Patents

Literature

100results about How to "Eco-friendly formula" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl wood-plastic composite and method for preparing same

InactiveCN101747641ALow cost of preparationBroad application prospectsPre treatmentPolyvinyl polymer

The invention discloses polyvinyl wood-plastic composite which comprises the following components: 100 portions of wood fiber powder, 1-3 portions of stearic acid, 20-30 portions of waste polyethylene plastic, 3-6 portions of coupling agent, 4-10 portions of lubricant, 0.1-1 portion of ultraviolet resistant agent and 1-3 portions of coloring agent. The surface of the wood fiber powder is preliminarily modified by the stearic acid so that a dense hydrophobic thin film is formed on the surface of wood fiber to ensure that the wood fiber is more compatible with the polyethylene polymer, the dispersion of the wood fiber in the polyethylene polymer is promoted, the polyvinyl wood-plastic composite has excellent comprehensive performance and good processing performance, and the product made from the polyvinyl wood-plastic composite is superior to the domestic similar product in appearance quality and physiochemical performance. In addition, the formula of the polyvinyl wood-plastic composite is more environmental-friendly than the prior art, the cost spent in preparing the polyvinyl wood-plastic composite is lower, and the polyvinyl wood-plastic composite is suitable for industrial production, meets the market demand and has broad application prospect.

Owner:SHANGHAI BESTON PLASTICS

Ionic crosslinking thermoplastic elastic body and preparation method thereof

ActiveCN102532770ACarboxylation transitionSimple preparation processMetal chlorideThermoplastic elastomer

The invention discloses an ionic crosslinking thermoplastic elastic body and a preparation method of the ionic crosslinking thermoplastic elastic body. The ionic crosslinking thermoplastic elastic body is prepared from the following ingredients in parts by mass: 100 parts of rubber, 2 to 20 parts of organic carboxylic acid, 0.1 to 2 parts of initiating agent and 2 to 30 parts of metallic oxide, metal hydroxide and / or metal chloride. The ionic crosslinking thermoplastic elastic body prepared by the method has good mechanical performance, the tensile strength of the ionic crosslinking thermoplastic elastic body at least reaches 6MPa, the tension fracture elongation at least reaches 700 percent, the Shore hardness (A) at least reaches 63, and the differential scanning calorimetry (DSC) glass-transition temperature can reach 10 DEG C. The preparation process of the ionic crosslinking thermoplastic elastic body is simple, and the preparation process and the product are environment-friendly, and the ionic crosslinking thermoplastic elastic body is expected to be widely applied to the fields of shoes, sealing rings, automobiles, oil transmission pipelines and the like.

Owner:FUJIAN NORMAL UNIV

Wear-resistant rubber sole and preparation method thereof

The invention discloses a wear-resistant rubber sole. The wear-resistant rubber sole comprises the following raw materials in parts by weight: 30 parts of natural rubber, 30 parts of butadiene styrene rubber, 150 parts of butadiene rubber, 150 parts of white carbon black, 90 parts of oil, 12 parts of zinc carbonate, 2.8 parts of stearic acid, 3 parts of DM, 0.75 parts of M, 0.26 parts of TMTM, 3.8 parts of insoluble sulfur, 2 parts of an anti-aging agent, 1.5 parts of anti-fogging agent, 3 parts of tackifying resin and 14 parts of PEG. The invention further provides a preparation method of the wear-resistant rubber sole. Compared with the prior art, the wear-resistant rubber sole has the advantages as follows: the formulation is environment-friendly; the amount of various components can be adjusted; through the addition of the anti-fogging agent, a protective film is formed on the surface of the wear-resistant rubber sole, thus effectively preventing a blooming phenomenon and delaying the aging of the rubber sole; through the addition of the butadiene rubber as well as through reasonable matching of the natural rubber, the butadiene rubber and the butadiene styrene rubber, not only is the wear resistance improved, but also the cost is reduced, thus obtaining good physical properties and economic benefits.

Owner:ANHUI HONGXIANG SHOES

Water-based thermosetting glass printing ink and preparation method thereof

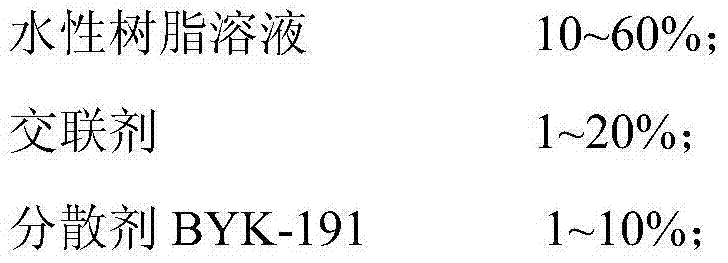

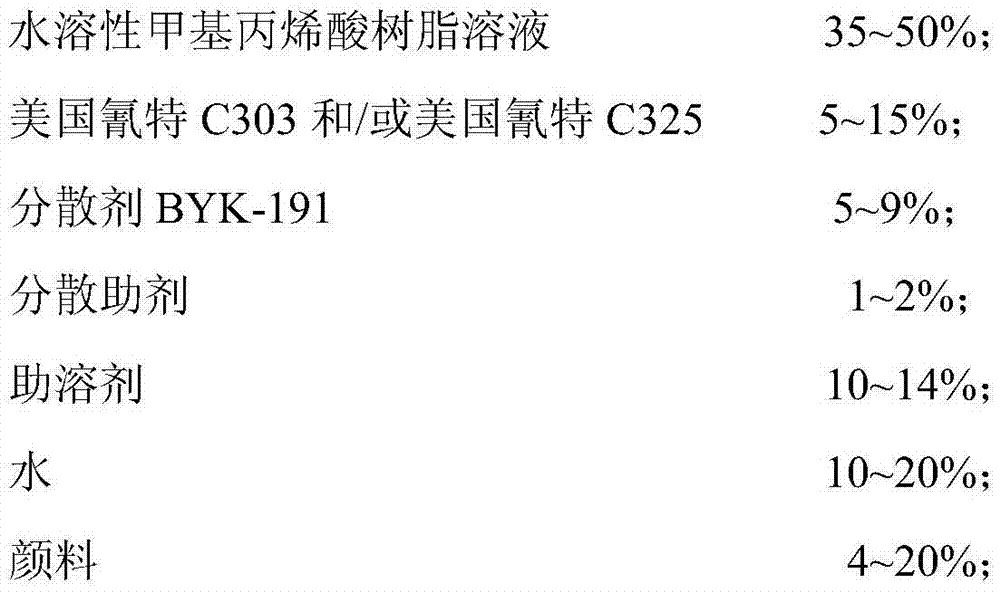

The invention discloses a water-based thermosetting glass printing ink and a preparation method thereof. The ink is composed of a water-based resin solution, a crosslinking agent, a dispersing agent BYK-191, an assistant, water and a pigment. The preparation method comprises the following steps: mixing part of the water-based resin solution with the dispersing agent BYK-191, assistant and pigment, and carrying out shear dispersion to obtain a slurry with the particle size of not greater than 20 micrometers; and adding the rest of water-based resin solution, assistant, crosslinking agent and water into the slurry, and sufficiently stirring. The preparation method is simple and cheap in raw materials; and the prepared water-based thermosetting glass printing ink has the characteristics of low cost, environment friendliness, favorable adhesive force with the glass substrate, favorable alcohol resistance, favorable water resistance, favorable abrasion resistance, high hardness and the like.

Owner:徐立新

Quintupling hyperconcentrated liquid detergent for garment

ActiveCN101671605AImprove washing effectGood value for moneyNon-ionic surface-active compoundsDetergent compounding agentsBleachHuman health

The invention relates to a quintupling hyperconcentrated liquid detergent for a garment, which is a neutral prescription, dose not damage skin and the garment, has high detergency and excellent hard water resistance, removes various spots, has no phosphorus and sodium alkyl benzene sulfonate, protects the environment and the human health, is used for low-temperature washing, is easy to wash and bleach and saves energy and water. The quintupling hyperconcentrated liquid detergent for the garment comprises the following raw materials in parts by weight: 30-50 fatty alcohol-polyoxyethylene ether,10-25 fatty acid methyl ester sodium sulfonate, 5-25 solvent, 0.1-2.0 enzymic preparation, 2-10 solubilizer, 0.1 Kathon preservative, 1.0-5.0 triethanolamine, a small amount of citric acid and essence and 1-17 water.

Owner:XIAN KAIMI

Insole of rubber foamed shoe and preparation method thereof

InactiveCN104817732AEasy to reboundEco-friendly formulaSolesDomestic footwearParaffin waxPolymer science

