Four-axis stamping manipulator

A manipulator and manipulator technology, applied in the field of four-axis stamping manipulators, can solve the problems of inability to realize rational utilization of space resources, cumbersome screw fixation, cumbersome screw replacement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

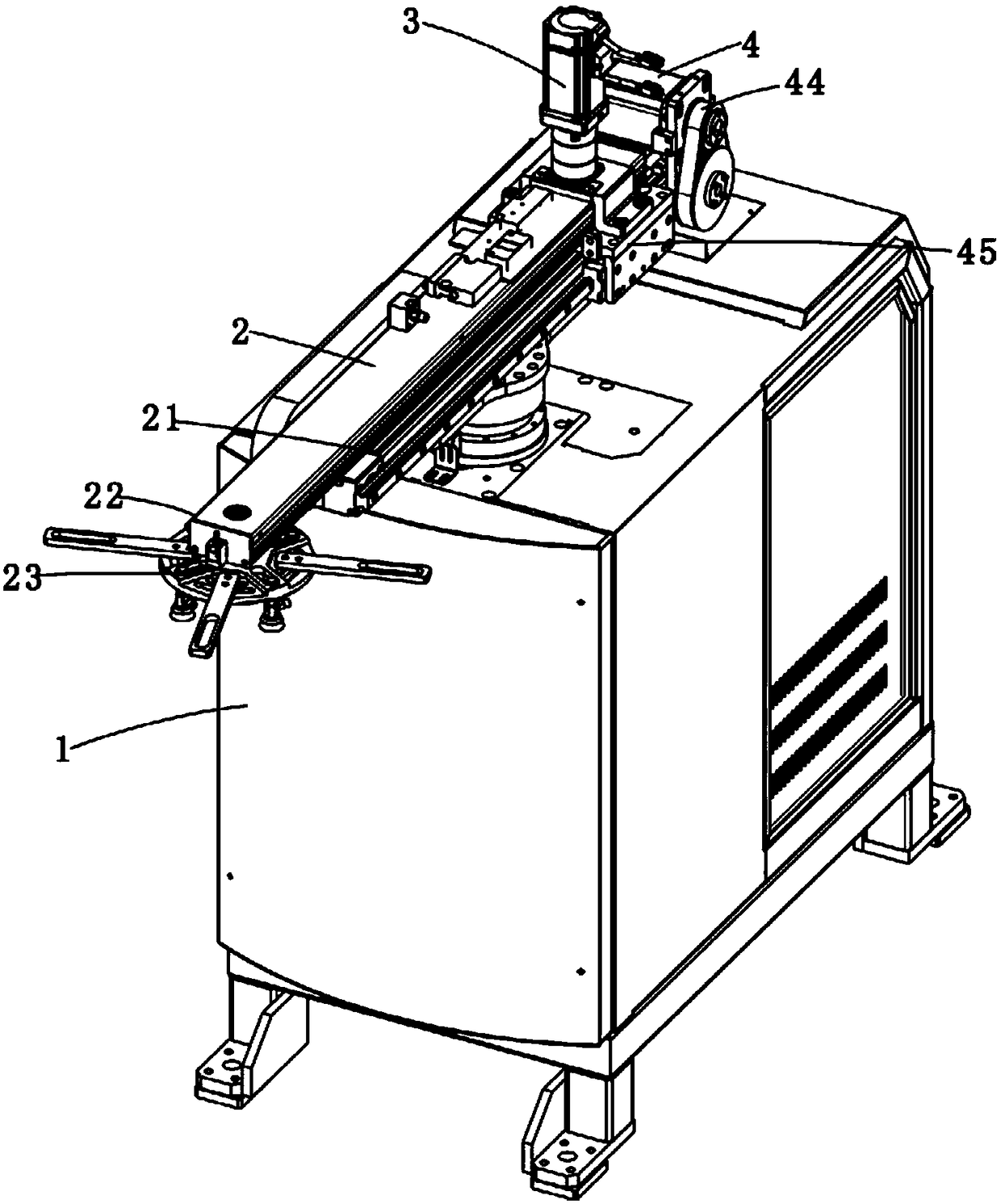

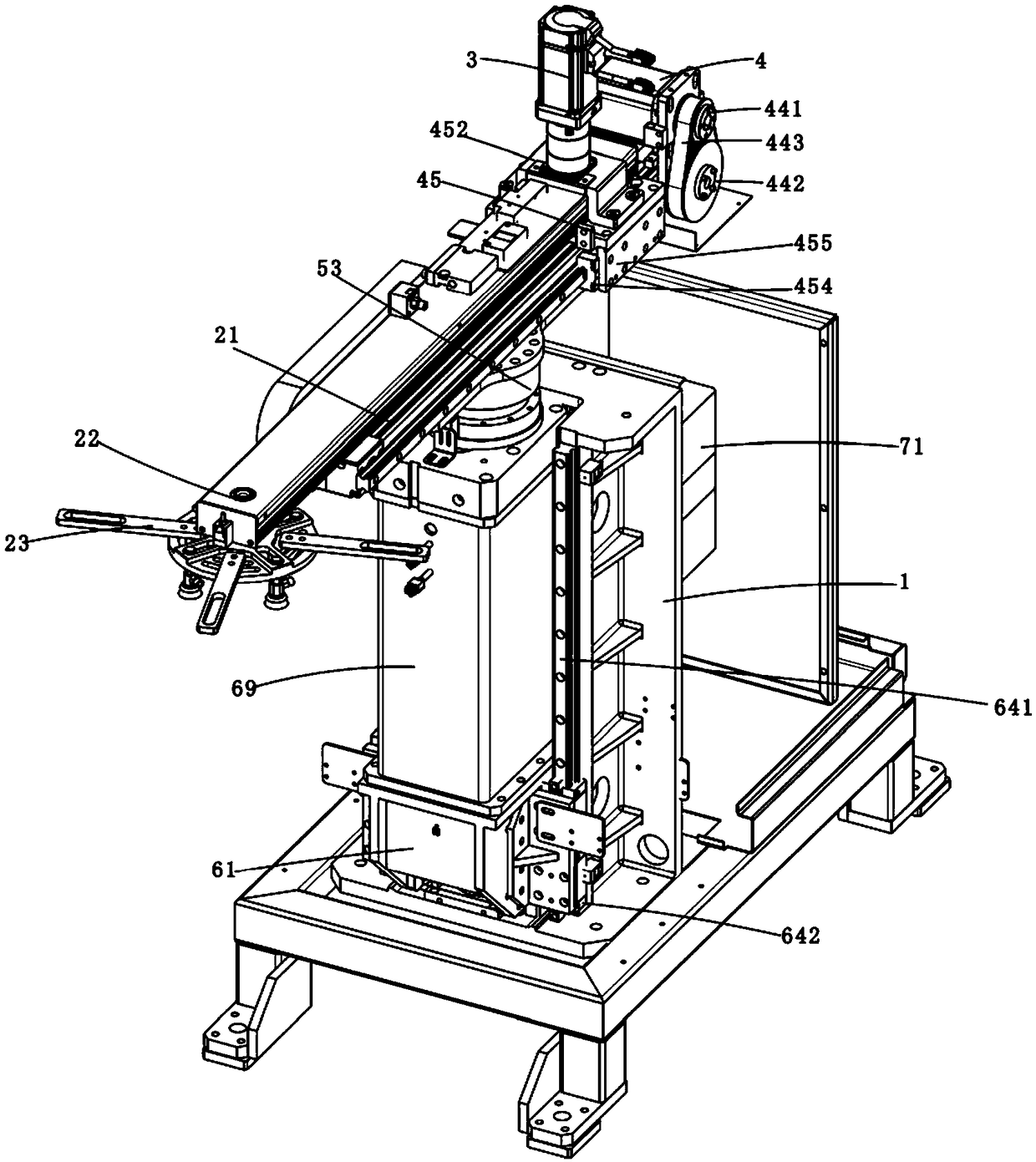

