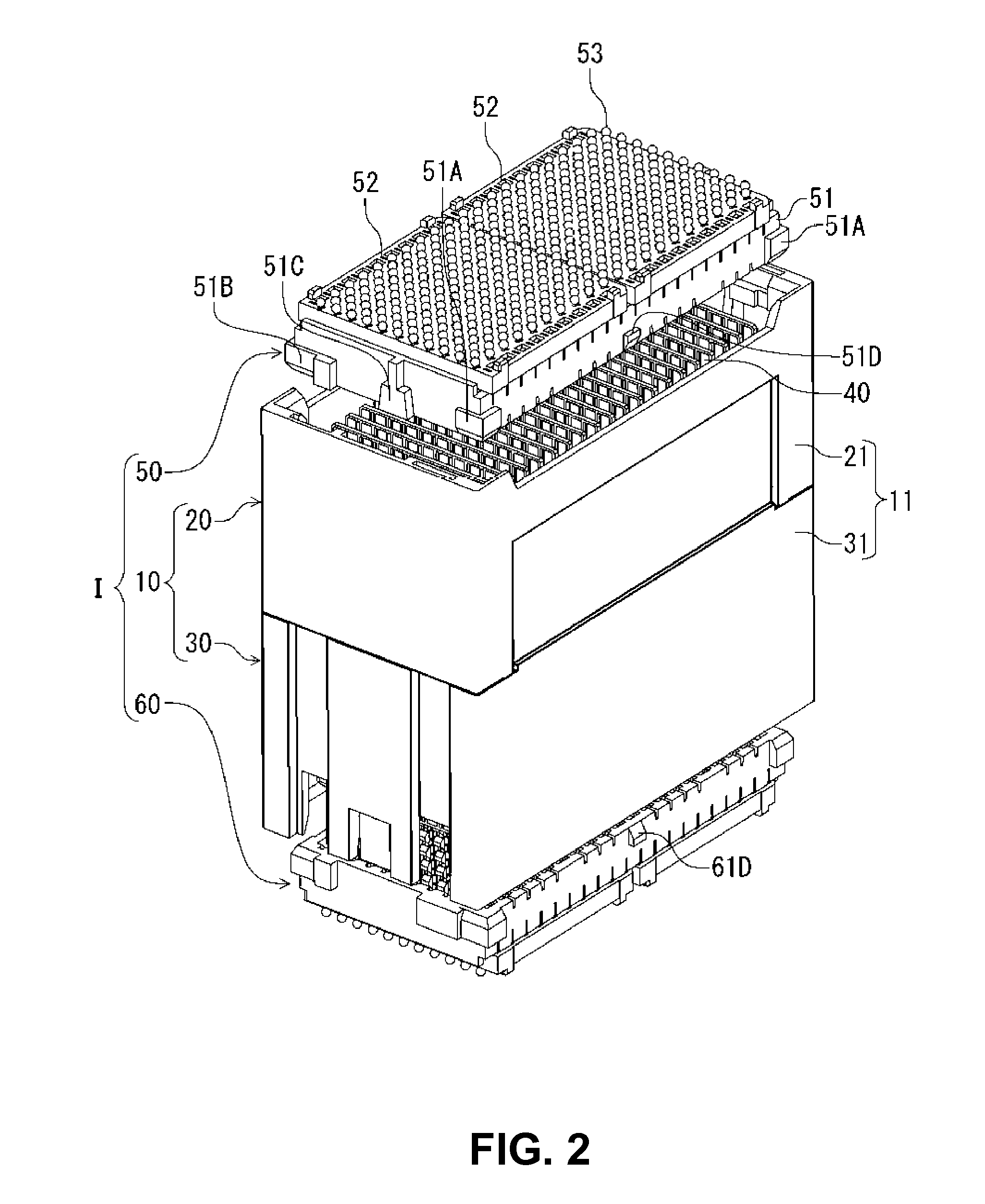

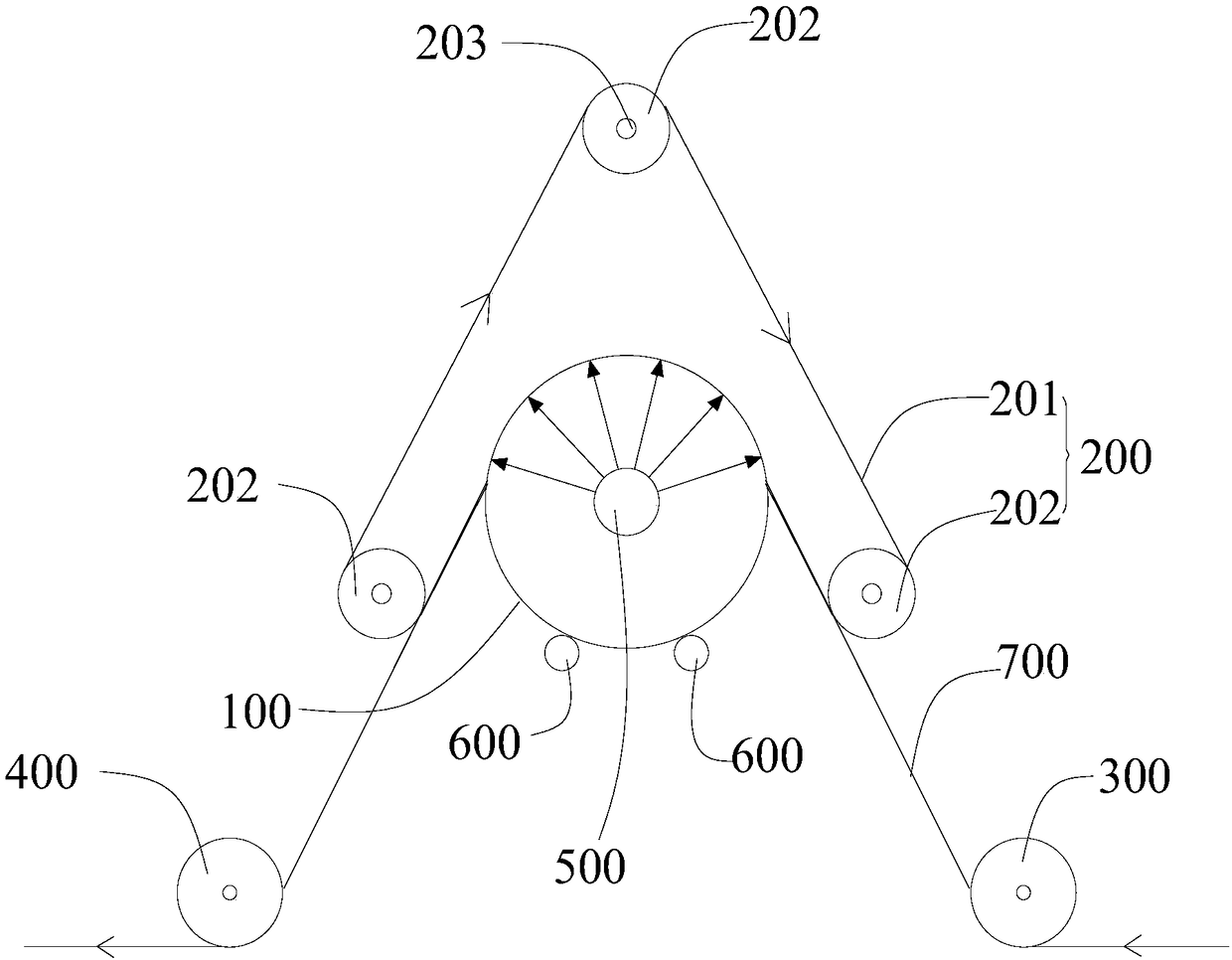

