Patents

Literature

30results about How to "Slow down the spin rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

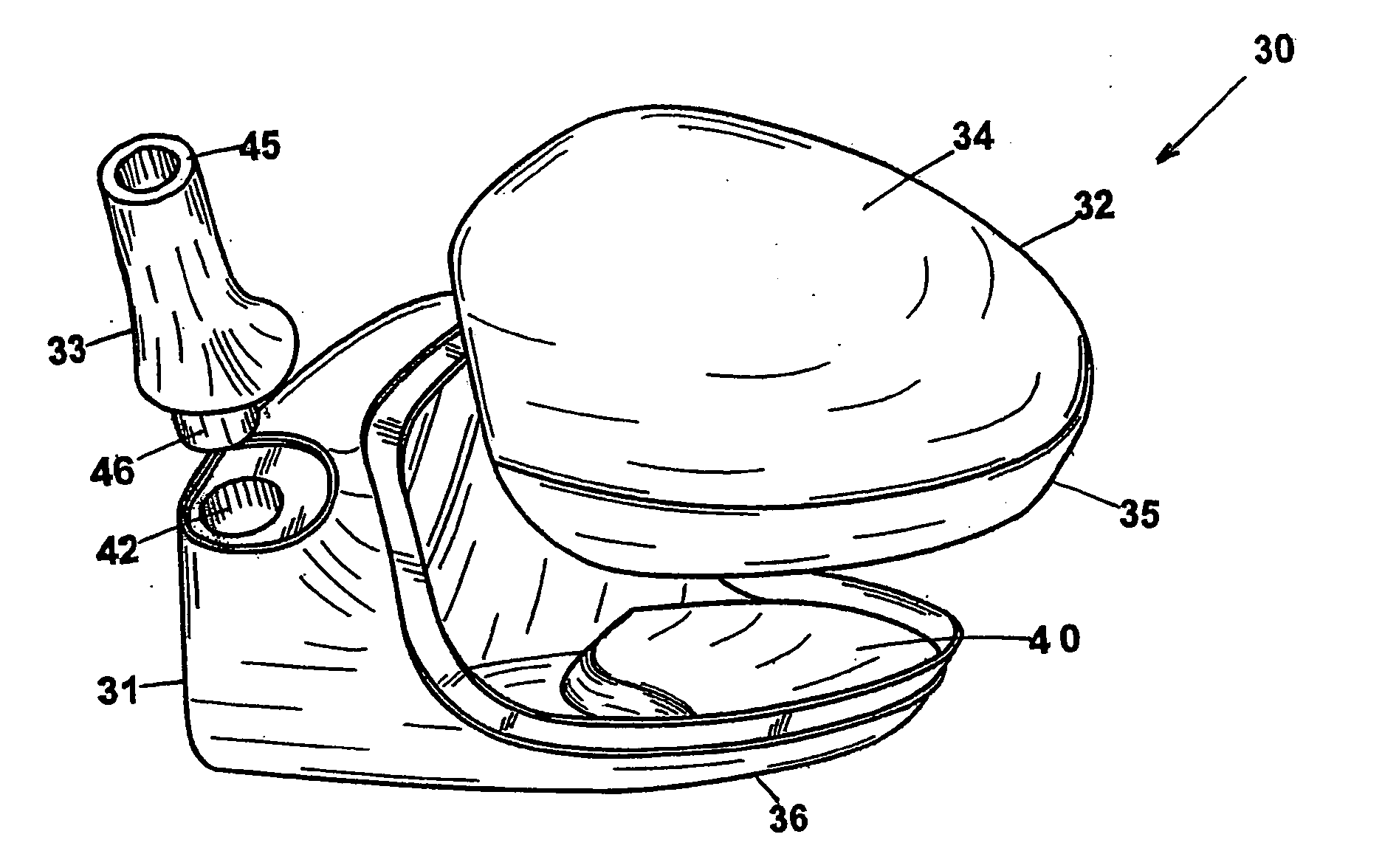

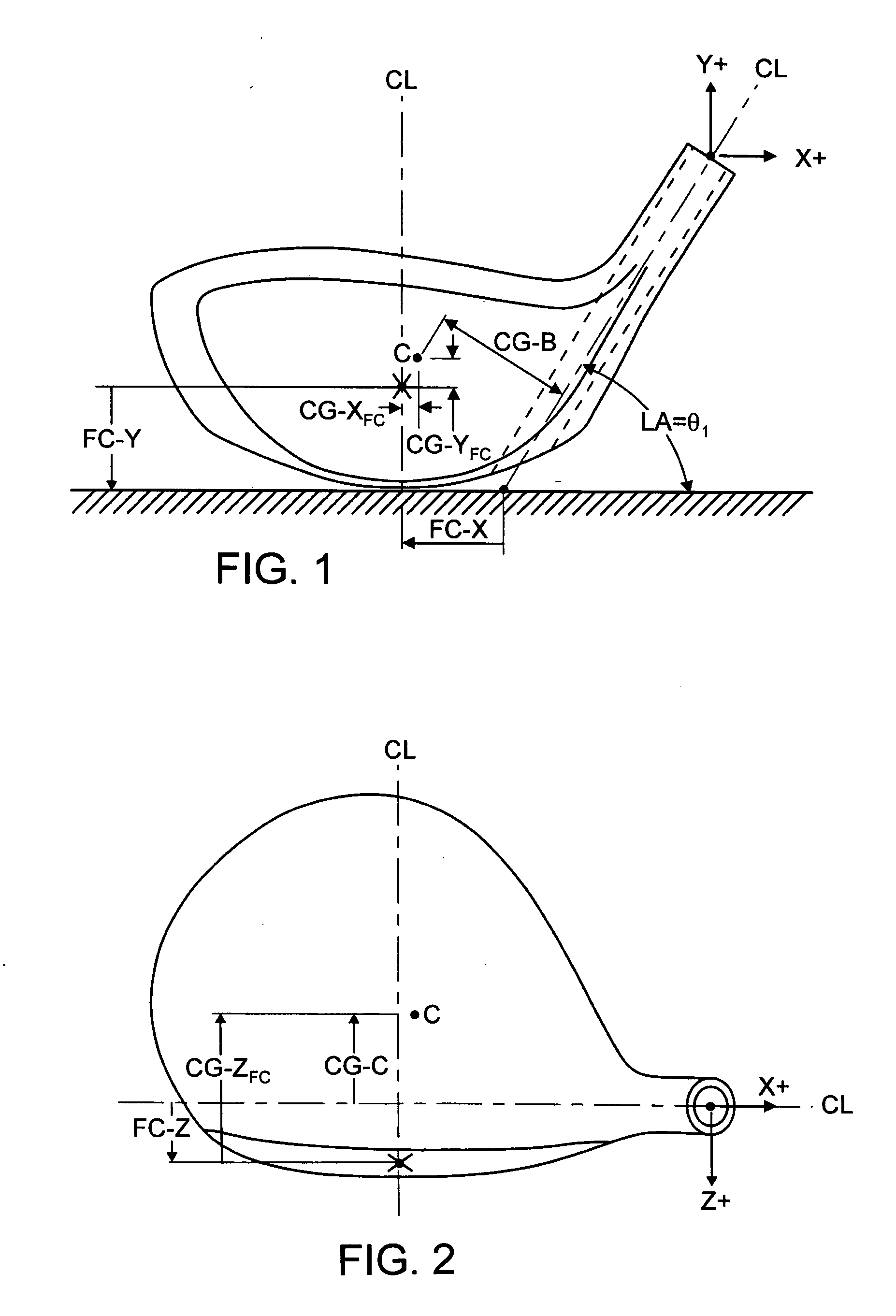

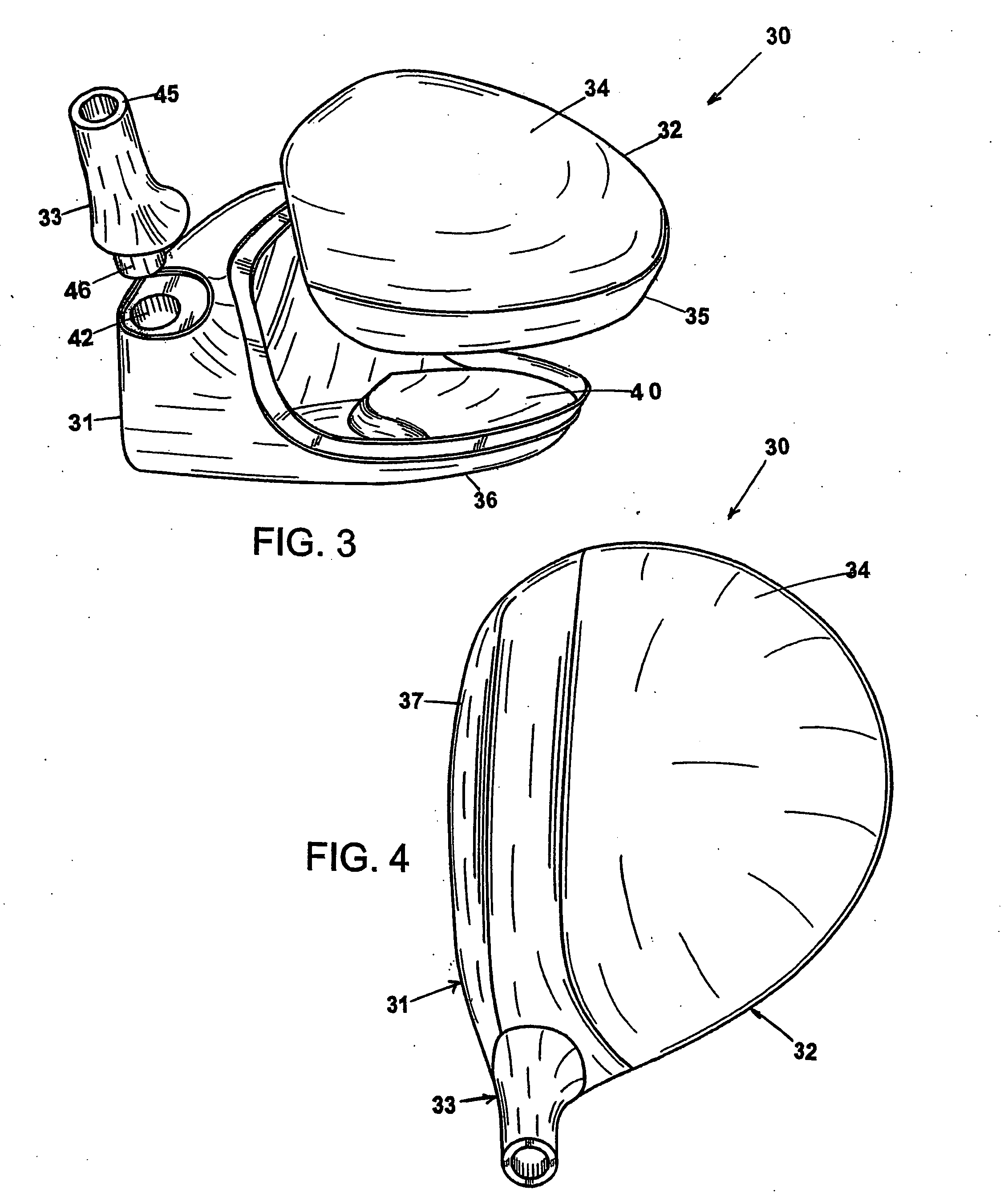

Golf club head

InactiveUS20060116218A1Increase deflectionSlow down the spin rateGolf clubsRacket sportsElastomerCoefficient of restitution

A metal wood golf club head is provided having a front face with an impact zone including a compliant area. Preferably, the compliant area is disposed in an upper portion of the front face. Preferably, a through-slit is provided in the front face to form the compliant area. The through-slit may be an elongated slot substantially parallel to a top of the front face and may include an elastomeric reinforcement. The compliant area creates an ultra-low center of gravity relative to the geometric face center, resulting in higher launch angles and spin rate ratios. The compliant area upwardly shifts the coefficient of restitution to the geometric center of the face and thereby increases the carry distance of a golf ball hit off the club head.

Owner:ACUSHNET CO

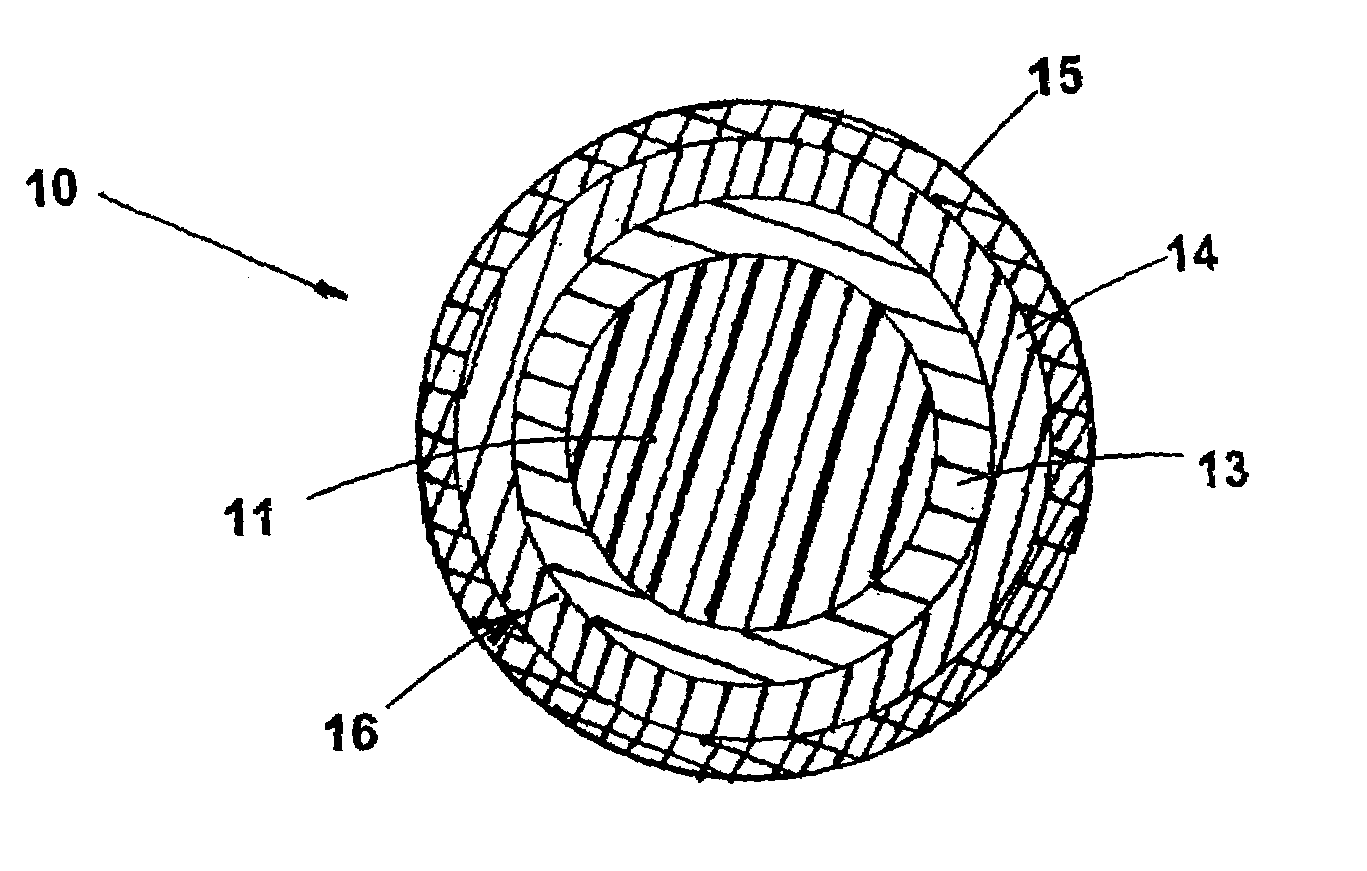

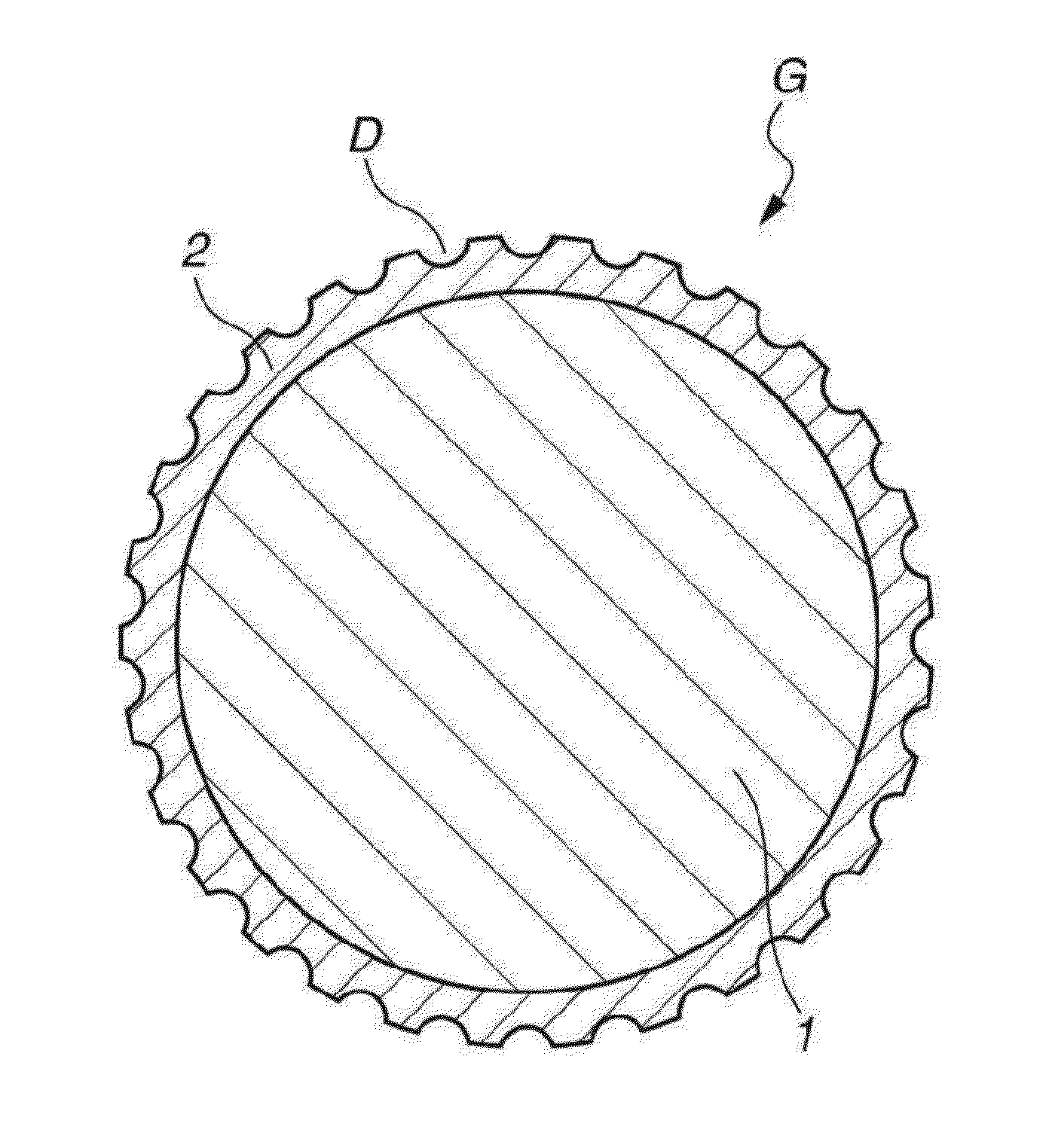

Golf ball

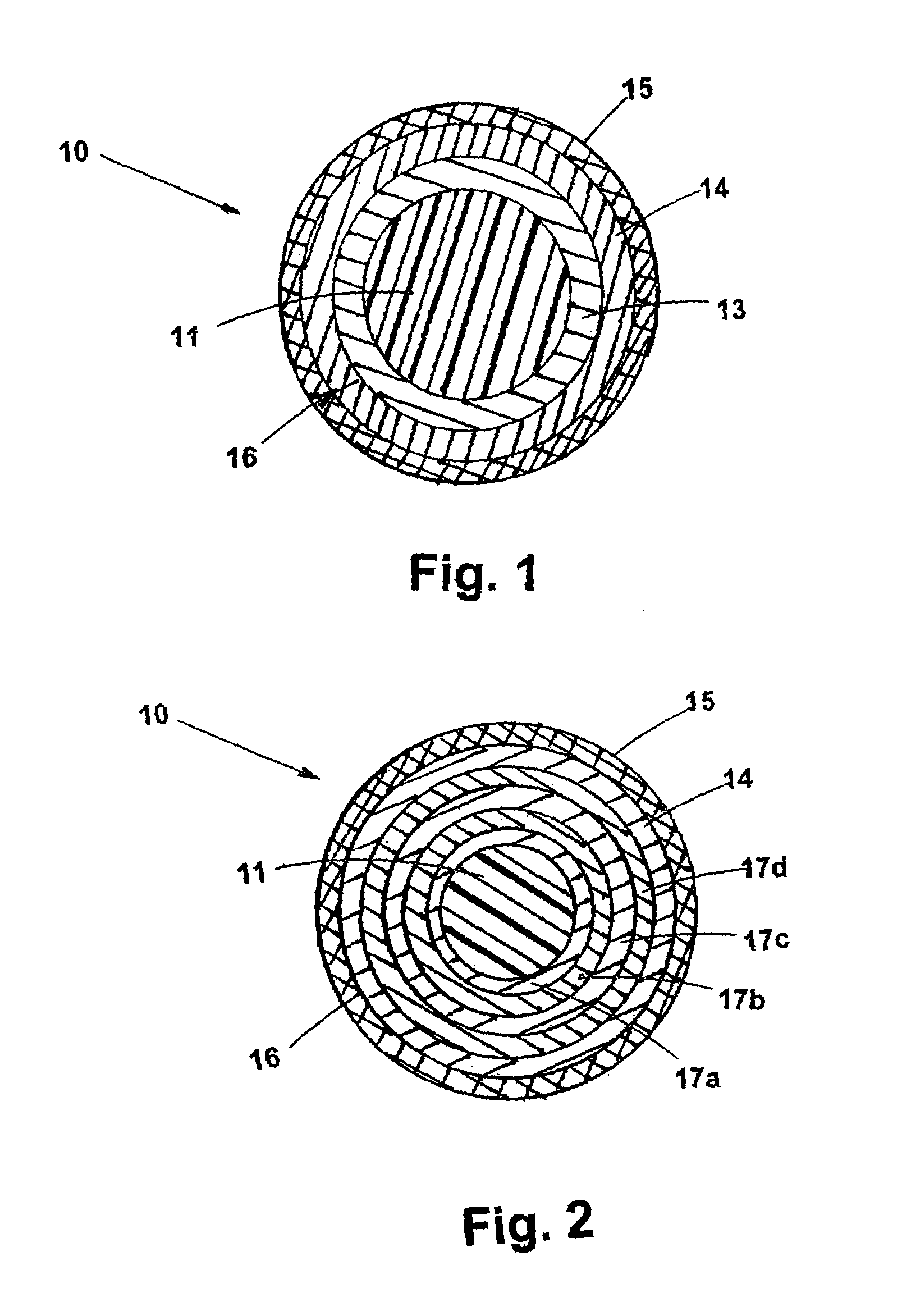

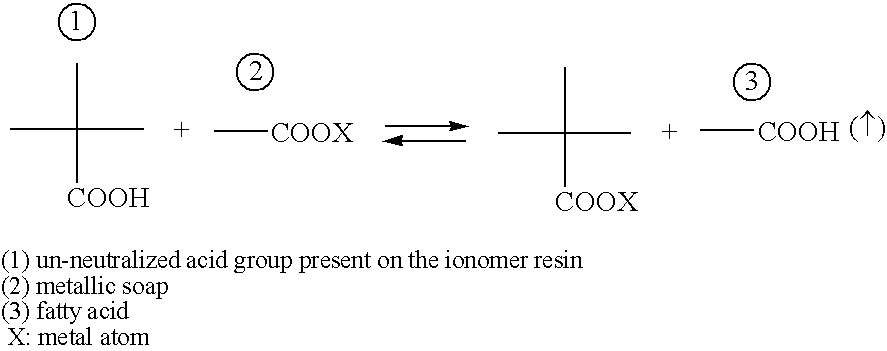

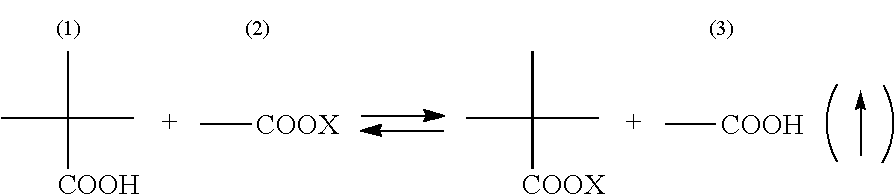

InactiveUS7074137B2Increasing moment of inertiaSlow down the spin rateLayered product treatmentSynthetic resin layered productsOuter coreIonomer

The present invention is directed towards a multi-layered core golf ball that comprises a thermoplastic inner casing layer molded between two polybutadiene core layers to create a faster golf ball with less spin, by designing a ball that has more of the stored energy of the core released at impact. One inner casing layer and / or an outer core layer is comprised of a partially or fully neutralized ionomer.