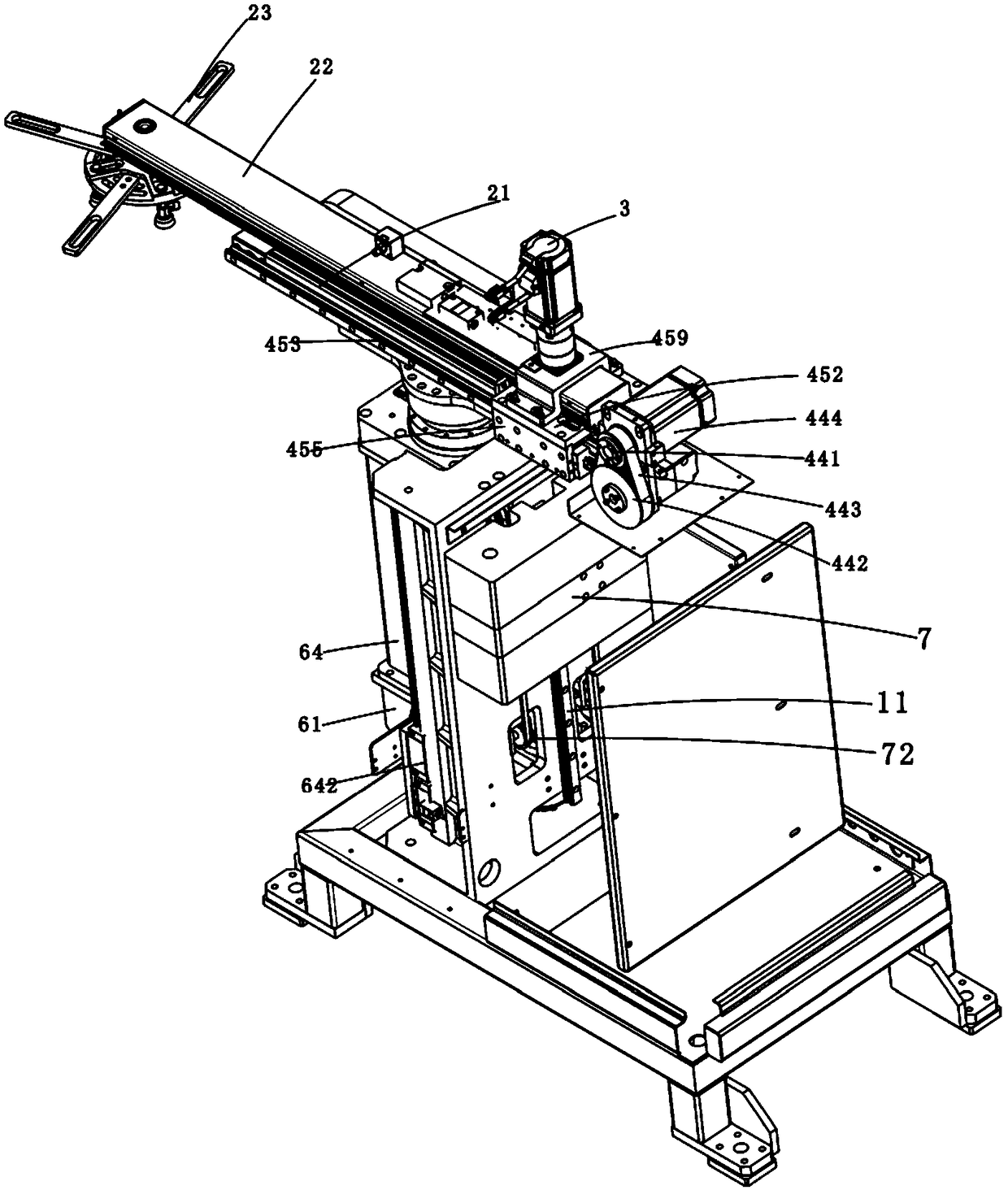

[0035] Such as Figure 1-11 As shown, a four-axis stamping manipulator includes a frame 1, a grabbing device 2, a first driving device 3, a second driving device 4, a third driving device 5, a fourth driving device 6 and a counterweight device 7. The frame 1 is a metal frame; the grabbing device 2 includes a first mechanical arm 21, a second mechanical arm 22 and a retrieving part 23 for grabbing materials, wherein the first mechanical arm 21 is horizontally arranged aluminum profile, the second mechanical arm 22 is also an aluminum profile; the third driving device 5 is arranged on the frame 1, and the first mechanical arm 21 is connected with the third driving device 5, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com