Outsole of rubber foamed shoe and preparation method thereof

A rubber foaming and outsole technology, applied in the field of shoes, can solve the problems of degumming of uppers and soles, easy pollution of the environment, and non-environmental protection, and achieve the effects of good sole rebound, simple process, and environmentally friendly formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

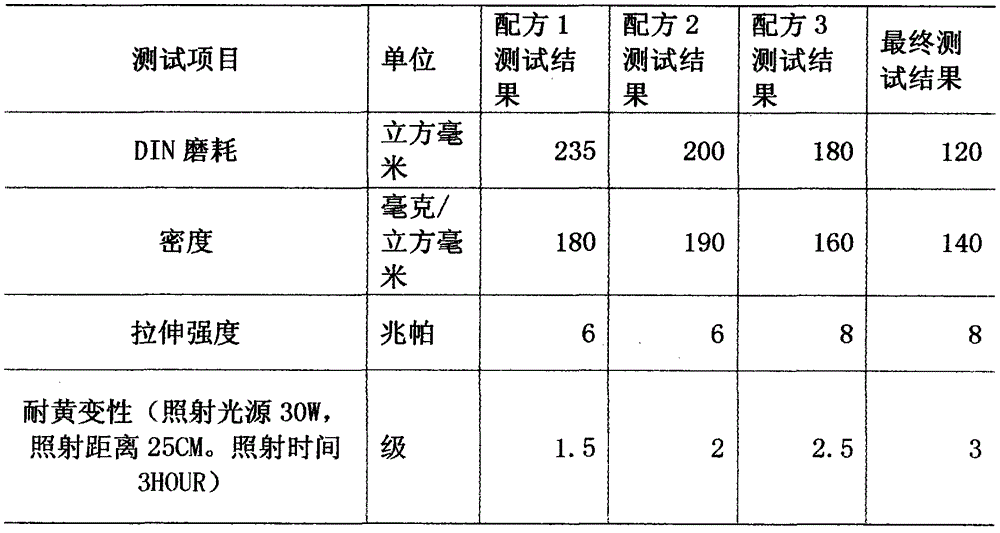

Examples

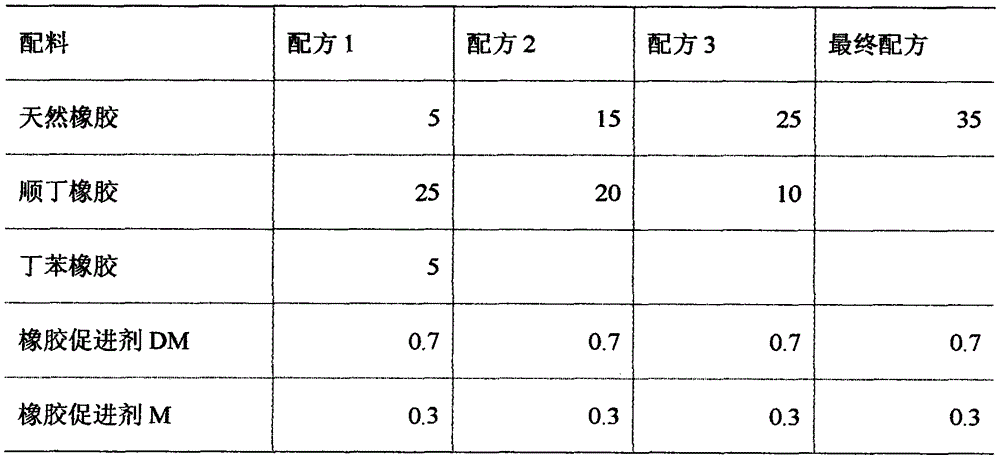

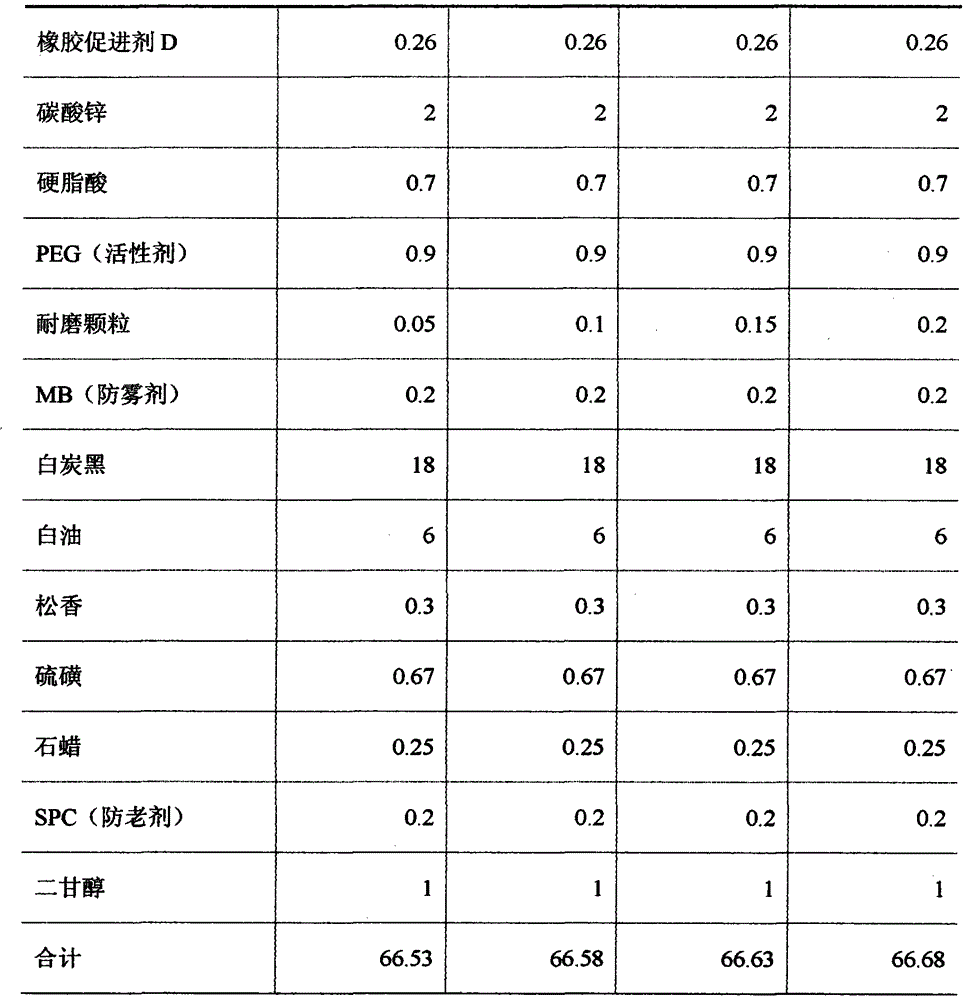

Embodiment 1

[0067] A kind of outsole of rubber foam shoes, described outsole comprises the raw material of following weight parts:

[0068] 5-35 parts of natural rubber

[0069] Butadiene rubber 0-25 parts

[0070] 0-5 parts of styrene-butadiene rubber

[0071] Rubber accelerator DM0.7-1 part

[0072] Rubber accelerator M0.3-0.5 parts

[0073] Rubber accelerator D0.25-0.3 parts

[0074] 2-3 parts of zinc carbonate

[0075] 0.5-0.7 parts of stearic acid

[0076] 0.9-1 part of PEG activator

[0077] Wear-resistant particles 0.05-0.2 parts

[0078] MB antifogging agent 0.1-0.2 parts

[0079] White carbon black 16-18 parts

[0080] 5-6 parts of white oil

[0081] Rosin 0.2-0.3 part

[0082] Sulfur 0.6-0.7 parts

[0083] 0.25-0.3 parts of paraffin

[0084] SPC anti-aging agent 0.2-0.3 parts

[0085] Diethylene glycol 0.5-1 part.

Embodiment 2

[0087] A further improvement is: the outsole includes the following raw materials in parts by weight:

[0088] 25-35 parts of natural rubber

[0089] Butadiene rubber 10-25 parts