Owner:ACUSHNET CO

Golf ball

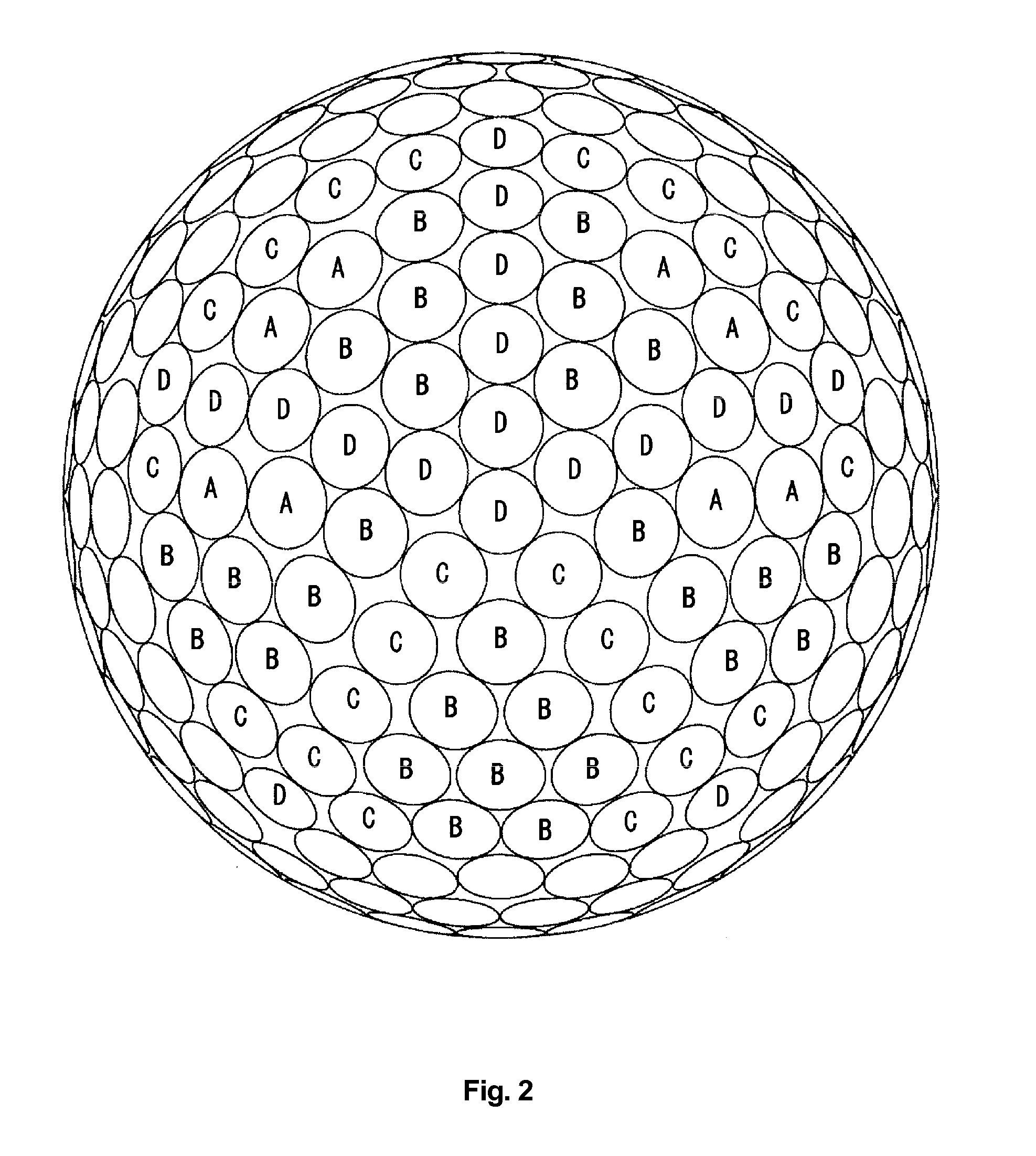

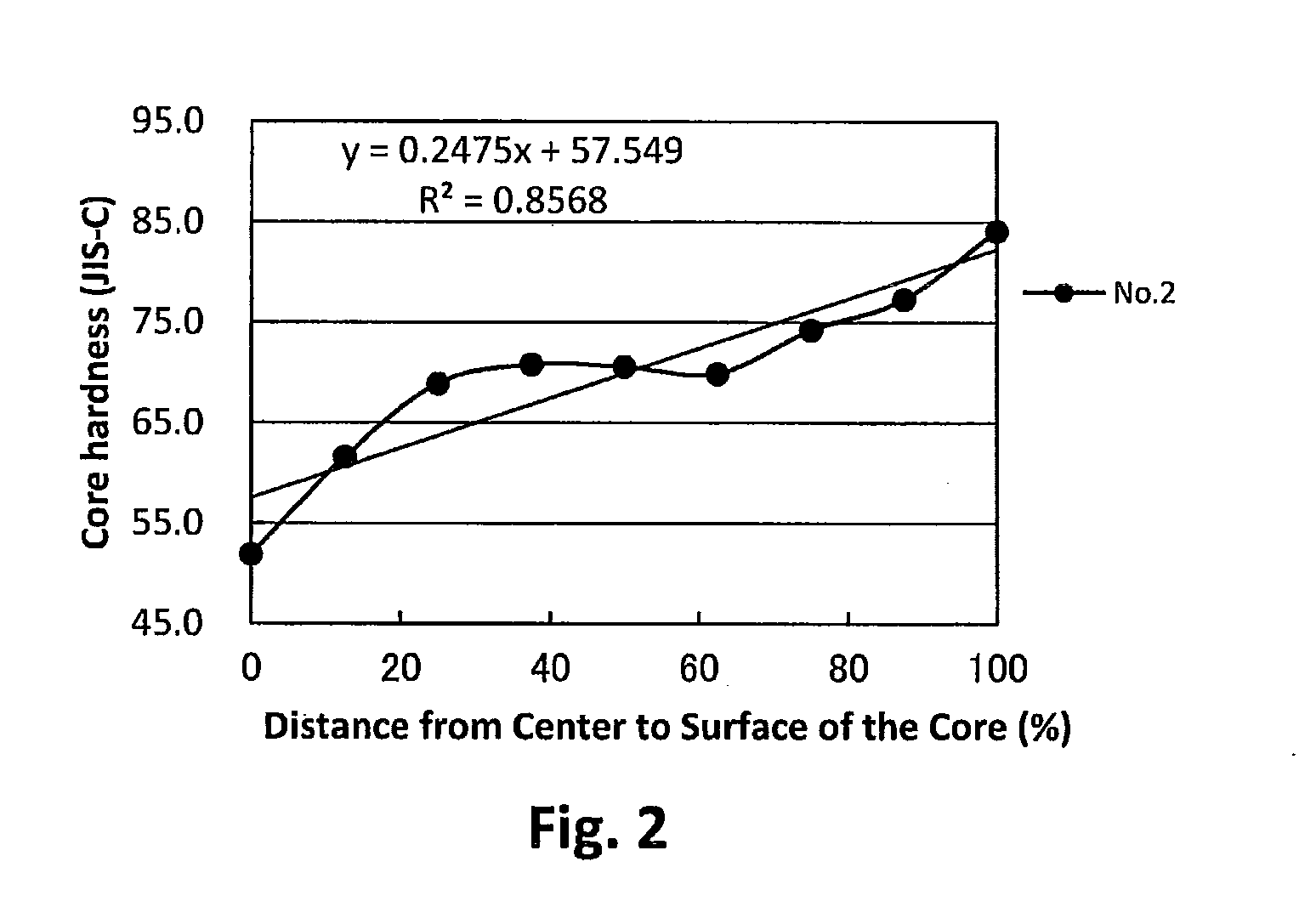

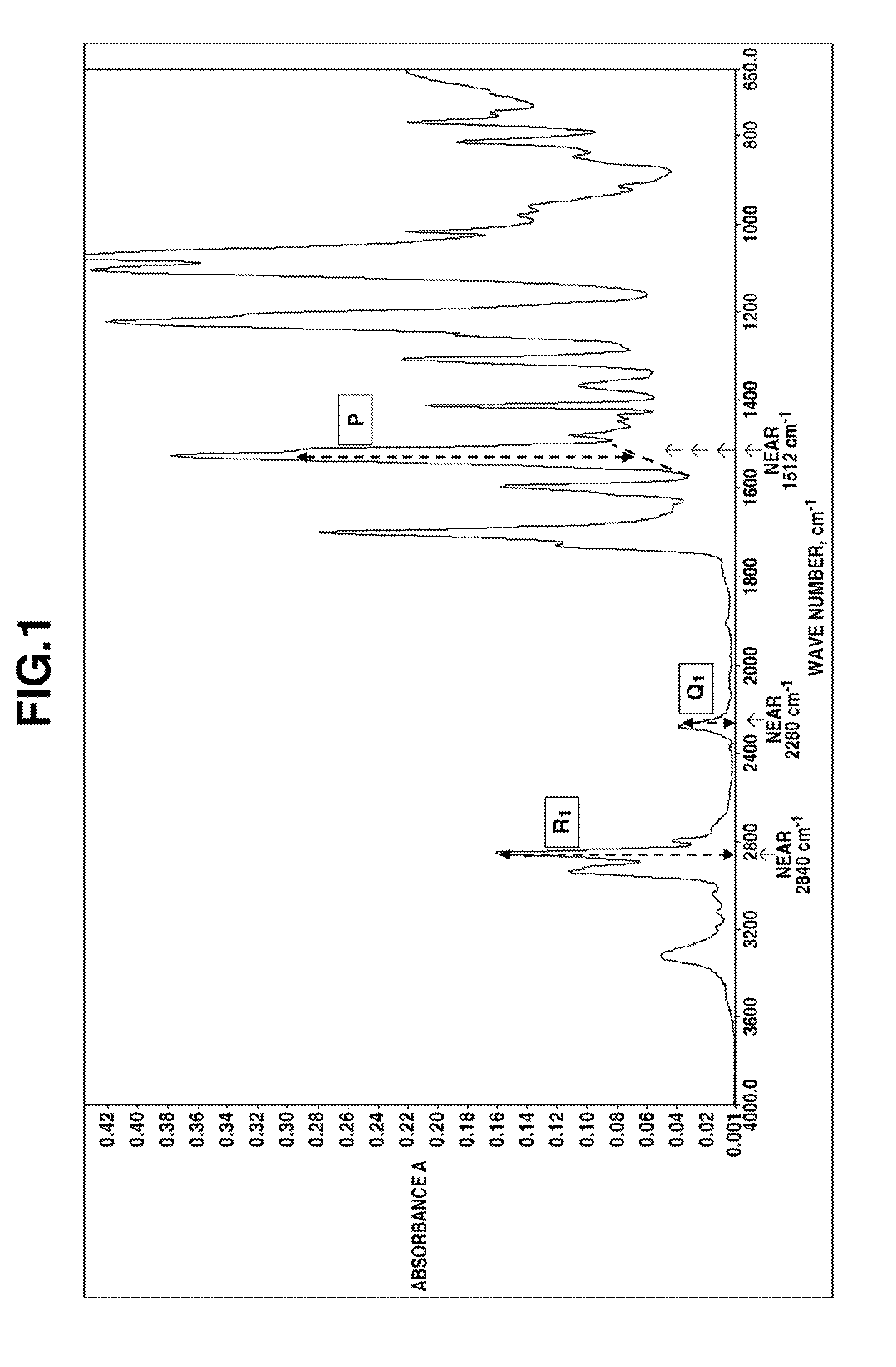

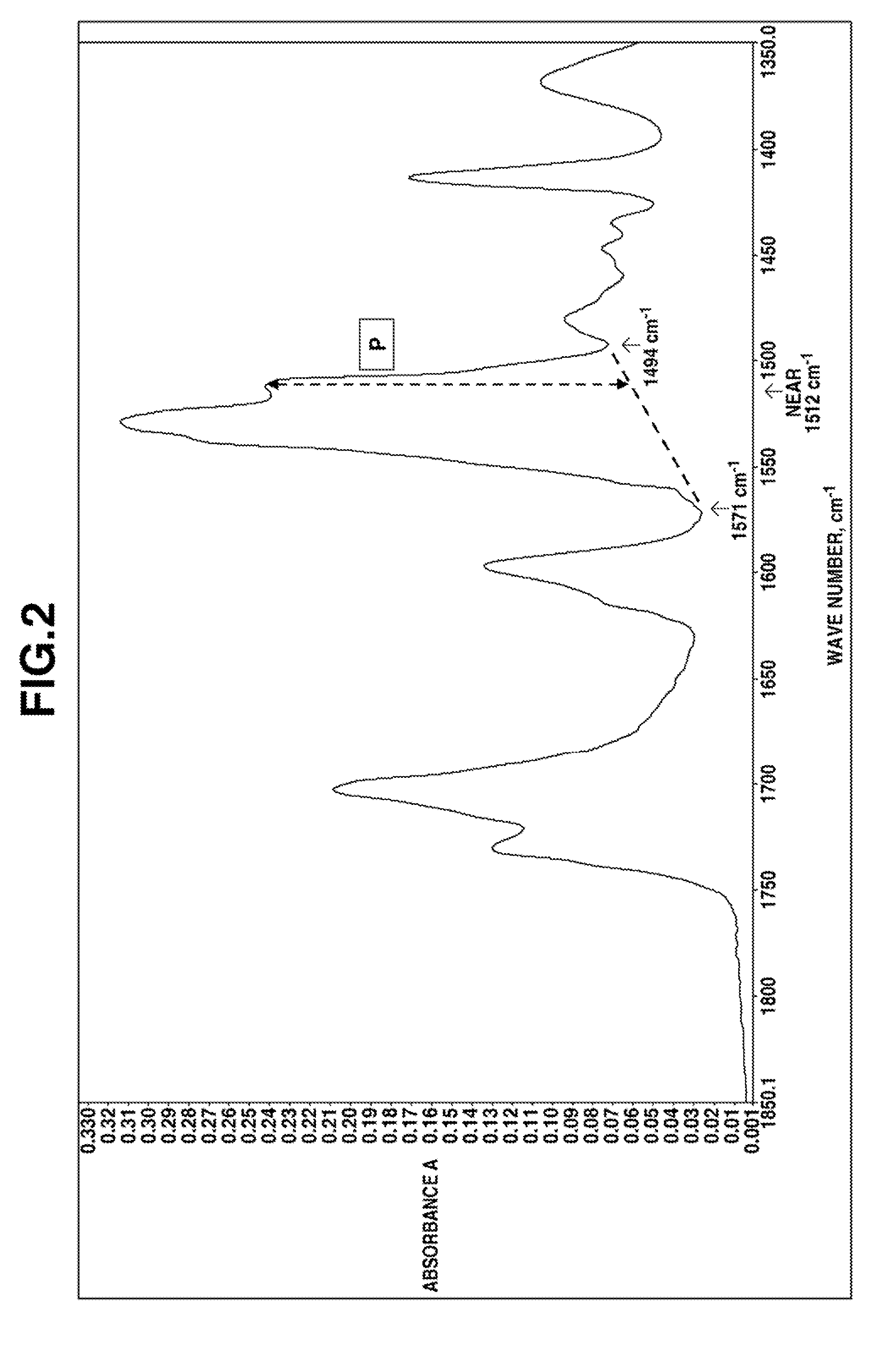

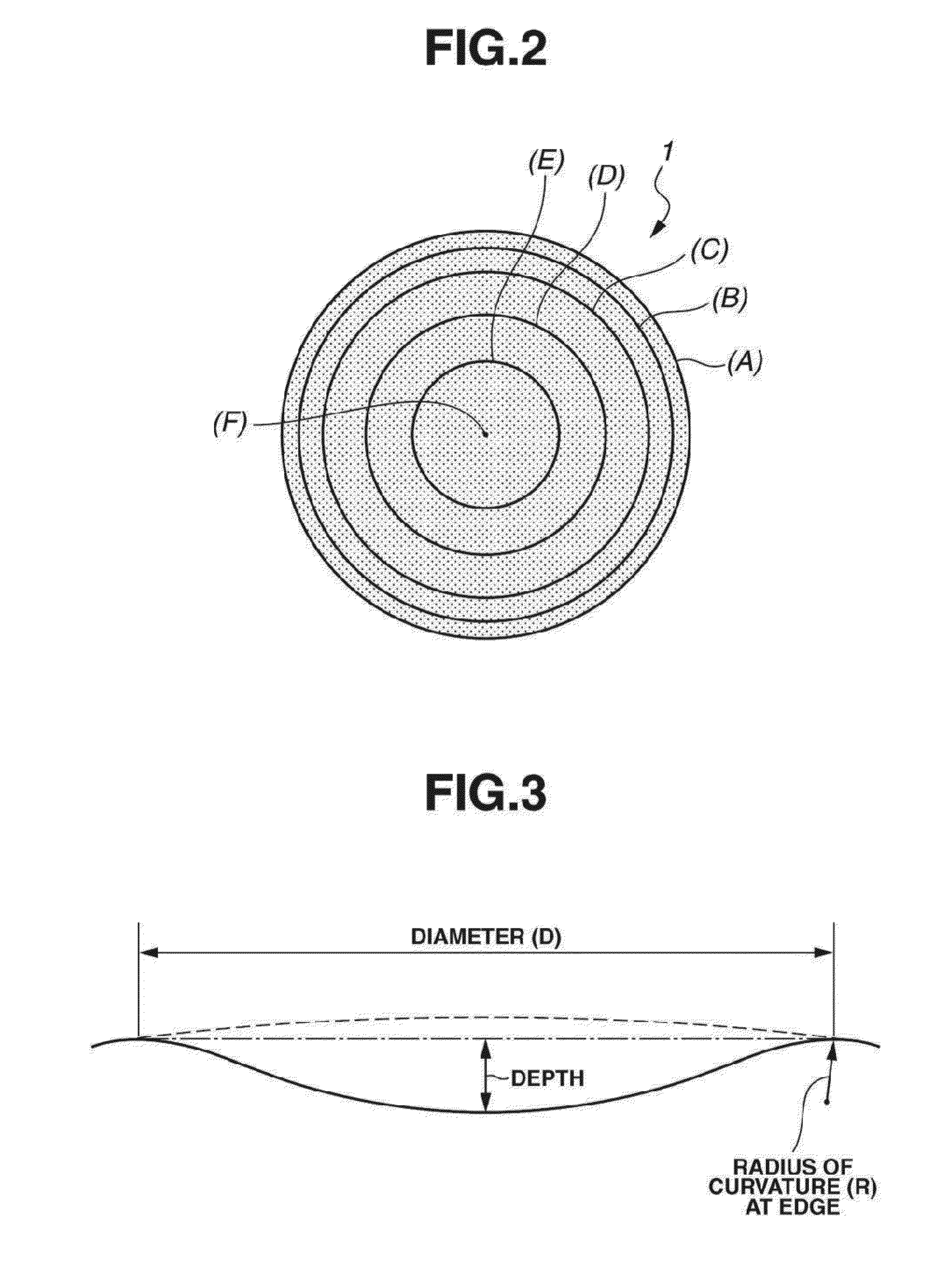

ActiveUS20130324318A1Improve controllabilitySlow down the spin ratePolyurea/polyurethane coatingsGolf ballsHardnessContact force

The present invention provides a golf ball comprising a golf ball body with a spherical core having one or more layers, an intermediate layer disposed outside the spherical core and a cover disposed outside the intermediate layer and a paint film formed on a surface of the golf ball body, and having a friction coefficient calculated using a contact force tester of 0.35 or more and 0.60 or less, wherein the golf ball body has specific plurality of dimples on the surface thereof, at least one layer of the spherical core is a rubber layer having a specific hardness distribution, and the rubber layer has a hardness at the outermost point which is greater than a hardness at the innermost point, and the intermediate layer has a slab hardness (Hm) which is greater than a slab hardness (Hc) of the cover.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

An object of the present invention is to provide a golf ball traveling a great flight distance on driver shots. The present invention provides a golf ball comprising a spherical core and at least one cover layer covering the spherical core, wherein the spherical core is formed from a rubber composition containing (a) base rubber, (b) an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and / or a metal salt thereof as a co-crosslinking agent, (c) a crosslinking initiator, (d) a carboxylic acid having 1 to 14 carbon atoms and / or a salt thereof, and (e) a halogen-substituted thiophenol and / or a metal salt thereof as an organic sulfur compound, provided that the rubber composition further contains (f) a metal compound in the case of containing only (b) the α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms as the co-crosslinking agent.