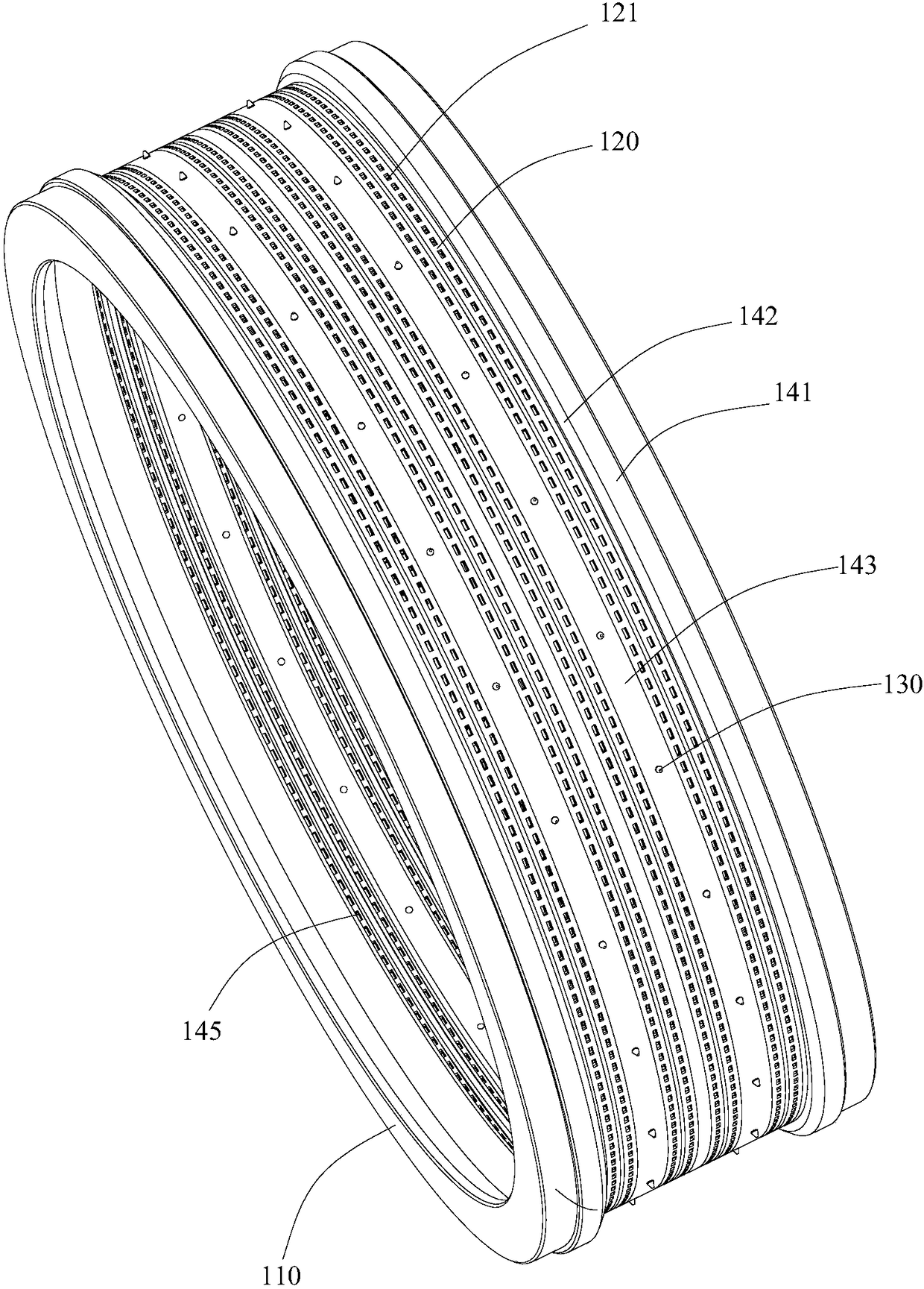

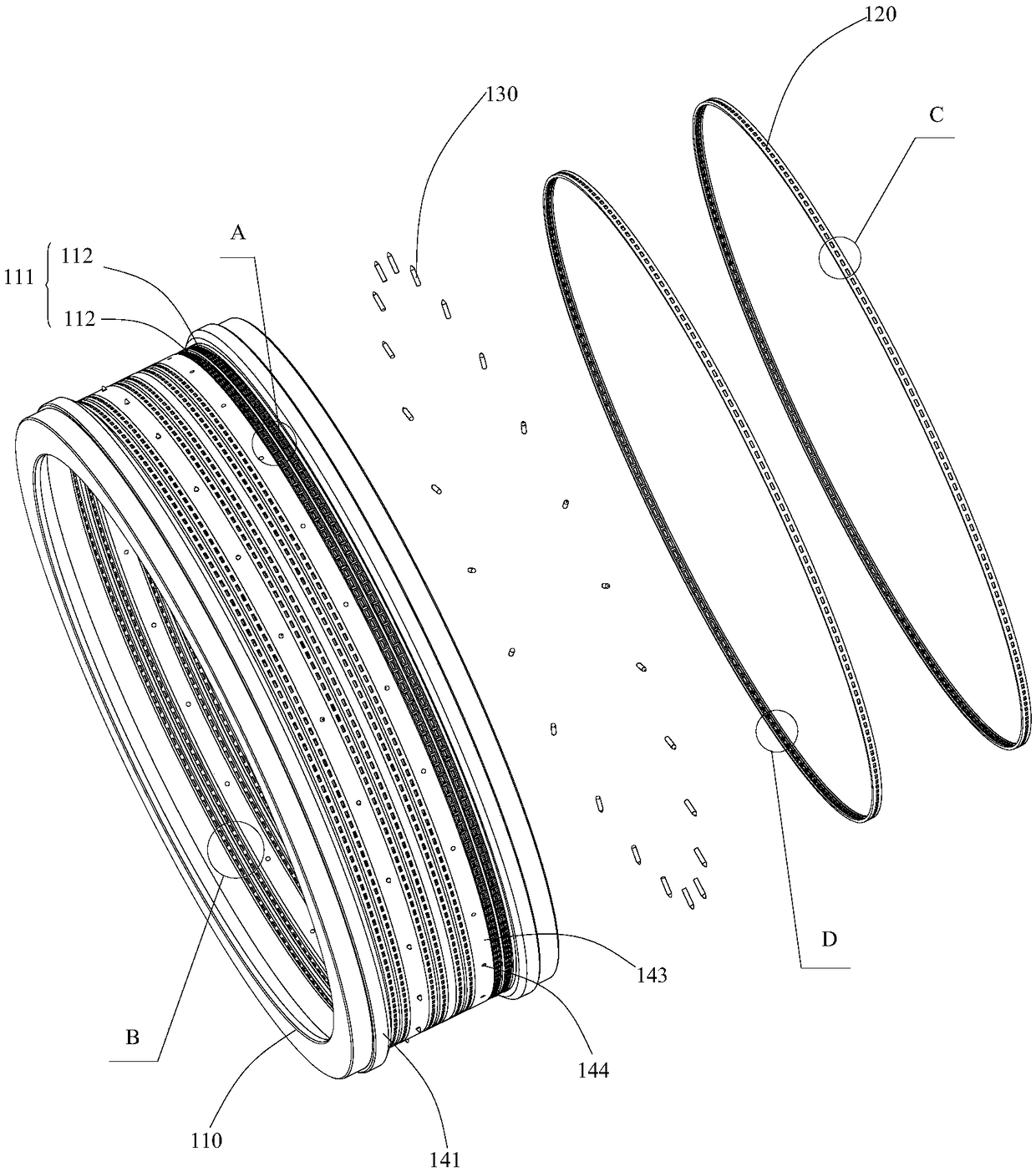

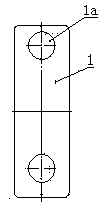

Multi-row lead frame electroplating equipment

PendingCN108385145AImprove plating efficiencyPrevent leakageElectrolysis componentsLead frameElectroplating