[0090] Rubber accelerator DM0.7-1 part

[0091] Rubber accelerator M0.3-0.5 parts

[0092] Rubber accelerator D0.26-0.3 parts

[0093] 2-3 parts of zinc carbonate

[0094] 0.5-0.7 parts of stearic acid

[0095] 0.9-1 part of PEG activator

[0096] Wear-resistant particles 0.15-0.2 parts

[0097] MB antifogging agent 0.1-0.2 parts

[0098] White carbon black 16-18 parts

[0099] 5-6 parts of white oil

[0100] Rosin 0.2-0.3 part

[0101] Sulfur 0.67-0.7 parts

[0102] 0.25-0.3 parts of paraffin

[0103] SPC anti-aging agent 0.2-0.3 parts

[0104] Diethylene glycol 0.5-1 part.

Embodiment 3

[0106] The final improvement is: the outsole includes the following raw materials in parts by weight:

[0107] 35 parts of natural rubber

[0108] 0.7 parts of rubber accelerator DM

[0109] Rubber accelerator M0.3 parts

[0110] 0.26 parts of rubber accelerator D

[0111] 2 parts zinc carbonate

[0112] 0.7 parts of stearic acid

[0113] 0.9 parts of PEG activator

[0114] Wear-resistant particles 0.2 parts

[0115] MB anti-fogging agent 0.2 parts

[0116] White carbon black 18 parts

[0117] 6 parts white oil

[0118] Rosin 0.3 parts

[0119] Sulfur 0.67 parts

[0120] 0.25 parts of paraffin

[0121] SPC anti-aging agent 0.2 parts

[0122] Diethylene glycol 1 part.

[0123] A method for preparing the outsole of rubber foam shoes, comprising the following steps:

[0124] (1) Prepare foamed rubber sheet: put the sole raw material of each weight part described in the formula into a rubber mixer and mix for 30-35min to obtain foamed rubber sheet;

[0125] (2) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com