Owner:SUMITOMO RUBBER IND LTD

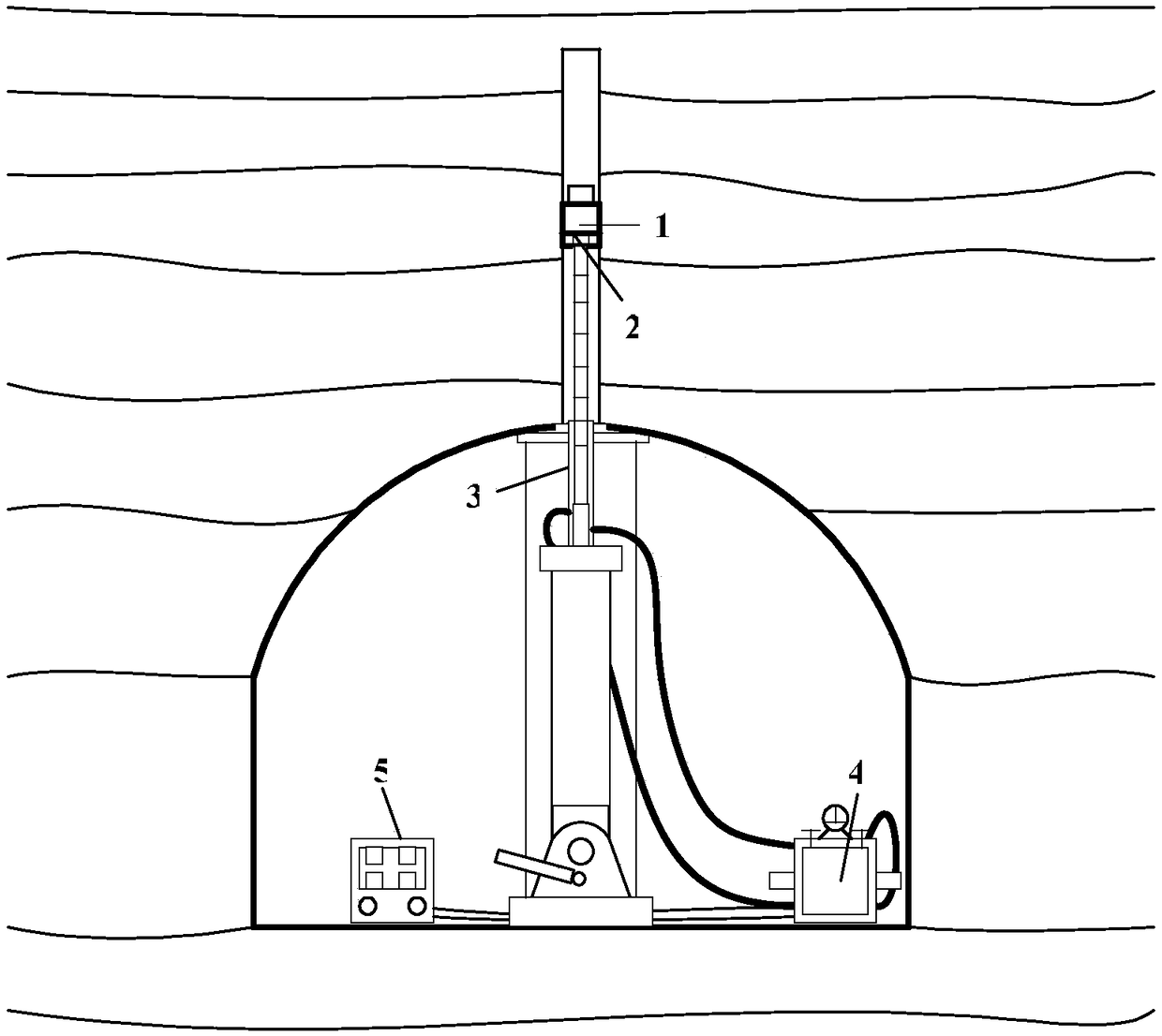

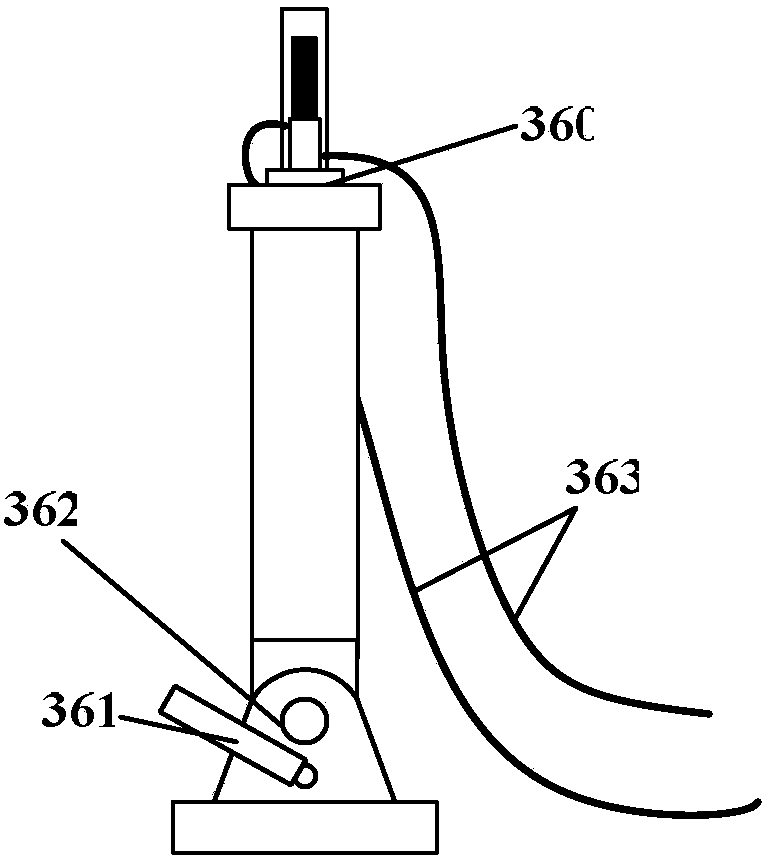

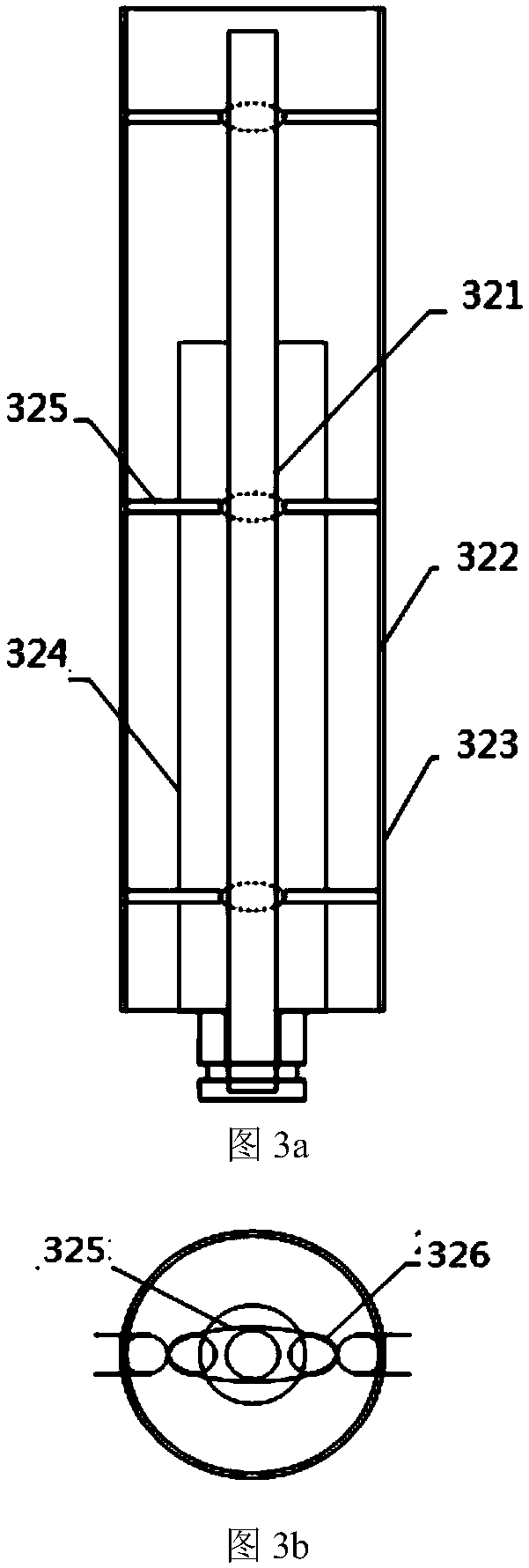

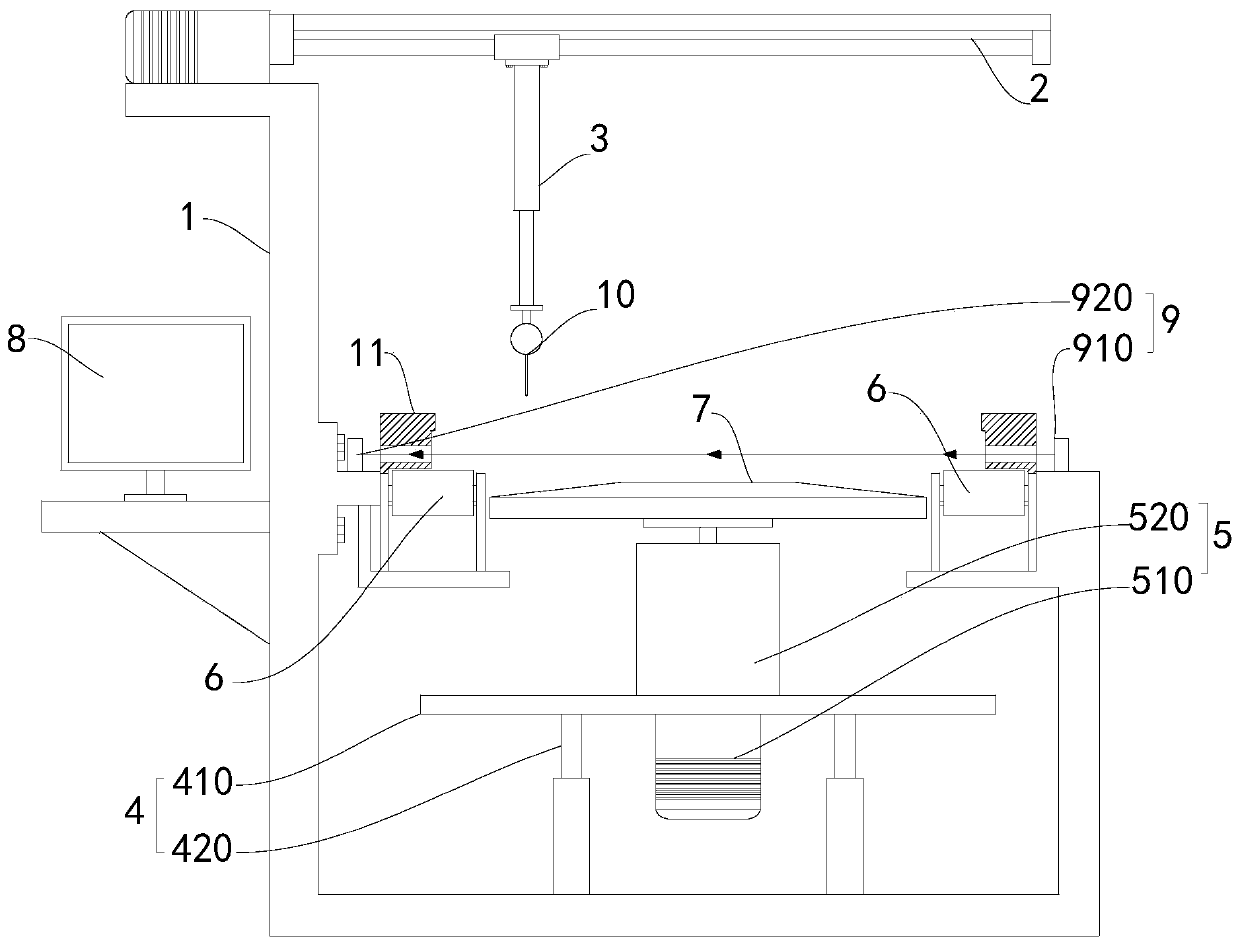

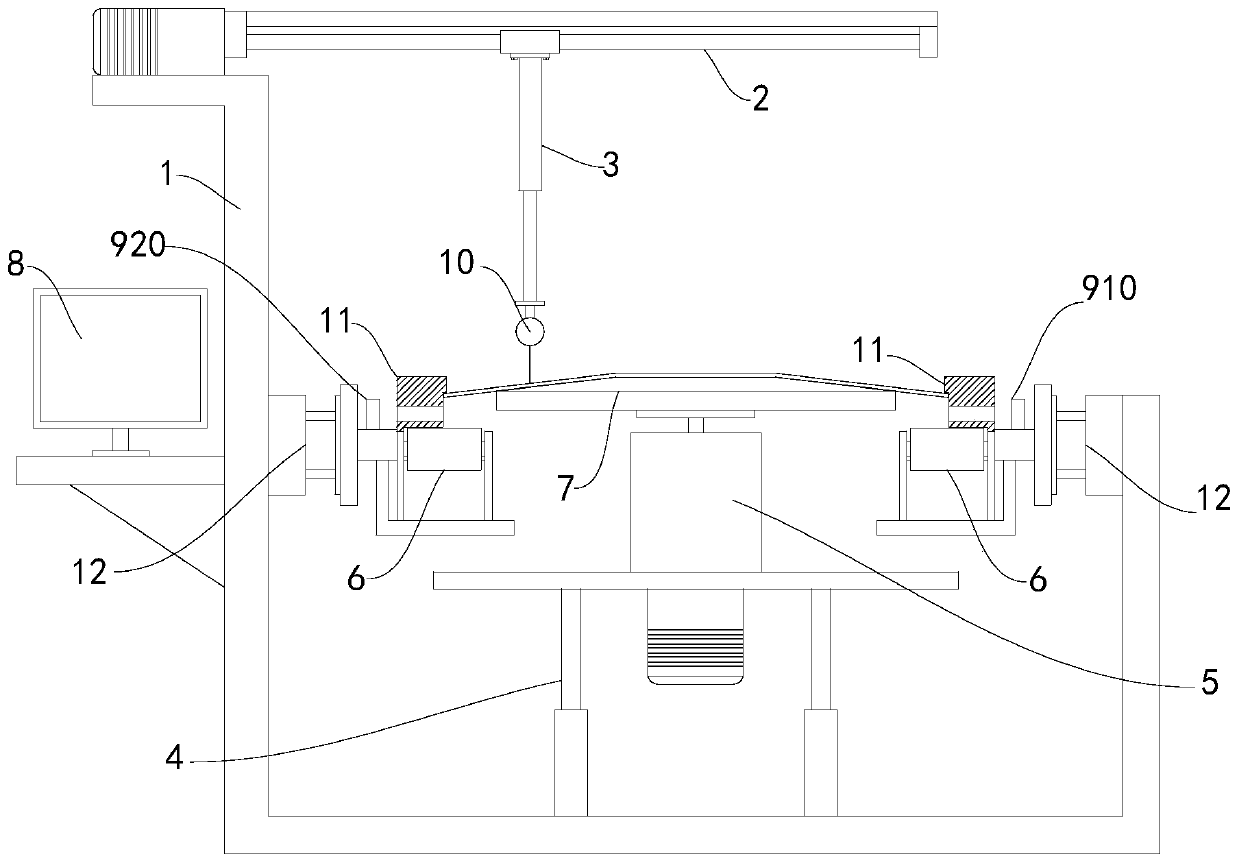

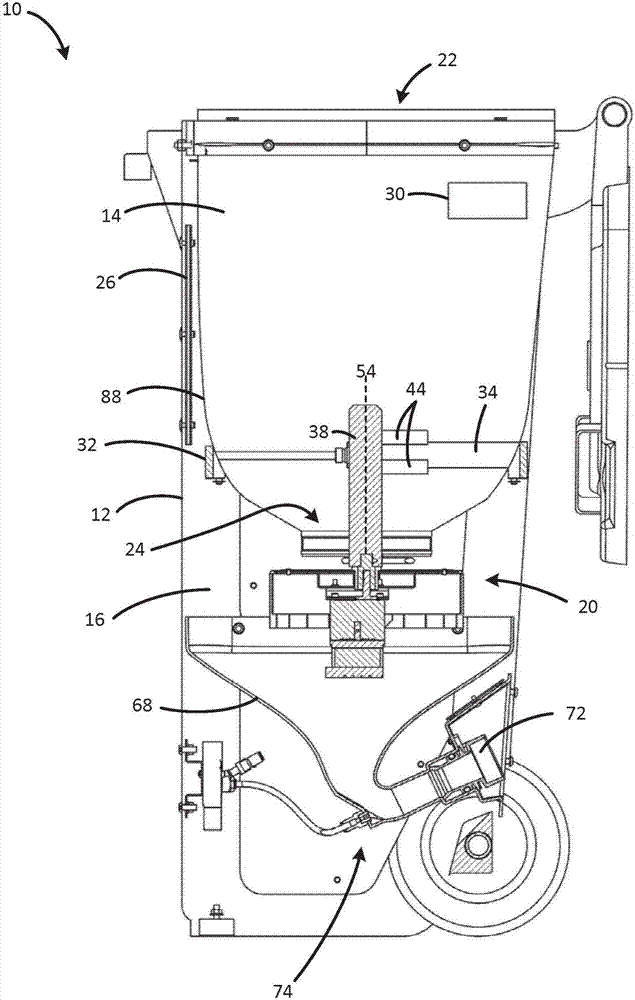

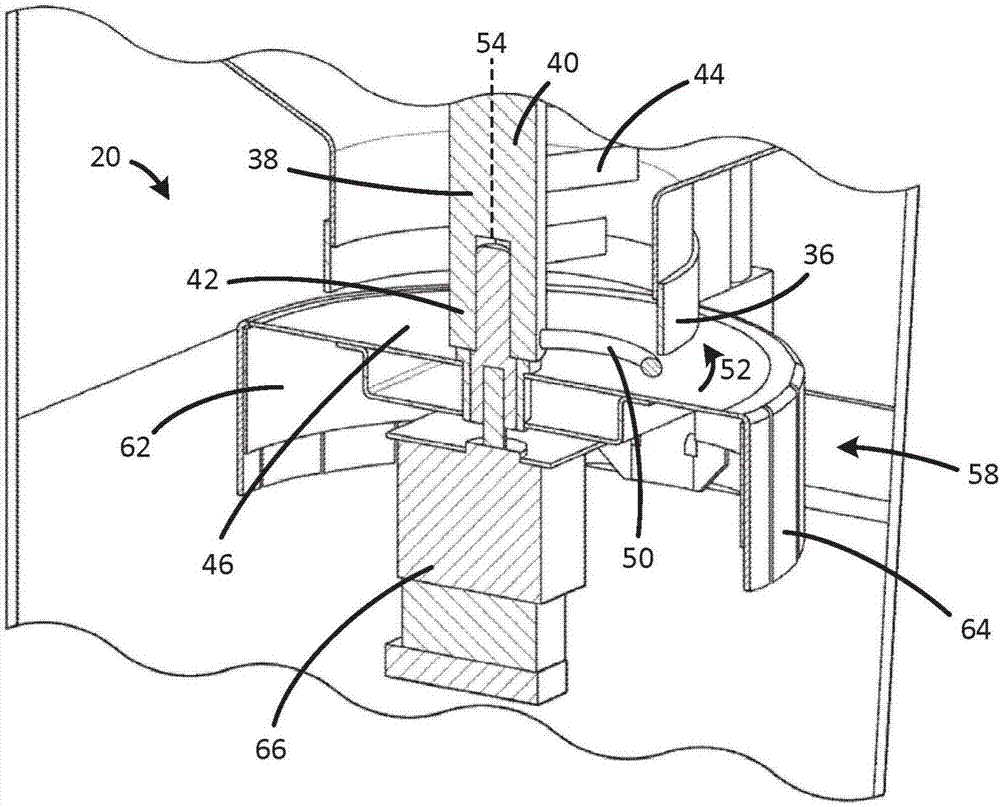

Drilling in-situ testing device for testing mechanical parameters of engineering rock mass and use method of drilling in-situ testing device

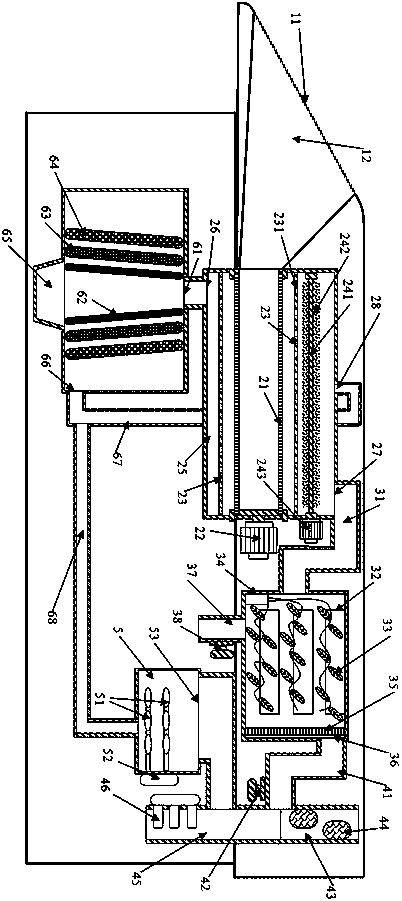

The invention discloses a drilling in-situ testing device for testing the mechanical parameters of an engineering rock mass and a use method of the drilling in-situ testing device. The device comprises a penetration sounding loading system, a multi-point testing rotational positioning system, a propelling support system, a hydraulic loading system and a control system. The penetration sounding loading system and the multi-point testing rotational positioning system are connected together through a bearing and can move along with a propelling lever of the propelling support system, and finally,the whole device is regulated and controlled through the hydraulic loading system and the control system. The device and the method drill and load and test the engineering rock mass in situ, the deformation and fracture characteristics of the rock mass having different lithological characters and different drilling depths and the load-displacement curve and data of a surrounding rock in the loading process are acquired, the relevant technical indexes and parameters are obtained through conversion, the device and the method are favorable for accurately simulating the numerical value and effectively designing the supporting scheme in the construction process, the supporting strength and the engineering strength are guaranteed, and the guarantee is provided for the safety construction of theengineering like rock and soil, water resources and hydropower, and mines.

Owner:SHANDONG UNIV OF SCI & TECH

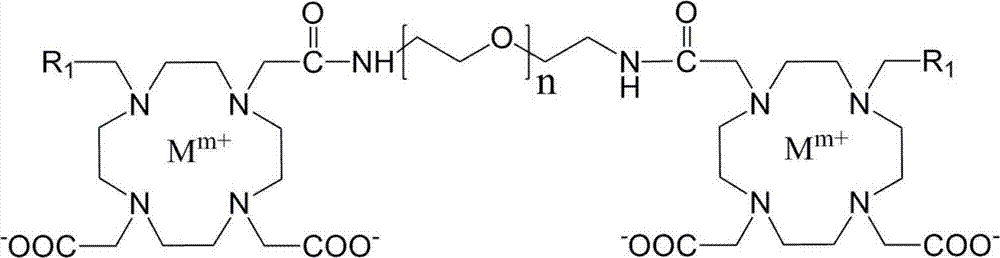

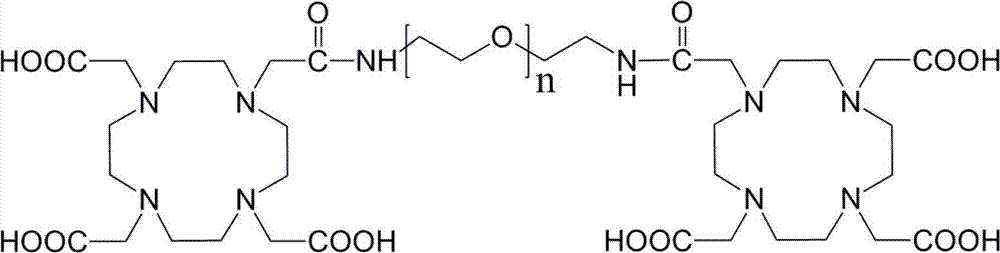

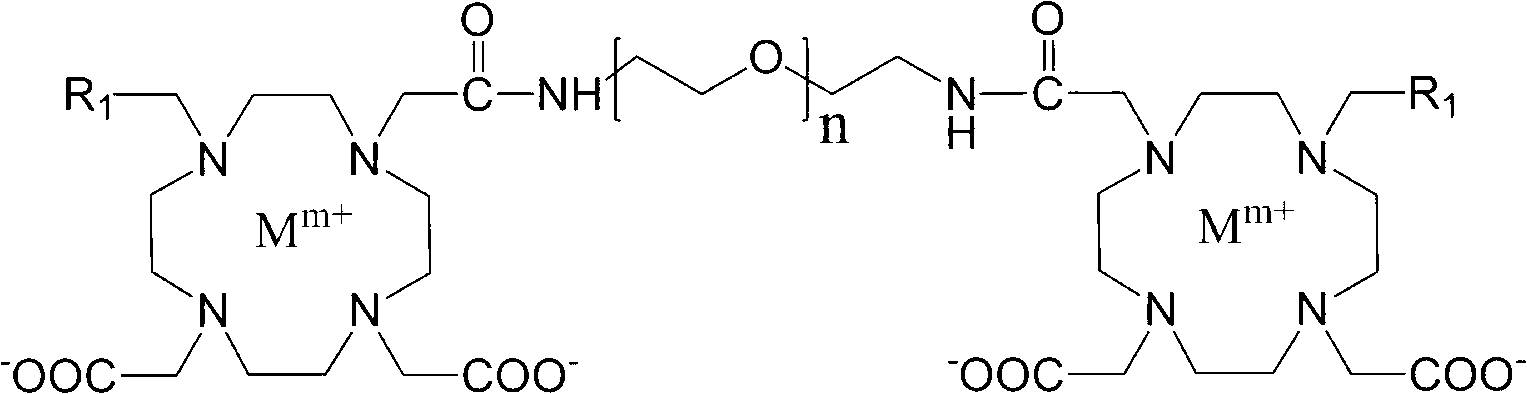

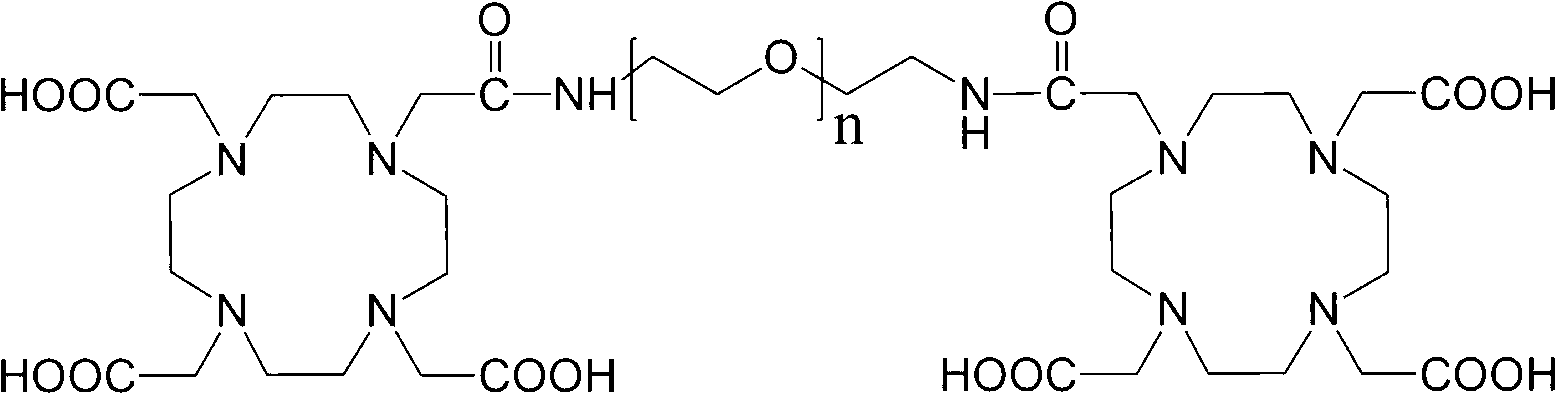

Diamino polyethylene glycol modified paramagnetic metal complex magnetic resonance imaging contrast agent

ActiveCN102727911AGood water solubilityConvenient IVEchographic/ultrasound-imaging preparationsX-ray constrast preparationsSolubilityRare-earth element

The invention provides a diamino polyethylene glycol modified paramagnetic metal complex magnetic resonance imaging contrast agent, and aims at solving the problems of low relaxation rate, high toxicity and large dosage of a contrast agent in the prior art. The contrast agent is prepared by the following steps: reacting 1,4,7,10-tetrazacyclododecane-1,4,7,10-tetraacetic acid compound with diaminopolyethylene glycol with different molecular weights; preparing a macromolecular ligand through an amidation reaction; and forming a paramagnetic metal complex with paramagnetic metal elements Sc, Ti, V, Mn, Cu, Mo, Ru, Fe or positive trivalent or divalent ion of lanthanide rare-earth elements. The contrast agent has the advantages of high stability, water solubility, relaxation rate and small dosage.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Multi-piece solid golf ball

InactiveUS20090036232A1Improved ball reboundSlow down the spin rateGolf ballsSolid ballsIonomerEngineering

The present invention provides a multi-piece solid golf ball having a core obtained by molding under heat a specific rubber composition and having a cover of at least three layers which is composed of a thermoplastic resin material and encases the core. By optimizing the deflection of the core under a specific load, optimizing the hardness at the center of the core and the hardnesses of the innermost cover layer, outermost cover layer and intermediate cover layer, setting the combined thickness of the cover layers to at least a specific value, and forming the innermost cover layer of a highly neutralized ionomer resin composition, the spin rate of the ball on shots taken with a driver can be significantly reduced, enabling the distance traveled by the ball to be increased. Moreover, the ball has a good feel on shots with a driver.

Owner:BRIDGESTONE SPORTS

Golf ball

InactiveUS20110201453A1Convenient distanceAppropriate speedGolf ballsSolid ballsThermoplastic polyurethaneEngineering

The invention provides a golf ball having a core, at least one intermediate layer encasing the core, and a cover. The intermediate layer is formed primarily of a specific ionomer resin composition that is highly neutralized. The cover is formed by injection molding a single resin blend composed primarily of a thermoplastic polyurethane and (g) a polyisocyanate compound in at least some portion of which all the isocyanate groups on the molecule are present in an unreacted state. The golf ball of the invention has a low spin rate on shots with a driver, enabling it to travel a good distance, and achieves a sufficient spin rate on shots with a short iron such as a wedge. The ball also has an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

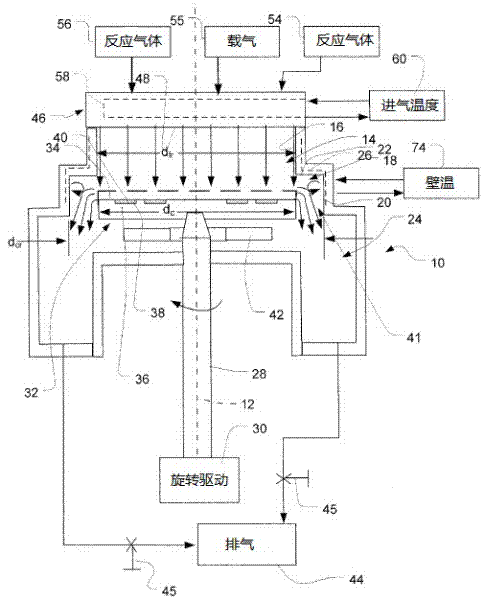

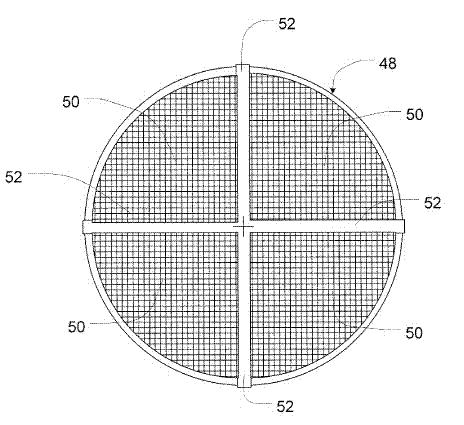

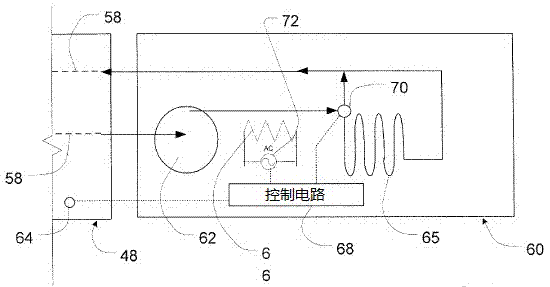

Chemical vapor deposition with elevated temperature gas injection

InactiveCN102272892ASlow down the spin rateLow airflow rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseReactive gas

A chemical vapor deposition reactor and method. Reactive gases, such as gases including a Group III metal source and a Group V metal source, are introduced into a rotating-disc reactor and directed downwardly onto a wafer carrier and substrates which are maintained at an elevated substrate temperature, typically above about 400° C. and normally about 700-1100° C. to deposit a compound such as a III-V semiconductor. The gases are introduced into the reactor at an inlet temperature desirably above about 75° C. and most preferably about 100°-250° C. The walls of the reactor may be at a temperature close to the inlet temperature. Use of an elevated inlet temperature allows the use of a lower rate of rotation of the wafer carrier, a higher operating pressure, lower flow rate, or some combination of these.

