Patents

Literature

142results about How to "Appropriate speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

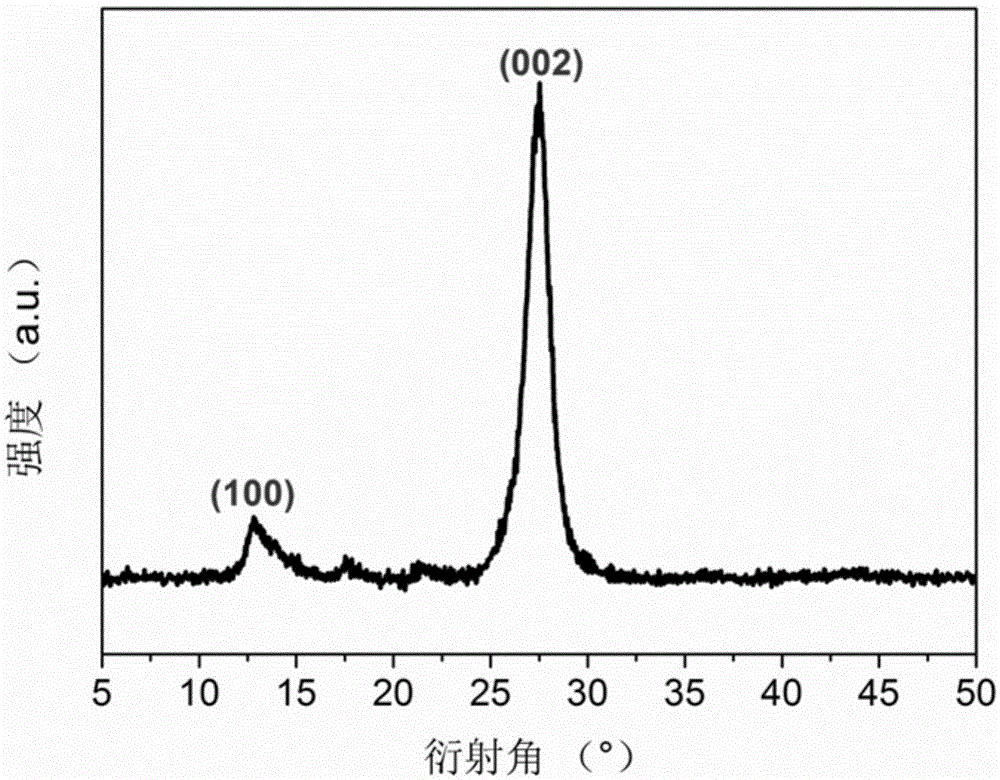

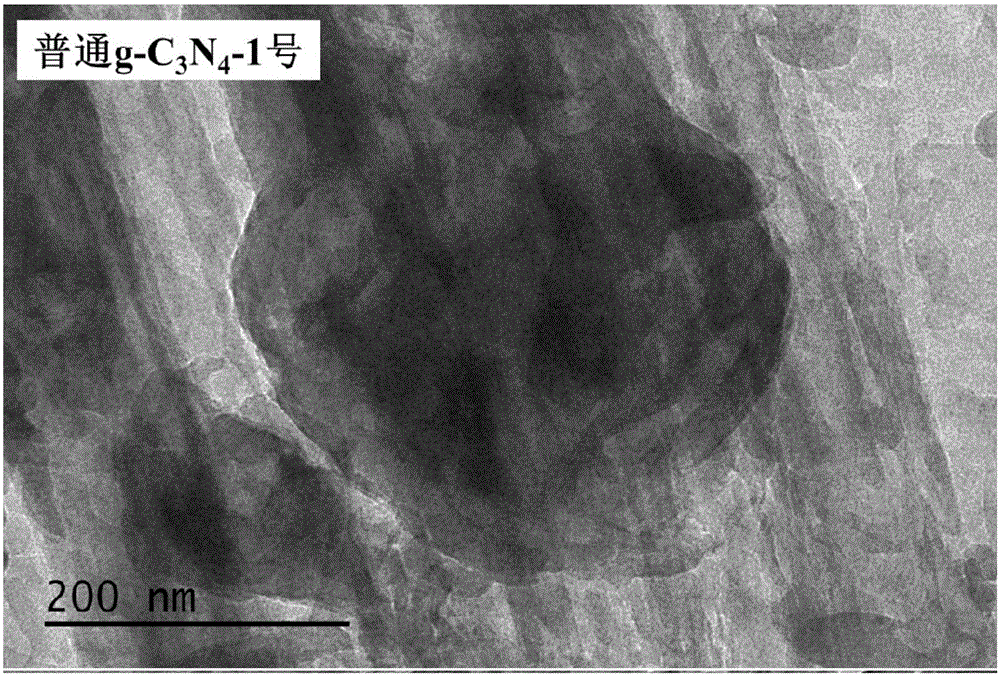

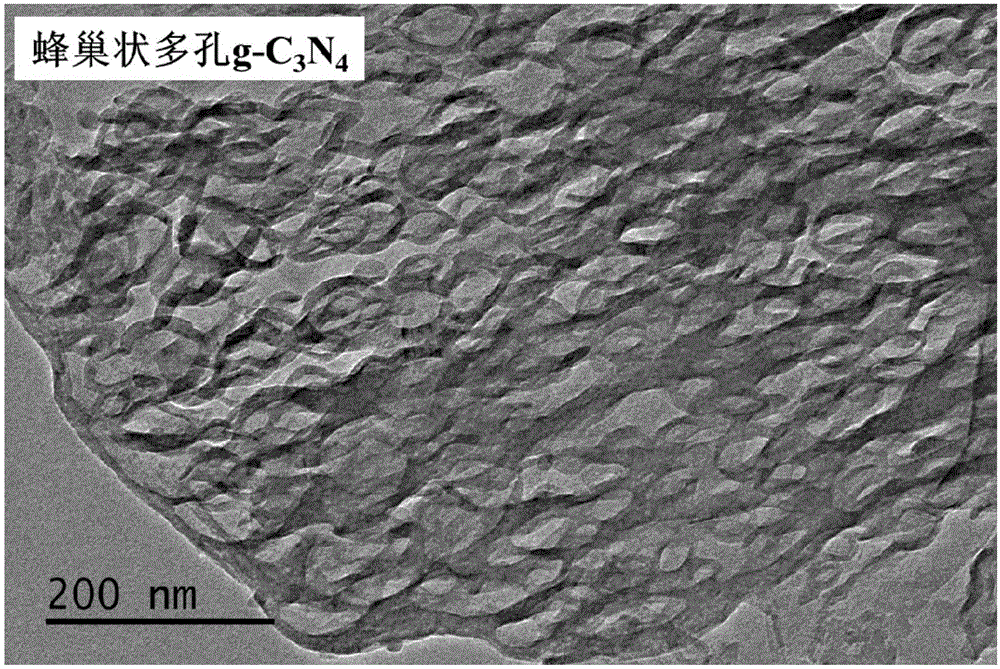

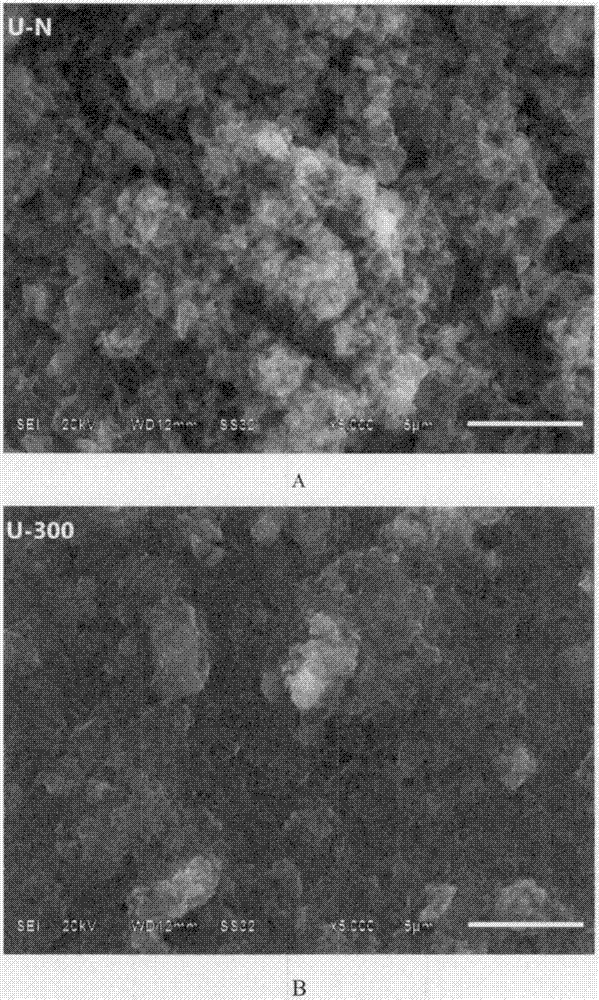

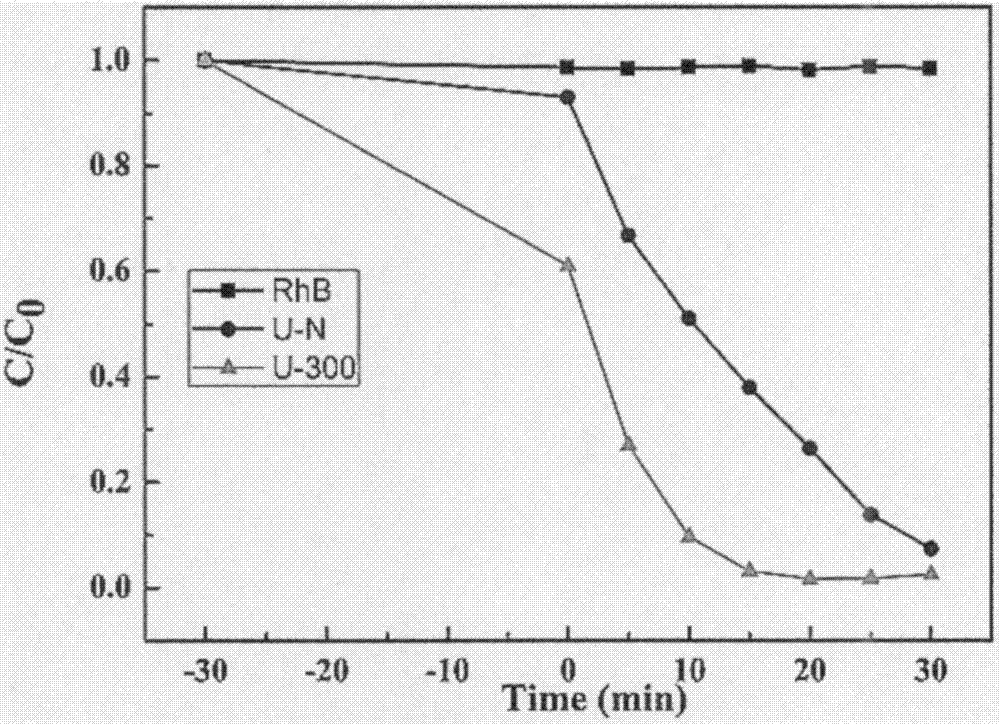

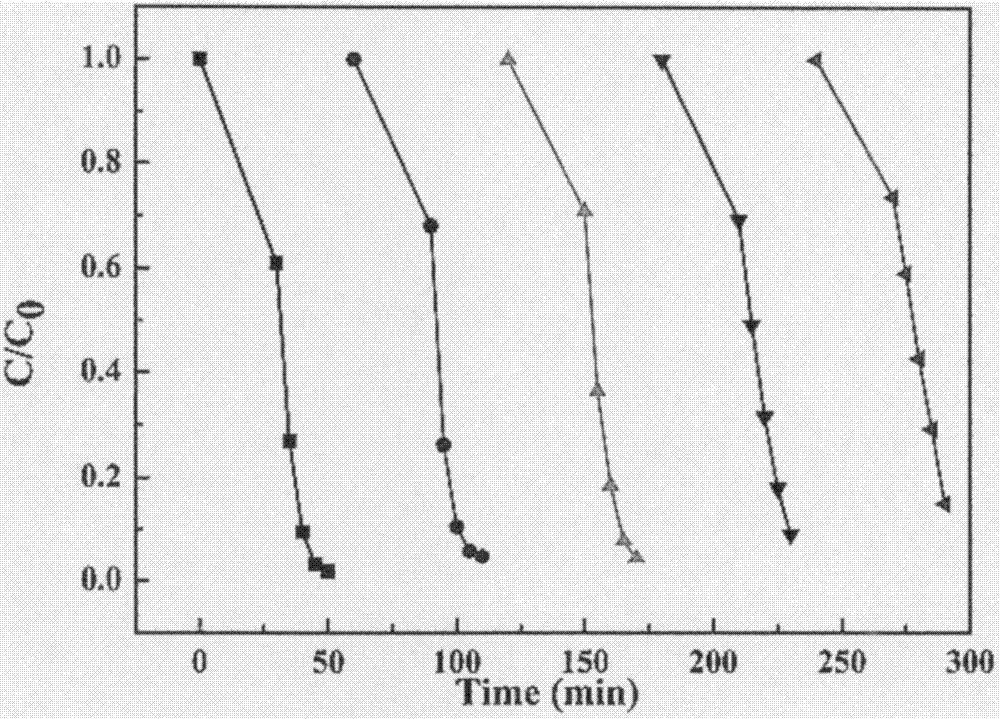

Graphite-phase carbon nitride (g-C3N4) material and preparation method and application thereof

ActiveCN105126893APlay a pore-forming roleAppropriate speedPhysical/chemical process catalystsWater/sewage treatment by irradiationCalcinationMaterials science

The invention relates to a method for preparing a graphite-phase carbon nitride (g-C3N4) material. The method includes the steps that a carbon nitride precursor and ammonium salt are evenly mixed, and then calcination is conducted so that the porous g-C3N4 material can be obtained. The ammonium salt is any one of ammonium base salts capable of generating ammonia gas through thermal decomposition or is the combination of at least two of the ammonium base salts. In the preparation process of the g-C3N4 material, the ammonium salt is added into the carbon nitride precursor to be mixed. In the high-temperature calcining process, the ammonium salt is subjected to pyrogenic decomposition to generate gas, a pore-forming effect on the g-C3N4 material is achieved, and the cellular porous g-C3N4 material is obtained. In the preparation process of the g-C3N4 material, template agents are not used, and thus the method is simple, efficient and environmentally friendly; the prepared g-C3N4 material is high in photocatalytic activity and can be used in the pollution control processes such as exhaust gas and wastewater treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