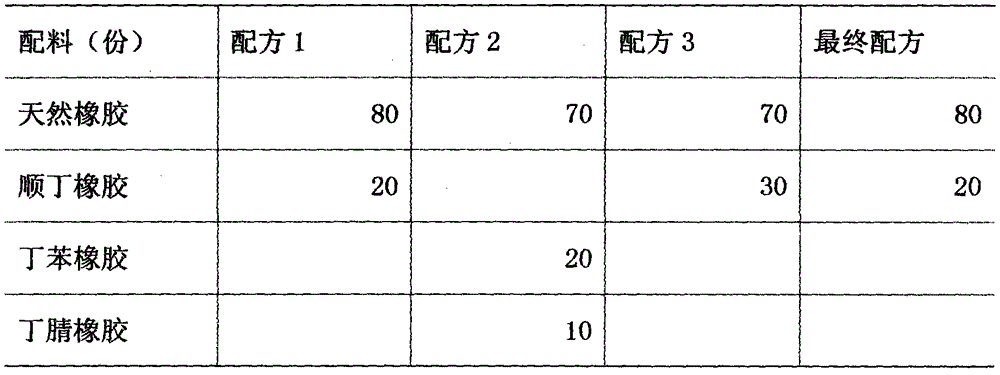

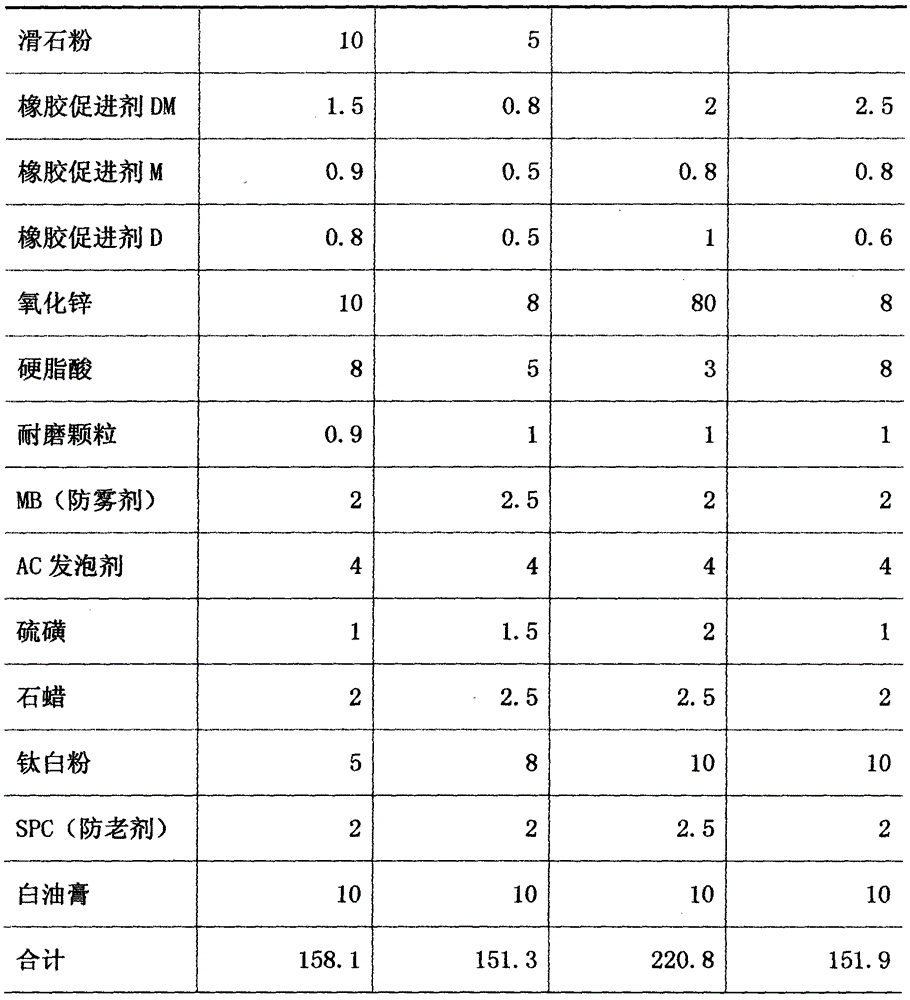

The invention discloses an insole of a rubber foamed shoe and a preparation method thereof. The insole comprises the following raw materials in parts by weight: 70-80 parts of natural rubber, 0-30 parts of cis-polybutadiene, 0.8-2.5 parts of rubber accelerator DM, 0.5-0.9 part of rubber accelerator M, 0.5-1 part of rubber accelerator D, 8-80 parts of zinc oxide, 3-8 parts of stearic acid, 0.9-1 part of wearproof particles, 2-2.5 parts of antifogging agent MB, 4-5 parts of foaming agent AC, 1-2 parts of sulfur, 2-2.5 parts of paraffin, 5-10 parts of titanium dioxide, 2-2.5 parts of anti-aging agent SPC and 10-15 parts of white factice. The preparation method comprises the following steps: putting the raw materials in the formula in a rubber mixing mill to be mixed for 30-35 minutes, thus obtaining a rubber foamed sheet; putting the prepared rubber foamed sheet in a bottom die, fixing a shoe last in a corresponding position on an upper die, sleeving the shoe last with an upper and carrying out foaming molding at a certain temperature for a certain time; removing the shoe last and the die, thus preparing the integrally formed rubber foamed shoe. The insole and the preparation method have the beneficial effects that the formula is environment-friendly; the process is simple; the shoe sole has good resilience; glue is not needed during one-time forming; the insole is free from debonding at high temperature and free from slipping at low temperature, is not broken, has light whole weight and is comfortable to wear.

Owner:郭萧

Preparation method of bacteriostatic softening agent for aged hard and dry leather

The invention relates to a preparation method of a bacteriostatic softening agent for aged hard and dry leather. The preparation method specifically comprises the following steps: adding phosphorus pentoxide into wool fat, and heating and stirring to modify; then, titrating to neutral by sodium hydroxide liquor and drying to obtain phosphorylated modified wool fat; and finally compounding wool fat with tween-80, 2-octyl-4-isothiazolin-3-one, tea saponins, ethanol and deionized water to prepare a bacteriostatic softening agent product. The preparation method provided by the invention has the advantages of multiple functions, remarkable effect, harmlessness and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of antibacterial and antifungal fat-liquoring agent suitable for aged leather

ActiveCN103571981AImprove antibacterial propertiesGood effectLeather impregnationAcetic acidSulfite salt

The invention relates to a preparation method of an antibacterial and antifungal fat-liquoring agent suitable for aged leather. The preparation method comprises the following specific steps: adding lactic acid and hydrogen peroxide into soybean oil, heating and mixing to carry out modification, then carrying out titration on a modified mixture by virtue of a sodium hydroxide solution until the mixture is neutral, and drying the mixture to obtain lactated modified soybean oil; compounding the lactated modified soybean oil, span-80, 2-octyl-4-isothiazoline-3-ketone, sodium sulfite, ethanol, acetic acid and deionized water to prepare an antifungal fat-liquoring agent finally. The preparation method has the advantages of versatility, obvious effect, harmlessness and the like.