Owner:VEECO INSTR

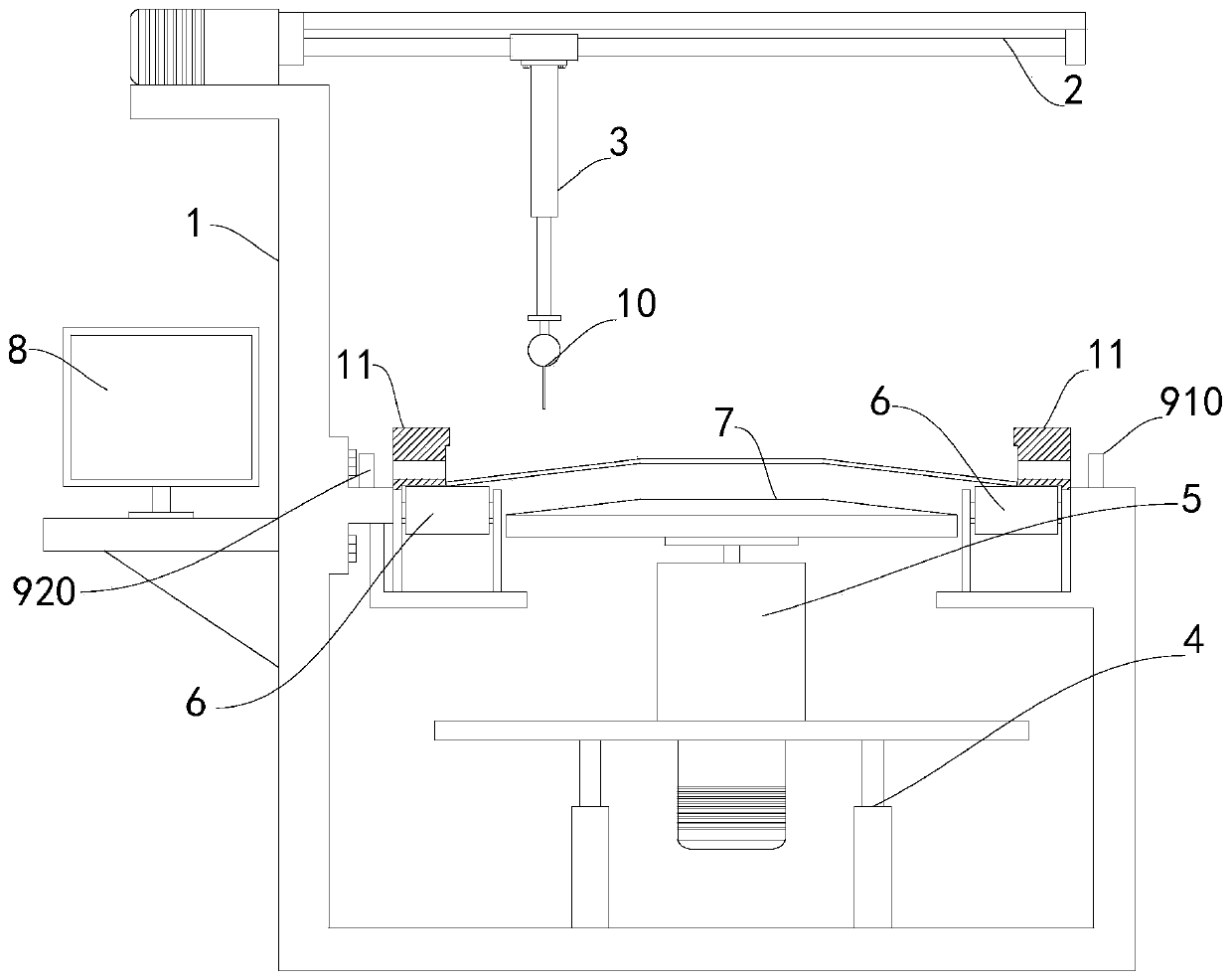

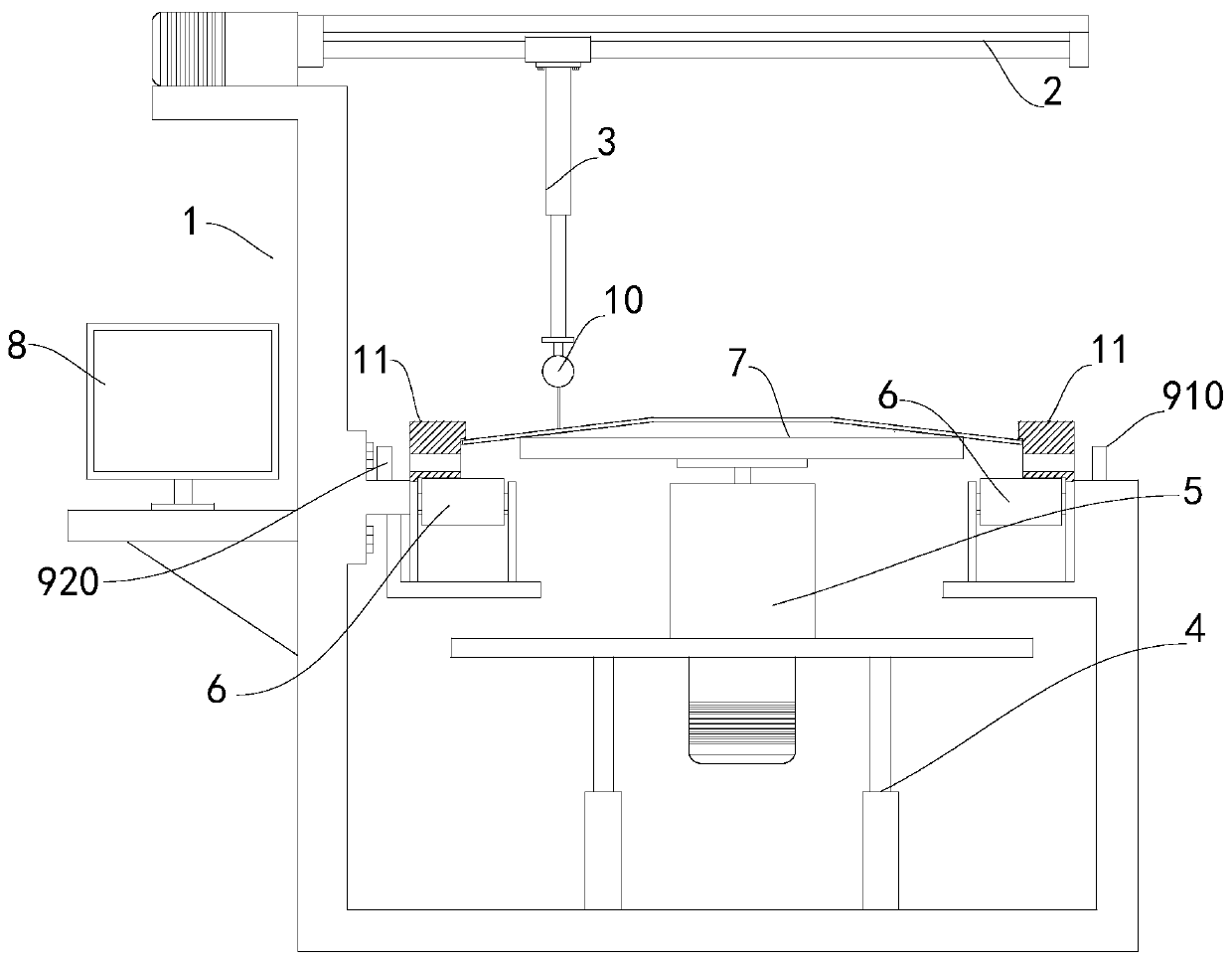

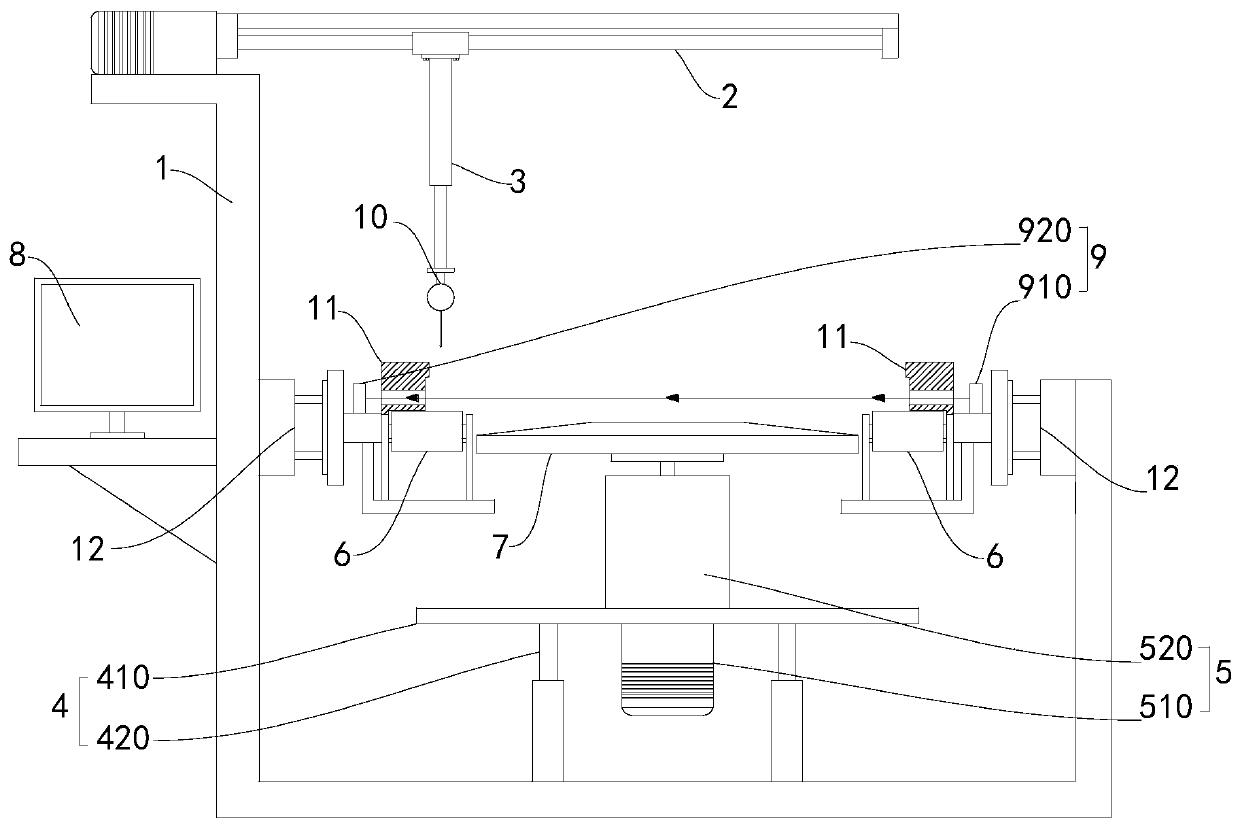

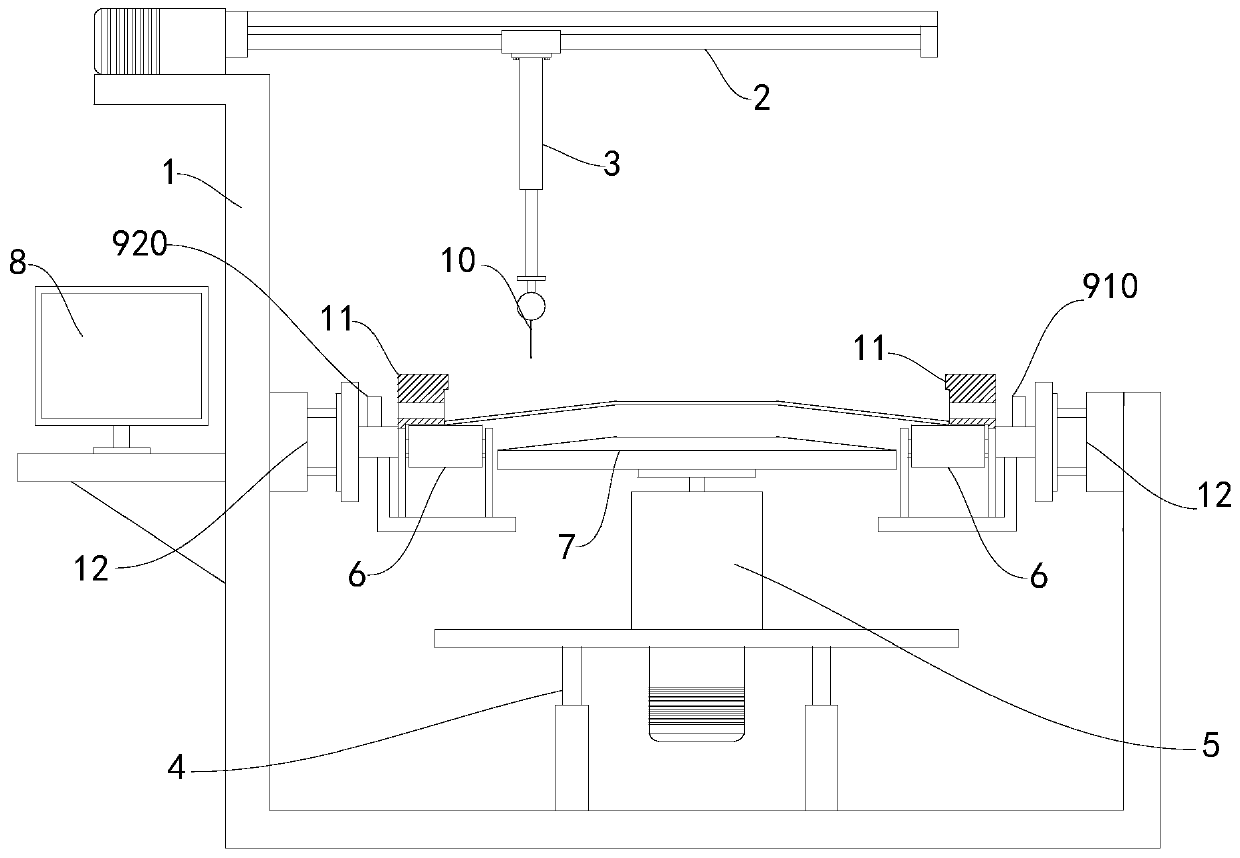

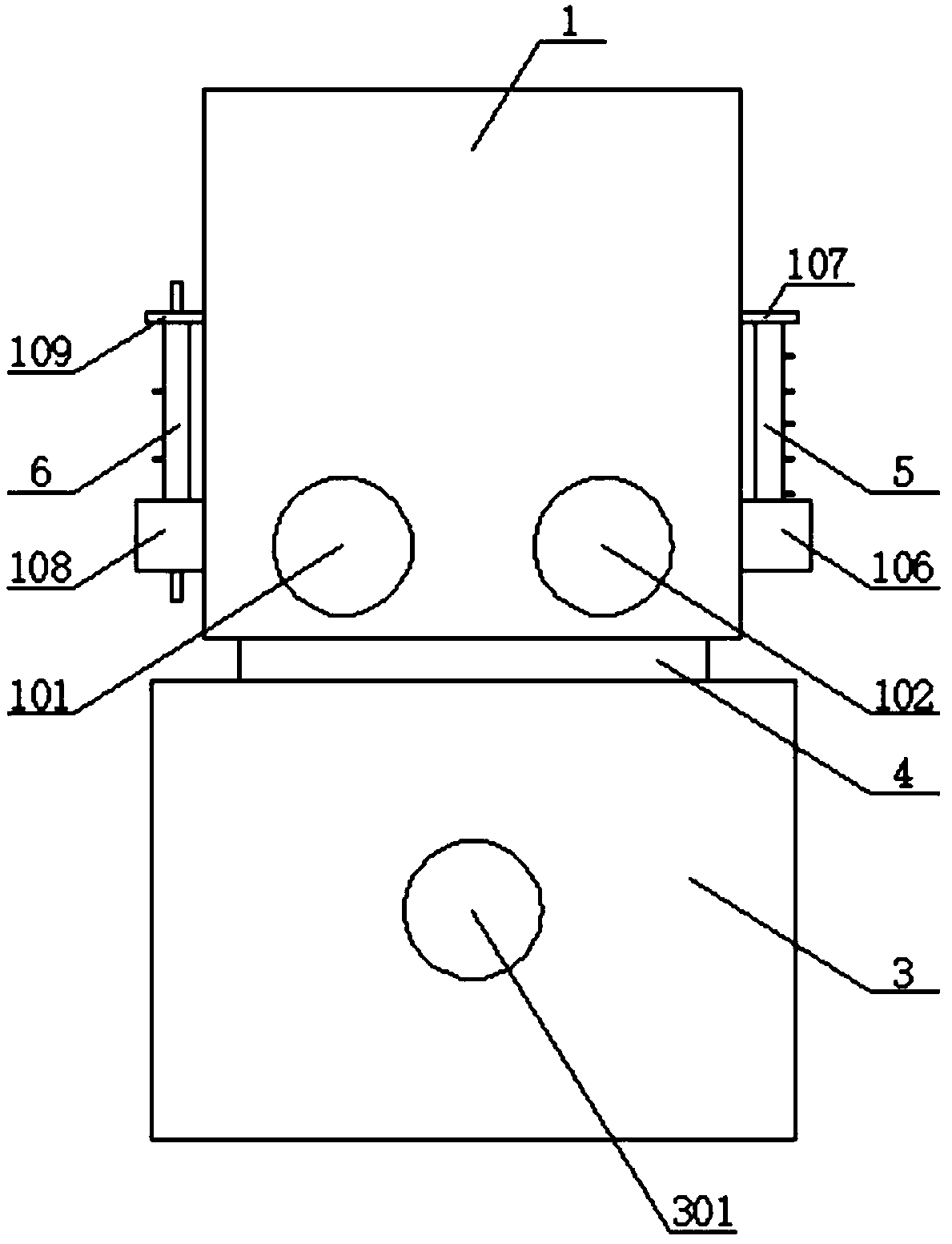

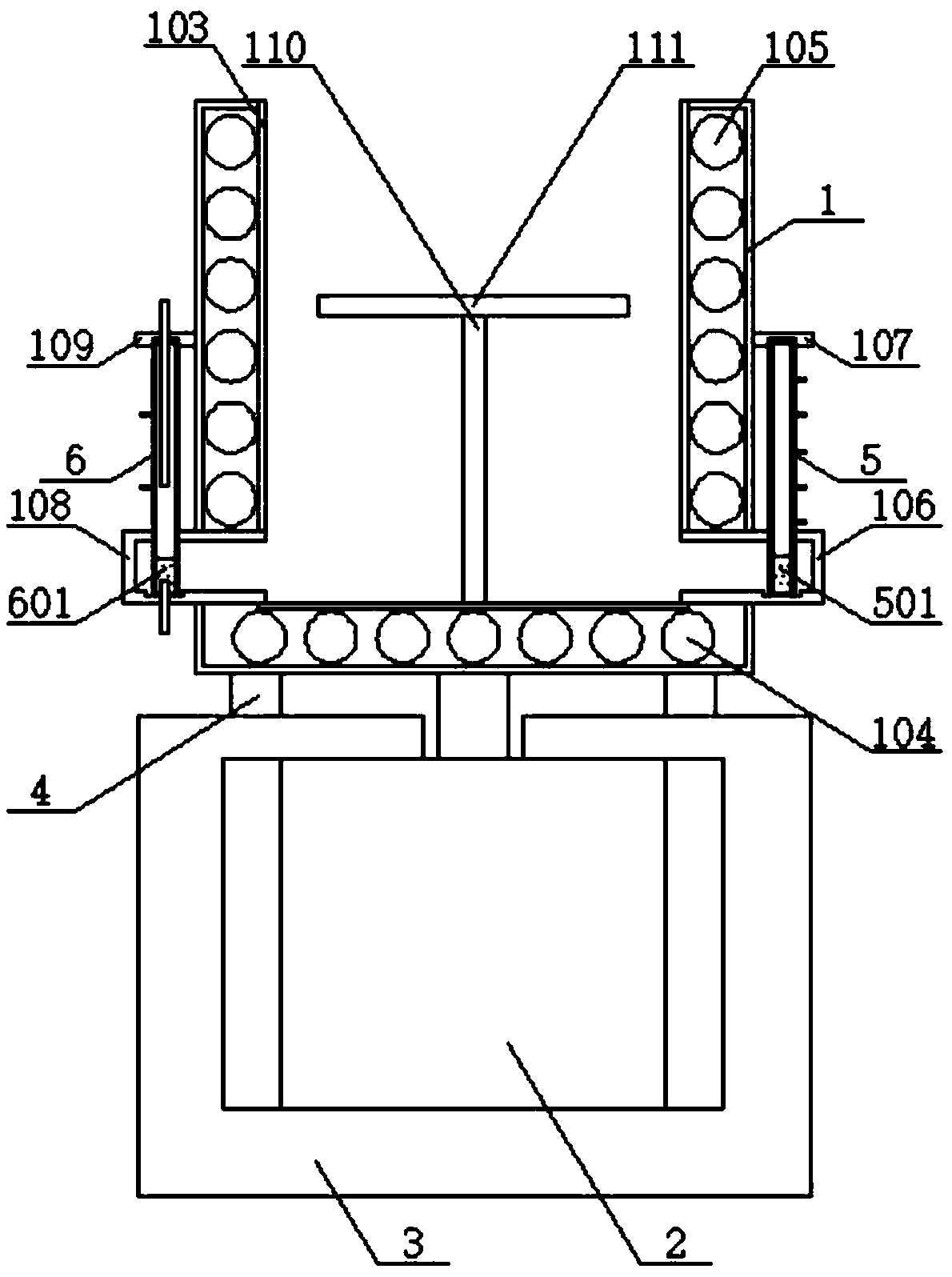

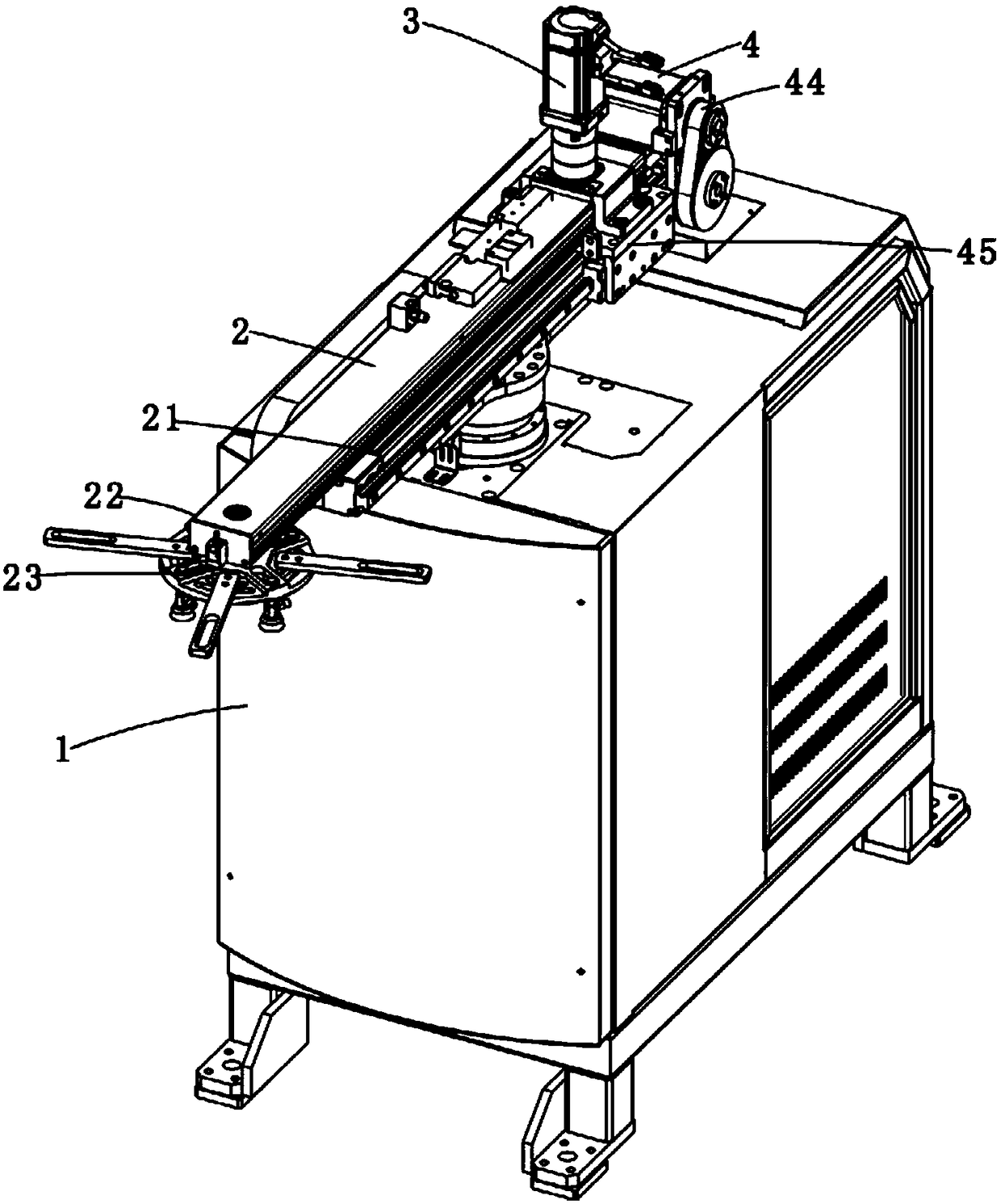

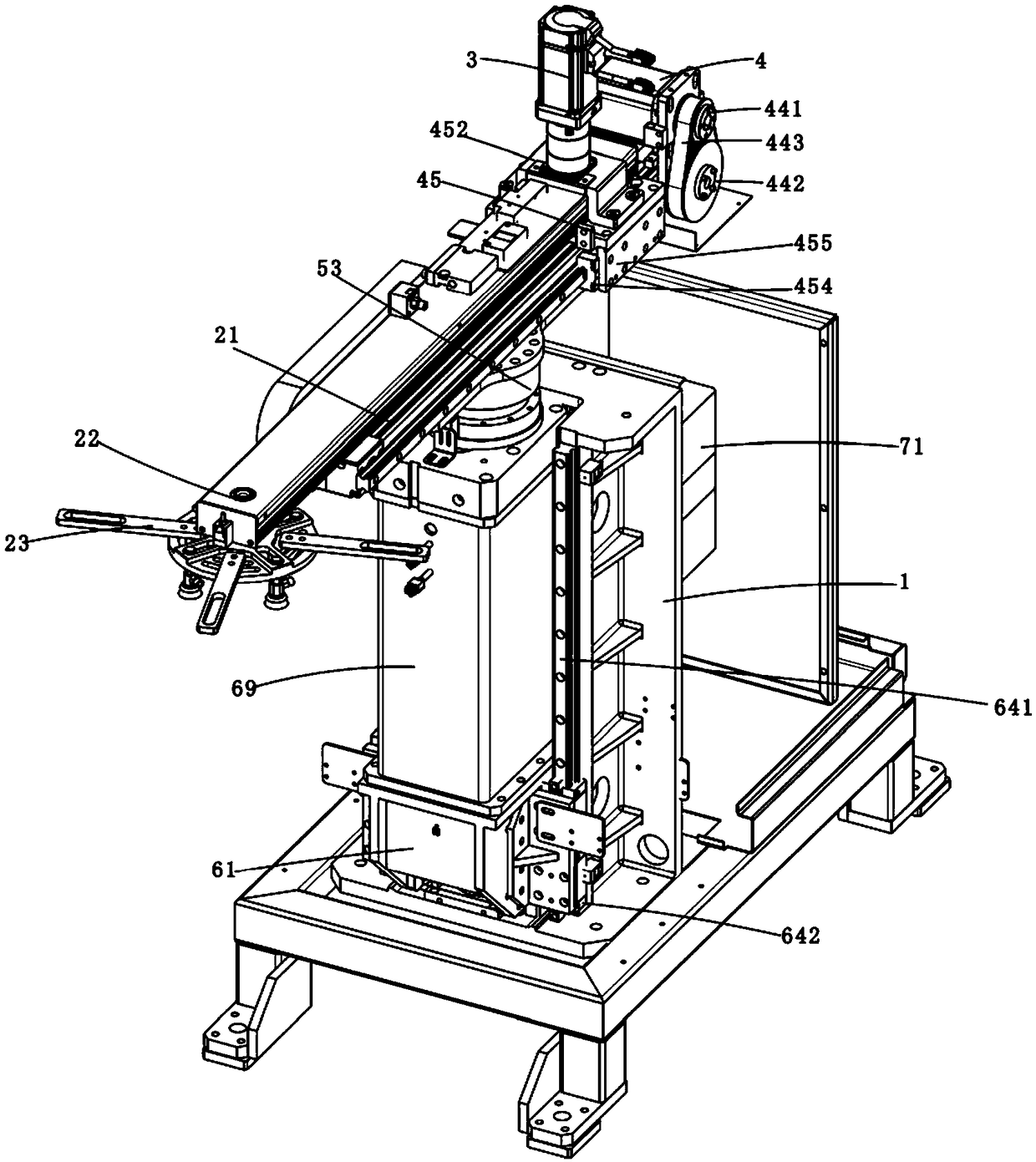

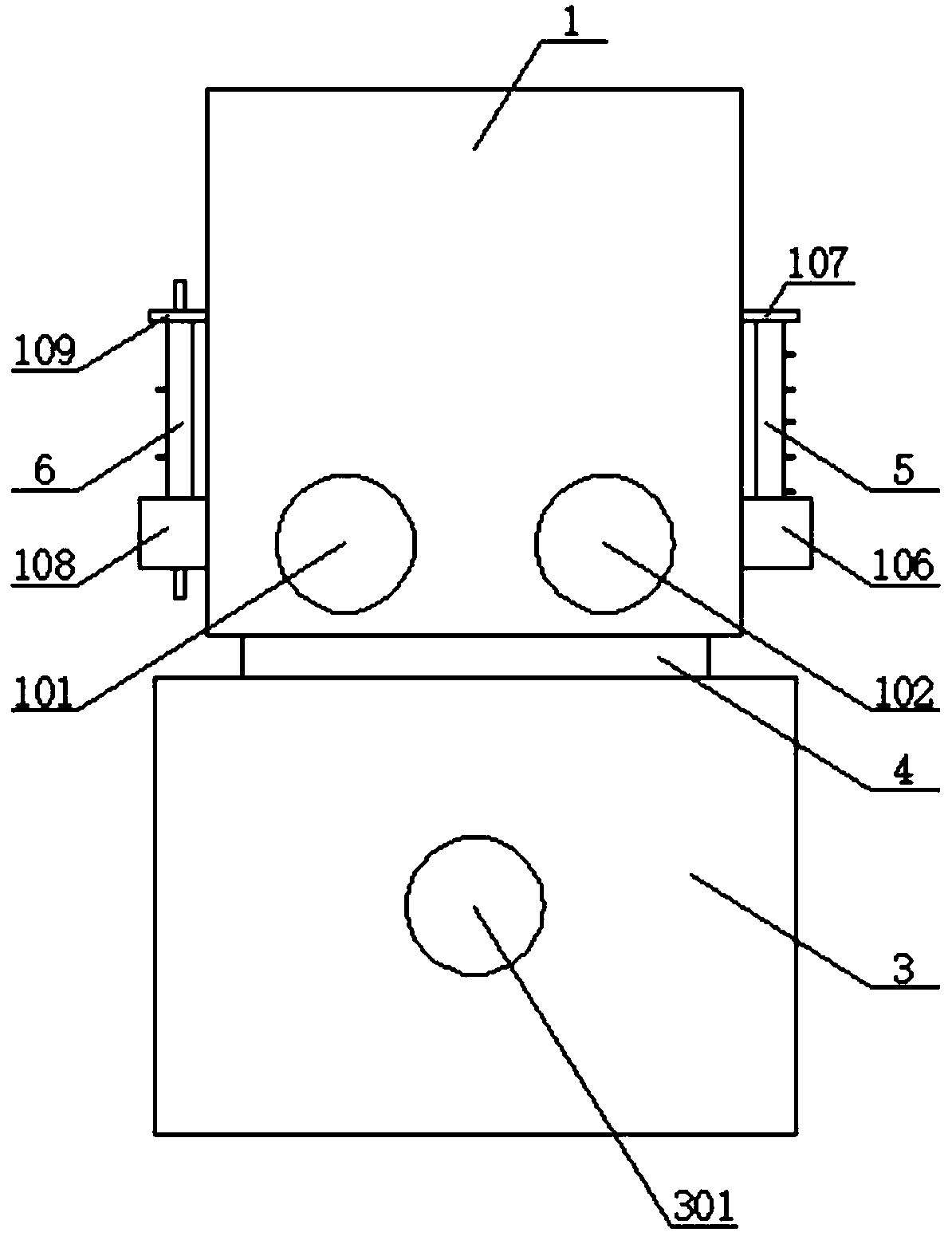

Diaphragm spring quality detecting device

PendingCN110207566ANo human intervention requiredImprove detection efficiencyAngles/taper measurementsMechanical roughness/irregularity measurementsElectricityIndustrial engineering