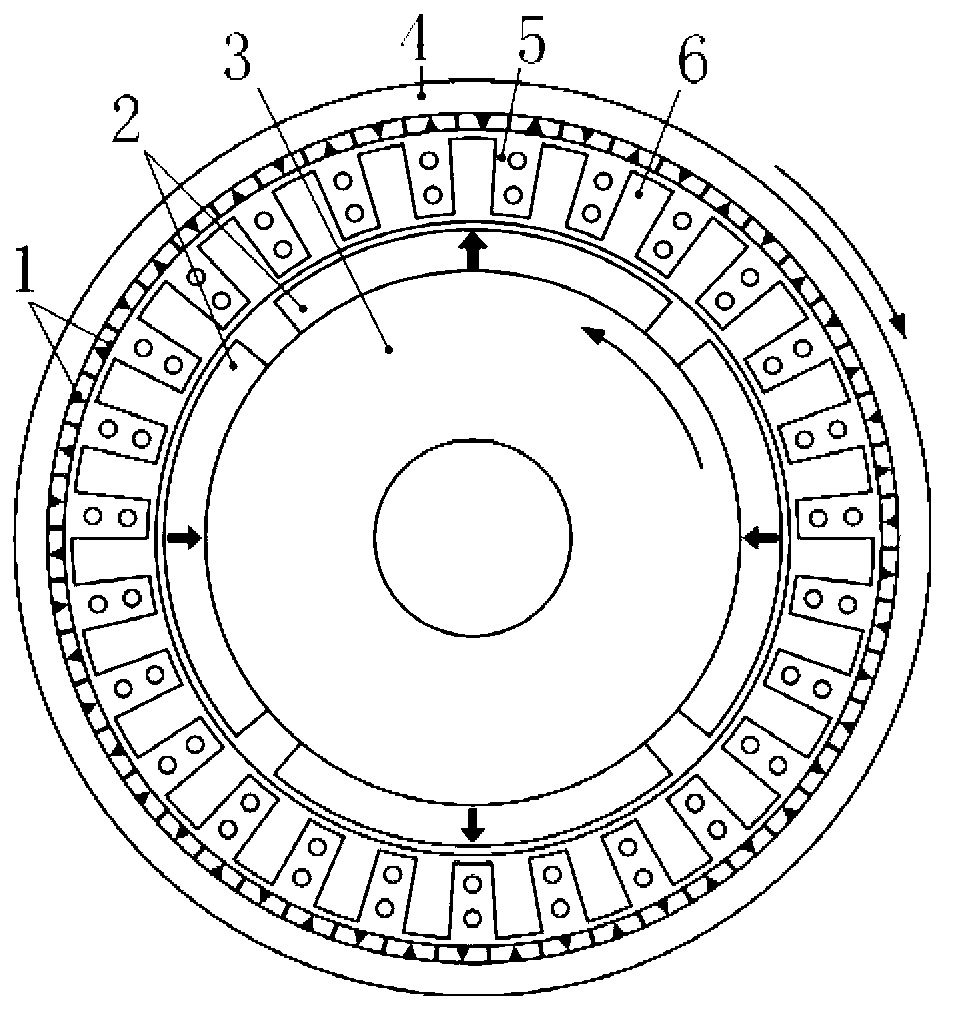

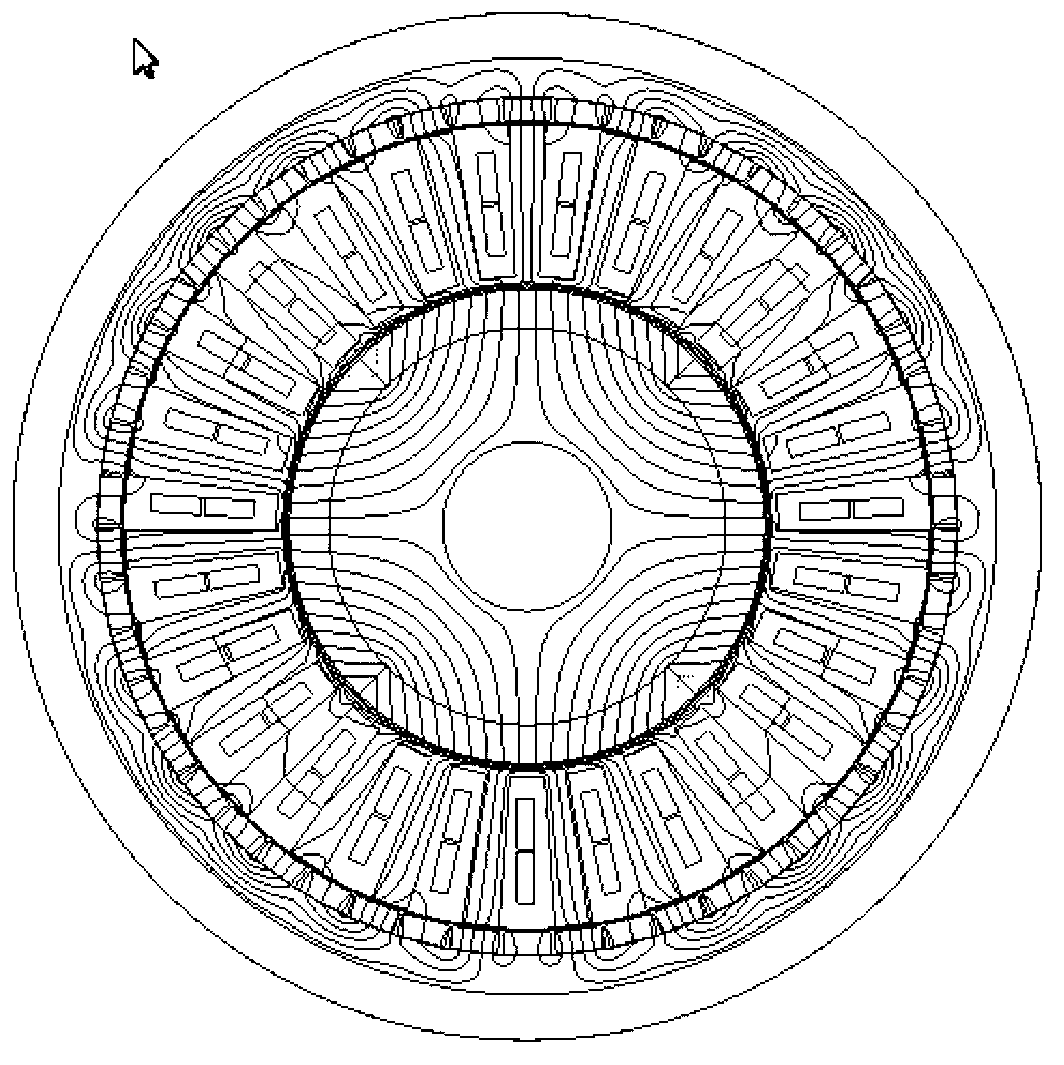

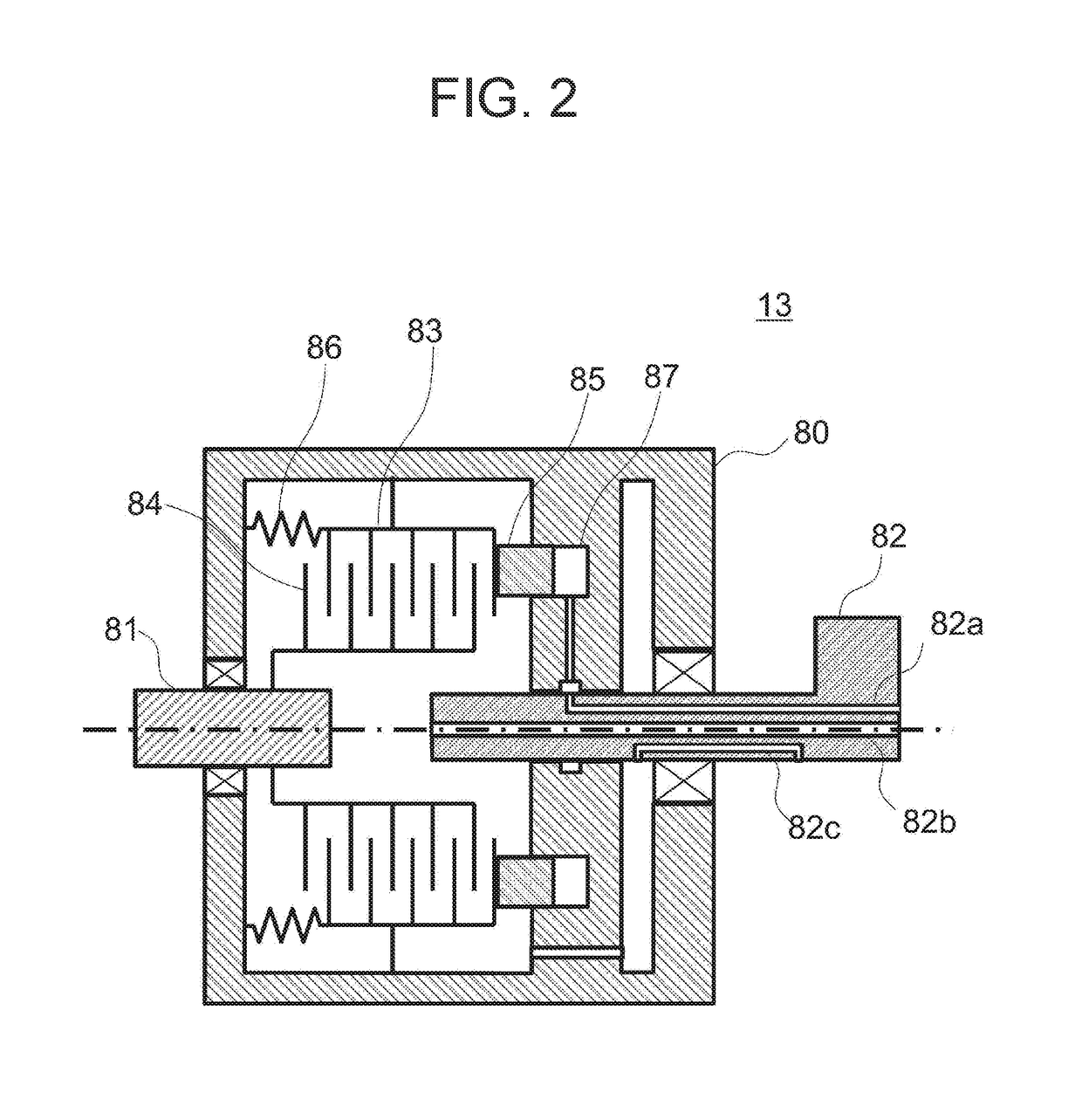

Birotor permanent magnet motor and washing machine

ActiveCN103346655ASpeed effectAppropriate speedMagnetic circuit rotating partsOther washing machinesPermanent magnet rotorElectric machine

The invention provides a birotor permanent magnet motor and a washing machine with the same. The birotor permanent magnet motor comprises an inner rotor, a stator and an outer rotator which are sequentially arranged from inside to outside, and is characterized in that both the inner rotor and the outer rotor are permanent magnet rotors, and the stator comprises a magnetic modulation ring and a stator winding arranged on the magnetic modulation ring in a wound mode. The birotor permanent magnet motor is based on the magnetic field modulation principle and has a birotor structure, the outer rotor and the inner rotor can rotate according to certain proportional relation, and high-performance output of the motor under operating conditions of a low speed and a high speed can be met at the same time. When the birotor permanent magnet motor drives the washing machine to operate, not only are design requirements for low-speed large torque output and high-speed small torque output of the motor under the optimal operating state met, but also the structures of a belt pulley, a reduction gearbox and the like in a traditional washing machine are eliminated, transmission efficiency of the motor is improved, and meanwhile the defects of high noise, machine body vibration and the like of the traditional washing machine are overcome.