Owner:ZHEJIANG SCI-TECH UNIV

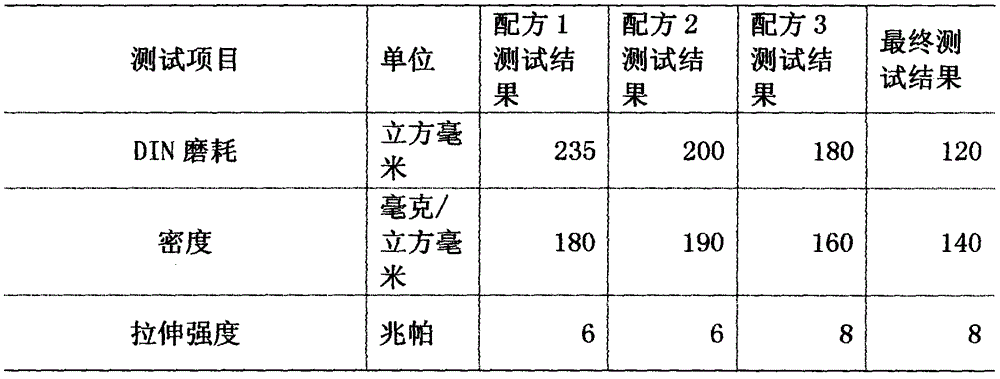

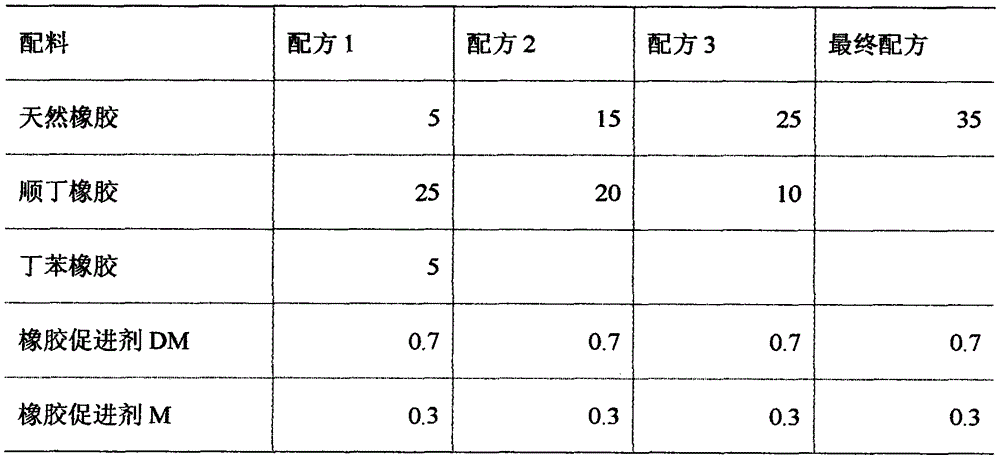

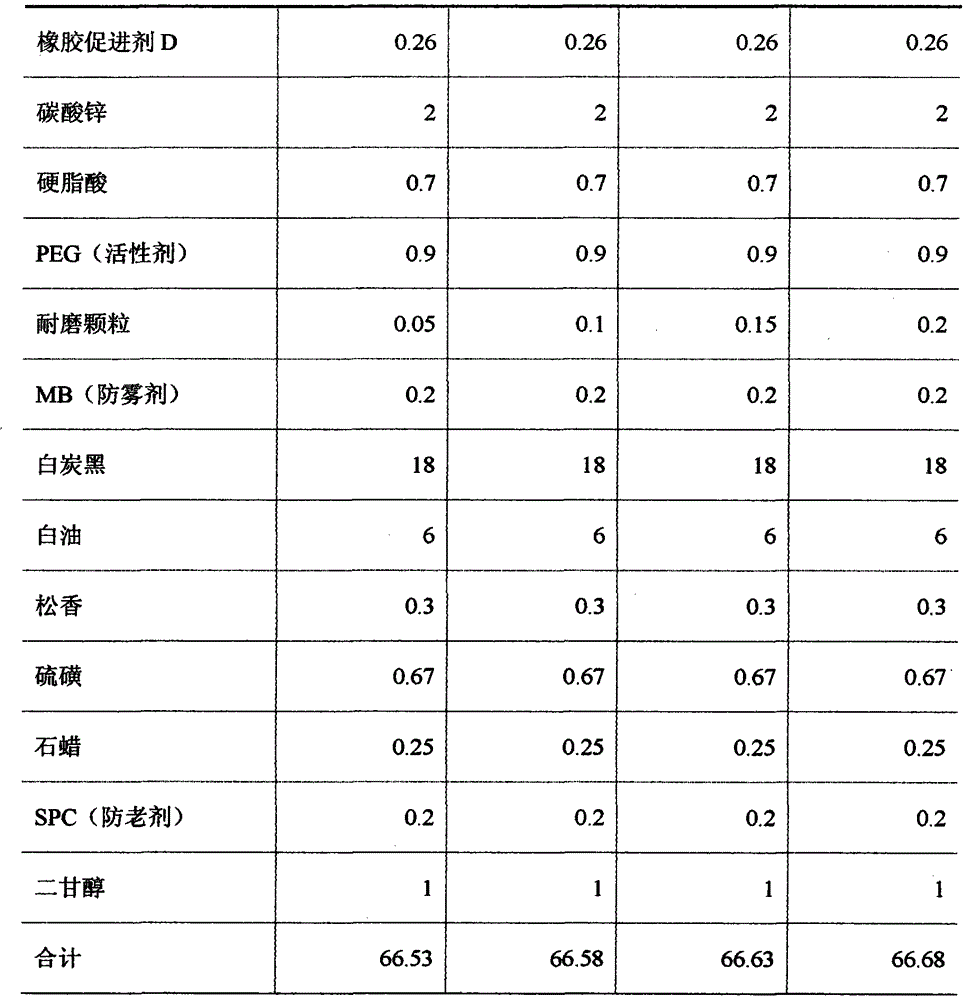

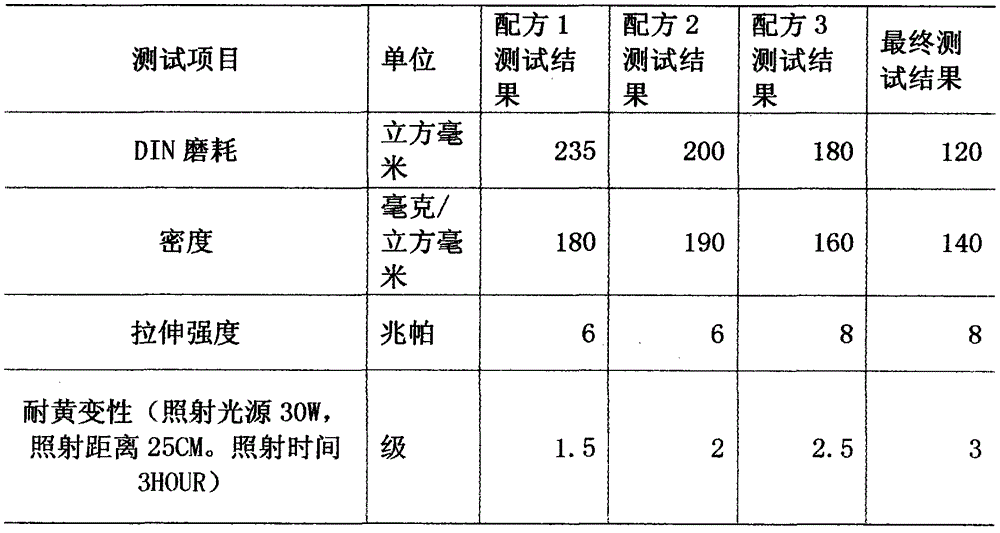

Outsole of rubber foamed shoe and preparation method thereof

The invention discloses an outsole of a rubber foamed shoe and a preparation method thereof. The outsole comprises the following raw materials in parts by weight: 35 parts of natural rubber, 0.7 part of rubber accelerator DM, 0.3 part of rubber accelerator M, 0.26 part of rubber accelerator D, 2 parts of zinc carbonate, 0.7 part of stearic acid, 0.9 part of activator PEG (polyethylene glycol), 0.2 part of wearproof particles, 0.2 part of antifogging agent MB, 18 parts of white carbon black, 6 parts of white oil, 0.3 part of rosin, 0.67 part of sulfur, 0.25 part of paraffin, 0.2 part of anti-aging agent SPC and 1 part of diethylene glycol. The preparation method comprises the following steps: putting the raw materials in the formula in a rubber mixing mill to be mixed for 30-35 minutes, thus obtaining a rubber foamed sheet; putting the prepared rubber foamed sheet in a bottom die and carrying out foaming molding at a certain temperature for a certain time; removing a shoe last and the die, thus preparing the integrally formed rubber foamed shoe. The outsole and the preparation method have the beneficial effects that the formula is environment-friendly; the process is simple; the shoe sole has good resilience; glue is not needed during one-time forming; the outsole is free from debonding at high temperature and free from slipping at low temperature, is not broken, has light whole weight and is comfortable to wear.

Owner:郭萧

Method for bonding aluminum or aluminum alloy surface with resin material

InactiveCN101712765AAchieving a tight bondThe program steps are conciseAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingHigh intensityMaterials science

The invention discloses a method for bonding an aluminum or aluminum alloy surface with a resin material. The method comprises the following steps of: firstly, self-assembling high-polymer nano-membranes on the aluminum or aluminum alloy surface bonded with the resin material and on the surface of the resin material; spraying low-concentration organic peroxide and auxiliary vulcanizing agent solution on the surface of the high-polymer nano-membrane so as to modify the surface; and realizing high-intensity bonding of the aluminum or aluminum alloy and the resin material by heating and compressing. The invention adopts a self-assembly dipping method, so that the method can treat materials and components with complex shapes and can realize bonding aluminum or aluminum alloy with complex shapes and the resin material. The method belongs to an environment-friendly formula and has simple and convenient operation process. Moreover, the method realizes high bonding intensity between the aluminum or aluminum alloy and the resin material and high stability.

Owner:NORTHWEST A & F UNIV

Wood-plastic composite profile prepared from waste polyethylene and its preparation method

The invention relates to a wood-plastic composite profile prepared from waste polyethylene and a preparation method thereof. The composition ratio of the wood-plastic composite profile is as follows: 100 parts of wood fiber powder, 0.5-1.2 parts of stearic acid, 15-20 parts of waste polyethylene plastic, 3-5 parts of phase solvent, 2-3 parts of lubricant, 0.2 parts of ~0.6 parts of anti-ultraviolet agent, 3-5 parts of coloring agent, 2-4 parts of CPE, 8-12 parts of calcium carbonate; the preparation method is to mix the dried wood fiber powder to 80°C at high speed, and then add stearic acid , high-speed mixing to 130°C; then add the rest of the above components, mix evenly and then add to the parallel twin-screw granulator, plasticize, extrude and pulverize at 140-220°C to obtain granules; the granules are extruded and formed. The polyethylene-based wood-plastic composite material prepared by the invention has excellent comprehensive performance and good processing performance, and the preparation method thereof is simple in operation, low in cost and easy for industrial implementation.