Owner:HUBEI DAFAN AUTO PARTS

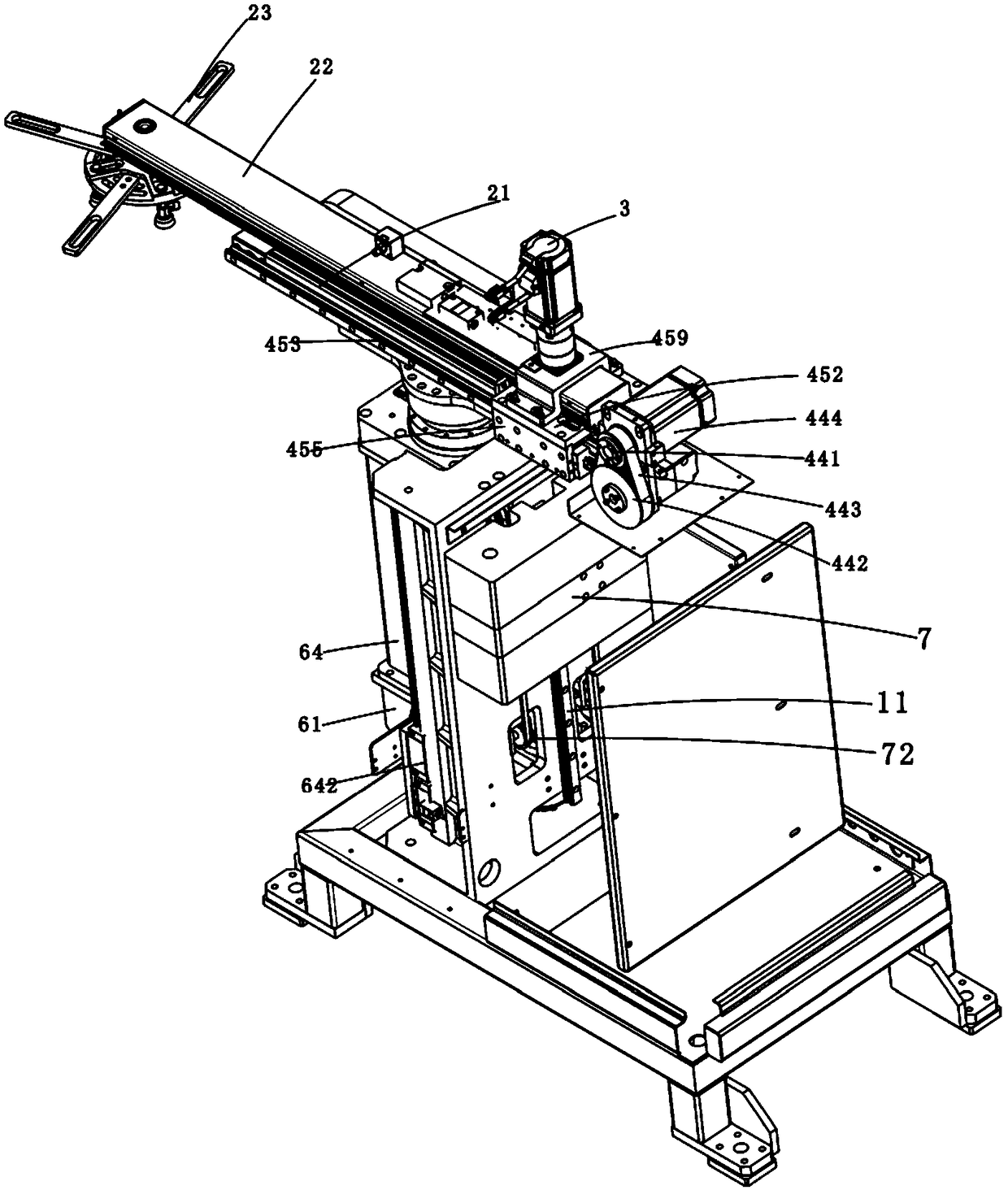

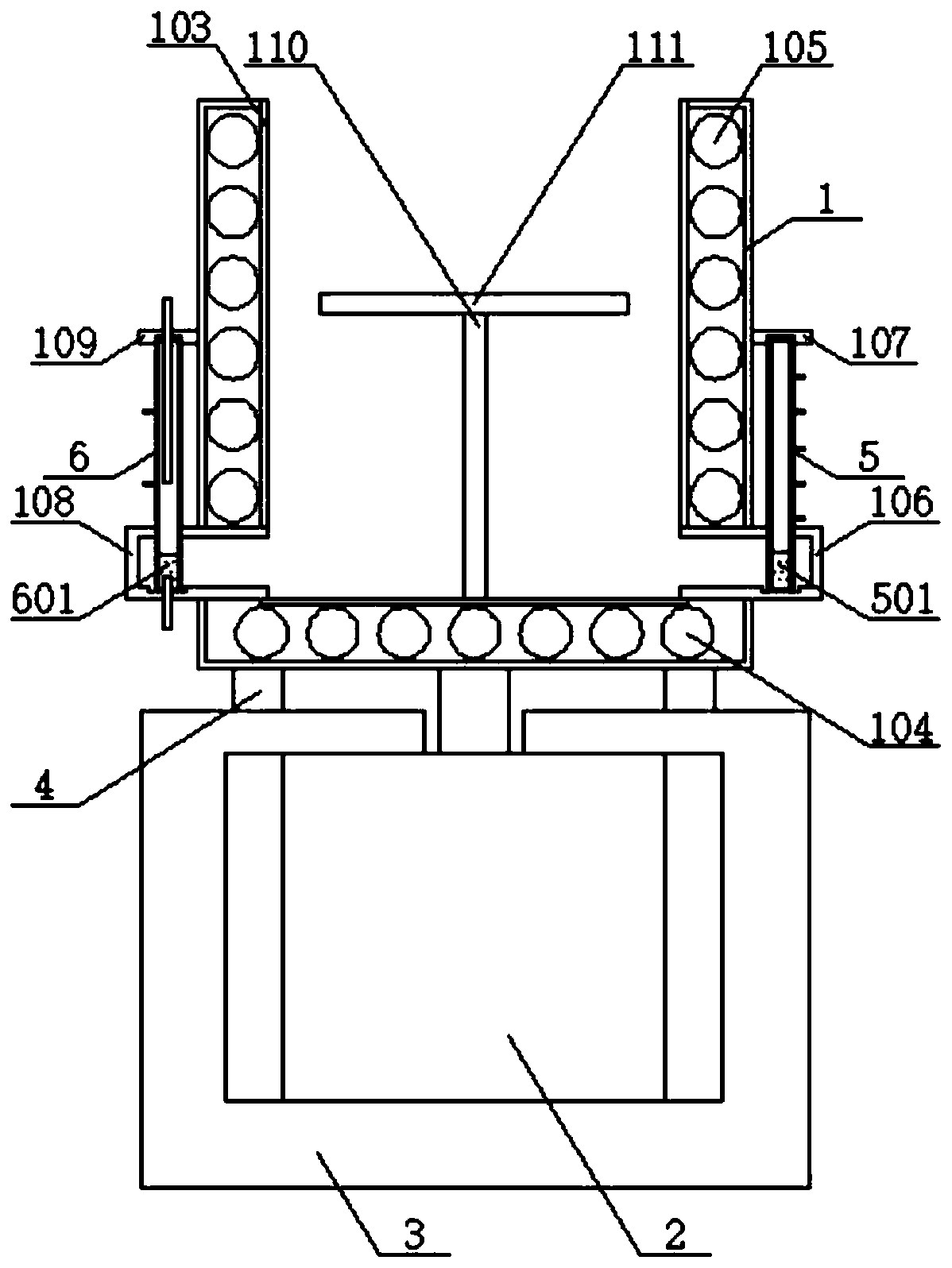

Device for detecting inclination angle and flatness of conical surface of diaphragm spring

PendingCN110220442APrecise deliveryConducive to follow-up detectionAngles/taper measurementsIncline measurementEngineeringConical surface

The invention relates to a device for detecting the inclination angle and flatness of a conical surface of a diaphragm spring. The device comprises a bracket, a horizontal position adjusting mechanism, a first lifting mechanism, a second lifting mechanism, a rotating mechanism, conveying lines, a bearing table, a digital display dial indicator, an industrial control computer and a telescopic mechanism, wherein the horizontal position adjusting mechanism is arranged on the bracket; the first lifting mechanism is vertically downwards arranged on the horizontal position adjusting mechanism, and the digital display dial indicator is arranged on the first lifting mechanism; the second lifting mechanism is vertically upwards arranged at the lower portion of the digital display dial indicator, the rotating mechanism is arranged on the second lifting mechanism, the bearing table is detachably arranged on the output shaft of the rotating mechanism, the conveying lines are respectively arrangedat the two sides of the bearing table, each conveying line is connected with the bracket through one telescopic mechanism, and the telescopic direction of the telescopic mechanism is perpendicular tothe conveying direction of the conveying lines. In the whole measuring process, manual participation is not needed, and the detection efficiency is effectively improved.

Owner:HUBEI DAFAN AUTO PARTS

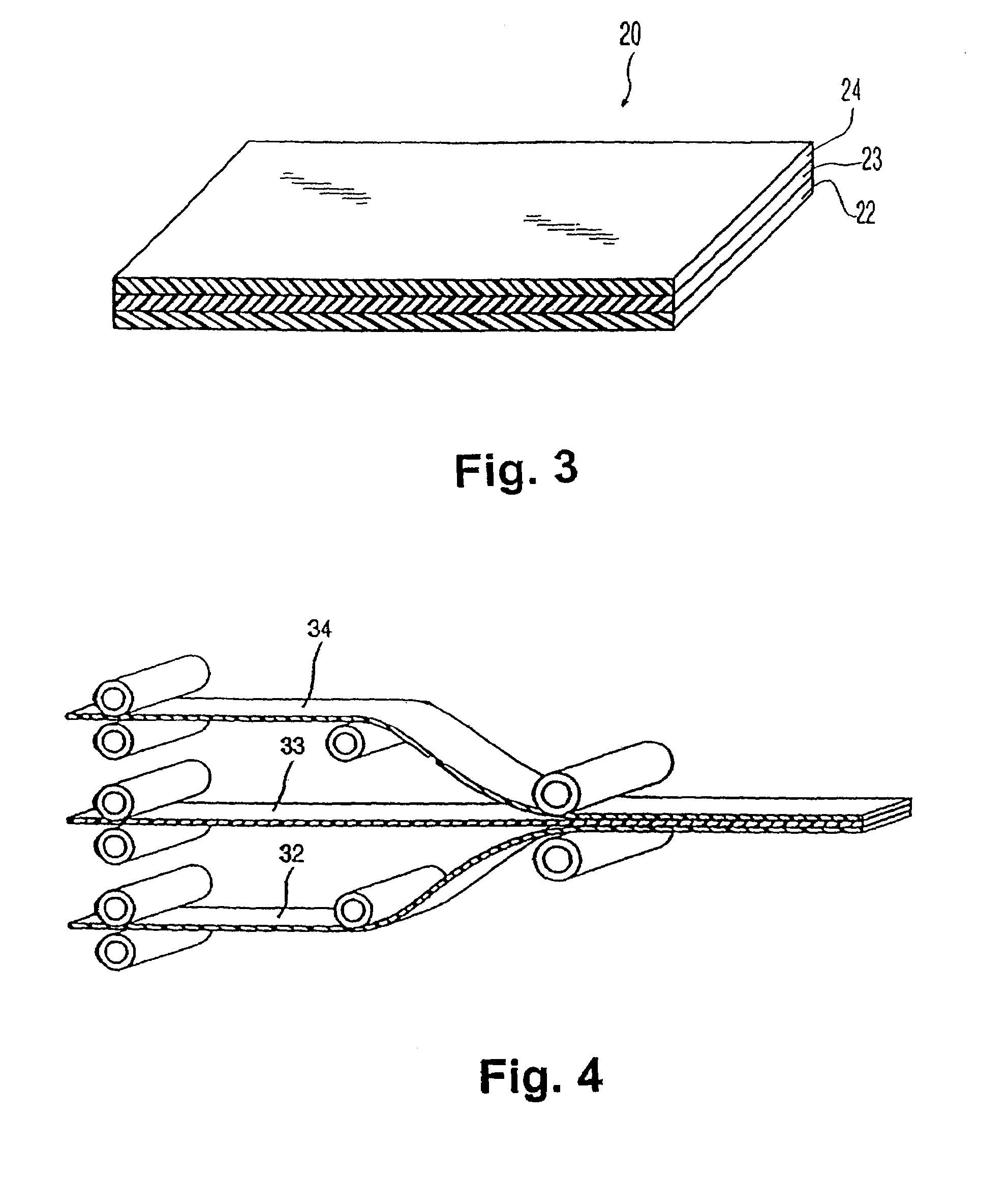

Golf ball manufacturing method

ActiveUS20160206932A1Reduce discolorationDiscoloration is often significantGolf ballsDomestic articlesPolymer scienceCyanate compound

The invention provides a method of manufacturing a golf ball having a core and a cover of one or more layer over the core, wherein an outermost layer of the cover is molded of a thermoplastic material selected from the group consisting of polyurethane, polyurea and mixtures thereof. The method includes at least the following steps (1) and (2):(1) treating a surface of the cover with an isocyanate compound; and(2) washing off and physically removing excess isocyanate compound by blasting the cover surface with a specific substance at high pressure.

Owner:BRIDGESTONE SPORTS

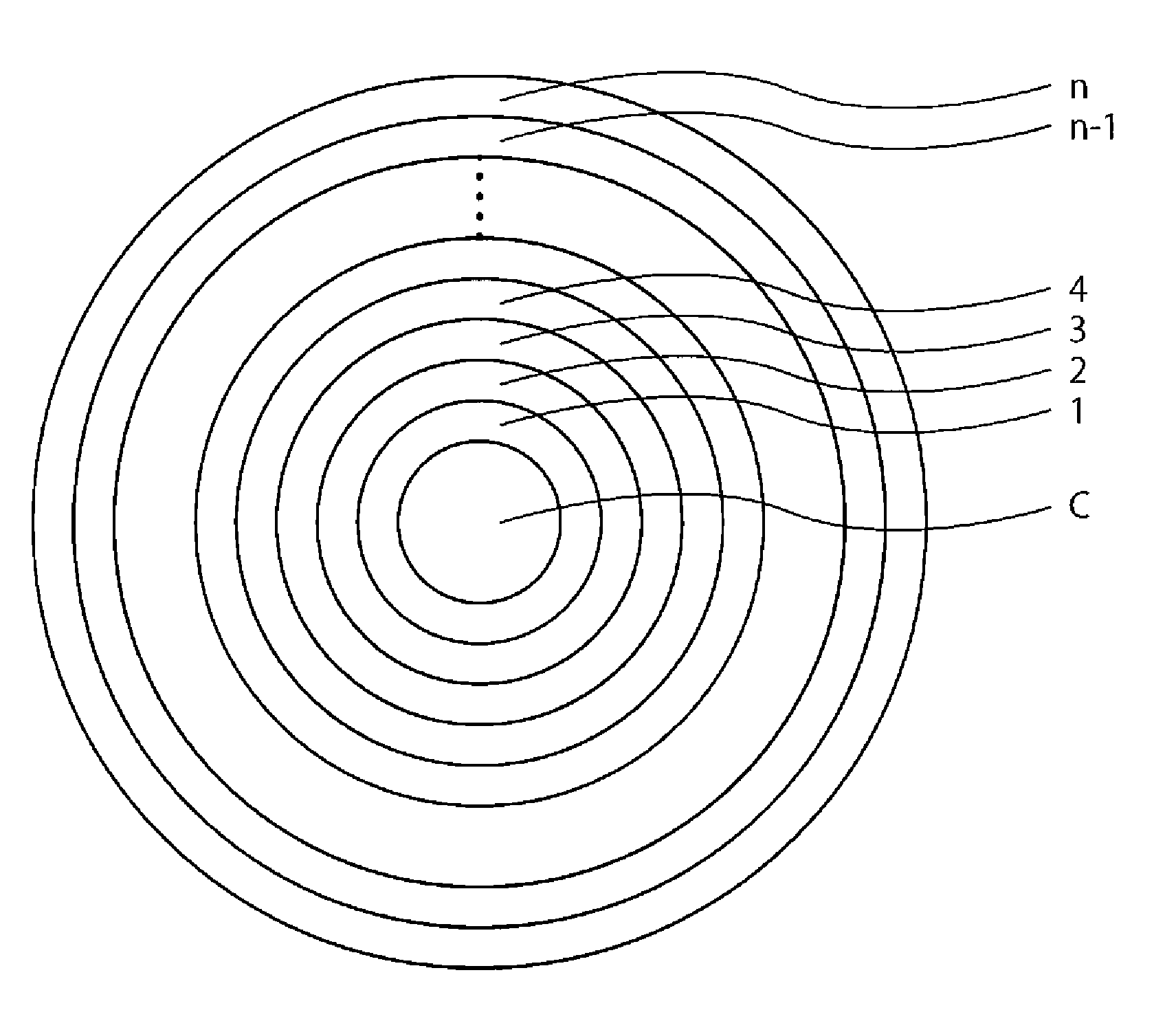

Multi-piece golf ball

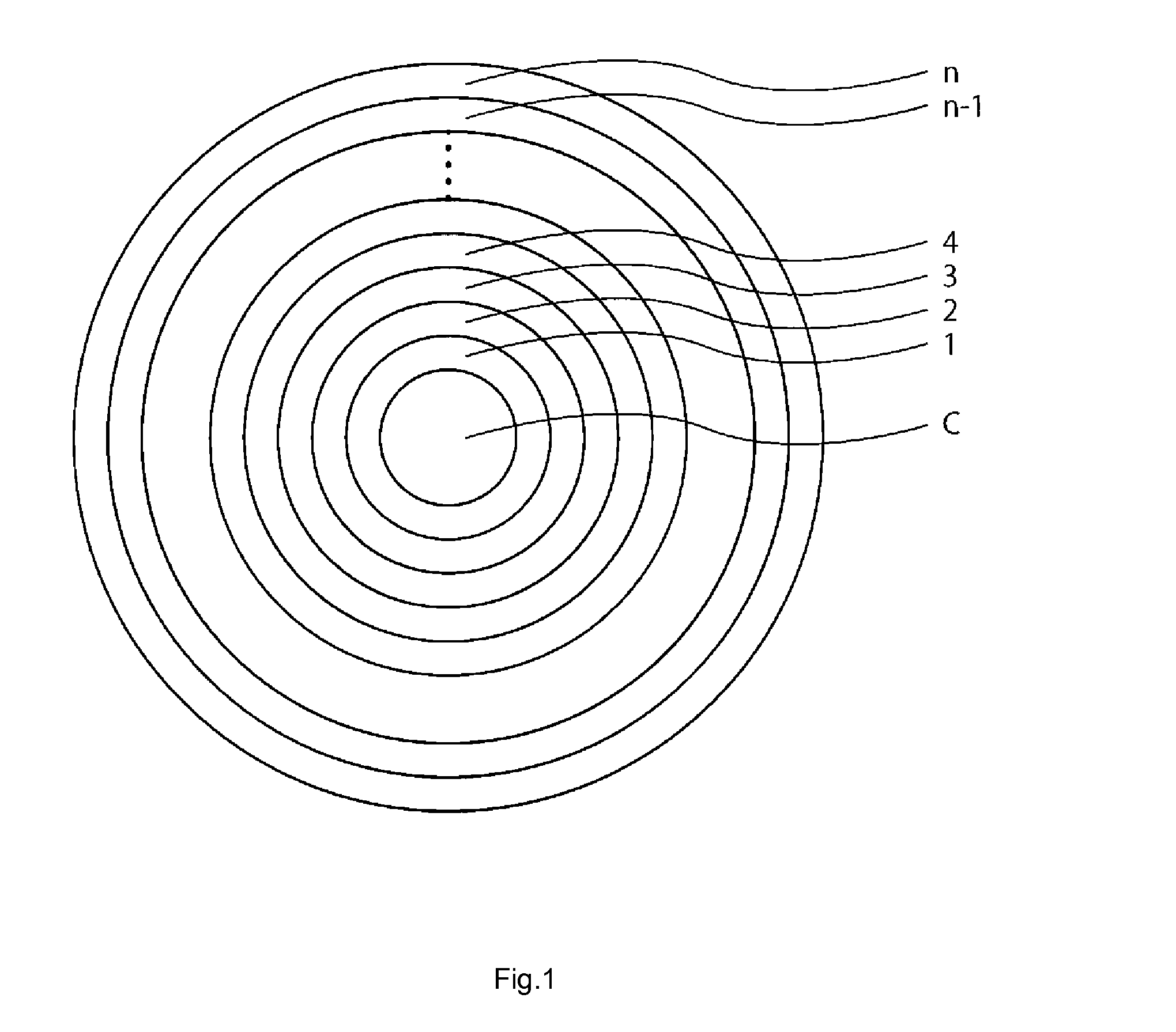

ActiveUS20150005102A1Slow down the spin rateImprove approachGolf ballsSolid ballsEngineeringGolf Ball

An object of the present invention is to provide a golf ball showing a low spin rate on driver shots and a high spin rate on approach shots. The present invention provides a multi-piece golf ball comprising a center and n (n is a natural number of 3 or more) envelope layers covering the center, wherein material hardness of the envelop layers satisfies H2<H0<Hn−1; where the envelope layers formed in order from the center side are referred to as a first envelope layer, a second envelope layer, a third envelope layer, a fourth envelope layer, . . . an n−1th envelope layer and an nth envelope layer (the outmost layer), respectively and H0 is a material hardness (Shore D hardness) of the center, and H1, H2, H3, H4, . . . Hn−1 and Hn are material hardness (Shore D hardness) of the first envelope layer, the second envelope layer, the third envelope layer, the fourth envelope layer, . . . the n−1th envelope layer and the nth envelope layer (the outmost layer), respectively; and the center is formed from a thermoplastic resin composition, and the second envelope layer is formed from a thermoplastic resin composition or a rubber composition.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

ActiveUS20160166887A1Easy to reboundSlow down the spin rateGolf ballsSolid ballsNuclear engineeringGolf Ball

Golf ball having a core and a cover of one or more layers, the core being formed of a material molded under heat from a rubber composition including a base rubber, an organic peroxide, and water and / or a metal monocarboxylate. Defining the tan δ slope as (tan δ10−tan δ1) / (10%−1%), where tan δ1 and tan δ10 are the loss tangents at dynamic strains of, respectively, 1% and 10% when the loss tangents of the core center and the core surface are measured at −12° C. and 15 Hz, the difference between the tan δ slopes at the core surface and the core center is larger than 0.002. Because a core material which undergoes little decrease in resilience over time and experiences little energy loss can be obtained, the golf ball maintains a good rebound, has a reduced spin rate and thus is able to achieve an increased distance.

Owner:BRIDGESTONE SPORTS

Equipment for processing disc-shaped suspension type porcelain insulator

ActiveCN113506662AReduce shockGuaranteed uniformityInsulatorsCeramic materials productionPhysicsElectric machinery

The invention provides equipment for processing a disc-shaped suspension porcelain insulator, and relates to the technical field of insulator processing. The equipment comprises a base, stirring mills are arranged on the front side and the rear side of the top of the left end of the base correspondingly, and each stirring mill comprises a material grinding tank, a first motor, a rotating shaft, a first gear, a cross, a second gear, a gear ring, a dredging plate, an annular groove, a slender rod, a sieve plate, a guide rod, a spring and a roller. The material grinding tank is fixedly connected to the top end of the base, the first motor is fixedly connected to the top end of the grinding tank, and the gear ring is rotationally connected to the inner side of the lower portion of the grinding tank and is in meshed connection with the four second gears. The uniformity of the particle size of the insulator is improved through the stirring mill, the stirring mill, the ball mill and the slurry iron removal machine are matched with the vacuum pug mill to degas the pug, the steep wave performance of the porcelain insulator is improved, and the equipment is worthy of being vigorously popularized.

Owner:萍乡强盛电瓷制造有限公司

One-bath dyeing process and device for viscose/cotton knitted fabric

ActiveCN108978079AEfficient heatingImprove dyeing efficiencyLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsPolymer scienceViscose

The invention relates to the technical field of one-bath dyeing and discloses a one-bath dyeing device for viscose / cotton knitted fabric. The one-bath dyeing device comprises an external dyeing barrel, the bottom center of the external dyeing barrel is fixedly connected with the shaft end face of the output shaft of a motor, an internal dyeing barrel is mounted in the cavity center of the externaldyeing barrel, a first expansion pipe and a second expansion pipe are respectively mounted on the right wall and the left wall of the axial bottom of the external dyeing barrel, a first mercury thermometer and a second mercury thermometer are respectively mounted in the first expansion pipe and the second expansion pipe, and a cylindrical cavity and an annular cavity between the outside of the internal dyeing barrel and the inside of the external dyeing barrel are respectively provided with a first heating resistor and a second heating resistor. The invention further discloses a one-bath dyeing process for the viscose / cotton knitted fabric. The problem that a one-bath dyeing solution cannot be heated and maintained at constant temperature efficiently simultaneously when the viscose / cottonknitted fabric is dyed by the one-bath method is solved.

Owner:绍兴华夏印染有限公司

Golf ball

InactiveUS20140073460A1Slow down the spin rateIncrease distanceGolf ballsSolid ballsPolymer scienceGolf Ball

The invention provides a golf ball endowed with an improved distance and durability. The ball has a core and a cover, the core being formed of a rubber composition containing a base rubber, a co-crosslinking agent, a crosslinking initiator and a metal oxide. The base rubber is a mixture of (A) polybutadiene with (B) styrene-butadiene rubber and / or isoprene rubber, the co-crosslinking agent is methacrylic acid, and the metal oxide is zinc oxide. The rubber composition contains the crosslinking initiator in an amount of from 1.2 to 5 parts by weight per 100 parts by weight of the base rubber.