Owner:ZHEJIANG UNIV

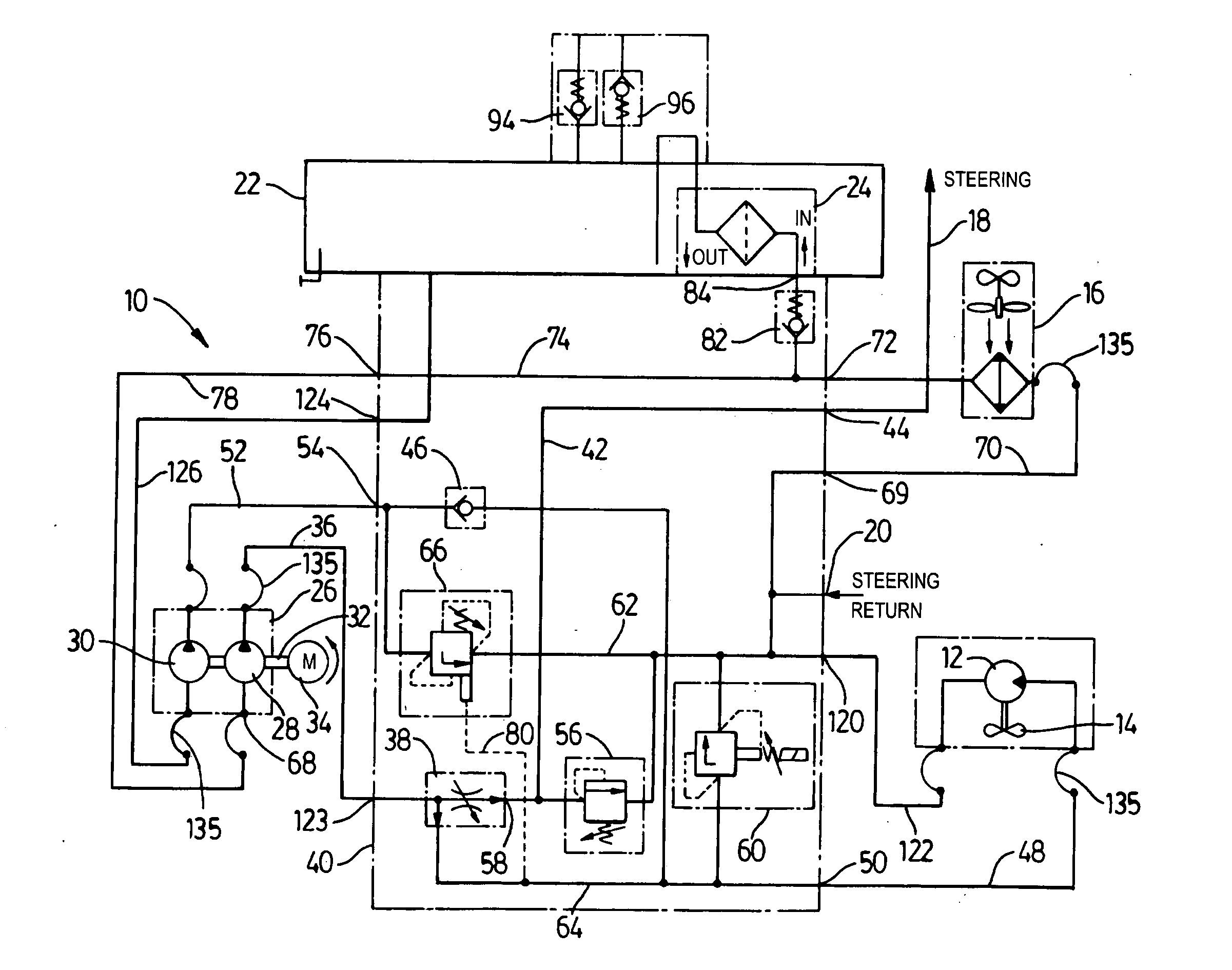

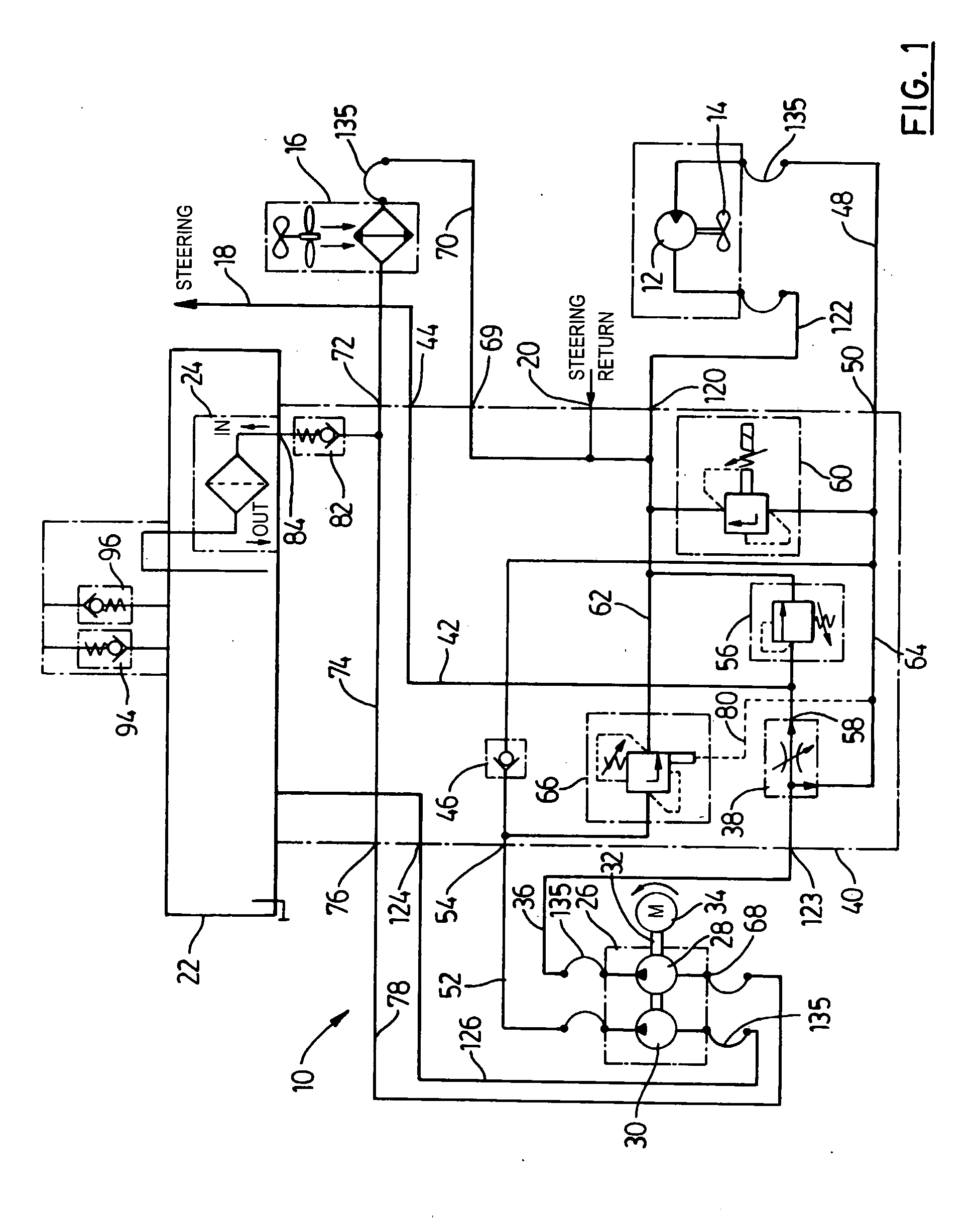

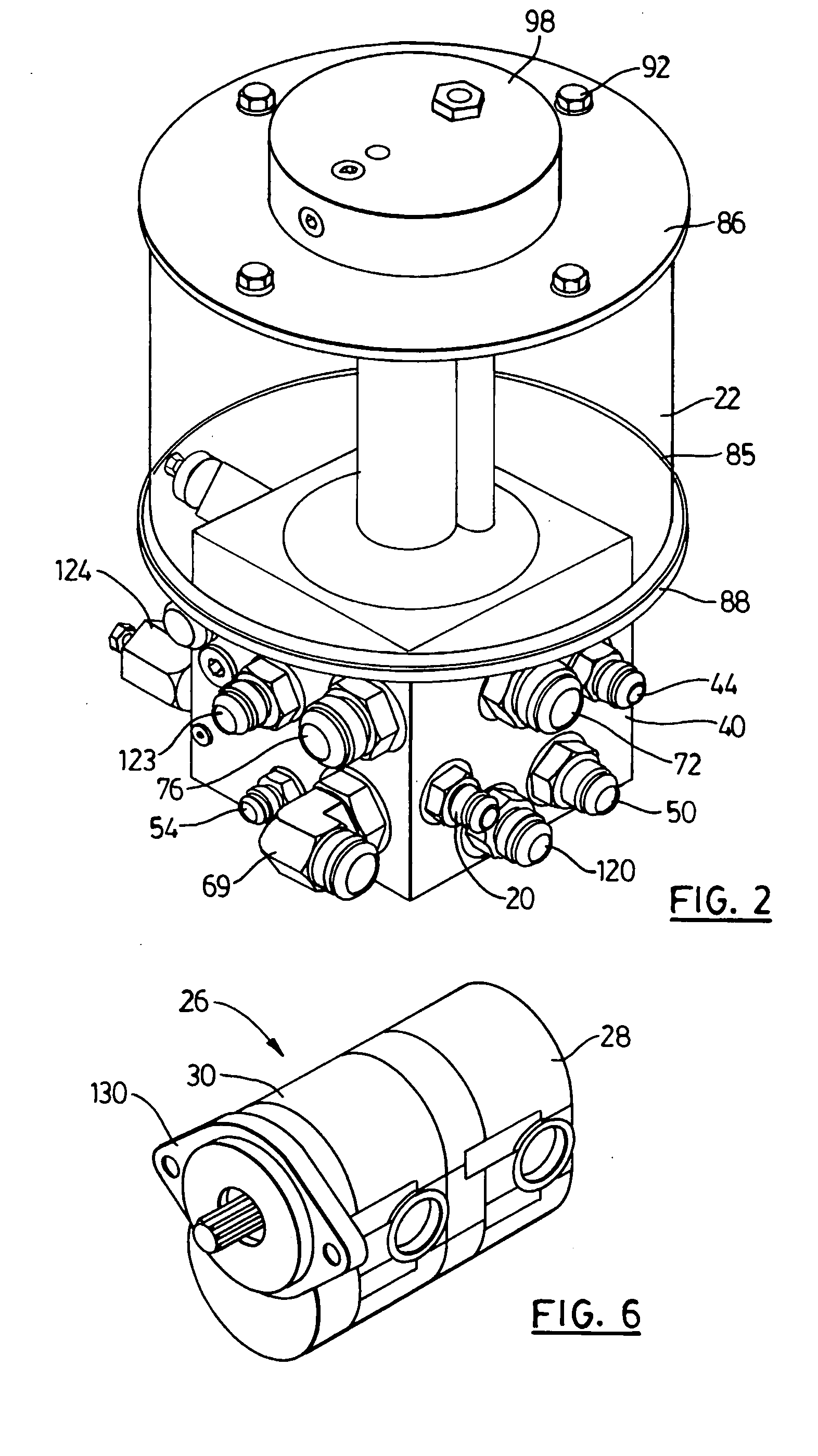

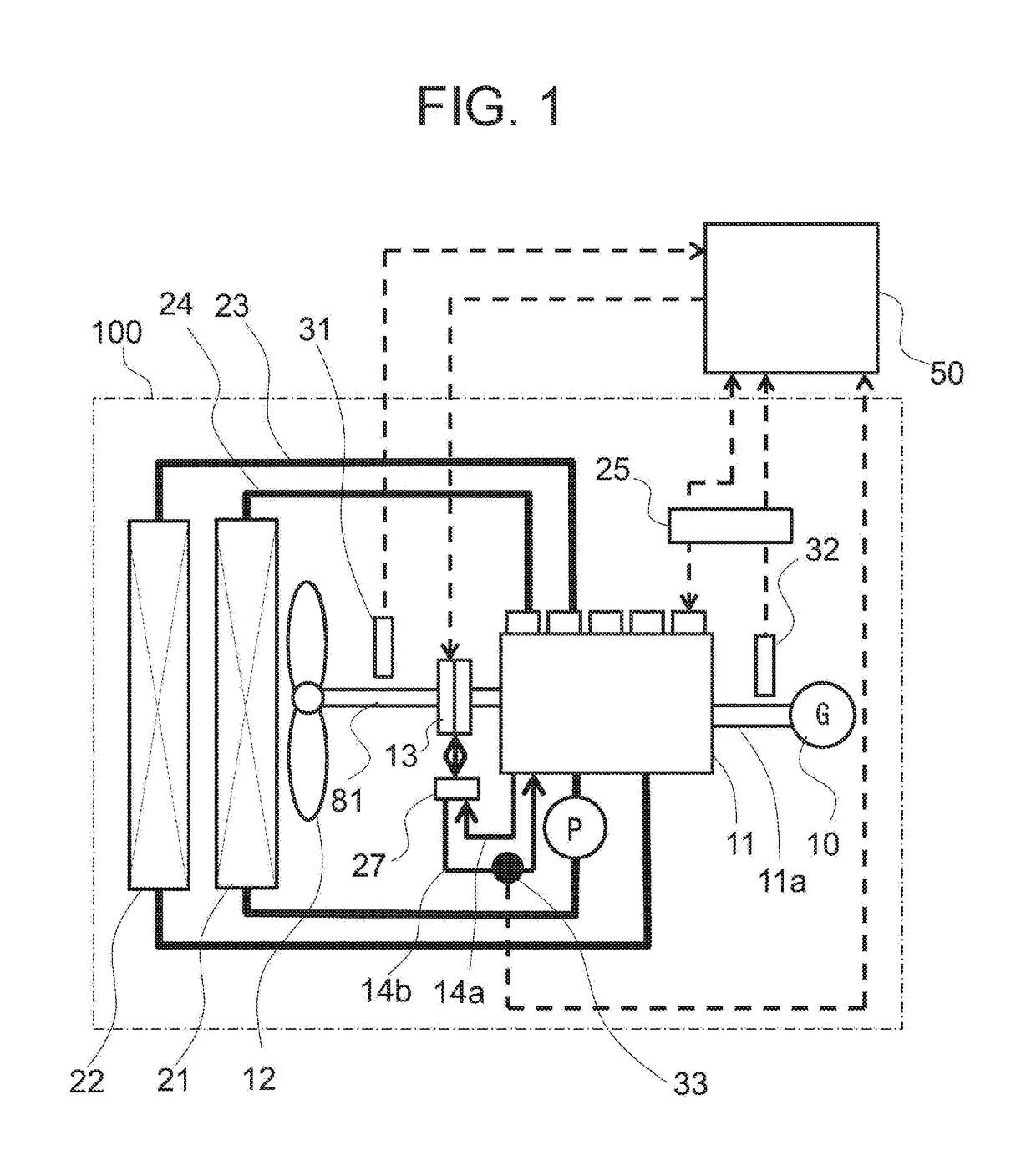

Electro-hydraulic fan drive cooling and steering system for vehicle

InactiveUS20050217260A1Appropriate speedCoolant flow controlRotary clutchesPower steeringElectro hydraulic

An electro-hydraulic system for operating a cooling fan and providing hydraulic fluid to a power steering system of the vehicle includes a hydraulic pump unit including first and second fixed displacement pumps and a common drive shaft for these pumps. A hydraulic fluid reservoir is connected to the inlet of each of the pumps. A priority valve is operatively connected to the outlet of the first pump and has an outlet connectible to the power steering system. This valve also has a second outlet connectible to a hydraulic motor for the cooling fan. This valve is arranged to provide a constant flow of hydraulic fluid to the power steering system. A hydraulic line connects an outlet of the second pump to the hydraulic motor. Hydraulic fluid flow through this line is combined with hydraulic fluid flow from the first pump to drive the motor. An electro-hydraulic proportional control valve has an inlet connected to the aforementioned line and an outlet connectible to the reservoir inlet and this control valve controls and limits the rotational speed of the motor. An electronic control device electrically operates and controls the control valve during use of the system.