Owner:恳达(上海)装饰材料有限公司

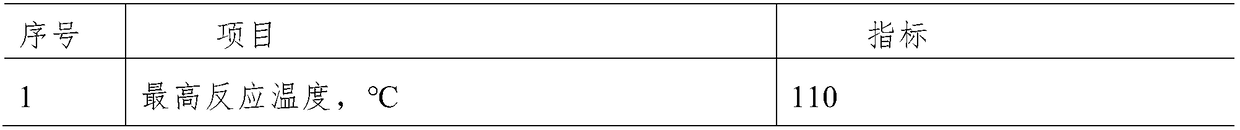

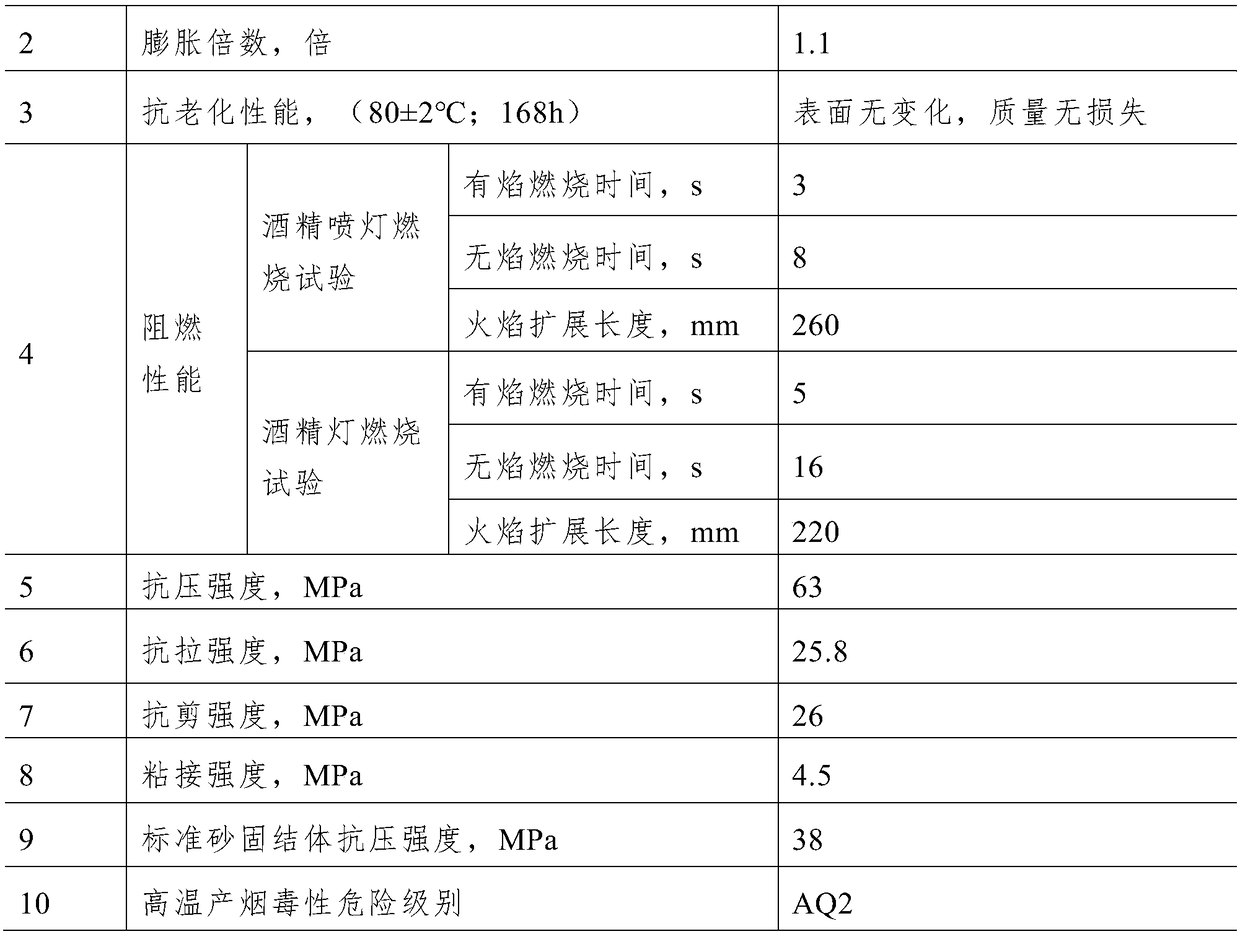

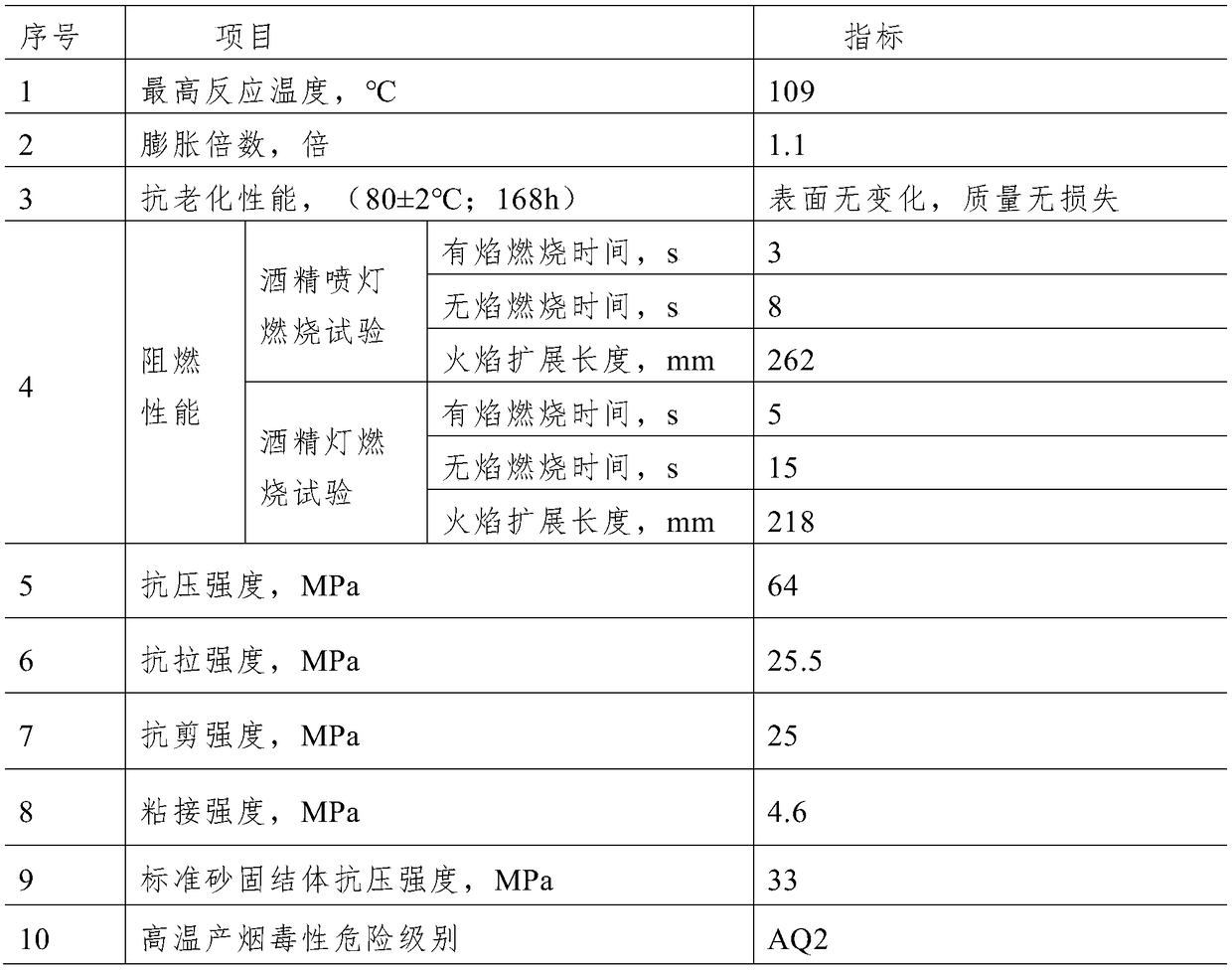

Low-heat polyurethane grouting reinforcement material

The invention relates to a low-heat polyurethane grouting reinforcement material. The reinforcement material comprises a component A and a component B, wherein the component A contains 60-90 parts byweight of polymeric MDI; the component B contains, by weight, 10-40 parts of polyether polyol, 10-20 parts of polymer polyol, 0.01-6 parts of a catalyst, 1-10 parts of a flame retardant and 10-20 parts of an assistant; and at least one of the component A and the component B further contains vegetable fat or modified vegetable fat. The above formula contains a certain amount of the vegetable fat ormodified vegetable fat, so the reinforcement material can quickly absorb heat released by a reaction of the polymeric MDI and the polyether polyol, and participates in some of chemical reactions, thereby the reaction of the whole system is mild, and the reaction heat is slowly aggregated, and the overall reaction temperature rise is significantly lower than that of existing polyurethane groutingmaterials; and the addition of the vegetable fat and modified vegetable fat has no negative influences on the application properties and the comprehensive mechanical properties of the polyurethane grouting materials.

Owner:BEIJING RUINUOANKE NEW ENERGY TECH

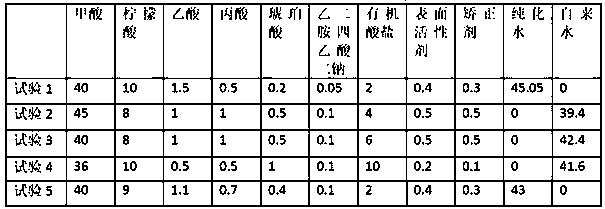

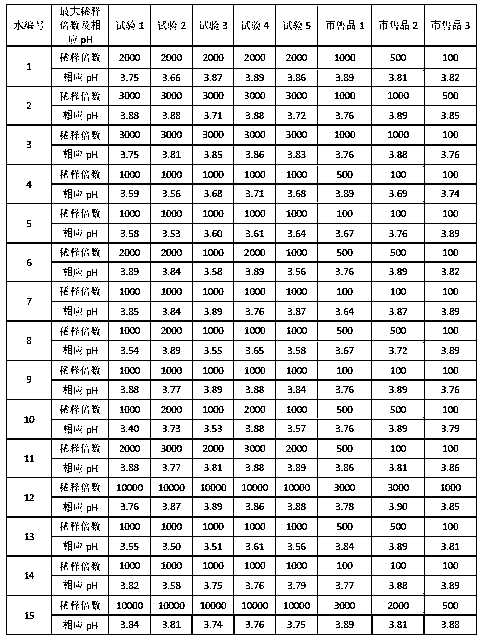

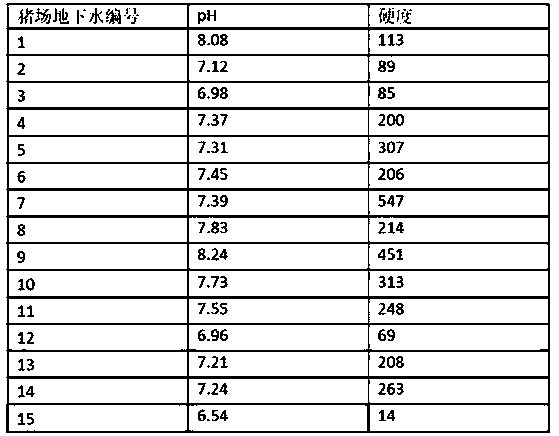

Composite acidifying agent, preparation method and applications thereof

The invention provides a composite acidifying agent, which comprises, by weight, 36-45 parts of formic acid, 8-10 parts of citric acid, 0.5-1.5 parts of acetic acid, 0.5-1.5 parts of propionic acid, 0.2-1 part of succinic acid, 0.05-0.1 part of ethylenediamine tetraacetic acid disodium salt, 2-10 parts of an organic acid salt, 0.2-1 part of a surfactant, 0.2-0.5 part of a correction agent and 35-46 parts of water. The invention also provides a preparation method and an application method of the acidifying agent. According to the invention, the acidifying agent is especially suitable for pig farm waterline disinfection, drinking water disinfection and pigsty flushing disinfection, has characteristics of high efficiency and low toxicity, can reduce the pH value of the digestive tract of animals, effectively control the diarrhea of weaned nursery piglets and improve the growth performance of animals, has good dilution effect and good buffer effect on different water qualities, and particularly has significant buffer effect compared with the similar products when the water quality hardness is relatively high.

Owner:HUNAN AGRI UNIV ANIMAL PHARMA

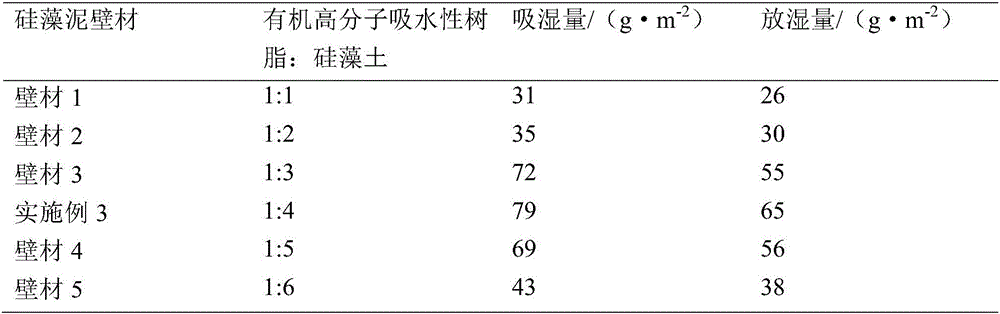

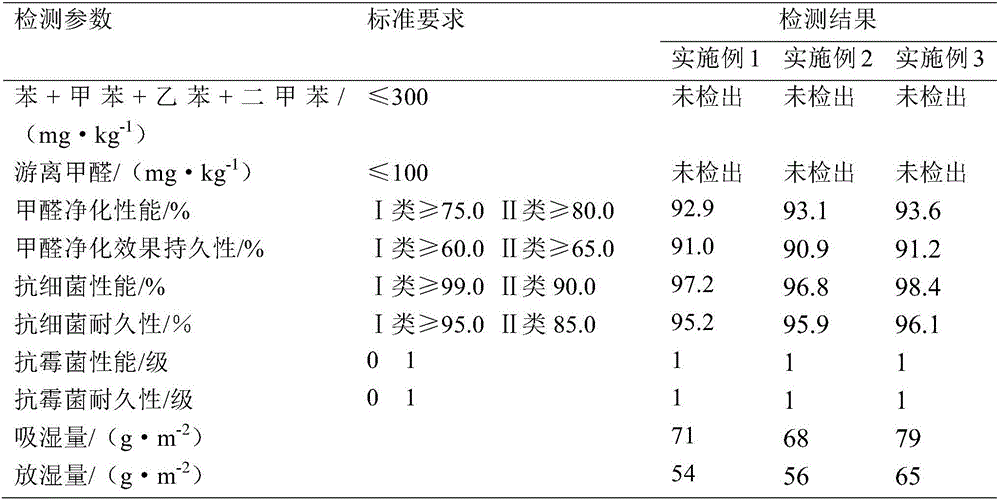

Novel humidity adjusting anti-bacterial environment-friendly diatom ooze wall material and preparing method thereof

ActiveCN106554646AEco-friendly formulaImprove water resistanceAntifouling/underwater paintsPaints with biocidesFiberCarbon fibers

The invention discloses a novel humidity adjusting anti-bacterial environment-friendly diatom ooze wall material. The novel humidity adjusting anti-bacterial environment-friendly diatom ooze wall material comprises, by weight, 50-60 parts of kieselguhr, 5-15 parts of quartz sand, 15-25 parts of wollastonite powder, 5-10 parts of redispersibility latex powder, 1.5-2 parts of a dispersing agent, 15-20 parts of anion powder, 10-15 parts of carbon fiber, 10-25 parts of a humidity adjusting agent, 5-10 parts of a cold catalytic agent and 5-10 parts of graphene. The invention further discloses a preparing method for the diatom ooze wall material. The preparing method comprises the steps that the raw materials are weighed according to the mass and evenly mixed, and a mixed dry powder material is obtained; and according to the mass ratio of the water to the mixed dry powder material being 1:1.3-1.5, water is added, stirring is conducted to the paste, and then the novel humidity adjusting anti-bacterial environment-friendly diatom ooze wall material is obtained. The preparing method for the diatom ooze wall material is simple, convenient to construct and has excellent humidity adjusting performance, water resisting performance and an anti-bacterial property, the formula is environment-friendly, free of pollution and free of toxicity and odor, and the body health is benefited.

Owner:吉林省北疆新材料科技有限公司

Lead-acid storage battery anti-aging plastic shell material

The invention discloses a lead-acid storage battery anti-aging plastic shell material, which is prepared from the following components by weight: 40-50 parts of an ABS resin, 20-30 parts of a PVC resin, 5-10 parts of surface modified bamboo fiber, 5-10 parts of modified aluminum hydroxide, 5-10 parts of chlorinated Polyethylene, 1-3 parts of a lubricant, 3-5 parts of modified zeolite powder, 0.5-1 part of an antioxidant AT-10, 0.1-0.5 part of an antioxidant 1078, and 0.5-1 part of dibutyltin dilaurate. According to the present invention, the lead-acid storage battery anti-aging plastic shell material has advantages of reasonable and scientific formula, environmental protection, low production cost, excellent flame retardant performance, excellent mechanical property, and excellent weather resistance.