Owner:BRIDGESTONE SPORTS

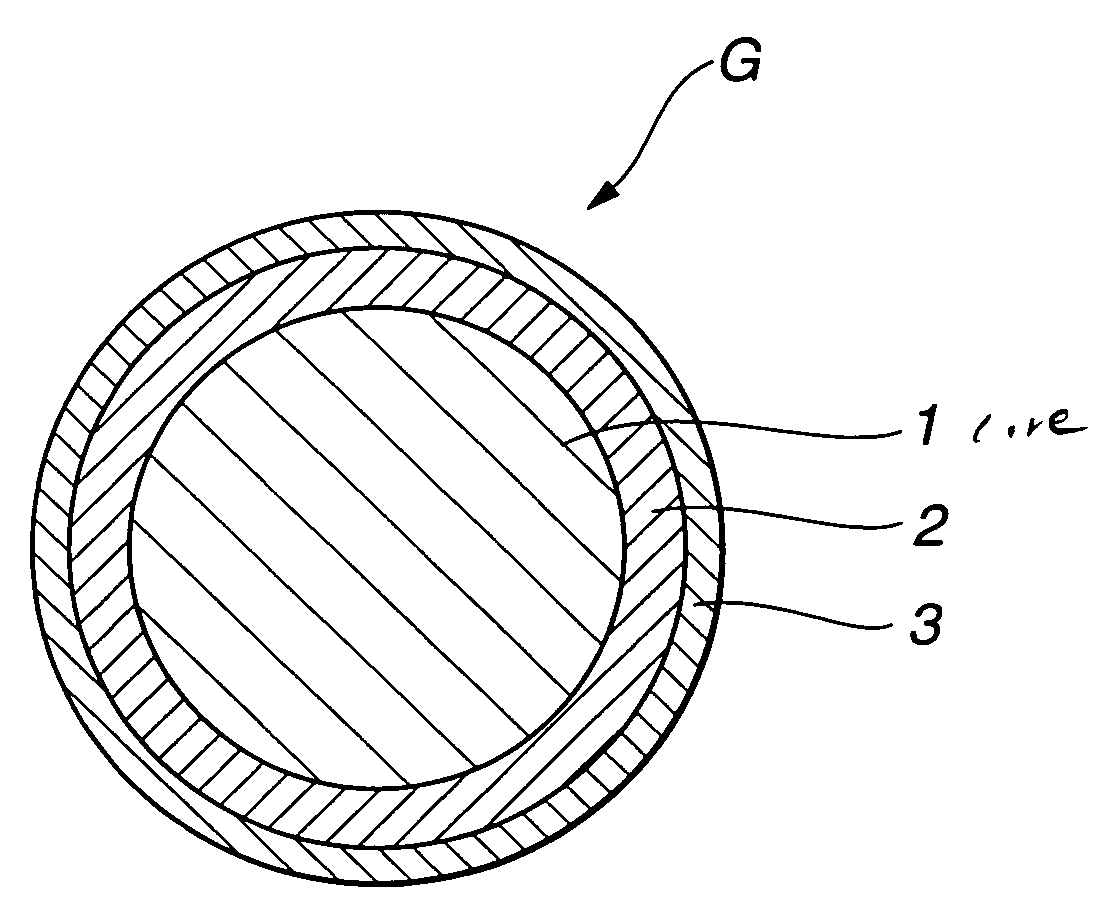

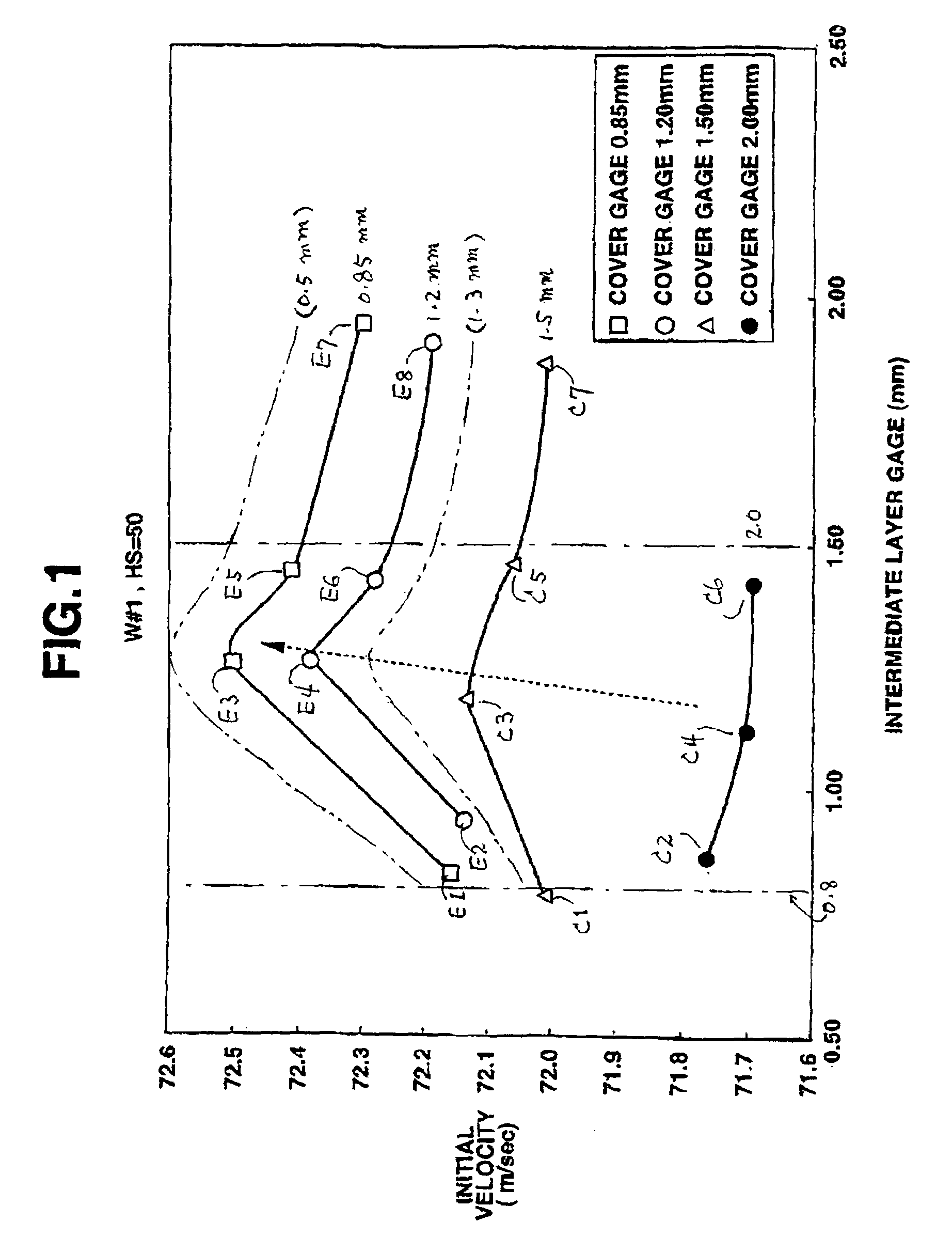

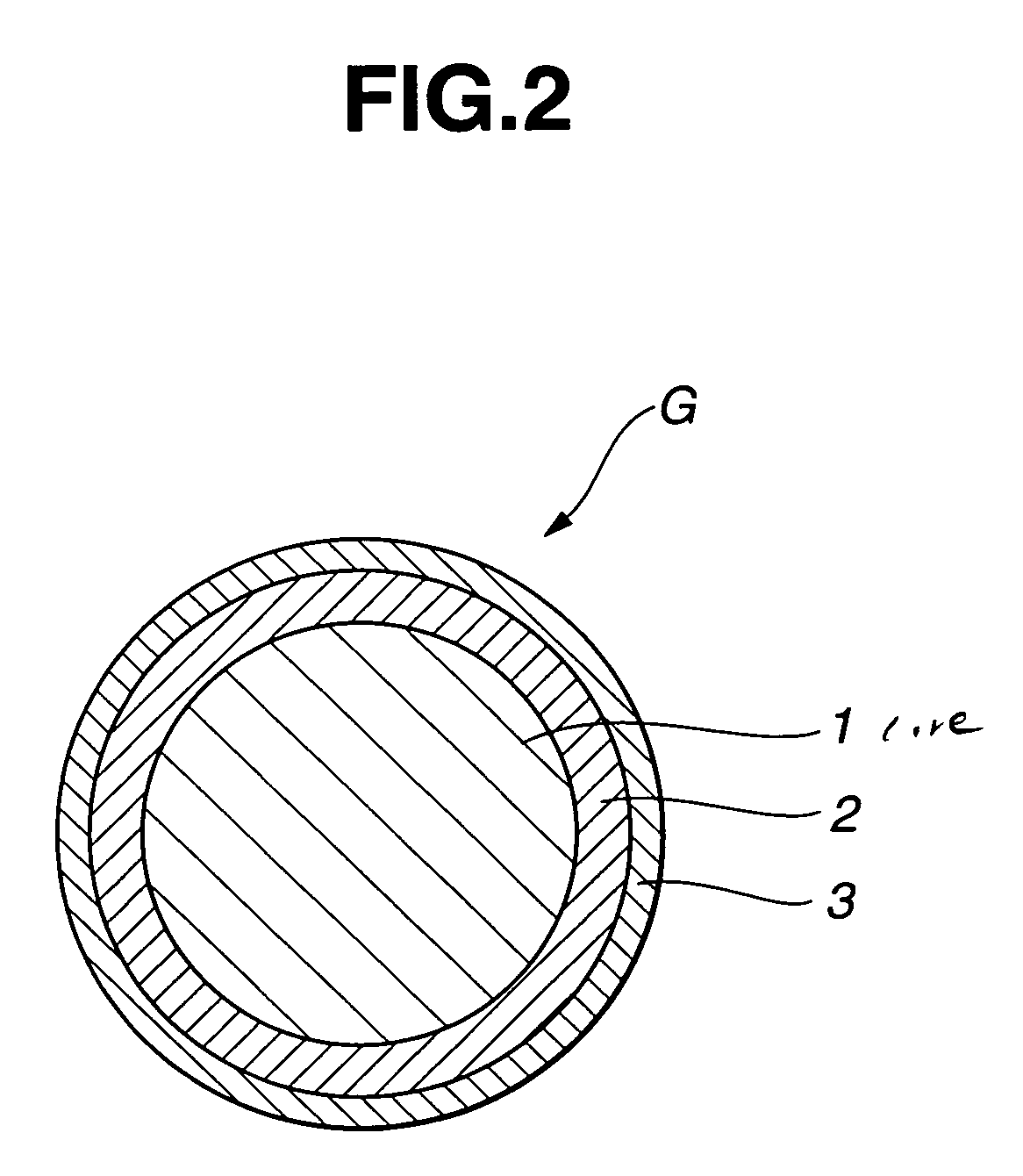

Multi-piece solid golf ball

In a multi-piece solid golf ball comprising a solid core, an intermediate layer, and a cover, the intermediate layer has a gage G1 of 0.8–2 mm and a Shore D hardness of 50–65, the cover has a gage G2 of 0.5–1.3 mm and a Shore D hardness of 37–53, and the intermediate layer gage G1 and the cover gage G2 satisfy [G1 / (G1+G2)]×100≧45%. Upon full shots with a driver, the ball gains a reduced spin rate and an increased initial velocity, which lead to an increase in travel distance.

Owner:BRIDGESTONE SPORTS

Diamino polyethylene glycol modified paramagnetic metal complex magnetic resonance imaging contrast agent

ActiveCN102727911BHigh molecular weightHigh relaxation rateEchographic/ultrasound-imaging preparationsRadioactive preparation carriersSolubilityRare-earth element

