System For Supplying Unmelted Hot Melt Adhesive Pieces

A technology of supply system and hot melt adhesive, which is applied to the device, container, transportation and packaging of the surface coating liquid, which can solve the problems of sticking together and rising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

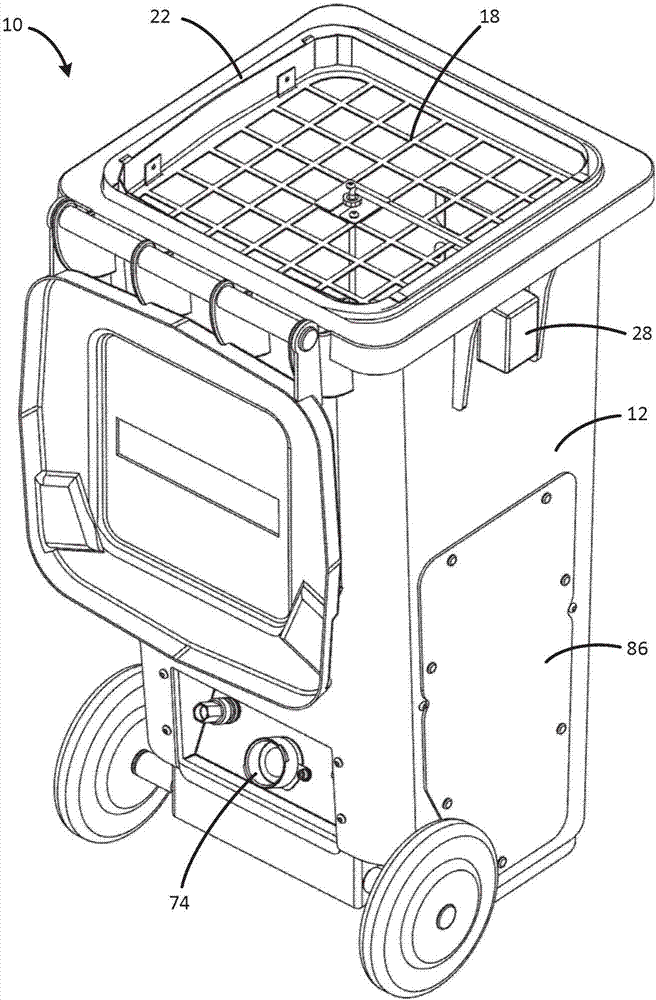

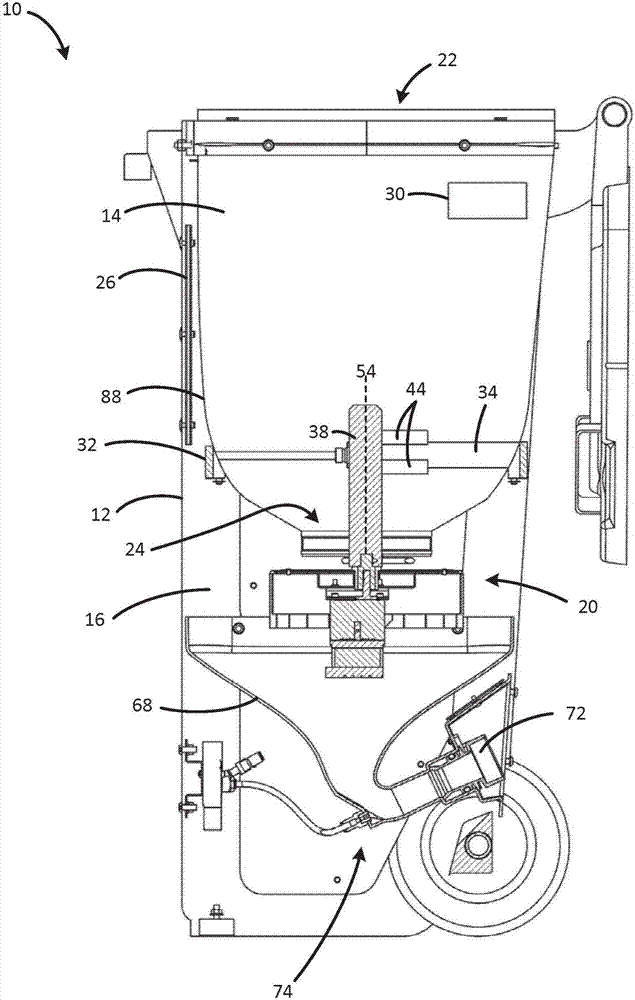

[0027] figure 1 with 2 An illustrative hot melt adhesive supply system 10 (hereinafter "supply system") is shown. In general, supply system 10 is configured to receive a supply of hot melt adhesive gobs, and to provide hot melt adhesive gobs in a controlled manner to an attached glue melter. The glue melter can then provide molten hot melt glue to the glue dispensing module.