Owner:ZHEJIANG CHANGTONG SCI & TECH

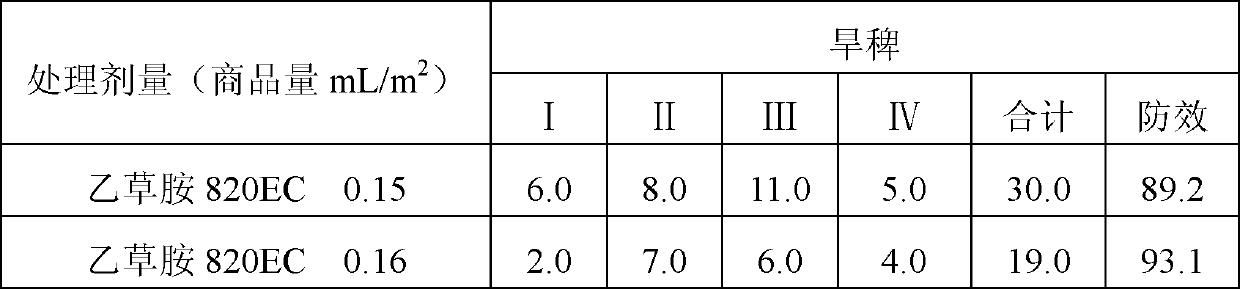

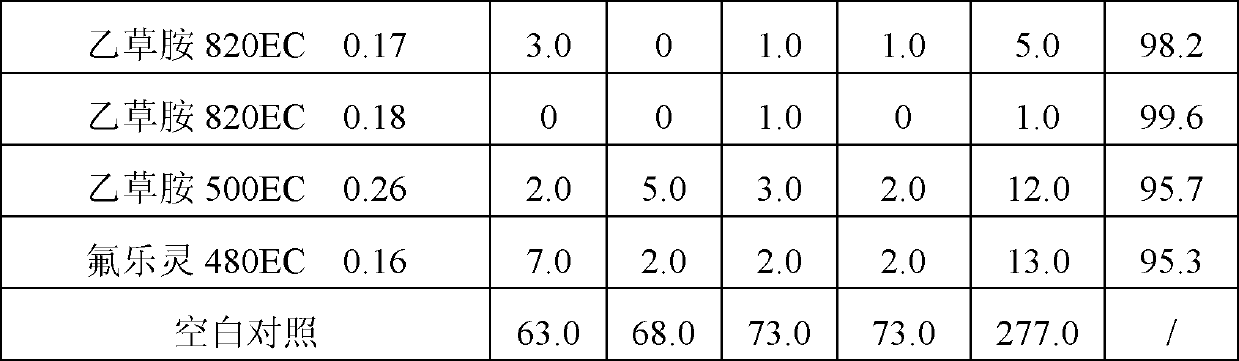

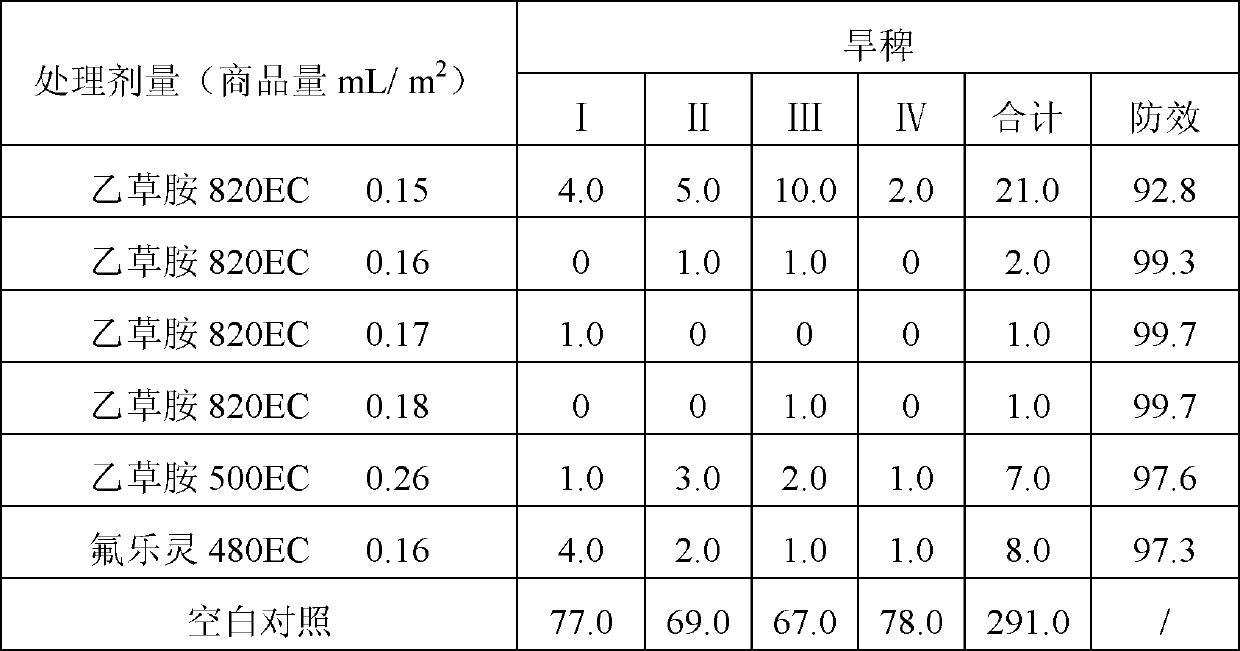

Environment-friendly potato field weeding combination

InactiveCN102885042AThe production process is simple to operateEasy to getBiocideAnimal repellantsSolventWeed

The invention relates to a weeding combination and particularly relates to an environment-friendly potato field weeding combination. The combination aims to solve problems that a conventional weedicide is not environment-friendly, difficult to operate, not stable in control effect and high in cost. The environment-friendly potato field weeding combination is composed of acetochlor, soybean oil, an emulsifier for the acetochlor and pine-stump light oil, wherein the emulsifier for the acetochlor is formed by mixing calcium dodecyl benzene sulfonate, phenethyl phenol polyoxyethylene ether and castor oil polyoxyethylene ether. The environment-friendly potato field weeding combination disclosed by the invention is capable of effectively controlling annual gramineous weeds and part broad-leaf weeds propagated by small seeds in potato fields, safe to potatoes, stable in weeding effect and environment-friendly; compared with the conventional weedicide using a turpentine solvent, the combination using the pine-stump light oil has the advantages that the production cost is reduced and the weed controlling effect of acetochlor missible oil taking the pine-stump light oil as the solvent is better through beneficial constituents such as wood vinegar and the like in the pine-stump light oil. The combination disclosed by the invention is safe in formula, convenient to use and easy to popularize.

Owner:哈尔滨利民农化技术有限公司

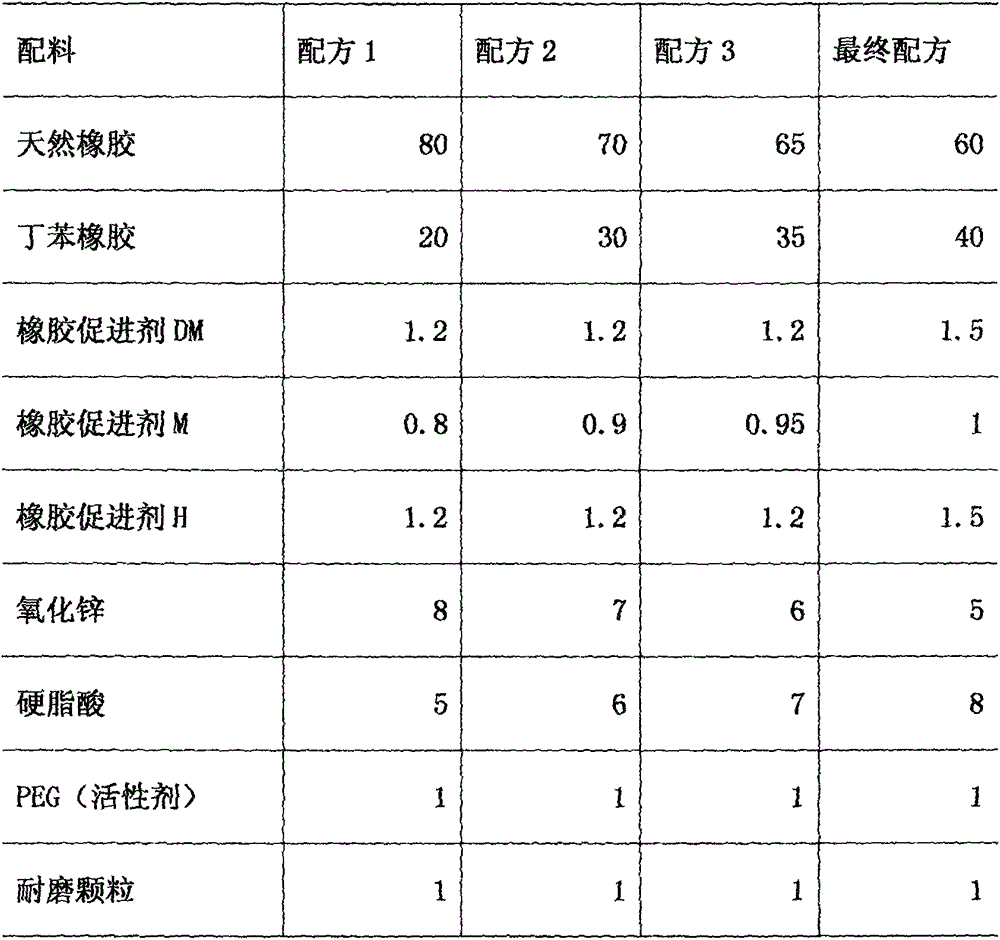

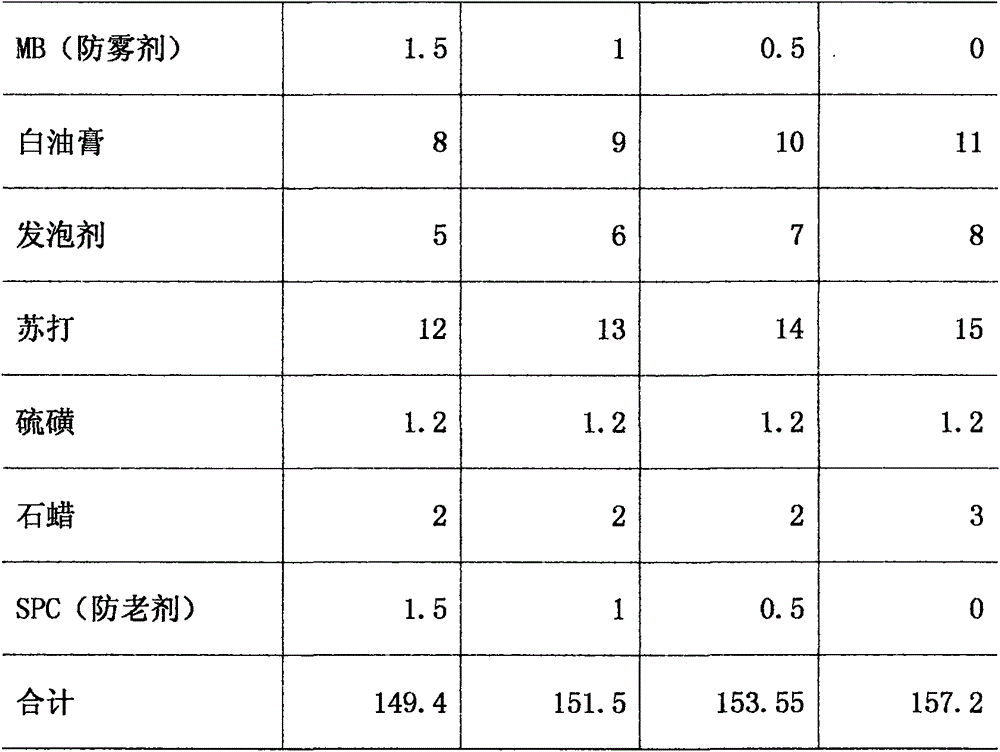

Rubber insole and preparation method thereof

The invention discloses a rubber insole and a preparation method thereof. The rubber insole is prepared from, by weight, 60-80 parts of natural rubber, 20-40 parts of styrene butadiene rubber, 1.2-1.5 parts of a rubber accelerator DM, 0.8-1 part of a rubber accelerator M, 1.2-1.5 parts of a rubber accelerator H, 5-8 parts of zinc oxide, 5-8 parts of stearic acid, 1 part of a PEG active agent, 1 part of wear-resistant particles, 0-1.5 parts of an MB anti-fogging agent, 8-11 parts of white factice, 5-8 parts of a foaming agent, 12-15 parts of soda, 1.2 parts of sulphur, 2-3 parts of paraffin and 0-1.5 parts of an SPC anti-aging agent. The preparation method comprises the following technological steps of rubber foaming sheet preparing, upper mold and bottom mold preparing and demolding. The rubber insole and the preparation method have the advantages that the formula is environmentally friendly, the process is simple, the breathability is good, deodorization and environment friendliness are achieved, the rubber insole does not fracture, the whole weight is small, and wearing is comfortable.