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

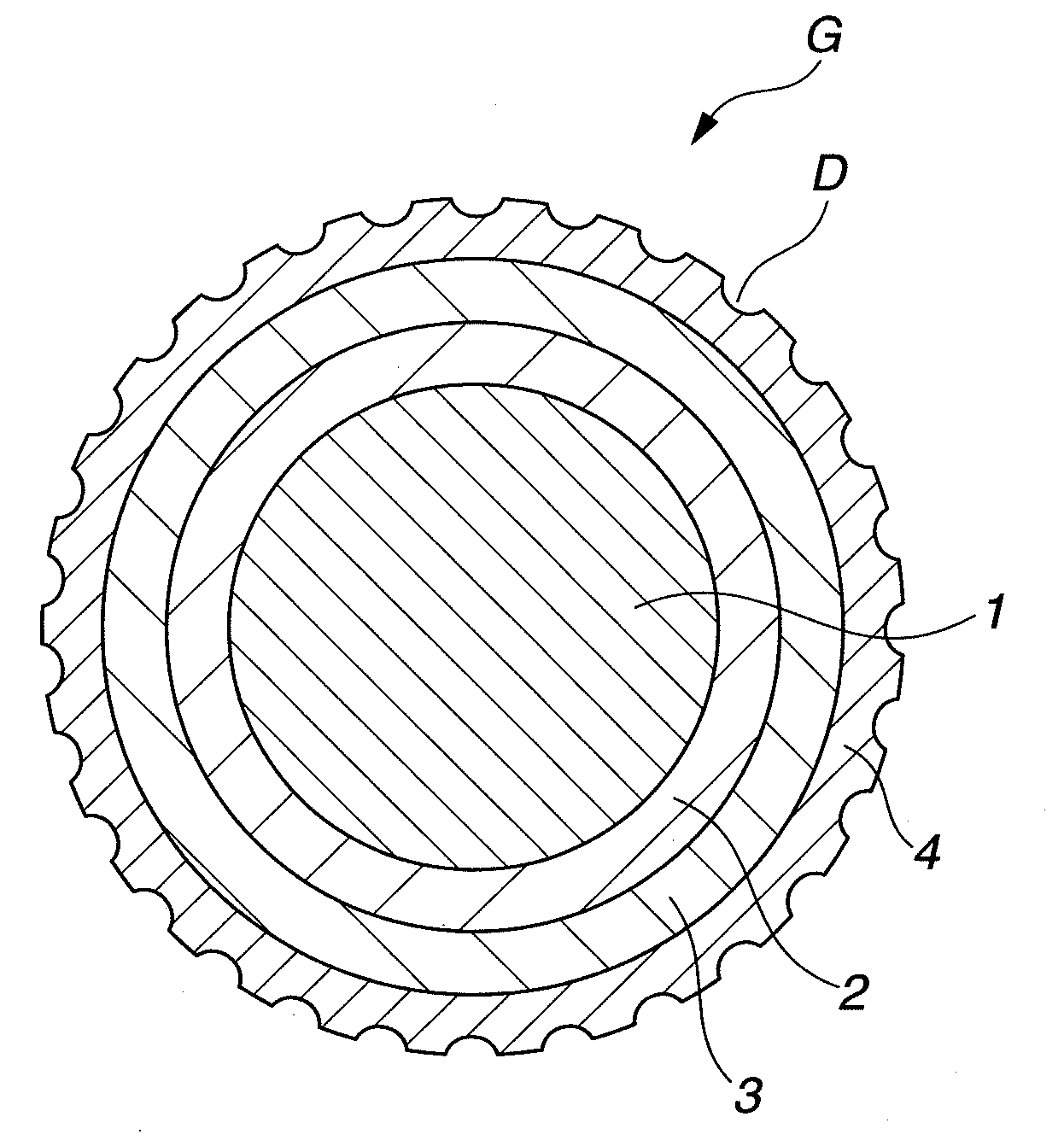

Golf ball

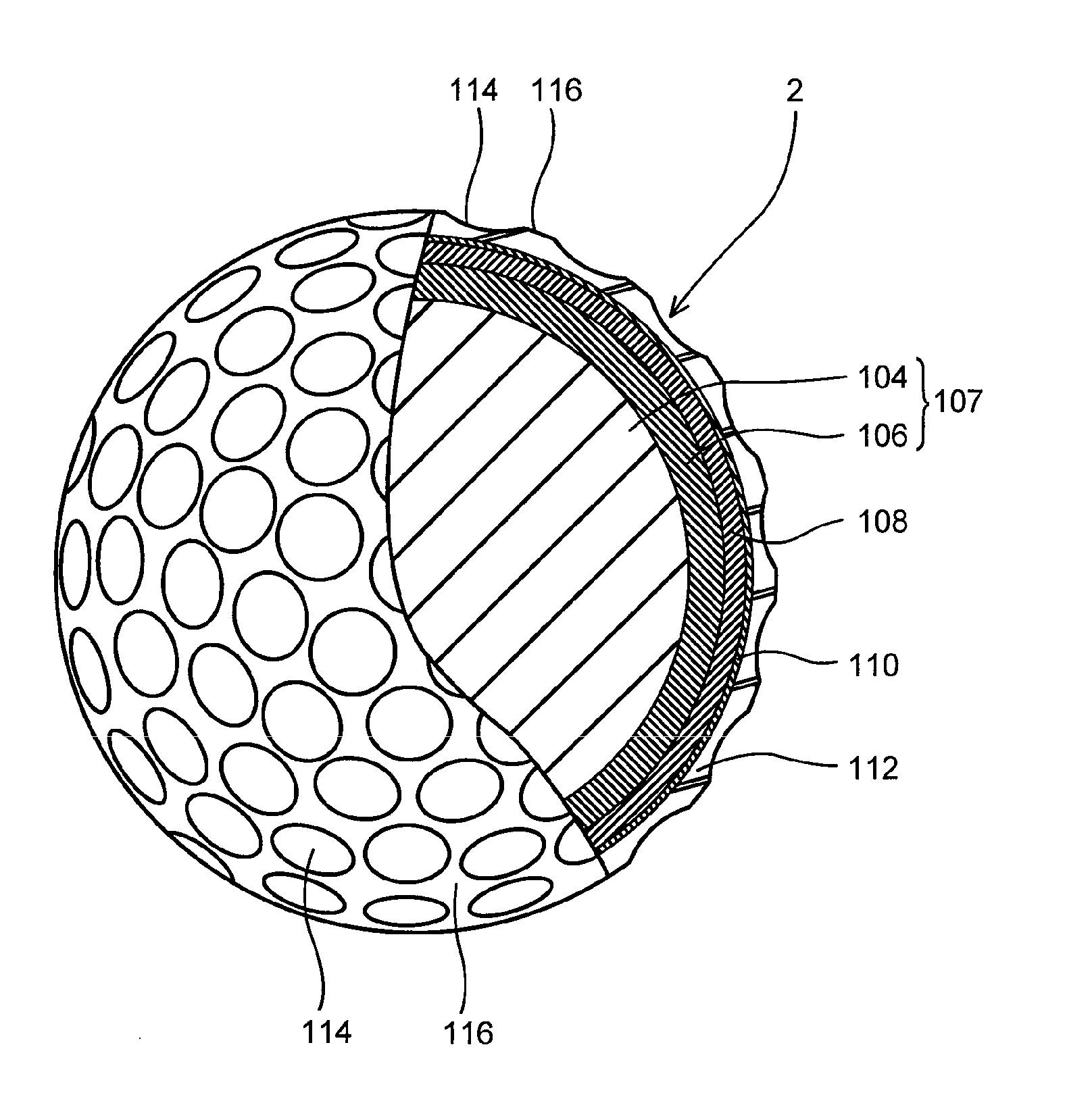

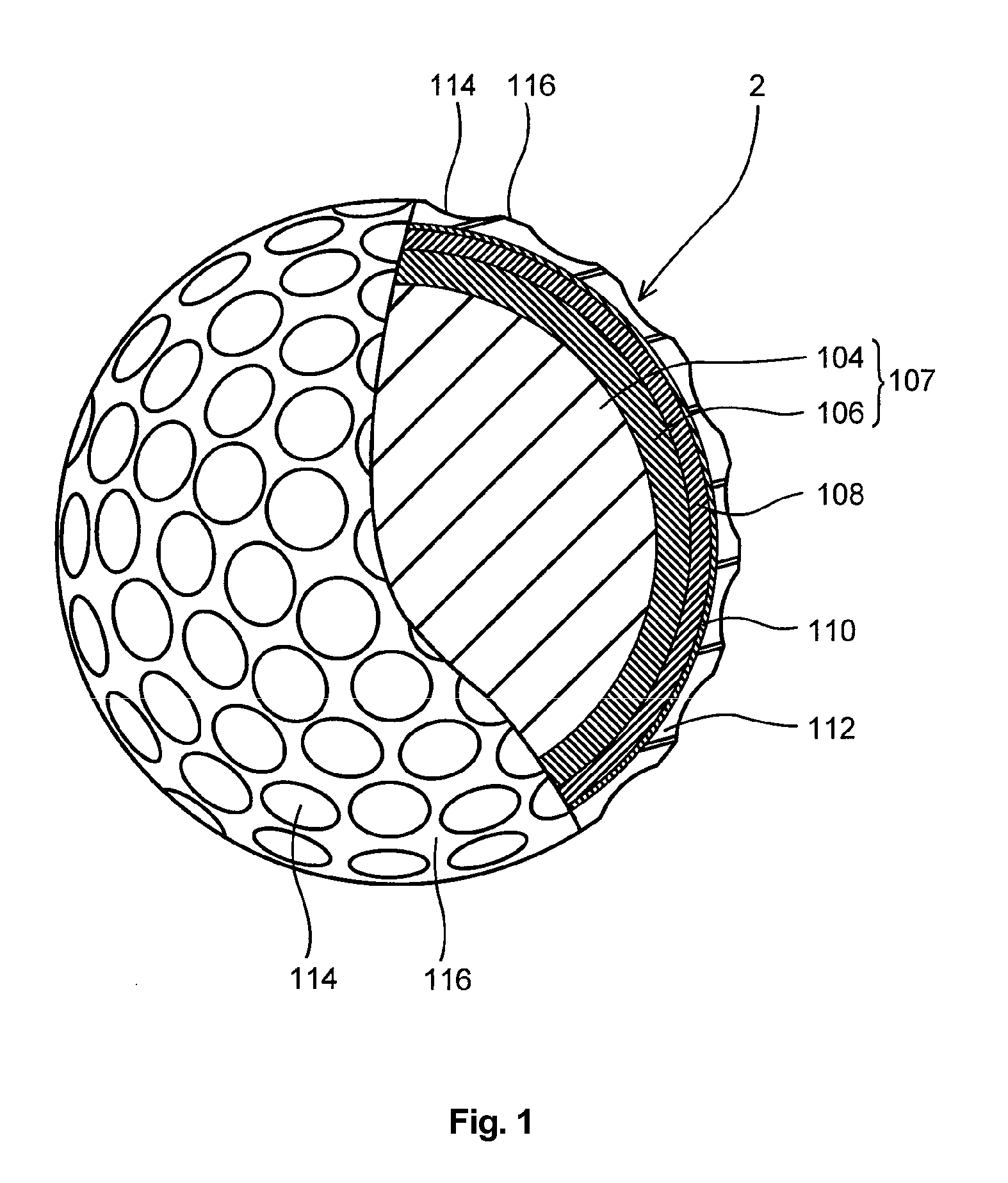

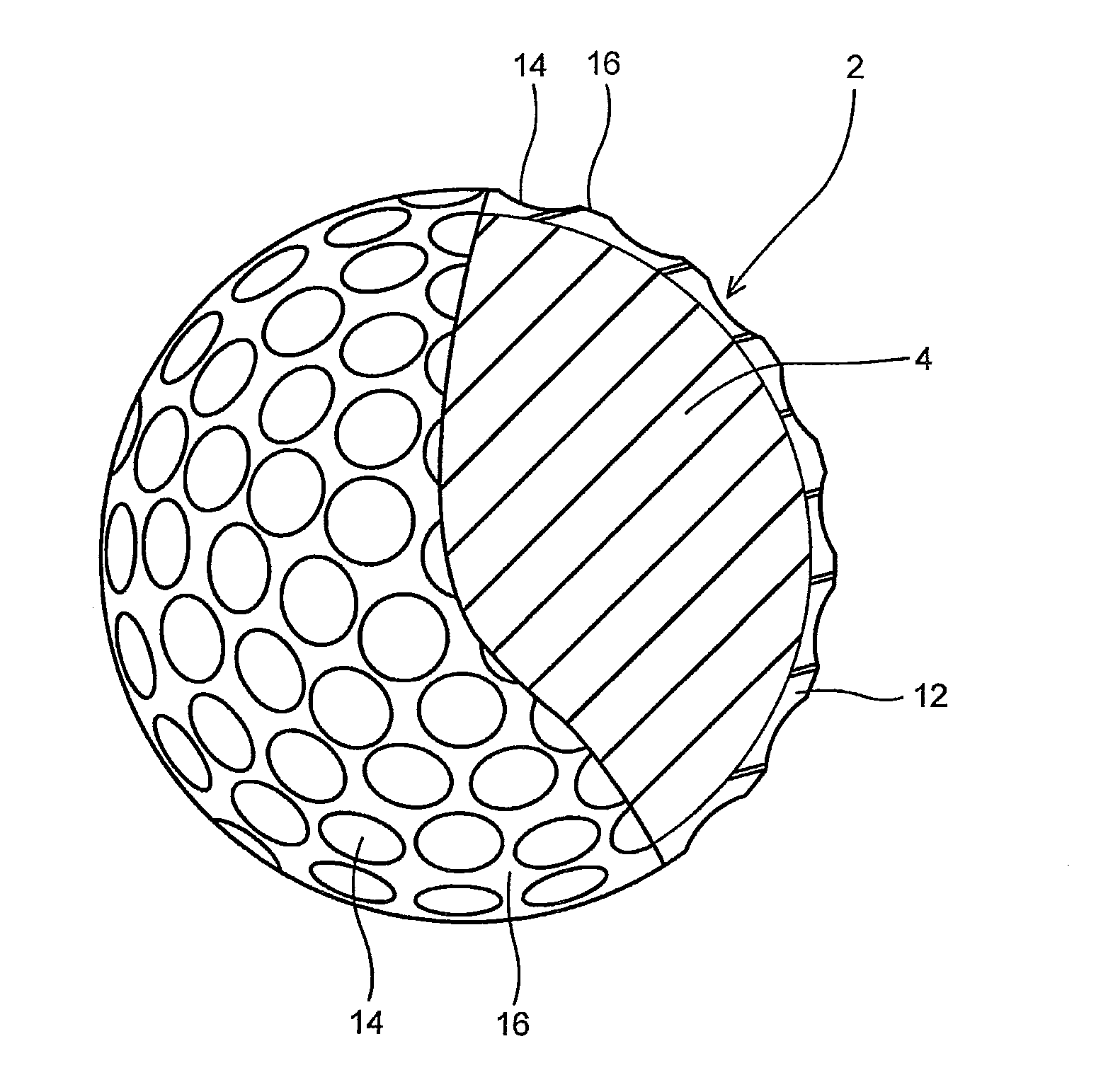

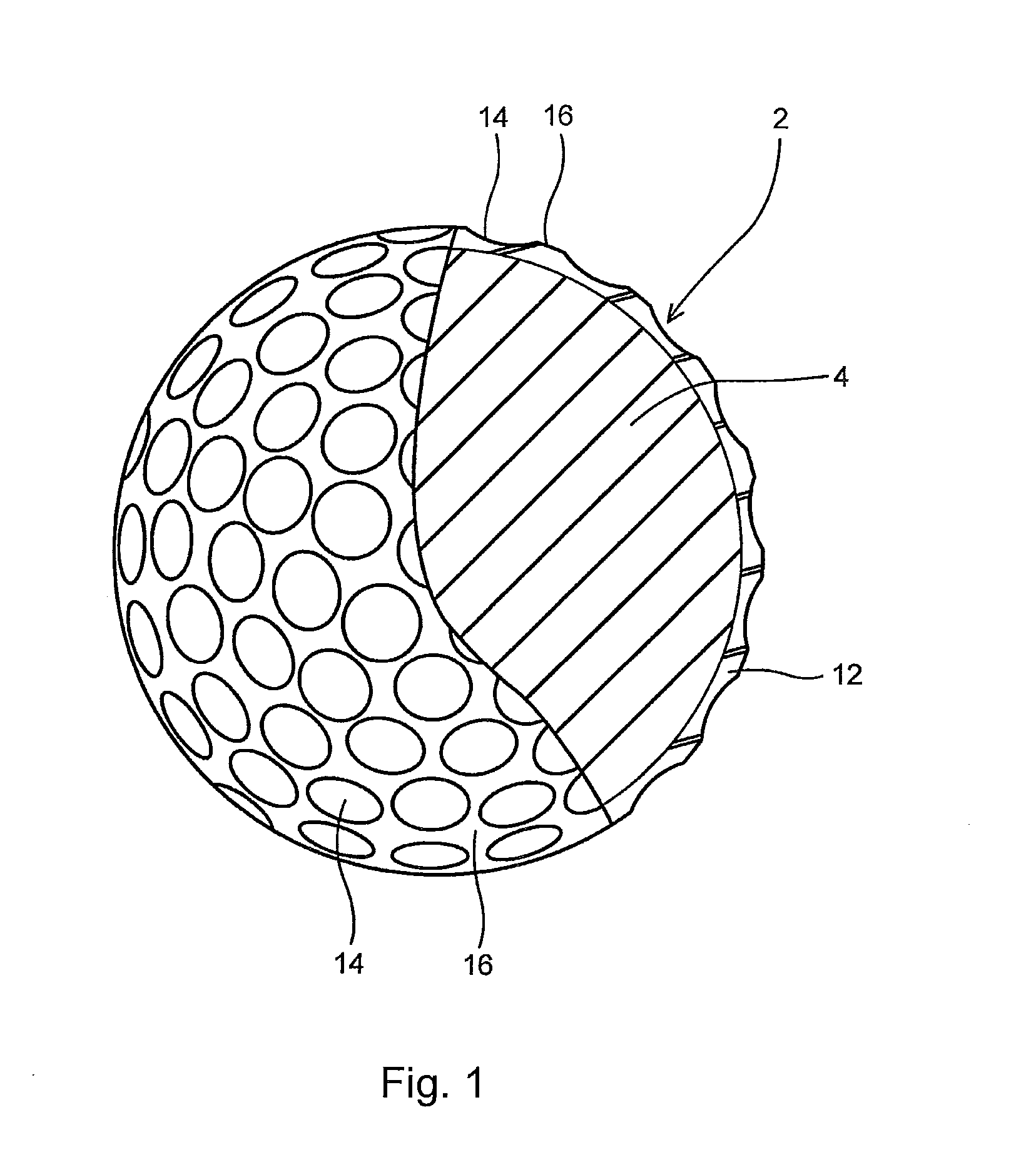

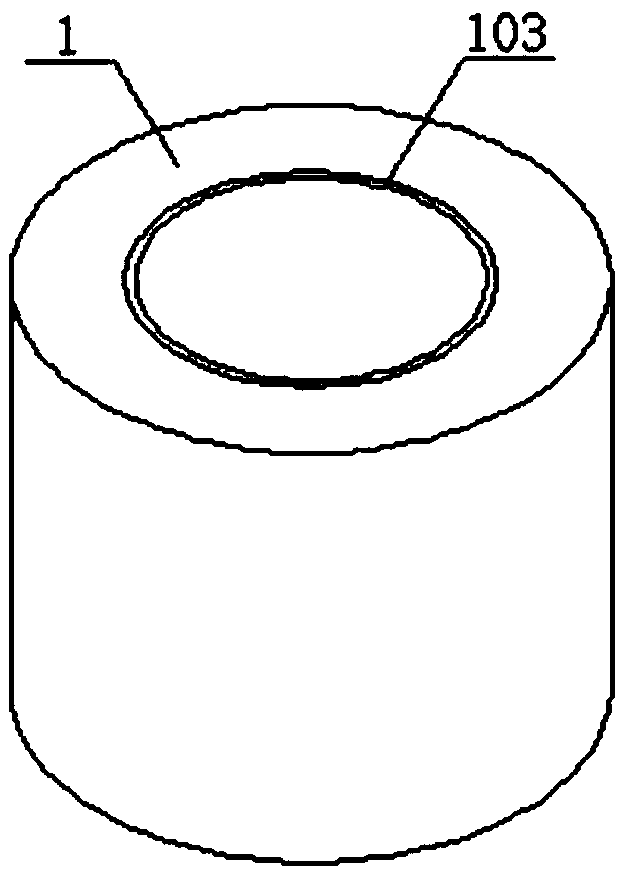

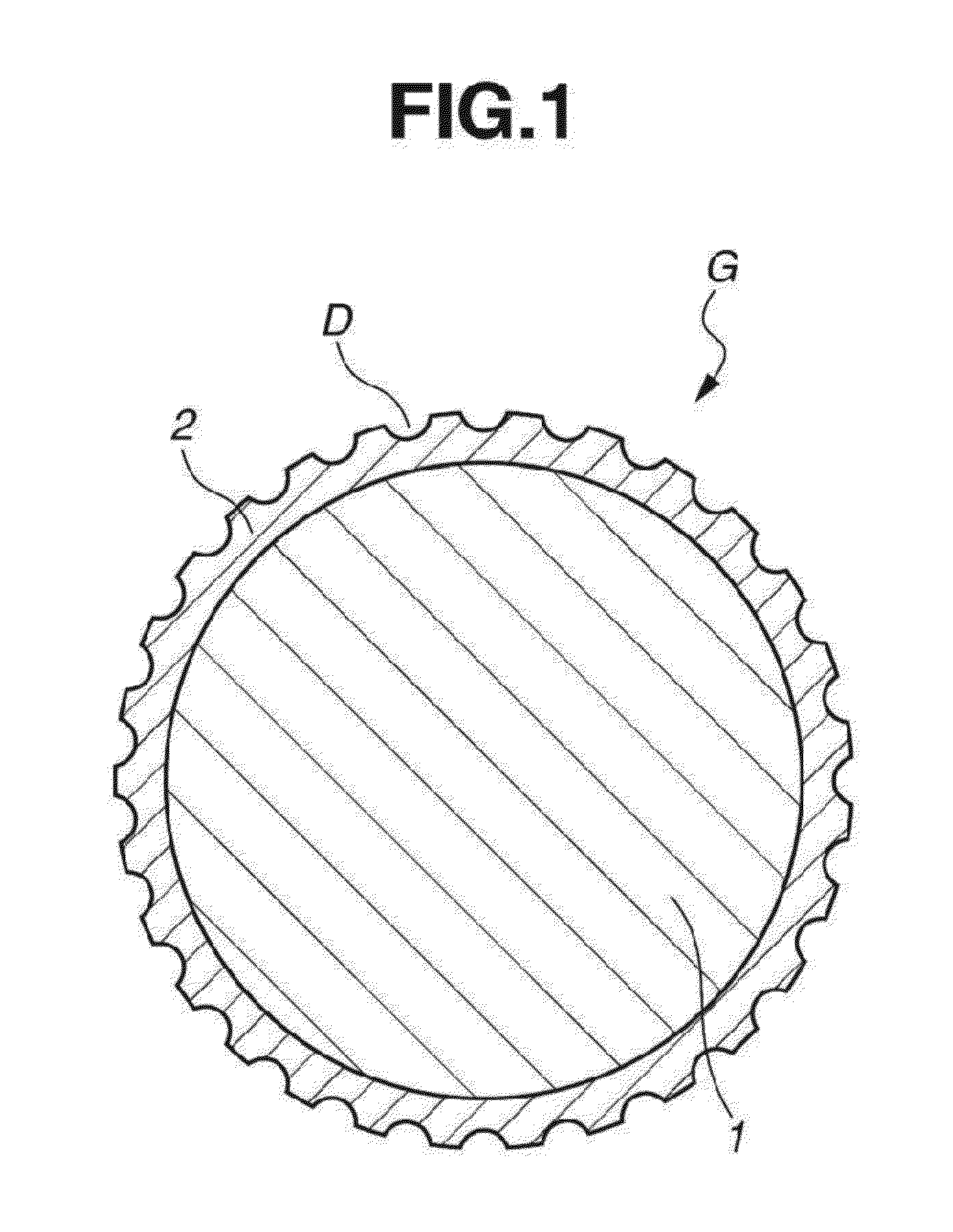

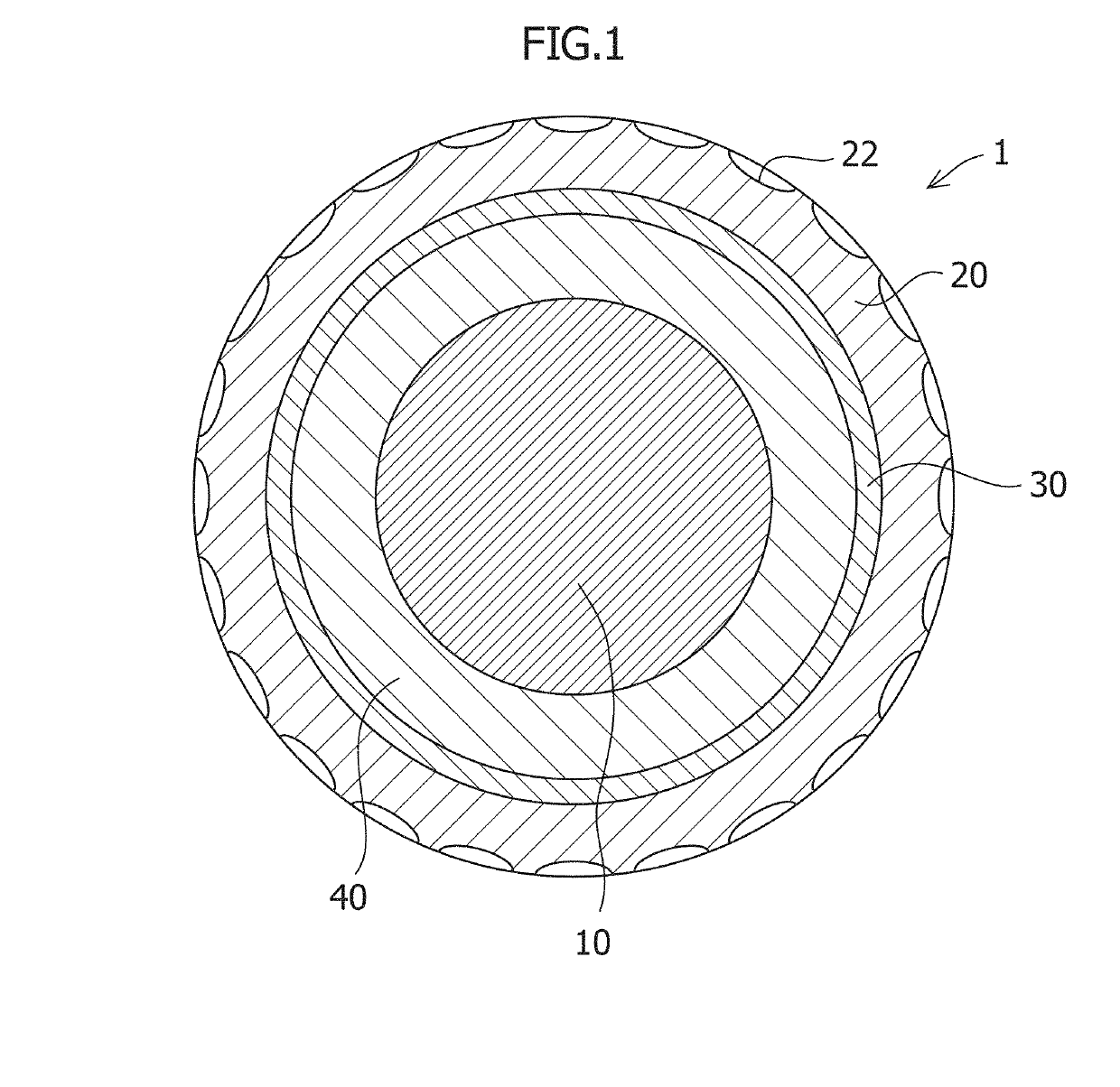

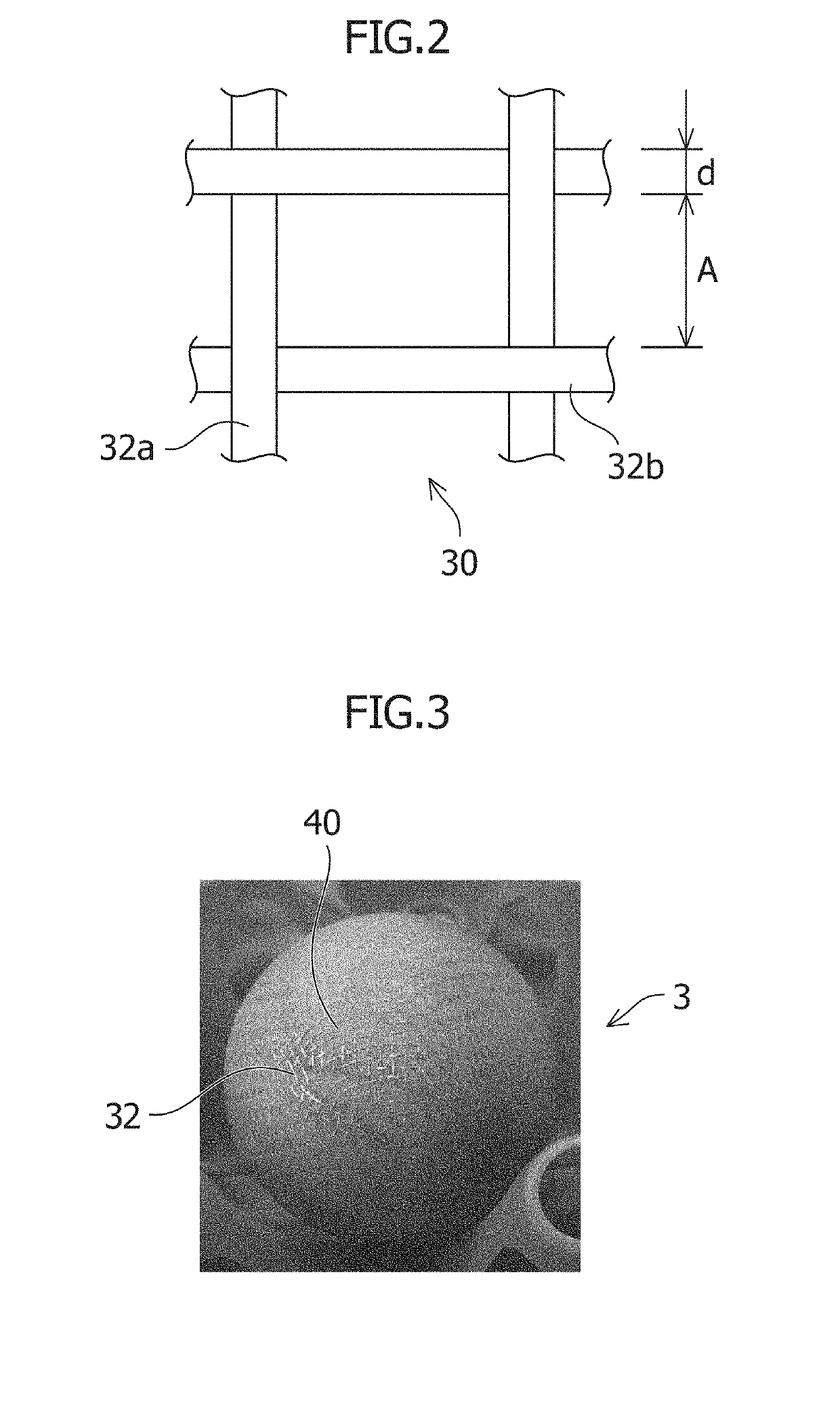

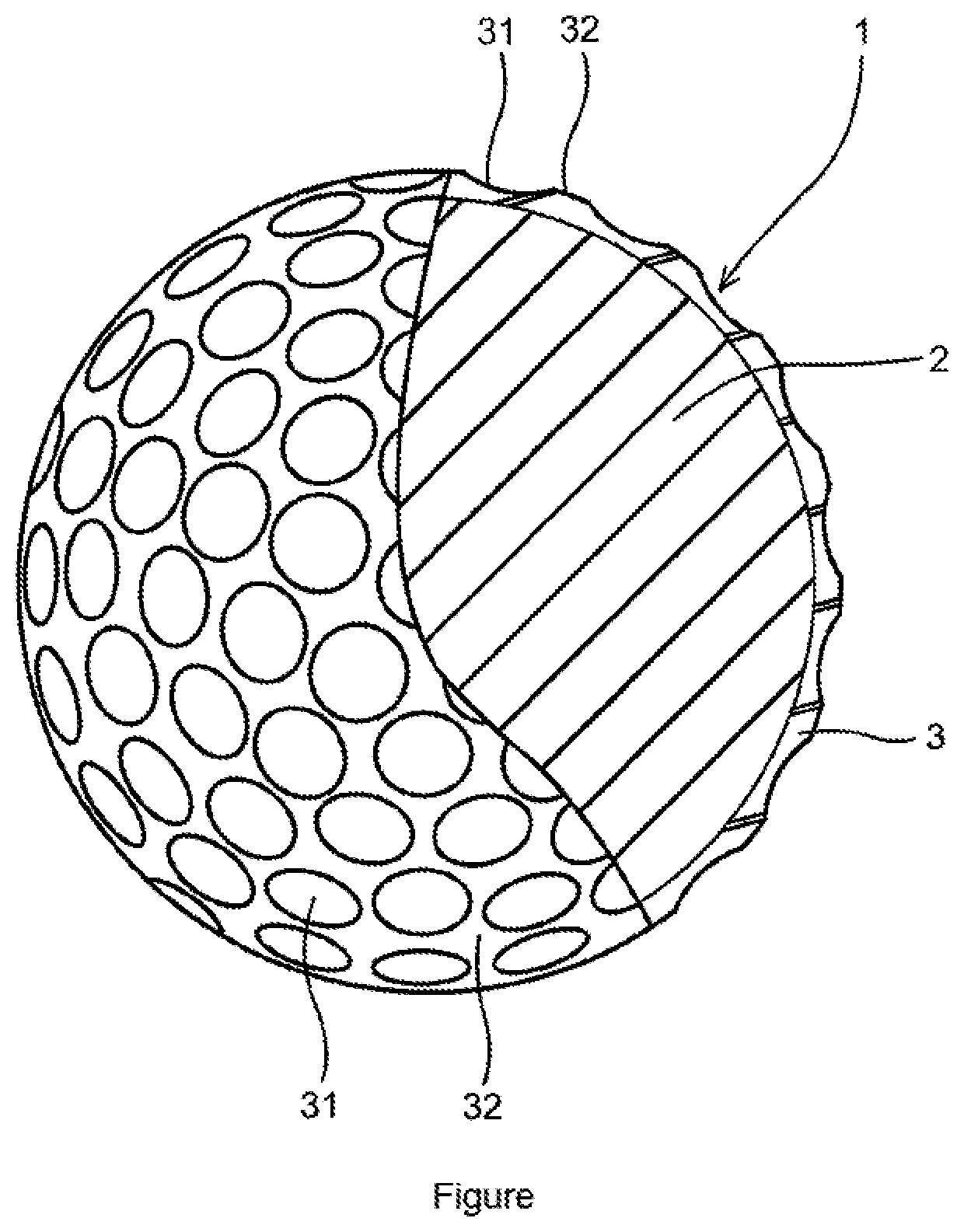

InactiveUS20190192919A1Slow down the spin rateIncreased durabilityGolf ballsSolid ballsMetal meshCHEEK DIMPLES

The present invention provides a golf ball capable of achieving a further decrease of the spin rate in the driver shot, and capable of more improving the flight distance, while maintaining high durability. The golf ball 1 of the present invention includes a core located in the center of the golf ball, a cover located outside the core and having a plurality of dimples on the surface thereof, and a metal mesh layer located between the core and the cover, wherein the metal mesh layer has a wire diameter falling within a range from 0.01 to 0.5 mm, and a mesh count falling within a range from 16 to 1000.

Owner:BRIDGESTONE SPORTS

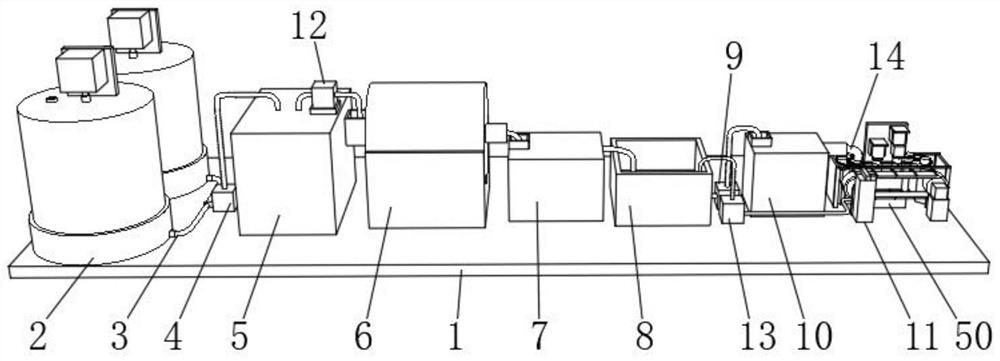

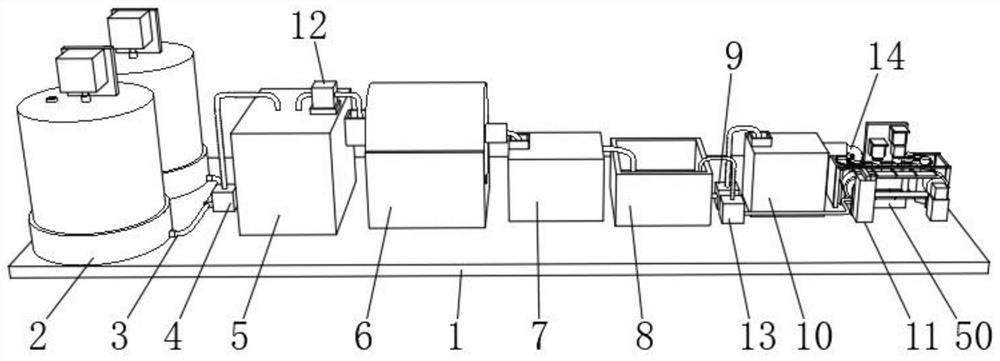

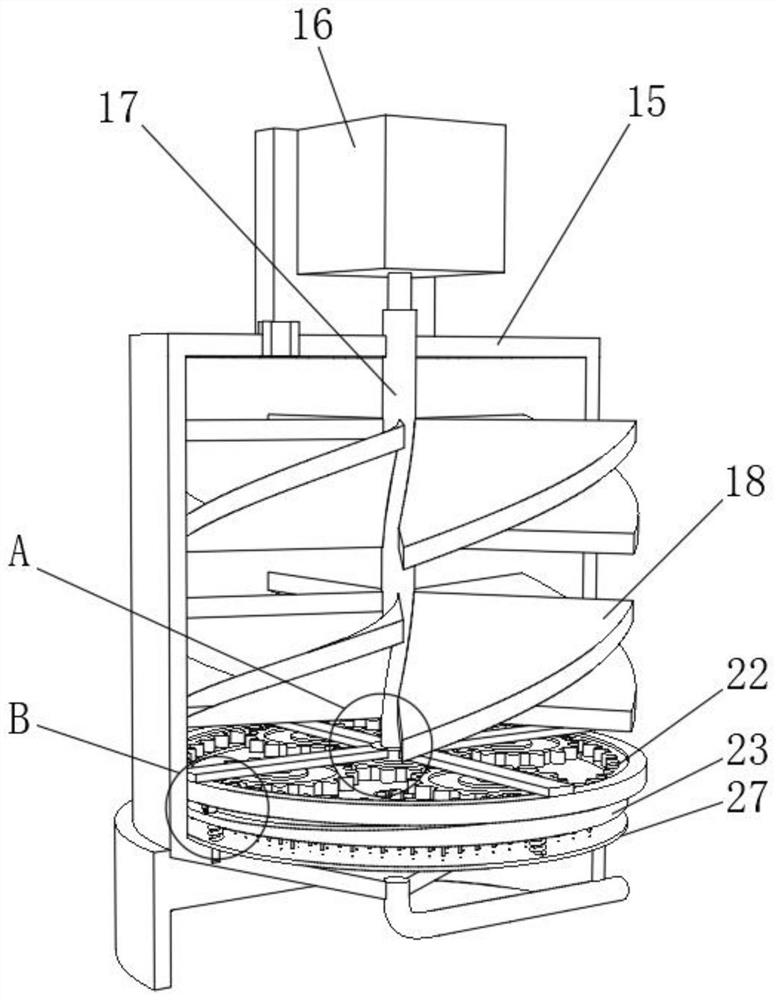

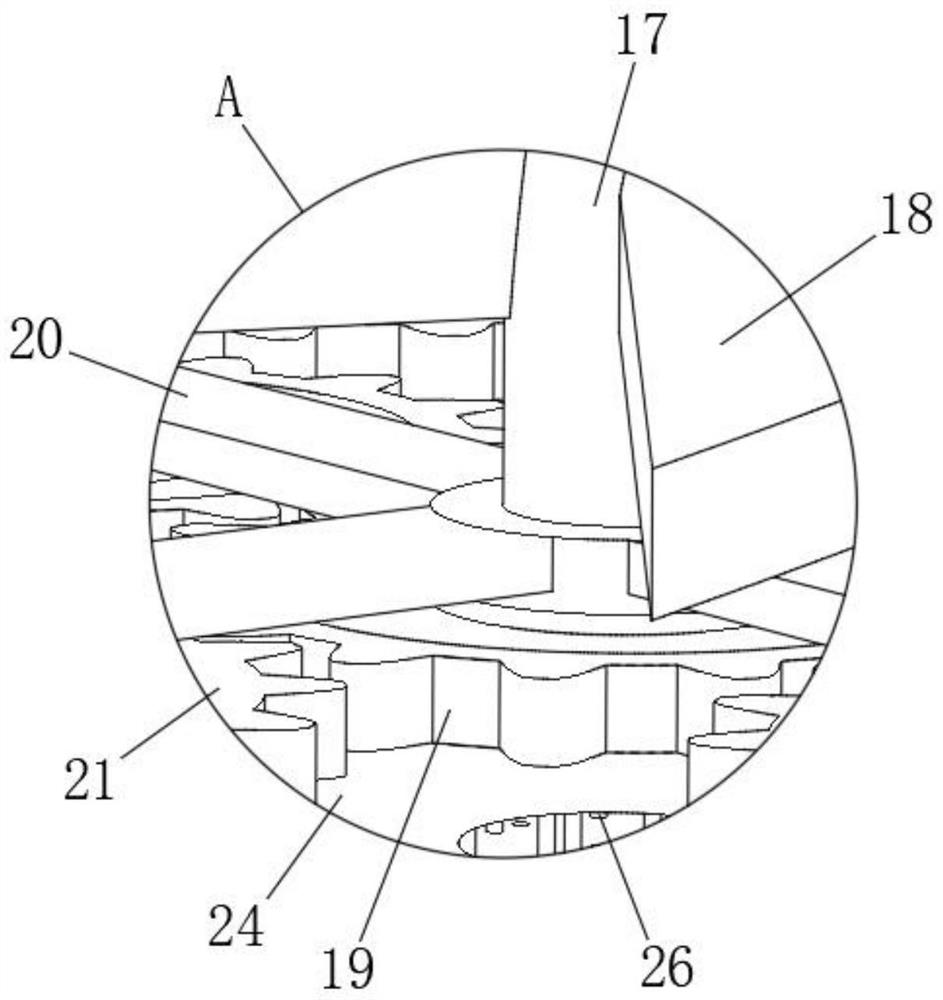

Continuous feed metering device

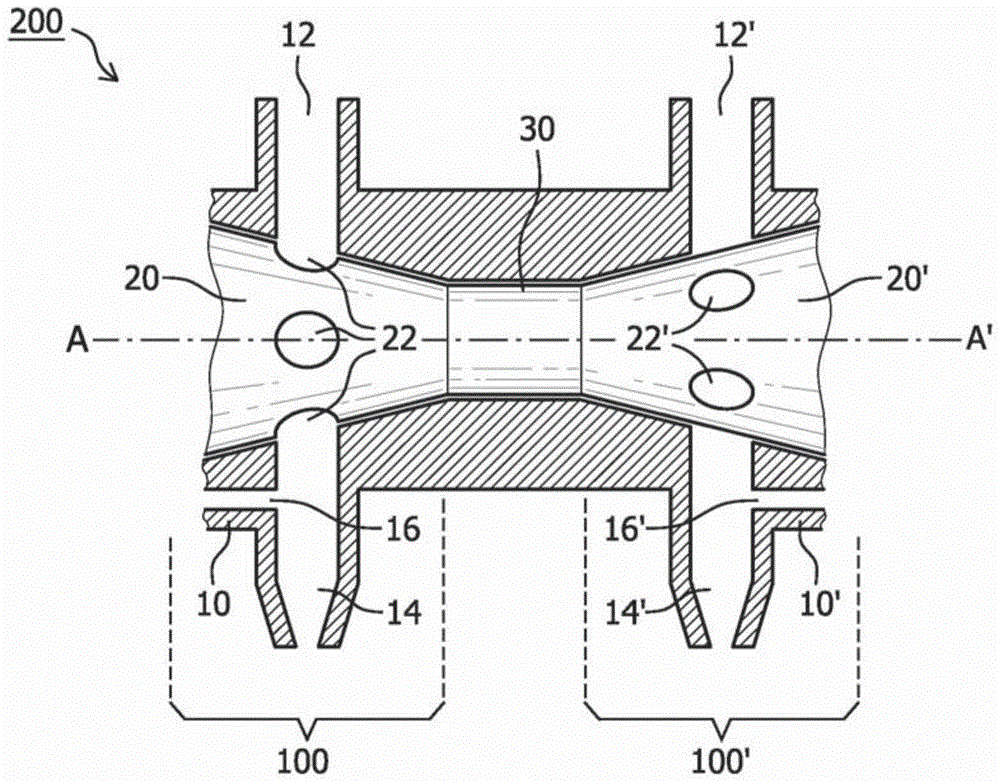

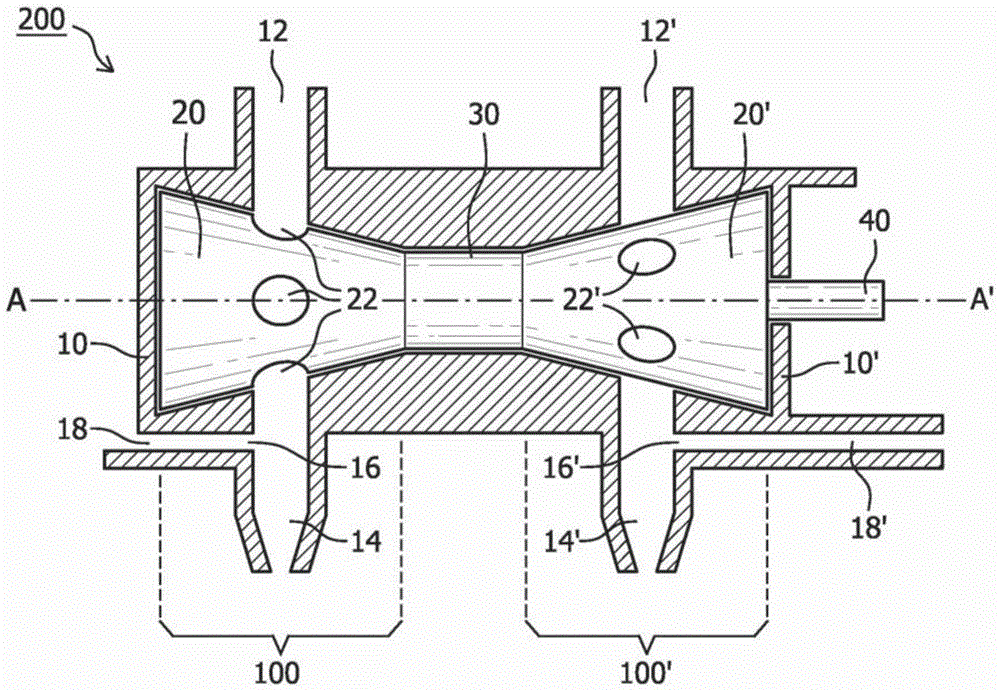

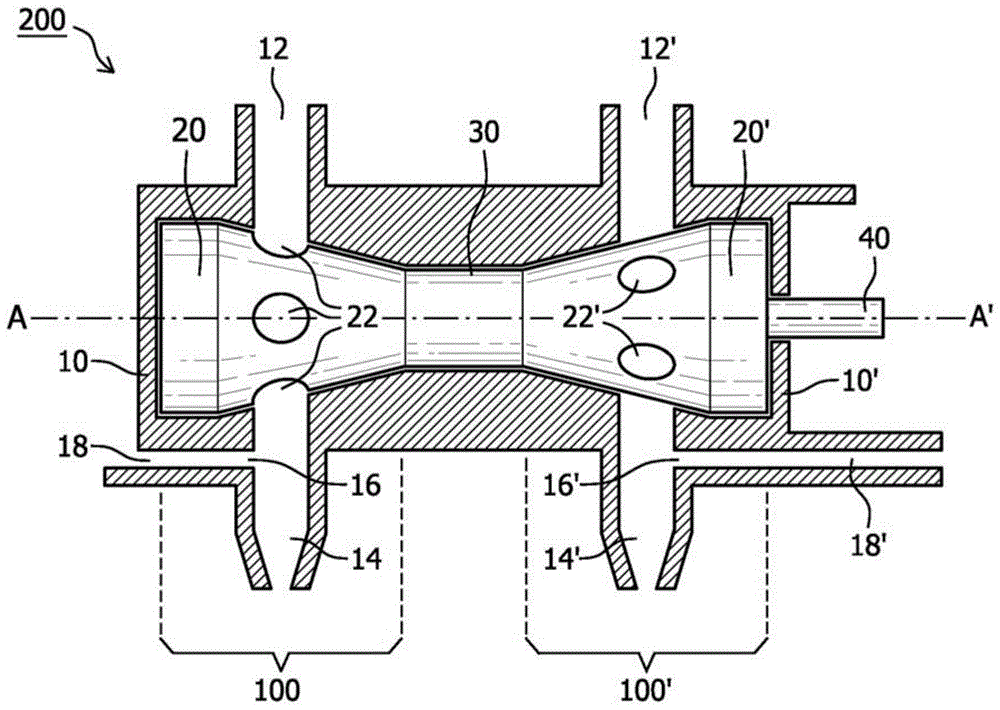

InactiveCN103998120BEfficient captureEfficient dischargeBulk conveyorsChemical/physical processesRotary valveEngineering

