Diatom ooze wall material for indoor wall decoration

A technology of diatom mud and inner wall, applied in the field of building materials, can solve the problems of strong corrosion, poor hygroscopicity, uneven layering and mixing of materials, etc., and achieve the effects of high porosity, strong adsorption capacity and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A diatom mud wall material for indoor wall decoration:

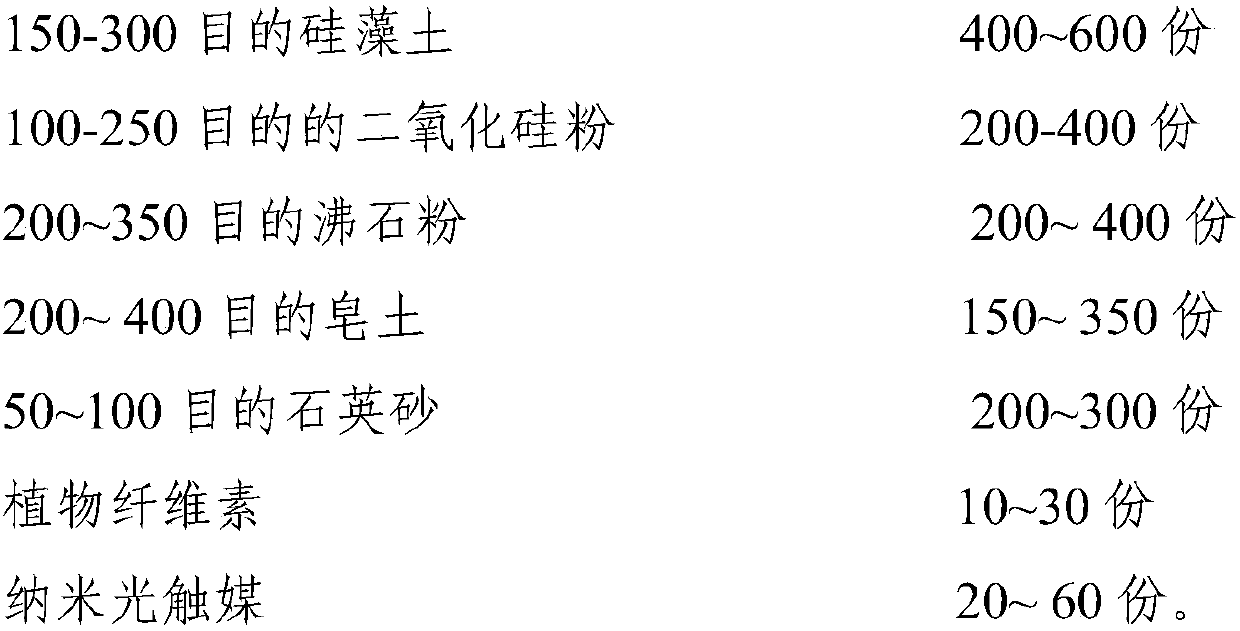

[0028] Formula: include the following components by weight:

[0029]

[0030] Preparation:

[0031] (1) Take by weight 600 parts of diatomite, 400 parts of silicon dioxide powder, 400 parts of zeolite powder, 350 parts of bentonite, 300 parts of quartz sand, 30 parts of hydroxymethyl cellulose, 60 parts of nano zinc oxide, Put 15 parts of iron red and 5 parts of sodium carboxymethyl cellulose into a high-speed disperser with a rotation speed of 1000r / min, stir and mix evenly to obtain wall material powder;

[0032] (2) Take a certain amount of water according to the mass ratio 1:1.1 of water and step (1) gained wall material powder;

[0033] (3) Slowly add the wall material powder obtained in step (1) into the water weighed in step (2), and stir evenly with a stirrer until it becomes a paste to obtain the diatom mud wall material.

Embodiment 2

[0035] A diatom mud wall material for indoor wall decoration:

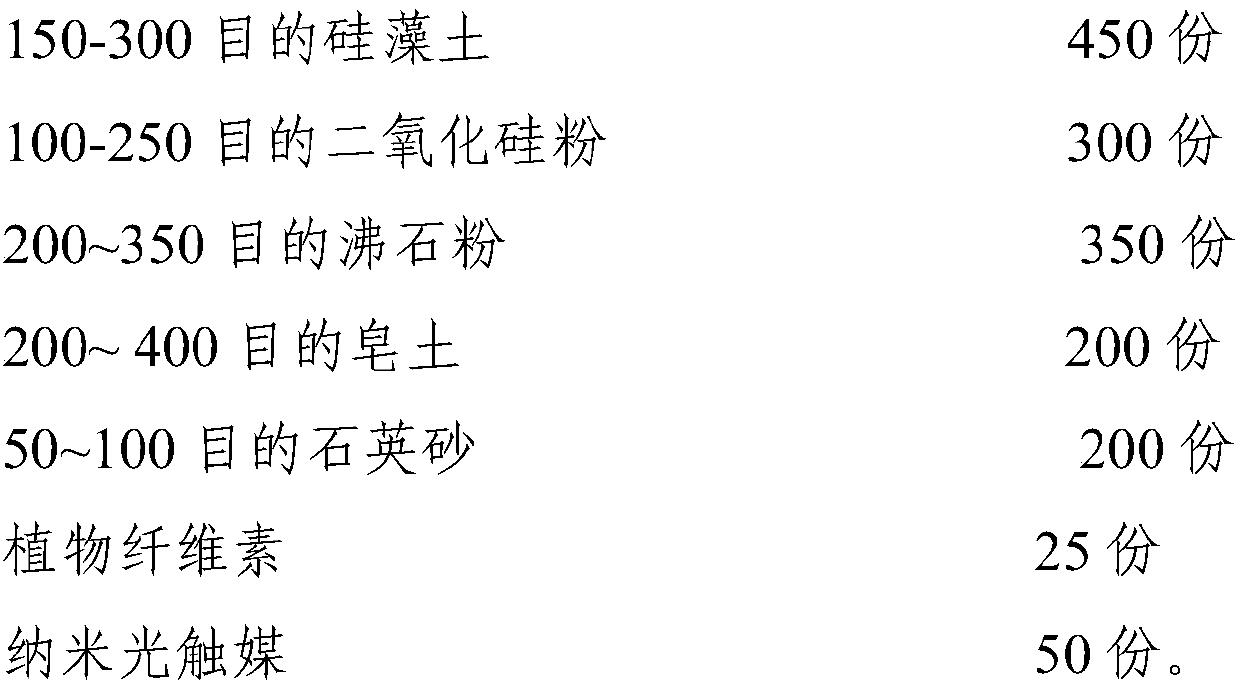

[0036] Formula: include the following components by weight:

[0037]

[0038]

[0039] Preparation:

[0040] (1) Weigh 450 parts of diatomite, 300 parts of silicon dioxide powder, 350 parts of zeolite powder, 200 parts of bentonite, 200 parts of quartz sand, 25 parts of methyl cellulose, 50 parts of nano-titanium dioxide, and titanium dioxide by weight. 5 parts and 2 parts of polyvinyl alcohol are put into a high-speed disperser with a rotating speed of 500r / min, stirred and mixed evenly, and wall material powder is obtained;

[0041] (2) Take a certain amount of water according to the mass ratio 1:0.8 of water and the wall material powder gained in step (1);

[0042] (3) Slowly add the wall material powder obtained in step (1) into the water weighed in step (2), and stir evenly with a stirrer until it becomes a paste to obtain the diatom mud wall material.

Embodiment 3

[0044] A diatom mud wall material for indoor wall decoration:

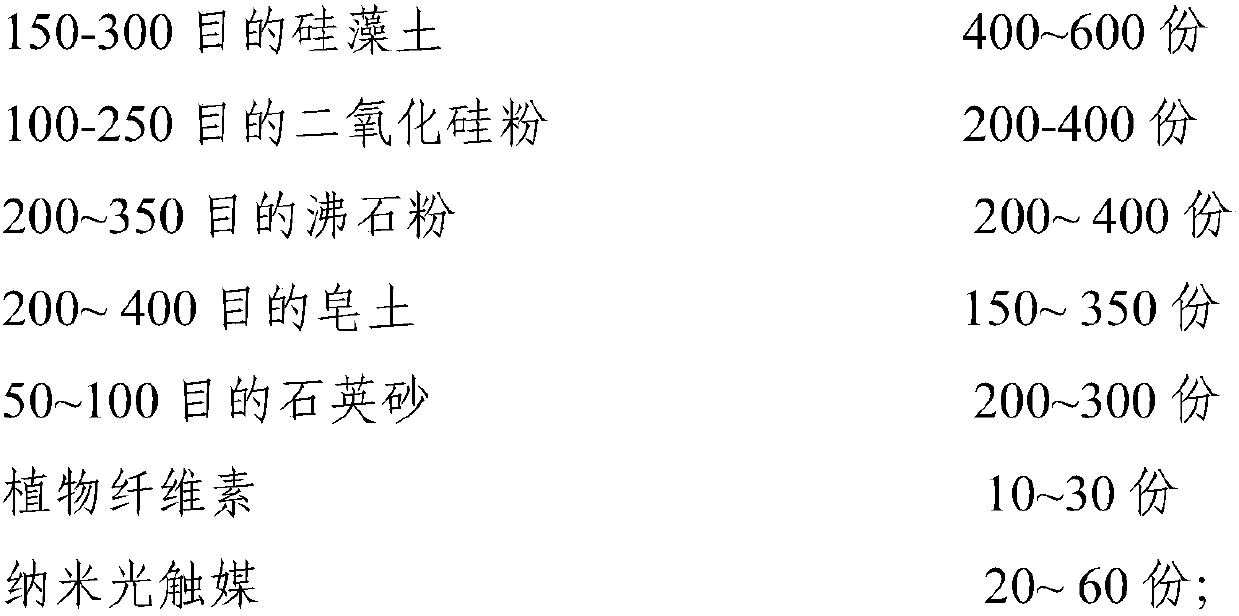

[0045] Formula: include the following components by weight:

[0046]

[0047] Preparation:

[0048] (1) Take by weight 400 parts of diatomite, 200 parts of silicon dioxide powder, 200 parts of zeolite powder, 150 parts of bentonite, 200 parts of quartz sand, 10 parts of hydroxypropyl cellulose, 20 parts of nano silver oxide, Put 5 parts of phthalocyanine blue and 1 part of polyacrylic acid into a high-speed disperser with a rotation speed of 500r / min, stir and mix evenly, and prepare wall material powder;

[0049] (2) Take a certain amount of water according to the mass ratio 1:1 of water and the wall material powder obtained in step (1);

[0050] (3) Slowly add the wall material powder obtained in step (1) into the water weighed in step (2), and stir evenly with a stirrer until it becomes a paste to obtain the diatom mud wall material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com