Owner:郭萧

Feed balanced in nutrition and capable of reducing morbidity of bass

InactiveCN107259206AReasonable nutritionNutritional balanceFood processingClimate change adaptationSOYBEAN SEED OILPeanut meal

The invention discloses feed balanced in nutrition and capable of reducing the morbidity of bass. The feed is prepared from the following raw materials: extruded soybeans, wheat flour, rice bran, peanut meal, fish meal, earthworm powder, seaweed powder, fermented blood meal, modified montmorillonoid, composite Chinese herbal medicine, decavitamin, probiotics, soybean oil, syringic acid, betaine, citric acid, sodium diacetate, inositol, xanthan gum and sodium polyacrylate. According to the feed balanced in nutrition and capable of reducing the morbidity of the bass, disclosed by the invention, the feed is reasonable in formula, balanced in nutrition and good in palatability, is green and environmentally friendly and is high in utilization rate, the physique of the bass is effectively improved, the morbidity of the bass is reduced, growth and development of the bass are promoted, the bass is good in meat quality, the economic benefit of bass cultivation is increased, and meanwhile, the ecological environment of a water body is effectively improved.

Owner:天长市金农农业发展有限公司

Special feed for breeding broiler chickens

InactiveCN106376723AIncrease feed intakePromote digestion and absorptionFood processingAnimal feeding stuffDigestionMicro environment

The invention relates to the technical field of feed processing and particularly relates to a special feed for breeding broiler chickens. The special feed mainly consists of the following raw materials by weight part: 32-45 parts of corn gluten meal, 23-32 parts of soybean protein powder, 11-15 parts of brewers' dried grains, 7-15 parts of dried sheep dung, 5-9 parts of tussah pupa powder, 4-8 parts of fish bone meal, 5-8 parts of meat and bone meal, 3-7 parts of cottonseed meal, 2-6 parts of spirulina powder, 4-9 parts of fine sand, 4-7 parts of chlorella powder, 6-12 parts of vitamin additives, 3-6 parts of table salt, 3-5 parts of shell powder, 2-5 parts of assistant, and 5-7 parts of EM bacterium stock solution. According to the invention, the special feed is rich in nutrition and high in protein content. One part of above raw materials is fermented and then is processed, so that the special feed is good in palatability. The feed intake of broiler chickens is increased, and the intestinal micro-environment of broiler chickens is improved. Meanwhile, the type and the number of the intestinal beneficial microorganisms of broiler chickens are increased, so that the feed digestion, the feed absorption and the healthy growth of broiler chickens are improved. The conversion rate of the feed conversion ratio and the growth rate are increased.

Owner:广西御汇堂生物科技有限公司

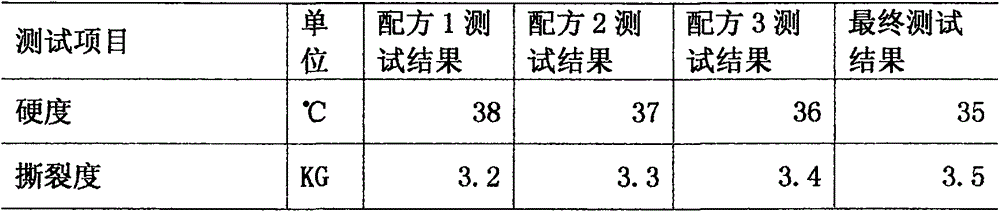

Nickel electroplating solution and application thereof

InactiveCN107587173ANot corrosiveImprove plating efficiencyJewellerySodium acetateSodium acetrizoate

The invention relates to a nickel electroplating solution. The nickel electroplating solution is prepared from the following components by mass concentration: 10 to 20 g / L of main salt, 40 to 50 g / L of a buffer agent, 300 to 500 g / L of conductive salt, 0.01 to 0.1 g / L of a stress relieving agent and 2 to 20 g / L of a stabilizing agent, wherein the main salt is one or more of nickel aminosulfonate,nickel sulfate, nickel chloride and nickel oxalate; the conductive salt is one or more of sodium sulfamate, sodium sulfate, sodium chloride and sodium acetate. The pH value of the nickel electroplating solution is 6.5 to 7.5. The nickel electroplating solution disclosed by the invention has the advantages of no corrosiveness, high electroplating efficiency and environment-friendly formula; a nickel layer obtained by electroplating of the nickel electroplating solution is uniform, compact, high in hardness and anti-corrosion; the nickel electroplating solution is particularly suitable for nickel electroplating for sheet elements.

Owner:广东羚光新材料股份有限公司

High adhesion environmental protection printing ink

The invention discloses a high-adhesion environmental protection printing ink, which comprises, in parts by weight, 10-15 parts of acrylic resin, 9-16 parts of phenolic resin, 8-12 parts of urea-formaldehyde resin, 3-7 parts of polyurethane resin solution, graphene 0.2-3 parts, 8-18 parts of oleic acid esters, 10-20 parts of isopropanol, 6-10 parts of fatty alcohol polyoxyethylene ether, 20-2 parts of fatty acid esters with 6-10 carbons, 1-permeating agent 3 parts, 3‑18 parts of pigment. The application formula of the present invention is simple and environmentally friendly, but its performance is not inferior to the high-performance pigments on the market, especially in terms of adhesion and long-lasting color retention, so it has high promotional value.

Owner:黄健俊

Anti-bite cable protective covering

The invention provides an anti-bite cable protective covering. A shell of the anti-bite cable protective covering is prepared from, by mass, 90-110 parts of polyvinyl chloride resin, 40-60 parts of calcium carbonate, 10-20 parts of o-benzene dioctyl, 11-16 parts of chlorinated paraffin, 2-4 parts of compound stabilizer, 0.4-0.8 part of stearic acid and 3-5 parts of anti-mouse-bite master batch 9074-FT-40. The anti-bite cable protective covering is environmentally friendly and safe in formula, is free of toxin and harms to human bodies and the environment, meets the ecological requirements, and meanwhile well achieves a mouse bite prevention function; the prepared cable protective covering is firm and durable, resistant to aging and higher in flexibility and can better achieve a cable core protecting effect.

Owner:ZHEJIANG COMMSPACE CABLE

Anti-freezing type automotive front windshield glass water

InactiveCN106554866AFormulation ScienceEco-friendly formulaOther chemical processesSurface-active non-soap compounds and soap mixture detergentsSodium metasilicateEngineering

The invention discloses anti-freezing type automotive front windshield glass water and belongs to the technical field of car accessories. The anti-freezing type automotive front windshield glass water is prepared from the following components in parts by weight: 2-5 parts of a surfactant, 4-8 parts of a cosolvent, 10-15 parts of an auxiliary, 0.5-1.5 parts of an antifogging agent, 0.01-0.1 part of a preservative, 0.01-0.15 part of an optical active factor, 5-10 parts of low-carbon alcohol, 5-9 parts of isopropyl alcohol, 5-12 parts of propylene glycol monomethyl ether, 2-6 parts of anhydrous sodium metasilicate, 0.2-5 parts of essence and 45-80 parts of deionized water. Glass water is scientific and environmentally friendly in formula, is low in freezing point, is simple to produce, is strong in cleaning force, is remarkable in scale inhibition effect, has very good scavenge capacity and can effectively block formation of new dirt.

Owner:徐永骏

Super-condensed laundry detergent

InactiveCN102485872AImprove washing effectGood value for moneyOrganic detergent compounding agentsNon-ionic surface-active compoundsHuman healthSolvent

The invention relates to a super-condensed laundry detergent. The super-condensed laundry detergent is prepared by using a neutral formula, thus the super-condensed laundry detergent has no damage to skin or fabrics, has strong detersive power and can remove a plurality of stains, contains no phosphor and no sodium alkyl benzene sulfonate and can protect the environment and human health, can be used for low temperature washing, has excellent resistance to hard water, is easy to wash and rinse, and can save energy and water. The super-condensed laundry detergent comprises the following ingredients: 30-50 weight parts of fatty alcohol polyoxyethylene ether, 10-25 weight parts of aliphatic acid methyl acetic sulfonate, 5-25 weight parts of solvent, 0.1-2.0 weight parts of enzyme preparation, 2-10 weight parts of solubiliser, 0.1 weight parts of Kathon antiseptic, 1.0-5.0 weight parts of triethanolamine, a few amount of citric acid and essence, and 1-17 weight parts of water.

Owner:淄博佳谊日用化工有限公司

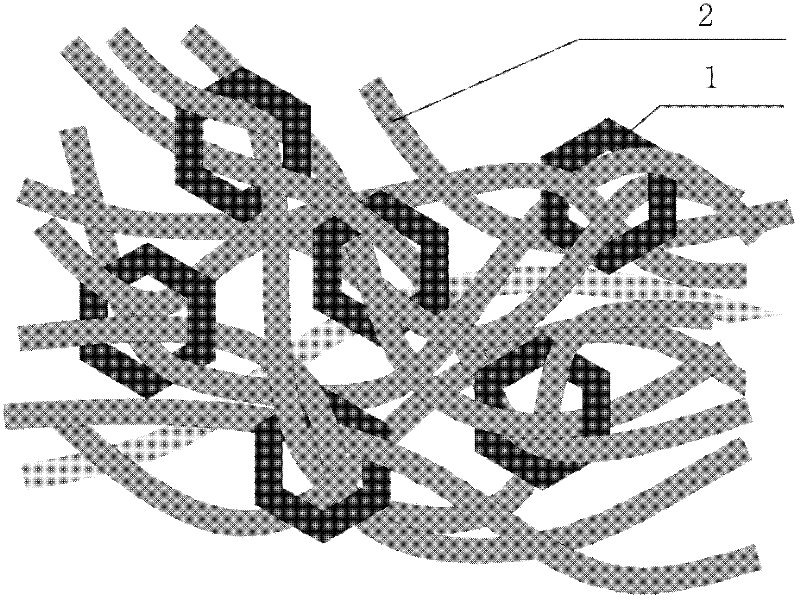

Renewable bundled and crosslinked rubber material

ActiveCN102532623AThe formula is simple and environmentally friendlyEnable recyclingPlastic recyclingSolventChemistry

The invention discloses a renewable bundled and crosslinked rubber material. The renewable bundled and crosslinked rubber material is in a three-dimensional net structure which is formed by bundling and crosslinking of rubber molecules formed by dehydration of dicarboxylic acid, and consists of the following components in percent by weight: 5wt%-30wt% of acid anhydride and 70wt%-95wt% of saturated or unsaturated rubber diad components. The renewable bundled and crosslinked rubber material comprises the main components in parts by mass: 100 parts of rubber, 5-40 parts of dicarboxylic acid and 2.5-20 parts of dehydrating agent; and all the components are mixed for 10 minutes at the temperature of 40-55 DEG C, and are molded for 5-60 minutes at the temperature of 150-200 DEG C. According to the renewable bundled and crosslinked rubber material, in a mixed solvent of water and an organic solvent, the ring acid anhydride opens the ring to form acid, the acid anhydride component is removed by extraction to obtain pure rubber components, so that the recycling of the rubber material is realized.