Owner:HYDRA FAB FLUID POWER

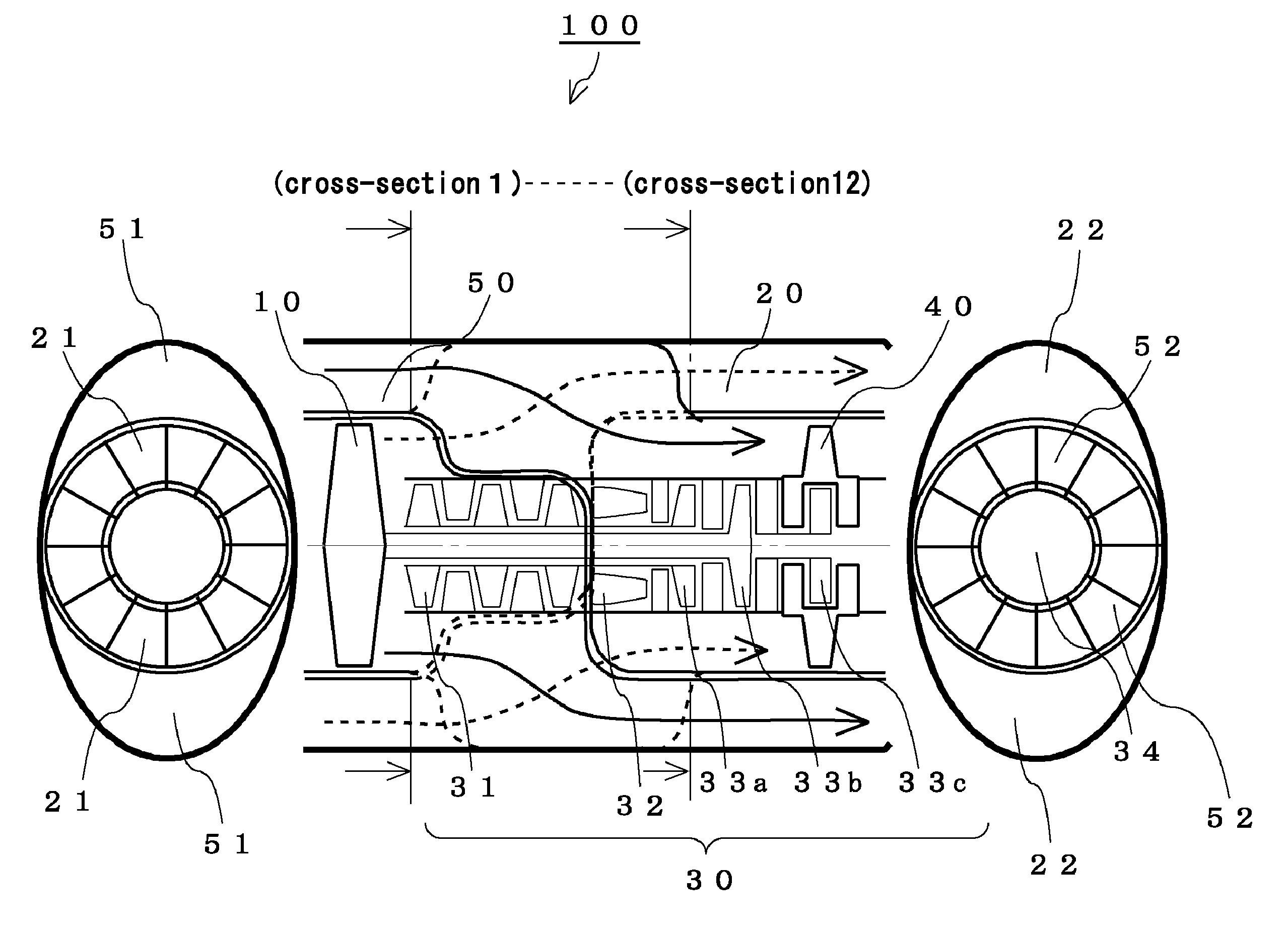

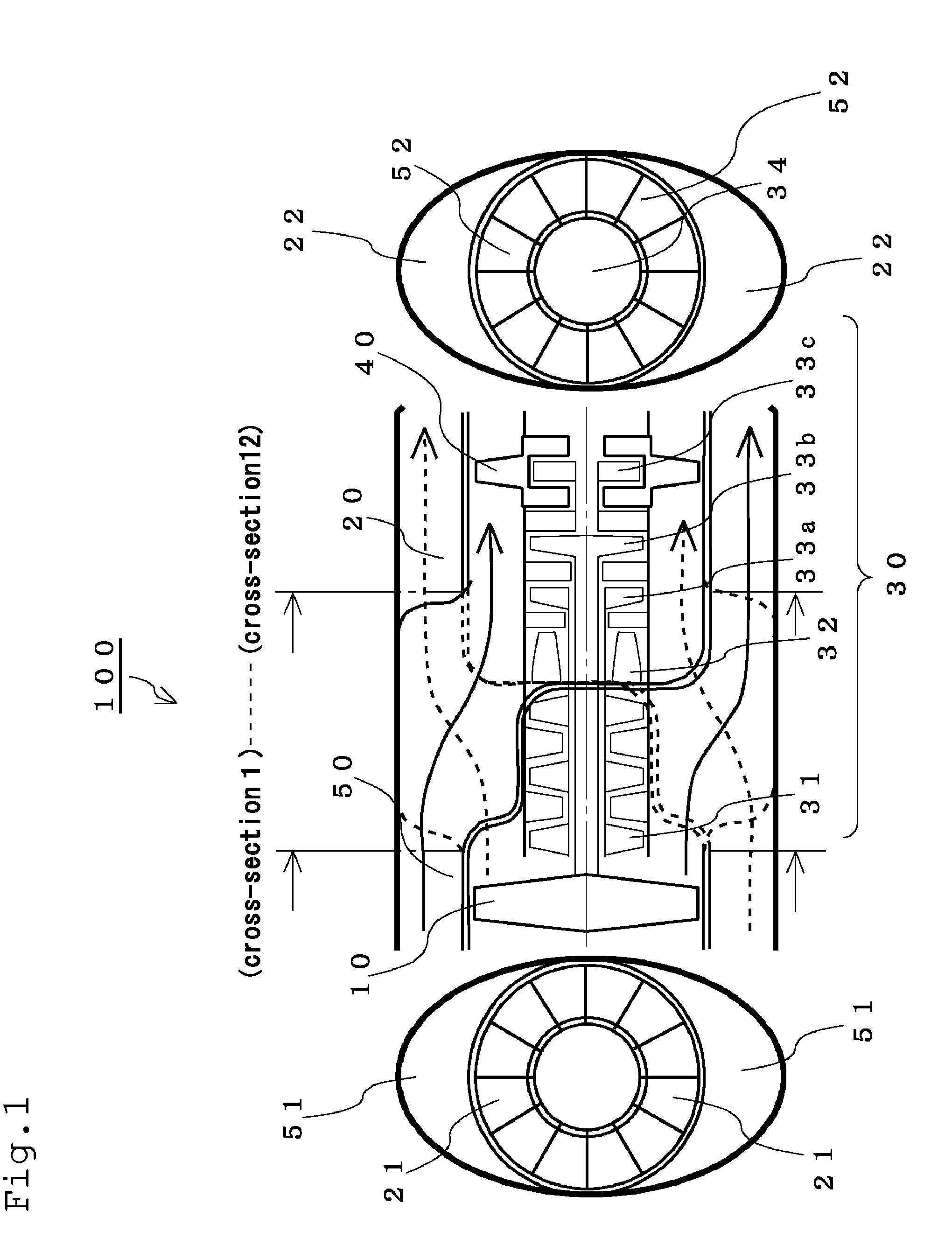

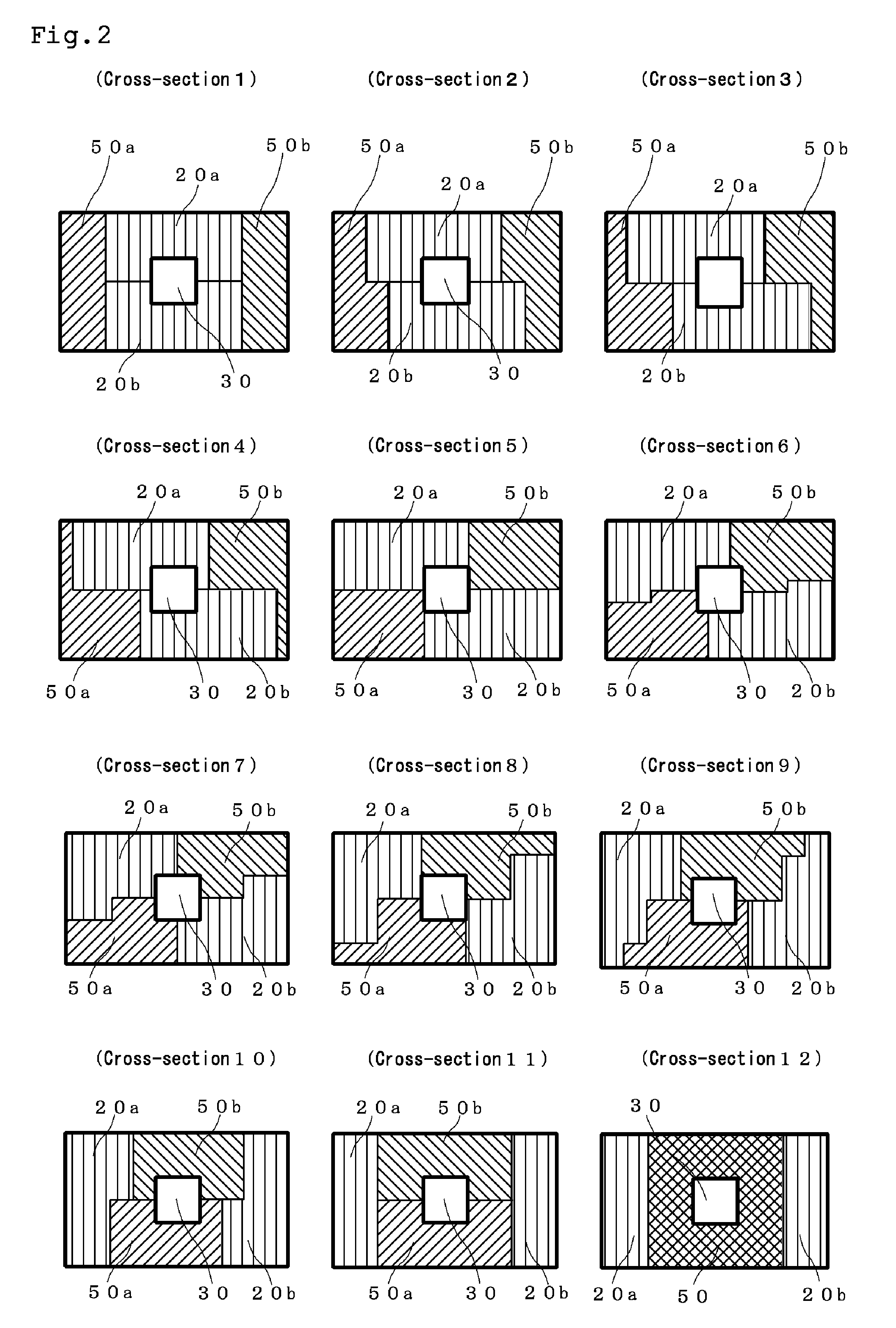

High bypass-ratio turbofan jet engine

InactiveUS20090226297A1Reduce air resistanceReduce the overall diameterEngine manufactureWind motor controlAerodynamic dragJet engine

To provide a turbofan jet engine which is capable of increasing the bypass ratio without increasing the fan diameter, and of reducing air resistance acting on the engine, a front fan duct that discharges air compressed by a front fan to the atmosphere and