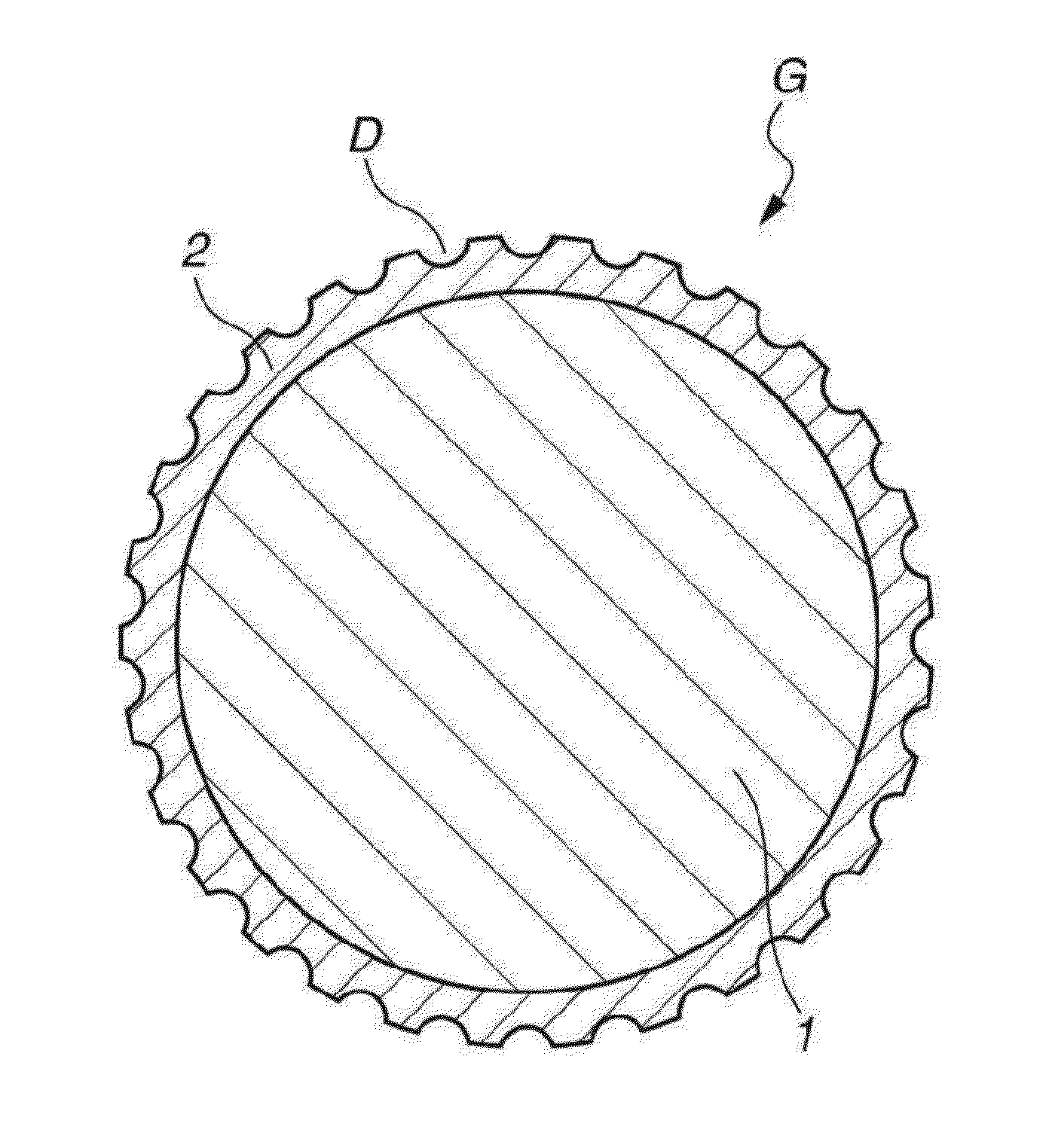

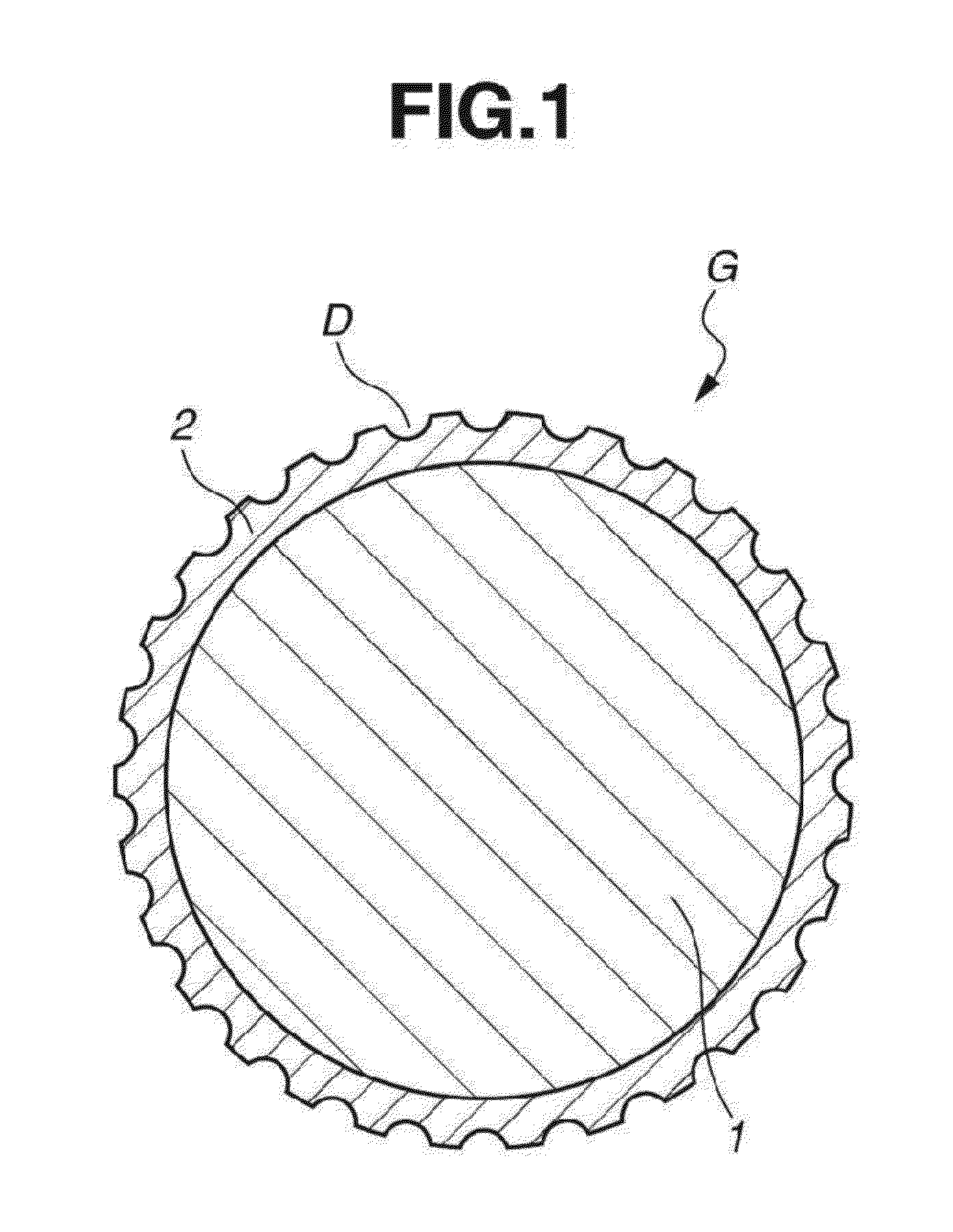

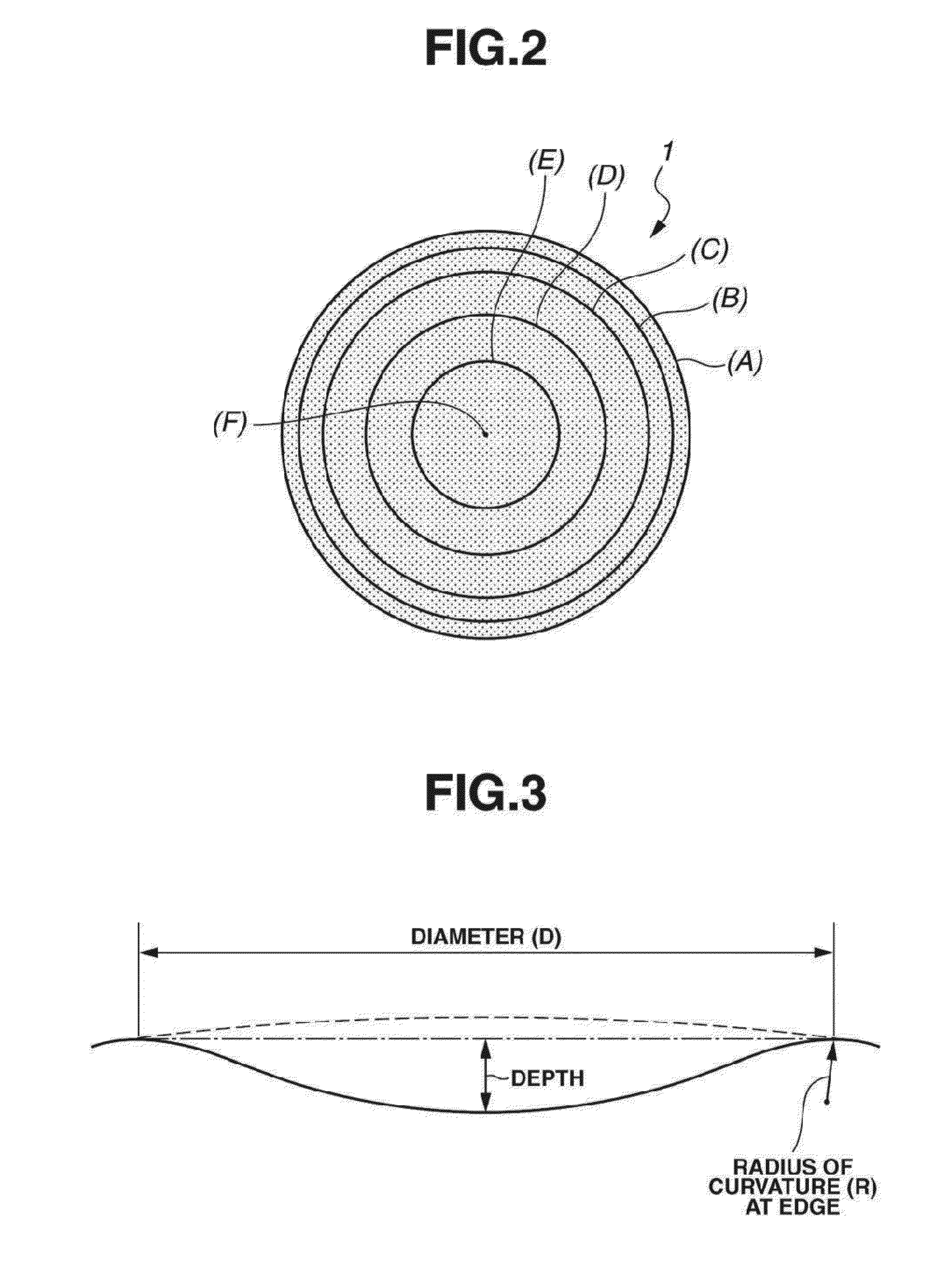

Golf ball

a golf ball and ball technology, applied in the field of golf balls, can solve the problems of prior-art golf balls lacking satisfactory durability to “surface loss", and difficult to achieve good ball durability in long-term use. , to achieve the effect of shortening the vulcanization time, reducing the spin rate, and increasing the distan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0101]The following Examples and Comparative Examples are provided to illustrate the invention, and are not intended to limit the scope thereof.

examples 1 to 4

, Comparative Examples 1 to 10

[0102]Rubber materials formulated as shown in Table 1 below were furnished for the fabrication of golf balls in the Examples and Comparative Examples. These rubber compositions were suitably mixed using a kneader or roll mill, then vulcanized under the temperature and time conditions in Table 1 to produce solid cores in the respective examples. Ingredient amounts in the table below are shown in parts by weight.

TABLE 1parts by weightNo. 1No. 2No. 3No. 4No. 5No. 6No. 7No. 8No. 9No. 10CoreBR018080808010010010010095formulationIR22002012.555SBR SL563207.515BR730100Perhexa C-400.60.60.6(40% dilution)Actual amount of0.240.240.24additionPercumyl D1.31.31.31.31.070.80.60.60.61.07Zinc oxide22.522.522.5222323669.523Antioxidant0.20.20.20.20.20.20.20.20.10.2Methacrylic acid23.523.523.52222.522.522.5Zinc methacrylate33Zinc acrylate3326Zinc stearate1.71.71.71.7Titanium oxide4VulcanizationTemperature (° C.)170170170170170170160160160170conditionsTime (minutes)181818182...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com