Nickel electroplating solution and application thereof

A technology of nickel electroplating solution and conductive salt, which is applied in jewelry, etc., can solve the problems of small metallized parts, rough crystallization of nickel layer, long plating time, etc., to reduce difficulty, good toughness and ductility, and bright and full appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

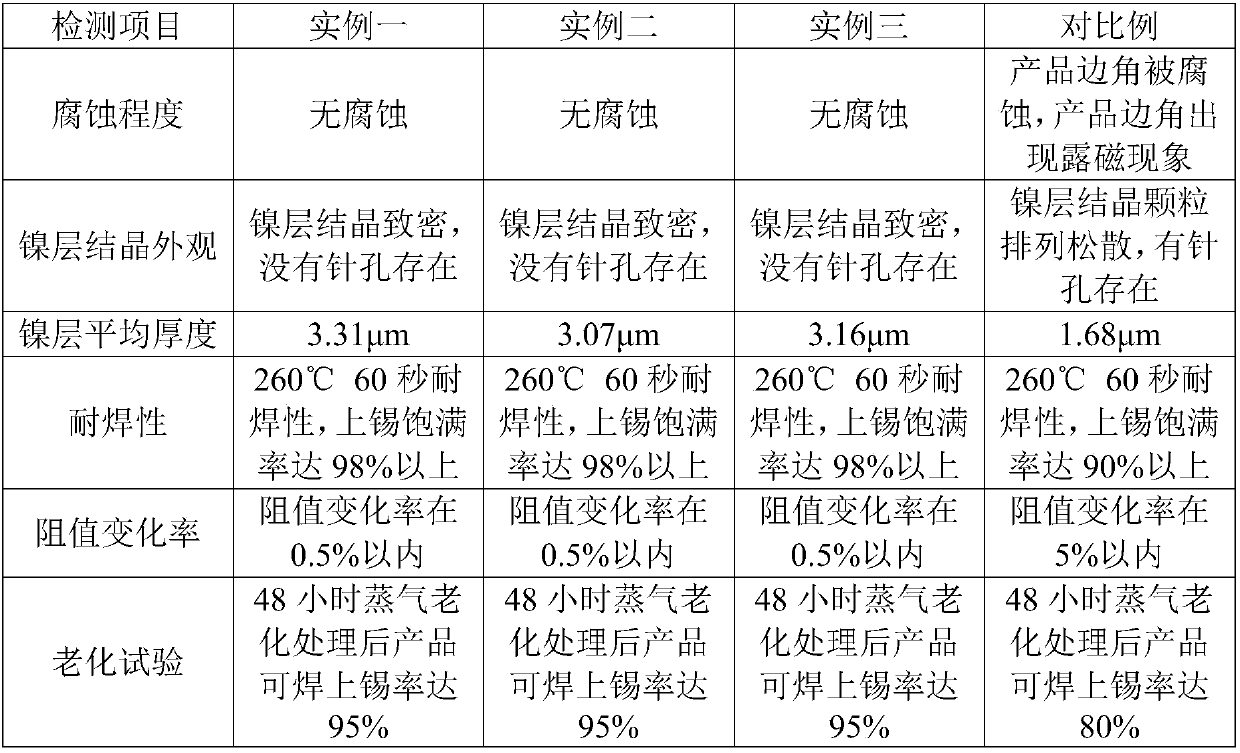

Examples

Embodiment 1

[0022] The nickel electroplating solution of the present embodiment comprises the component of following mass concentration: nickel sulfate 15g / L, sodium tetraborate 40g / L, sodium sulfate 300g / L, bisbenzenesulfonimide 0.1g / L, ethylenediaminetetraacetic acid Disodium 10g / L. The pH value of the nickel electroplating solution is 7.0.

[0023] The nickel electroplating solution is prepared by conventional mixing method from nickel sulfate, sodium tetraborate, sodium sulfate, bisbenzenesulfonimide, disodium edetate and deionized water.

[0024] At a plating temperature of 50°C and a plating current density of 0.4A / dm 2 1. Under the electroplating condition that the electroplating time is 100min, use the nickel electroplating solution to perform nickel electroplating treatment on the 0201 type chip resistor.

Embodiment 2

[0026] The nickel electroplating solution of the present embodiment comprises the component of following mass concentration: nickel sulfamate 20g / L, boric acid 45g / L, sodium sulfamate 400g / L, sodium o-benzoylsulfonimide 0.05g / L, Sodium potassium tartrate 20g / L. The pH value of the nickel electroplating solution is 7.5.

[0027] The nickel electroplating solution is prepared by conventional mixing method from nickel sulfamate, boric acid, sodium sulfamate, sodium o-benzoylsulfonimide, potassium sodium tartrate and deionized water.

[0028] At a plating temperature of 40°C and a plating current density of 0.6A / dm 2 1. Under the electroplating condition that the electroplating time is 80 minutes, use the nickel electroplating solution to perform nickel electroplating treatment on the 0201 type chip resistor.

Embodiment 3

[0030] The nickel electroplating solution of the present embodiment comprises the component of following mass concentration: nickel chloride 10g / L, sodium oxalate 45g / L, sodium chloride 400g / L, sodium propyne sulfonate 0.05g / L, sodium alginate 20g / L L. The pH value of the nickel electroplating solution is 6.5.

[0031] The nickel electroplating solution is prepared from nickel chloride, sodium oxalate, sodium chloride, sodium propyne sulfonate, sodium alginate and deionized water through a conventional mixing method.

[0032] At a plating temperature of 60°C and a plating current density of 0.2A / dm 2 1. Under the electroplating condition that the electroplating time is 120min, use the nickel electroplating solution to perform nickel electroplating treatment on the 0201 type chip resistor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com