Owner:SHENZHEN XUJING LIBO ENVIRONMENTAL PROTECTION TECH

Cleaning agent for removing emulsion deposits and preparation method and application of cleaning agent

ActiveCN108118353AImprove stabilitySimple preparation processDrilling compositionSaline waterEmulsion

The invention provides a cleaning agent for removing emulsion deposits and a preparation method and application of the cleaning agent. The cleaning agent for removing the emulsion deposits comprises,by 100 parts of weight, 10-30 parts of glycol ether compounds and esterification products of glycol ether compounds and alkyl carboxylic acid compounds, 10-40 parts of a double alkyl chain quaternaryammonium salt cationic surfactant, 0.1-5 parts of polyether amine compounds, 0-10 parts of a corrosion inhibitor, 0-10 parts of a defoaming agent and the balance water or saline water. The invention further provides a preparation method of the cleaning agent for removing the emulsion deposits. The cleaning agent can effectively remove the emulsion deposits of a gathering and transportation systemand has the advantages that the formula is environmentally friendly, the usage amount is low, the cleaning effect is good, oil and water are separated after cleaning, and a using method is simple.

Owner:PETROCHINA CO LTD

Special organic fertilizer for tea trees

InactiveCN112358353AGood physical propertiesIncrease the amount of substitutionBio-organic fraction processingBioloigcal waste fertilisersTea leafPesticide

The invention discloses a special organic fertilizer for tea trees. The special organic fertilizer is prepared from the following raw materials: bagasse, rice husk, soybean meal, blueberry straw, amino acid and a fermentation inoculant. According to the invention, physical properties of tea garden soil can be improved, microbial growth of the soil is promoted, tea tree absorption and utilization are activated, the problems of tea yield reduction, quality reduction and the like caused by use of pesticides and herbicides to ancient tea trees are relieved, and treatment of the ancient tea trees is achieved.

Owner:西双版纳旺仓农业科技有限公司

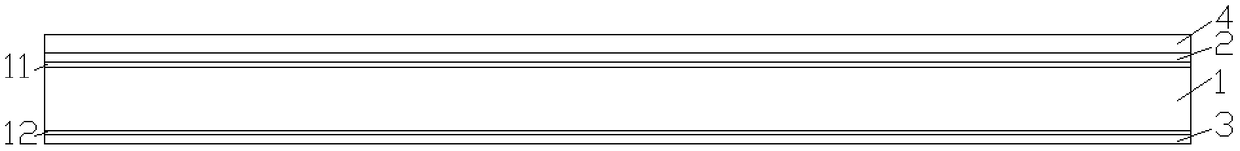

Clean-type slitting rewound paper unlikely to be stained with dust and preparation method thereof

ActiveCN108894060ANot easy to stainNovel structural designAntifouling/underwater paintsSpecial paperBiochemical engineeringEthyl acetate

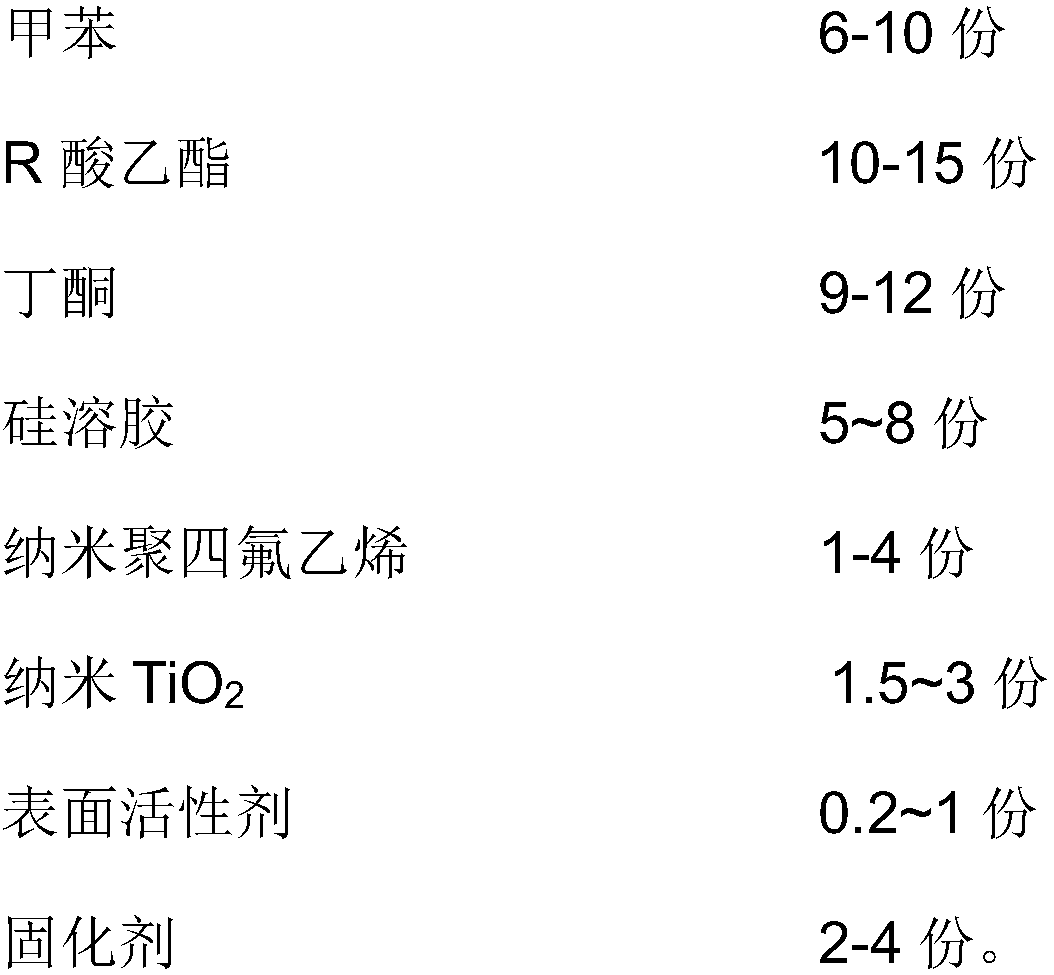

The invention discloses clean-type slitting rewound paper unlikely to be stained with dust. The rewound paper comprises a raw paper layer, a first coating layer, a second coating layer and a dustprooflayer. The first coating layer and the second coating layer are respectively distributed at the upper part and the lower part of the raw paper layer, the dustproof layer covers the upper part of thefirst coating layer, and a first glue layer and a second glue layer are also respectively arranged between the first coating layer, the second coating layer and the raw paper layer; the dustproof layer is formed by spraying a dustproof liquid to the first coating layer; the dustproof liquid is prepared from the following components in parts by weight: 120-200 parts of deionized water, 6-10 parts of methylbenzene, 10-15 parts of ethyl acetate, 9-12 parts of butanone, 5-8 parts of a silica sol, 1-4 parts of nano polytetrafluoroethylene, 1.5-3 parts of nano TiO2, 0.2-1 part of a surfactant and 2-4 parts of a curing agent. The paper disclosed by the invention is novel in design, is unlikely to be stained with dust by arranging the dustproof layer on the premise of relatively good mechanical anti-wear fastness and waterproof performance, and is simple in process step and is popularized and applied favorably.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