The invention relates to a device (200) for dispensing granular material, comprising at least two rotary valves (100, 100'), each having an inlet (12, 12') and an outlet (14, 14) provided for granular material ')'s stator (10, 10'), and a rotor (20, 20') located in the stator (10, 10') that isolates the inlet (12, 12') and the outlet (14, 14'), each The rotor is provided with at least one cavity (22, 22') for receiving and distributing granular material when the rotor (20, 20') rotates about its central axis (A-A'); wherein the rotor (20, 20') is set to rotate synchronously; wherein the chambers (22, 22') of at least two rotors (20, 20') are set to dispense the granular material asynchronously, and wherein the rotors (20, 20) of the device (200) are set '), such that the combined flow of granular material is substantially continuous. The invention also relates to a method for dispensing granular material.

Owner:TOTAL RES & TECH FELUY

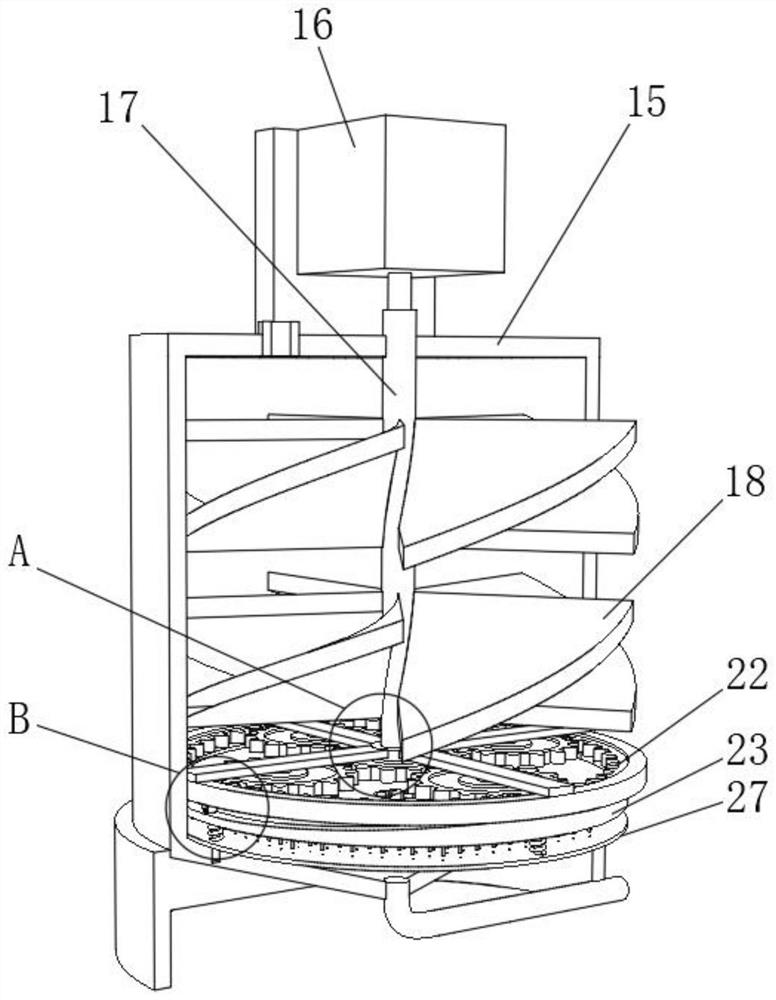

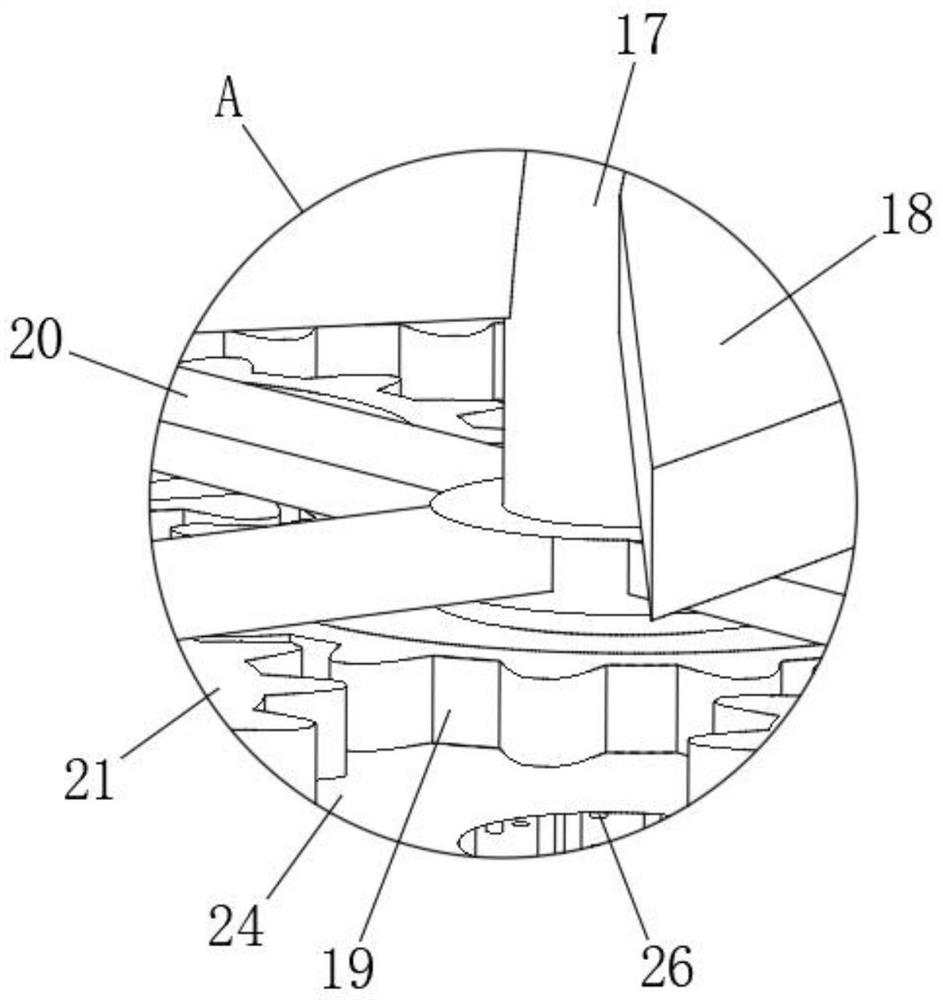

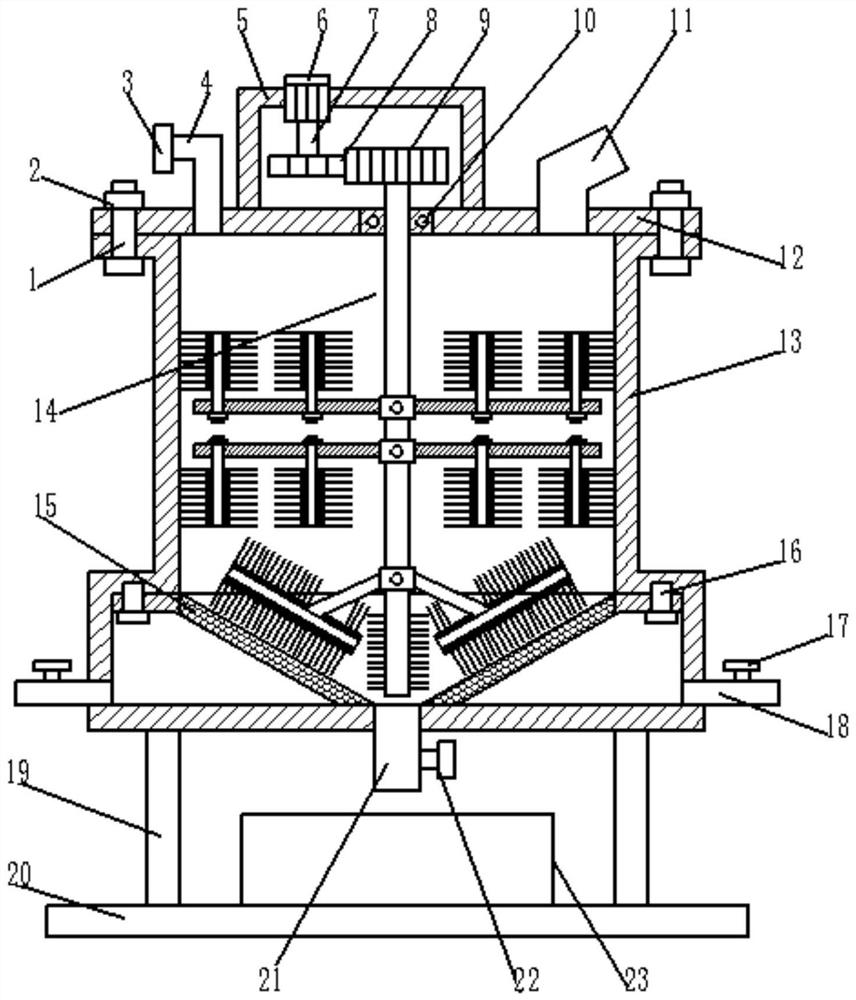

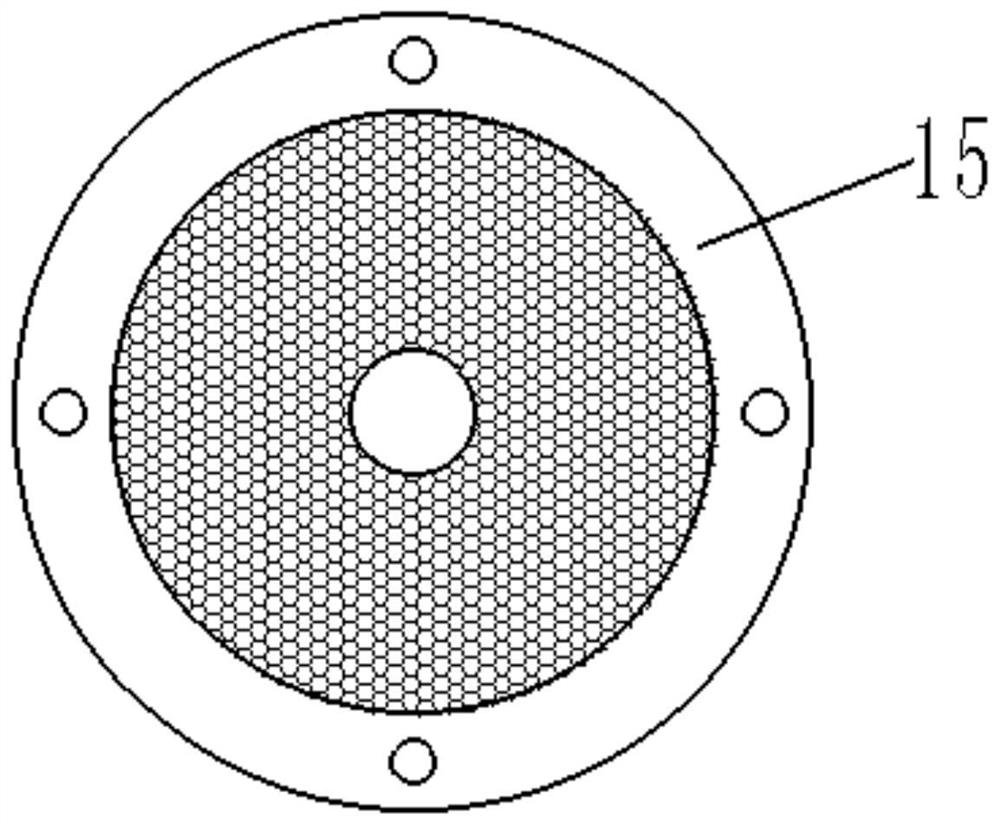

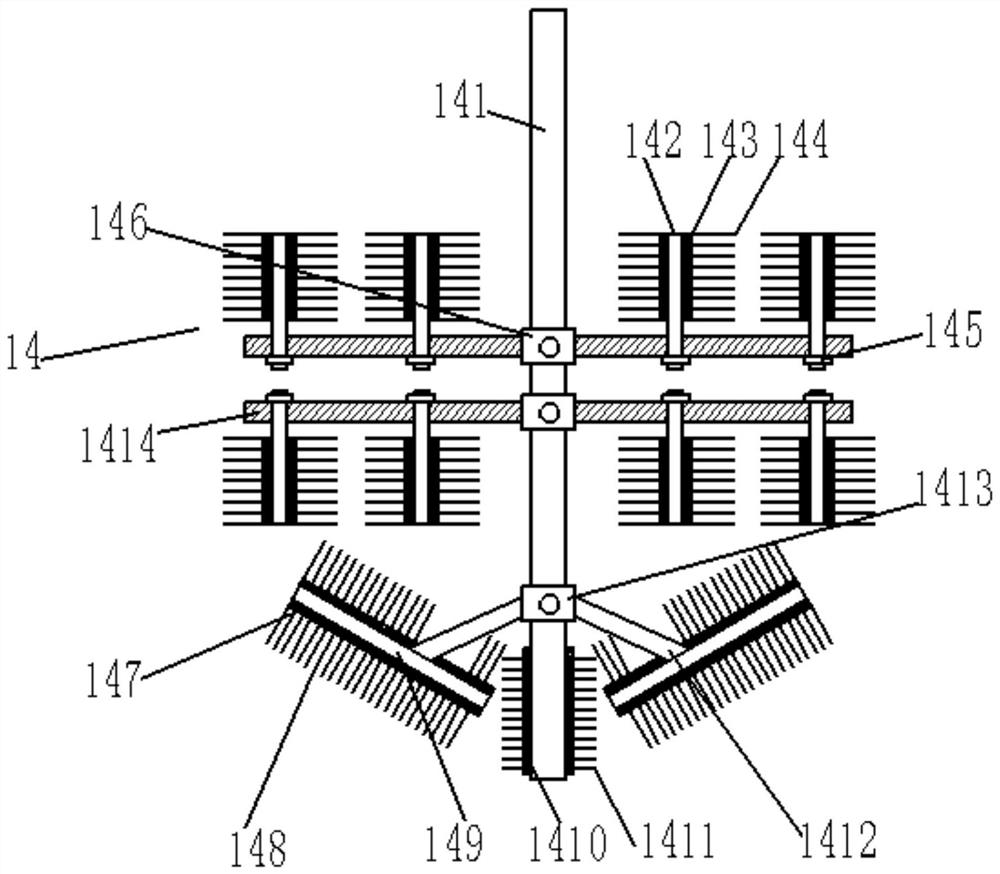

Stirring soybean cleaning device

ActiveCN107981382BAvoid breakingSlow down the spin rateFood treatmentAgricultural engineeringStructural engineering

The invention provides a stirring-type soybean cleaning device, and belongs to the field of agriculture. The stirring-type soybean cleaning device comprises a water inlet pipe, a motor, a soybean adding box, a cleaning cylinder, a stirring and scouring device, a cleaning and filtering hood, a drainage valve, a discharging cylinder and a collecting box; the cleaning cylinder is welded to the upperends of two supporting shelves; the lower end of the cleaning and filtering hood is closely attached to the lower end face of the interior of the cleaning cylinder, and the upper end of the cleaning and filtering hood is fixed to the inner wall of the cleaning cylinder through bolts; the discharging cylinder is welded to the lower end of the cleaning cylinder; the collecting box is arranged at theupper end of a fixed baseboard; the drainage pipe is welded to the lower end wall of the cleaning cylinder; the lower end of the water inlet pipe is welded to the left end wall of a cover plate; thelower end of the stirring and scouring device is arranged in the cleaning cylinder, and the upper end of the stirring and scouring device is arranged in a motor hood; the motor is fixed to the upper end wall of the motor hood; the soybean adding box is welded to the right end wall of the cover plate. The stirring-type soybean cleaning device is reasonable in design, stirring-type cleaning is adopted, and the stirring-type soybean cleaning device is good in cleaning effect, high in cleaning speed and convenient to operate.

Owner:河南中坤农业科技有限公司

Four-axis stamping manipulator

PendingCN109108955AReduce volumeReduce weightProgramme-controlled manipulatorMetal-working feeding devicesManipulatorConveyor belt

The invention discloses a four-axis stamping manipulator which comprises a rack, a grabbing device, a first drive device, a second drive device and a third drive device. The grabbing device is used for grabbing materials and comprises a first mechanical arm, a second mechanical arm capable of moving front and back along the length direction of the first mechanical arm, and a material taking part arranged on the second mechanical arm; the first drive device is used for driving the material taking part to rotate on the second mechanical arm; the second drive device is used for driving the firstmechanical arm to act front and back relative to the second mechanical arm through a conveyor belt; and the third drive device is arranged on the rack and is used for driving the grabbing device to rotate relative to the rack. According to the four-axis stamping manipulator provided by the invention, the second drive device drives the second mechanical arm to act front and back through the conveyor belt, the volume is small, the weight is light, and the volume of the whole manipulator is reduced, so that the volume of the whole equipment is small, less space is occupied, and reasonable arrangement of the space of the whole workshop can be improved.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

System For Supplying Unmelted Hot Melt Adhesive Pieces

ActiveCN107444928ASlow down the spin rateLiquid surface applicatorsLarge containersHot meltMechanical engineering

A hot melt adhesive supply system is disclosed. The hot melt adhesive supply system includes an outer container defining an upper cavity and a lower cavity. The upper cavity includes an inner container having a top opening to receive unmelted hot melt adhesive pieces and a bottom aperture. The system also includes a dispensing mechanism between the upper cavity and the lower cavity. The dispensing mechanism regulates the dispensing of the unmelted hot melt adhesive pieces from the upper cavity to the lower cavity. The dispensing mechanism includes a base plate and one or more rotating members that rotate to move the unmelted hot melt adhesive pieces through a gap defined between the base plate and the bottom aperture. The system also includes a transfer conduit that communicates the unmelted hot melt adhesive pieces from the lower cavity to a hot melt adhesive melter.

Owner:NORDSON CORP

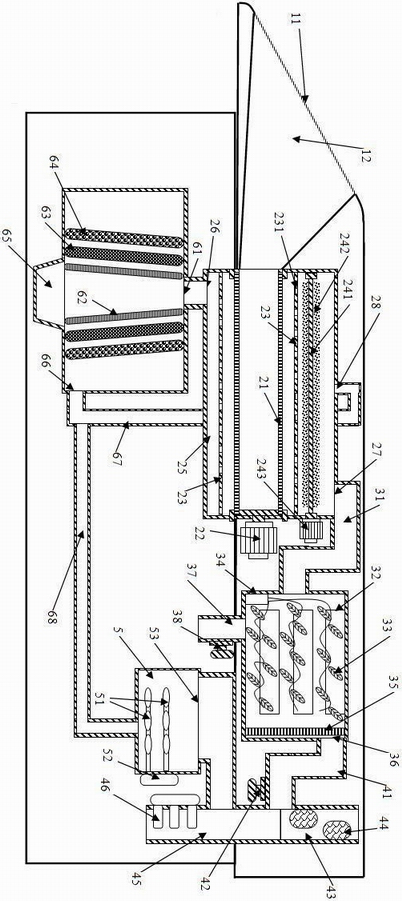

Large bus fresh air system

ActiveCN110227313BEasy to cleanHigh speedGas treatmentUsing liquid separation agentThermodynamicsFresh air

The invention belongs to the field of air purification and auto parts, and specifically relates to a fresh air system for a large passenger car, which includes an inlet part, an air washing chamber, a plant treatment chamber, an outlet part, an atomization chamber and an adsorption filter chamber. By rotating the centrifugal washing chamber components, the external gas that enters the system at high speed achieves efficient contact with the water body and purifies the gas through the water body, and then realizes the enrichment and oxidation of the overall gas components through the vines. There may be harmful organic gases to achieve adsorption, and finally, by setting the outlet parts, the dry gas and hot and humid gas can be discharged separately in a timely manner, which improves the comfort in the bus.

Owner:ZHENGZHOU XINJIEYE AUTOMOTIVE ELECTRONICS

A kind of disc-shaped suspension porcelain insulator processing equipment

ActiveCN113506662BReduce shockSlow down the spin rateInsulatorsCeramic materials productionIron removalGear wheel

The invention provides a disc-shaped suspension type porcelain insulator processing equipment, which relates to the technical field of insulator processing. The disc-shaped suspension porcelain insulator processing equipment includes a base, and a stirring mill is arranged on the top, front and rear sides of the top of the left end of the base. The stirring mill includes an abrasive tank, a first motor, a rotating shaft, a first gear, a cross, The second gear, the ring gear, the dredging plate, the annular groove, the thin rod, the sieve plate, the guide rod, the spring and the roller, the abrasive tank is fixedly connected to the top of the base, and the top of the abrasive tank is fixedly connected with the first motor, so A ring gear is rotatably connected to the inner side of the lower part of the abrasive tank, and the ring gear is meshed with the four second gears. The uniformity of the particle size of the insulator is improved by the stirring mill, and the stirring mill, the ball mill and the slurry iron remover are combined with the vacuum mud machine to degas the mud material and improve the steep wave performance of the porcelain insulator, which is worthy of vigorous promotion.

Owner:萍乡强盛电瓷制造有限公司

One-bath dyeing process and equipment for brocade blended fabric

ActiveCN108978079BEfficient heatingImprove dyeing efficiencyLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsPolymer scienceViscose

The invention relates to the technical field of one-bath dyeing and discloses a one-bath dyeing device for viscose / cotton knitted fabric. The one-bath dyeing device comprises an external dyeing barrel, the bottom center of the external dyeing barrel is fixedly connected with the shaft end face of the output shaft of a motor, an internal dyeing barrel is mounted in the cavity center of the externaldyeing barrel, a first expansion pipe and a second expansion pipe are respectively mounted on the right wall and the left wall of the axial bottom of the external dyeing barrel, a first mercury thermometer and a second mercury thermometer are respectively mounted in the first expansion pipe and the second expansion pipe, and a cylindrical cavity and an annular cavity between the outside of the internal dyeing barrel and the inside of the external dyeing barrel are respectively provided with a first heating resistor and a second heating resistor. The invention further discloses a one-bath dyeing process for the viscose / cotton knitted fabric. The problem that a one-bath dyeing solution cannot be heated and maintained at constant temperature efficiently simultaneously when the viscose / cottonknitted fabric is dyed by the one-bath method is solved.

Owner:绍兴华夏印染有限公司

Central ventilation system for large passenger car

ActiveCN110227313AImprove the effectAvoid discomfortGas treatmentUsing liquid separation agentProcess engineeringDry gas

The invention belongs to the fields of air purification and auto spare parts, and concretely relates to a central ventilation system for a large passenger car. The central ventilation system comprisesan inlet part, an air washing chamber, a plant processing chamber, an outlet part, an atomizing chamber and an adsorption and filtration chamber. The rotary centrifuging air washing chamber part is used to realize high-efficiency contact of outside gas, entering the system at a high speed, with water and purify the gas through the water, vine plants are used to realize the oxygen enrichment of the whole components of the gas and realize the adsorption of possible harmful organic gases, and the outlet part is arranged to respectively discharge dry gas and wet warm gas timely in order to improve the comfortableness inside the passenger car.

Owner:ZHENGZHOU XINJIEYE AUTOMOTIVE ELECTRONICS

Golf ball

ActiveUS20190247721A1Improve injection molding effectSlow down the spin rateGolf ballsSolid ballsGolf BallChemistry

In a golf ball having a core and a cover of at least one layer, the outermost layer of the cover is formed of a resin composition that includes (A) 100 parts by weight of a thermoplastic resin, and (B) 1 to 30 parts by weight of a compound having a fluorene skeleton, or a derivative thereof, and the resin composition has a melt flow rate of at least 3.0 g / 10 min. This resin composition for golf balls has an improved injection-moldability and thus enables the ball to achieve both a reduced spin rate and a good durability (scuff resistance).

Owner:BRIDGESTONE SPORTS

Golf ball

ActiveUS20210086035A1Slow down the spin rateIncrease elasticityGolf ballsSolid ballsClassical mechanicsEngineering

An object of the present invention is to provide a golf ball having a decreased spin rate on driver shots. The present invention provides a golf ball comprising a spherical core and at least one cover layer covering the spherical core, wherein the spherical core is formed from a rubber composition containing (a) a base rubber, (b) two or more α,β-unsaturated carboxylic acids having 3 to 14 carbon atoms and having no substituent group at a carbon atom bonding to the carboxy group, and / or a metal salt thereof, and (c) a crosslinking initiator.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com