The invention relates to multi-row lead frame electroplating equipment. The multi-row lead frame electroplate equipment comprises a mold, a pressing device, a sheet feeding wheel, a sheet dischargingwheel and an anode nozzle arranged in the mold. The mold comprises a mold body, a plurality of mold belts and at least two rows of mold nail groups, wherein the mold body is rotatable, the mold beltsare arranged on the outer peripheral wall of the mold body, and the mold nail groups are arranged on the outer peripheral wall of the mold body at intervals. The mold body is provided with a pluralityof groups of electroplating areas which can simultaneously complete electroplating of a multi-row lead frame, thereby effectively improving the electroplating efficiency of the lead frame and reducing the electroplating cost. The pressing device presses the multi-row lead frame on the periphery of the mold, mold pins are used for penetrating through positioning holes in the multi-row lead frame to position the lead frame, so that the lead frame can be tightly adhered to the mold body to prevent electroplating solution from leaking, and the electroplating effect is good.

Owner:ACKOTEC ZHONGSHAN ELECTRONICS PARTS

Hard chromium plating process of hard film mould of rubber component

The invention discloses a hard chromium plating process of a hard film mould of a rubber component, comprising the steps of pre-cleaning, activation, hard chromium plating, post-cleaning, deoxidization and detection of the hard film mould. The hard chromium plating process is characterized in that plating solution chemical components subject to the hard chromium plating comprises the following contents: 200-250g / L of chromium trioxide, 1-1.2g / L of SO4<2-> ion and 3-4g / L of Cr<3+> ion; the temperature of the plating solution in electro-plating is between 55 DEG C and 60 DEG C, the concentrationof anode current is between 25A / dm<2> and 45A / dm<2> and the electro-plating time is between 25 minutes and 40 minutes; and the anode material for the hard chromium plating selects lead-tin alloy materials which contain 7-10 percent of tin. The invention ensures that a groove of the hard film mould has even hard chromium plating, improves the production efficiency and prolongs the service life ofthe hard film mould.

Owner:安徽宁国中鼎模具制造有限公司

Silvering touch finger electroplating hanger of circuit breaker

ActiveCN103730296AReduce plating costEnsure plating efficiencyElectrolysis componentsElectric switchesElectricityElectroplating

The invention relates to a silvering touch finger electroplating hanger of a circuit breaker. The silvering touch finger electroplating hanger of the circuit breaker is characterized in that an electroplating support, an electric conductive assembly and a shielding assembly are included; the electric conductive assembly comprises a stainless steel electric conductive substrate and a plurality of sets of touch finger electric conductive contact sockets which are distributed in the horizontal direction and are arranged on the stainless steel electric conductive substrate; the shielding assembly comprises an insulation shielding plate and insulation shielding plates arranged on the two side faces; all the sets of the touch finger electric conductive contact sockets are respectively provided with a rubber shielding bar and a pressing plate in the horizontal direction. The silvering touch finger electroplating hanger of the circuit breaker has the advantages that circuit breaker touch fingers are placed on all the sets of the touch finger electric conductive contact sockets, the electroplating support, the stainless steel electric conductive substrate, metal springs of the touch finger electric conductive contact sockets and the touch fingers are electrically connected to form a cathode, the cathode is matched with a silvering solution which is used as an anode in an electroplating pool so that electroplating can be realized, then a silvering layer is plated in a non-rubber shielding bar area, local electroplating can be achieved, electroplating cost is lowered, electroplating efficiency can be guaranteed, and the problem of production efficiency restriction caused by local protection impregnation is solved.