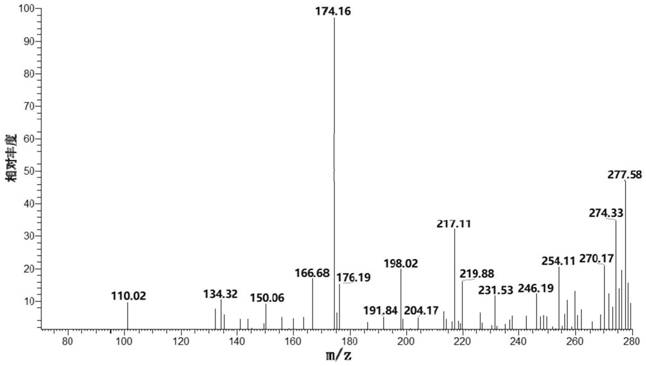

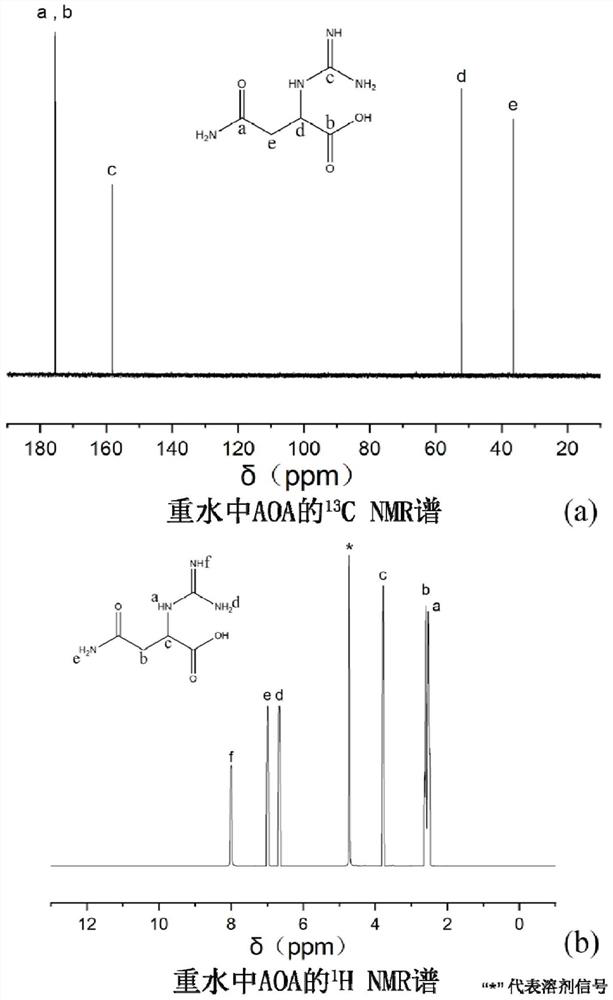

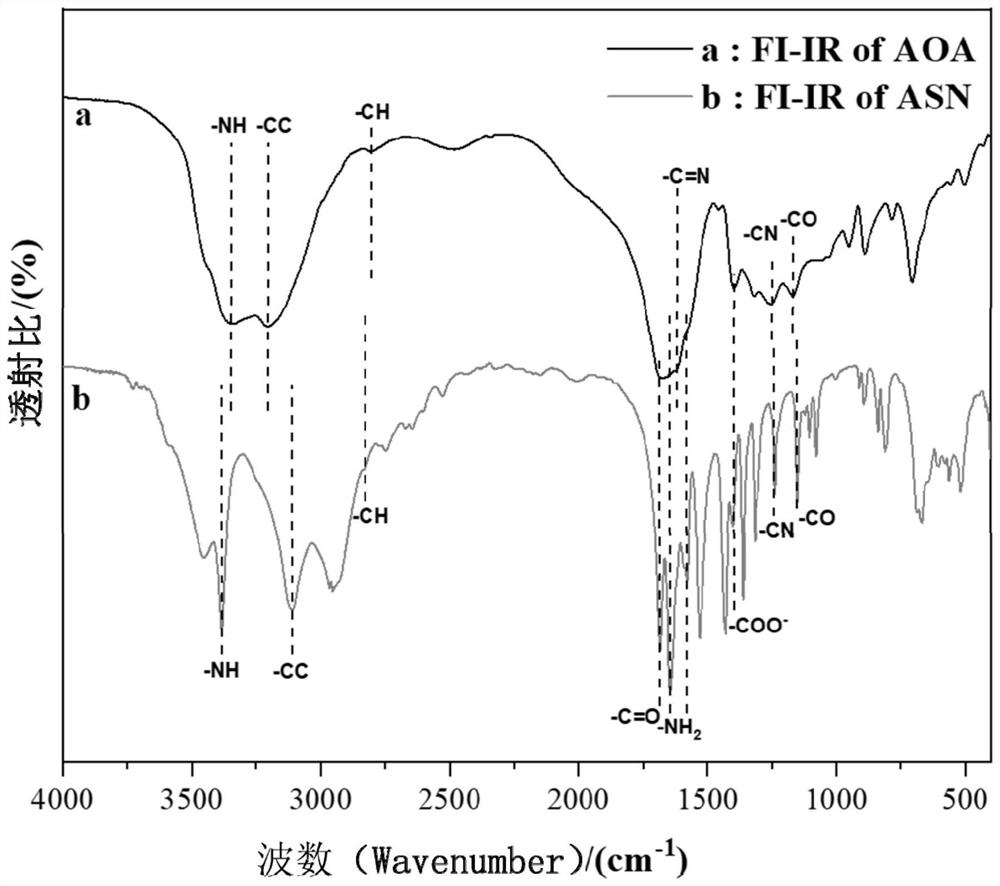

Guanidyl organic compound and preparation method and application thereof

ActiveCN112521314AHigh electrochemical impedance valueLow toxicityOrganic chemistryOrganic compound preparationSimple Organic CompoundsAnti solvent

The invention relates to a guanidyl organic compound and a preparation method and application thereof. The guanidyl organic compound has a structure as shown in the following general formula I, wherein R is selected from (CH2)nCONH2, and n is an integer from 1 to 6. The guanidyl functional group in the guanidyl organic compound provides antibacterial and anti-bio-fouling capability, and a structure similar to amino acid provides a corrosion inhibition capability, so that an anti-bio-fouling function and a corrosion inhibition function are creatively combined together, and a surface protectivefilm constructed by the compound has a relatively high electrochemical impedance value and excellent anti-solvent pollution adhesion, anti-biomass contamination and anti-fouling capabilities.

Owner:HUNAN UNIV

Diatom ooze wall material for indoor wall decoration

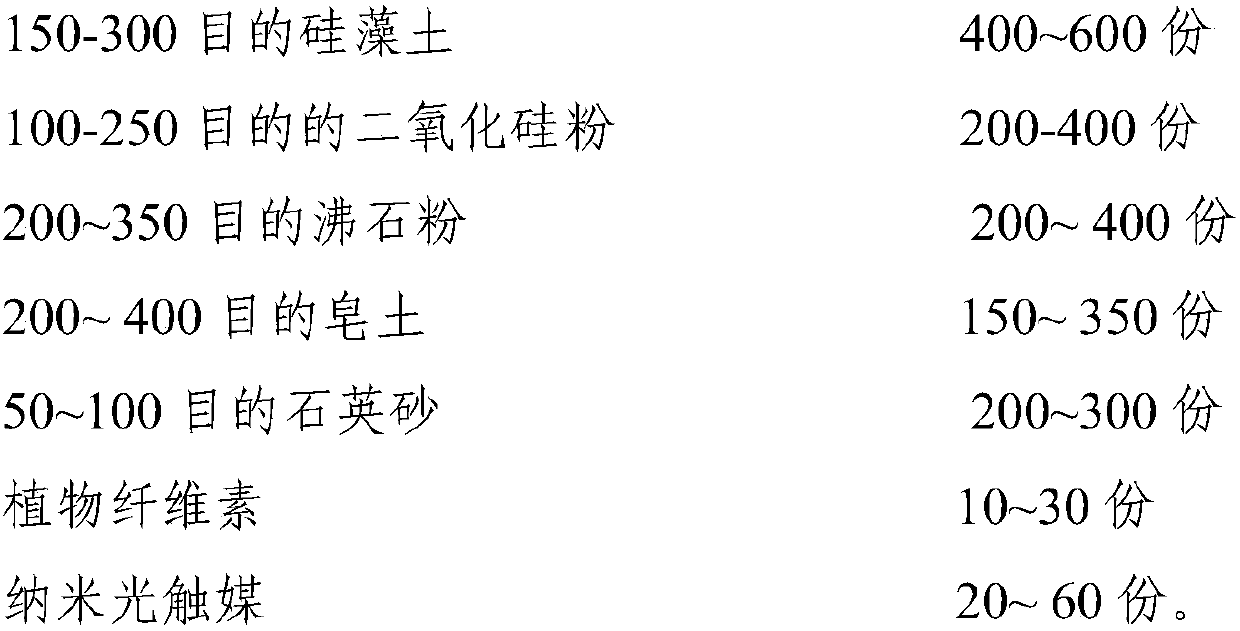

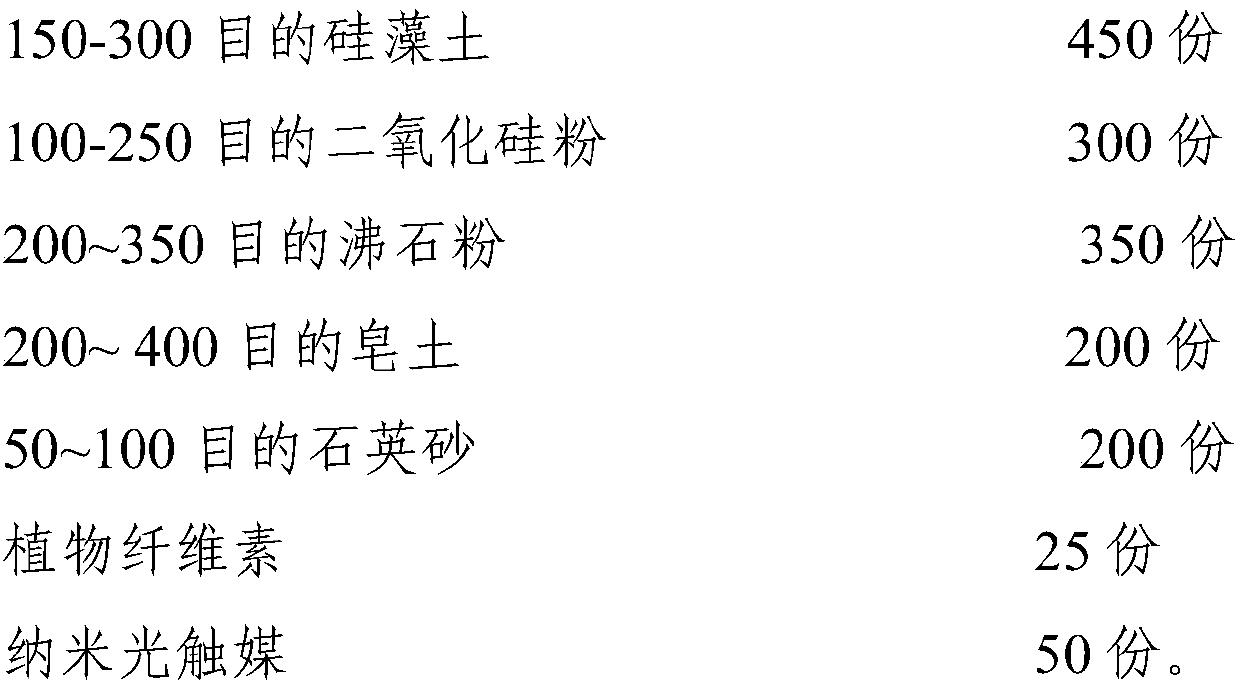

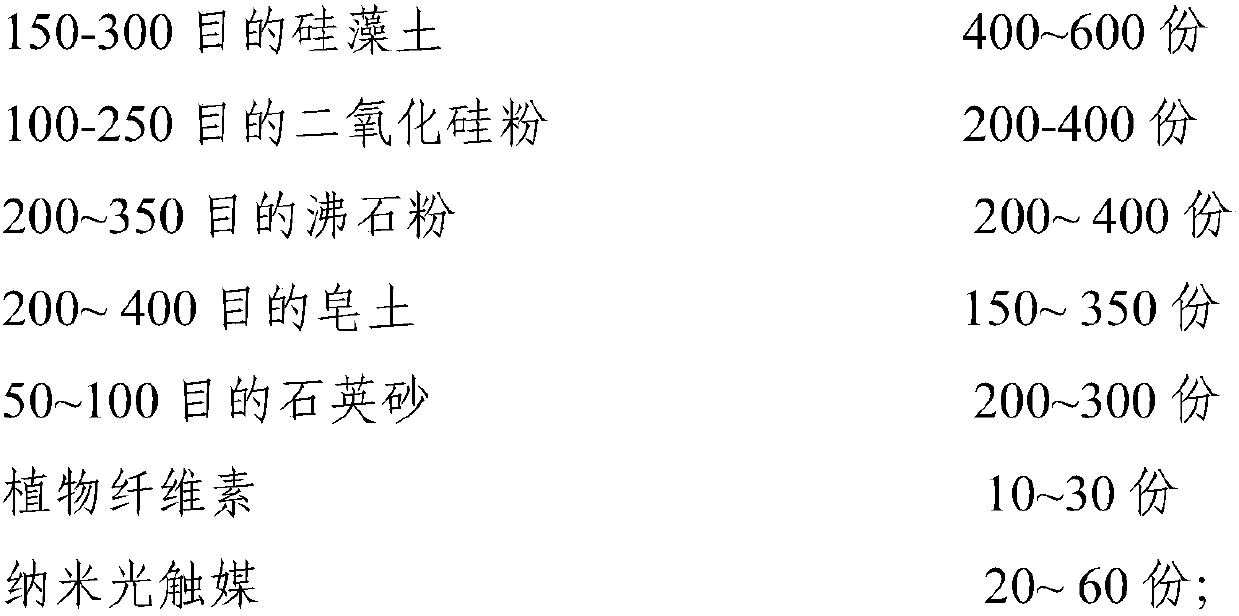

The invention relates to a diatom ooze wall material for indoor wall decoration. The wall material is prepared from the following components in parts by weight: diatomaceous earth, silica powder, zeolite powder, bentonite, quartz sand, plant cellulose, nano photocatalyst and the like. The preparation method comprises the following steps: stirring and uniformly mixing, and then adding water for stirring. The diatom ooze wall material disclosed by the invention is large in specific surface area, high in porosity, high in strength and extremely high in adsorption capacity, water can be adsorbed while harmful substances are adsorbed, and the purpose of automatically adjusting the air humidity is achieved, the photocatalytic effect can be realized under the action of light, harmful substances such as formaldehyde and toluene can be decomposed, and the effect of purifying indoor air for a long time is achieved, the preparation method is simple, strong in operability, and the formula is environment-friendly and pollution-free, non-toxic and harmless, and beneficial to body health.

Owner:东莞市爱乐居环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com