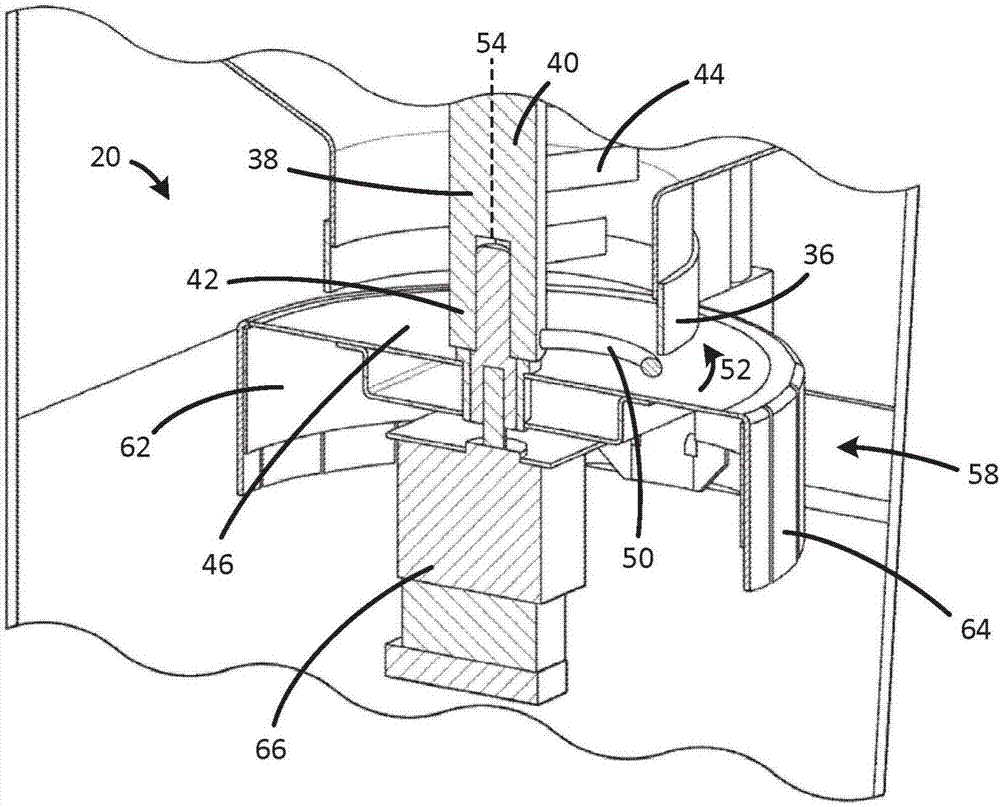

[0028] The hot melt adhesive supply system 10 may include a rigid outer container 12 . In some aspects, outer container 12 may be formed from a plastic box that was originally intended to contain waste. The outer container 12 may comprise an upper cavity 14 initially receiving a supply of hot melt adhesive, and a lower cavity 16 from which the hot melt adhesive is delivered via a transfer member 72 to an attached glue melter. . The upper cavity 14 may be defined by an upper receptacle 88 . A dispensing mechanism 20 may be disposed between the upper cavity 14 and the lower cavity 16 to facilitate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com