Chemical vapor deposition with elevated temperature gas injection

A chemical vapor deposition, gas technology, used in gaseous chemical plating, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as limited operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

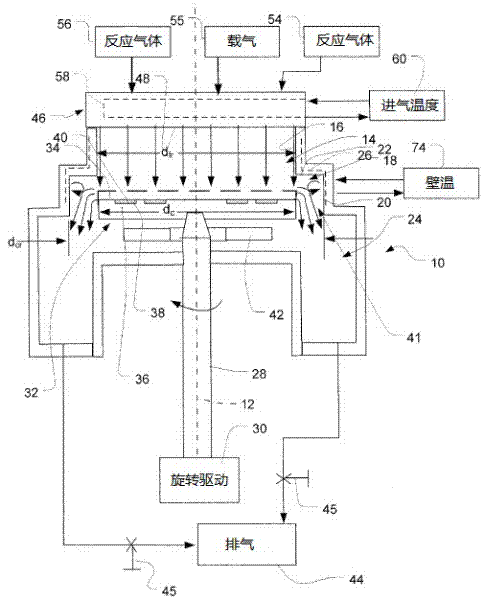

[0022] A device according to one embodiment of the present invention ( figure 1 ) includes a reaction chamber 10 with a central axis 12 . In this embodiment, axis 12 is generally vertical, as seen in a normal gravitational frame of reference. The inner walls of the reaction chamber 10 are generally in the form of surfaces that rotate about an axis 12 . In the flow region 14 at the top of the reaction chamber, an inner wall 16 exists approximately in the form of a cylinder with a diameter d concentric to the axis FR . The region 18, referred to herein as the "carrier region", has a cylindrical inner wall 20, which likewise generally has the form of a cylinder coaxial to the axis 12, with a diameter d CR greater than d FR , the reaction chamber has a downwardly facing transition surface 22 at the junction of the flow region and the carrier region. The reaction chamber likewise has an outlet region 24 located below the carrier region. The walls of the reaction chamber have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com