Owner:JIANGSU RUGAO HIGH VOLTAGE ELECTRIC APP

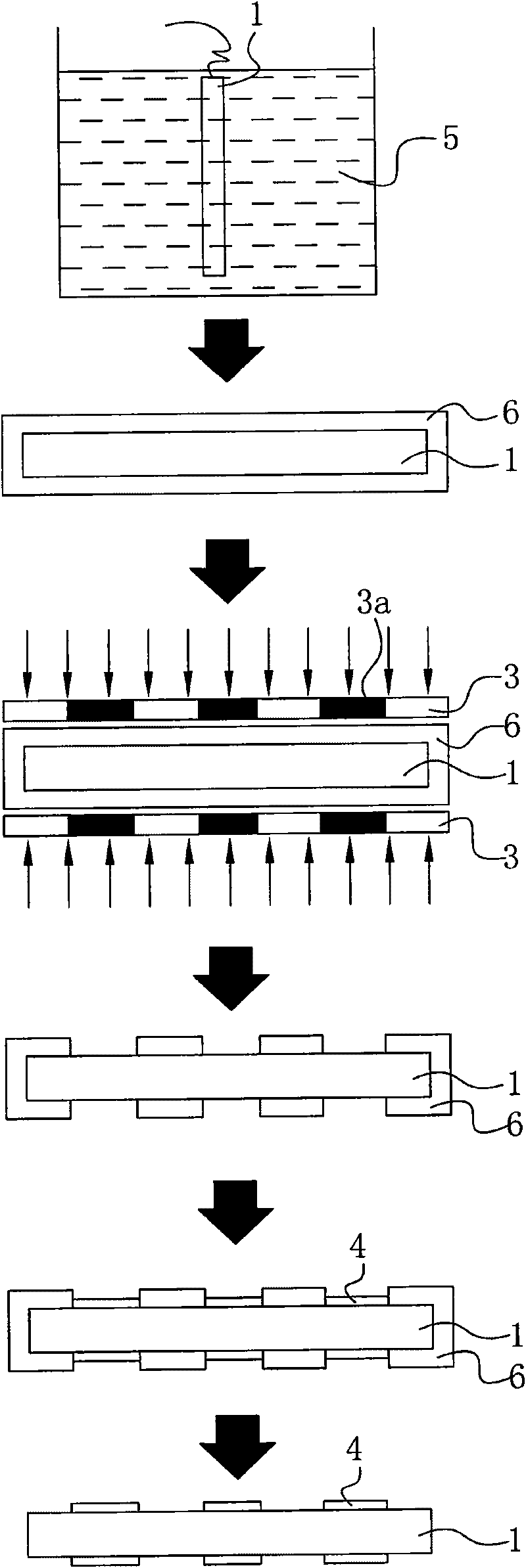

Method for electroplating lead frame

ActiveCN101707185AGuarantee the quality of platingLow priceSemiconductor/solid-state device manufacturingElectrolytic organic material coatingBiochemical engineeringLead frame

The invention discloses a method for electroplating a lead frame, which comprises the following steps: (1) preparing a wet-film solution (5); (2) electroplating a film layer on the lead frame; (3), cleaning and drying the lead frame; (4) exposing the lead frame; (5) developing the lead frame; (6) electroplating a metal layer on the lead frame; (7) performing film removal treatment; and (8) cleaning and air-drying the lead frame. Compared with the prior art, the method has the advantages that: because a mask treatment is performed on the lead frame by using an electroplated film before the metal layer is plated on the lead frame, the side edge of the lead frame is also electroplated with a mask, a metal plating layer cannot be plated on the side edge of the lead frame when the metal layer is electroplated on the lead frame, and the electroplating quality of the lead frame is ensured; and simultaneously the price of the film is lower than that of a dry film. Thus, the method has a low electroplating cost, is favorable for batch production and has a high yield of finished products.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com