an aft fan duct that introduces air into an aft fan are disposed such as to change cross-sectional shapes thereof by rotating around a core engine in a counterclockwise direction, so that the cross-sectional geometric relationship between the front fan duct and the aft fan duct at a position immediately posterior to the front fan and a cross-sectional geometric relationship between the front fan duct and the aft fan duct at a position immediately anterior to the aft fan are inverted.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

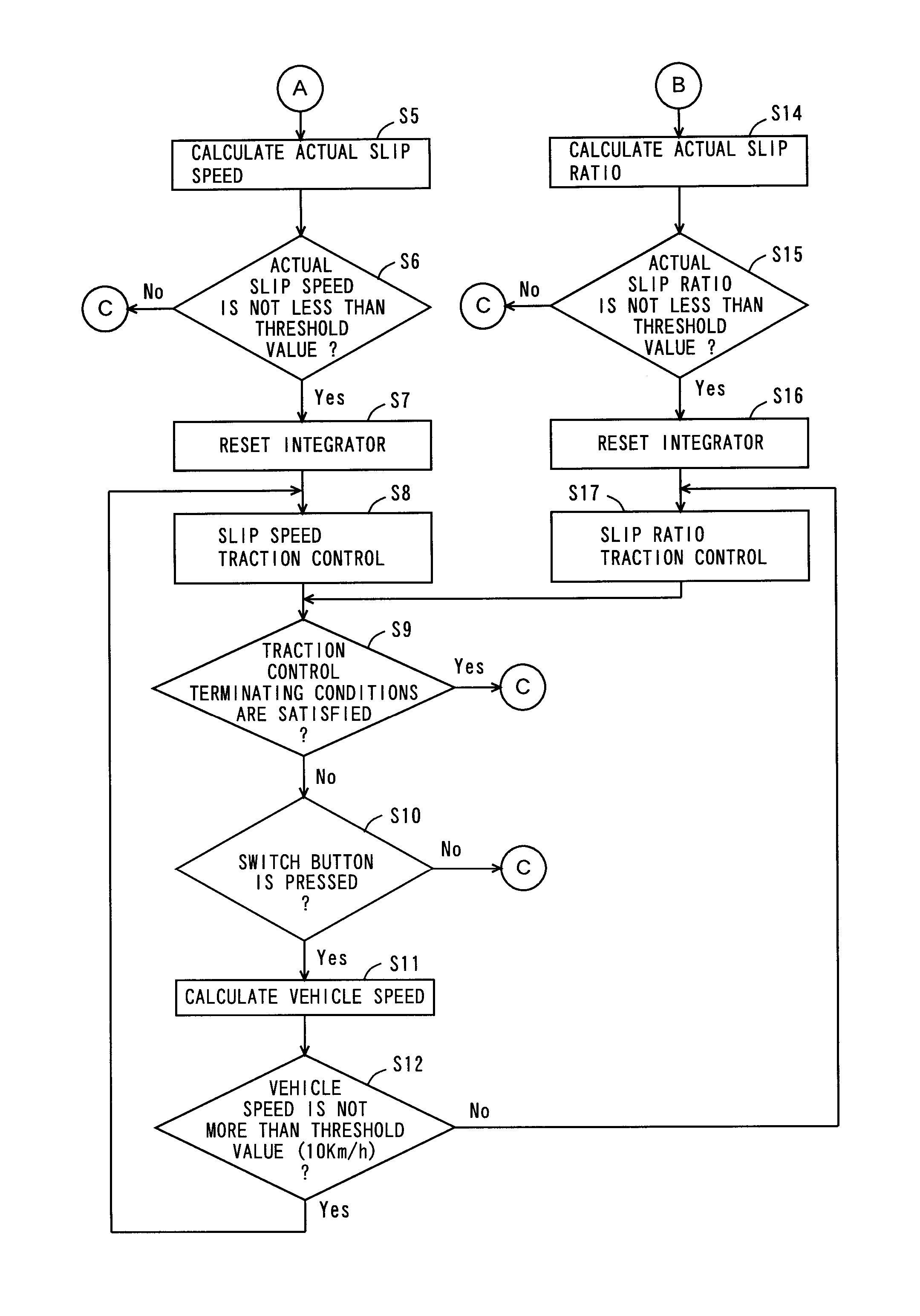

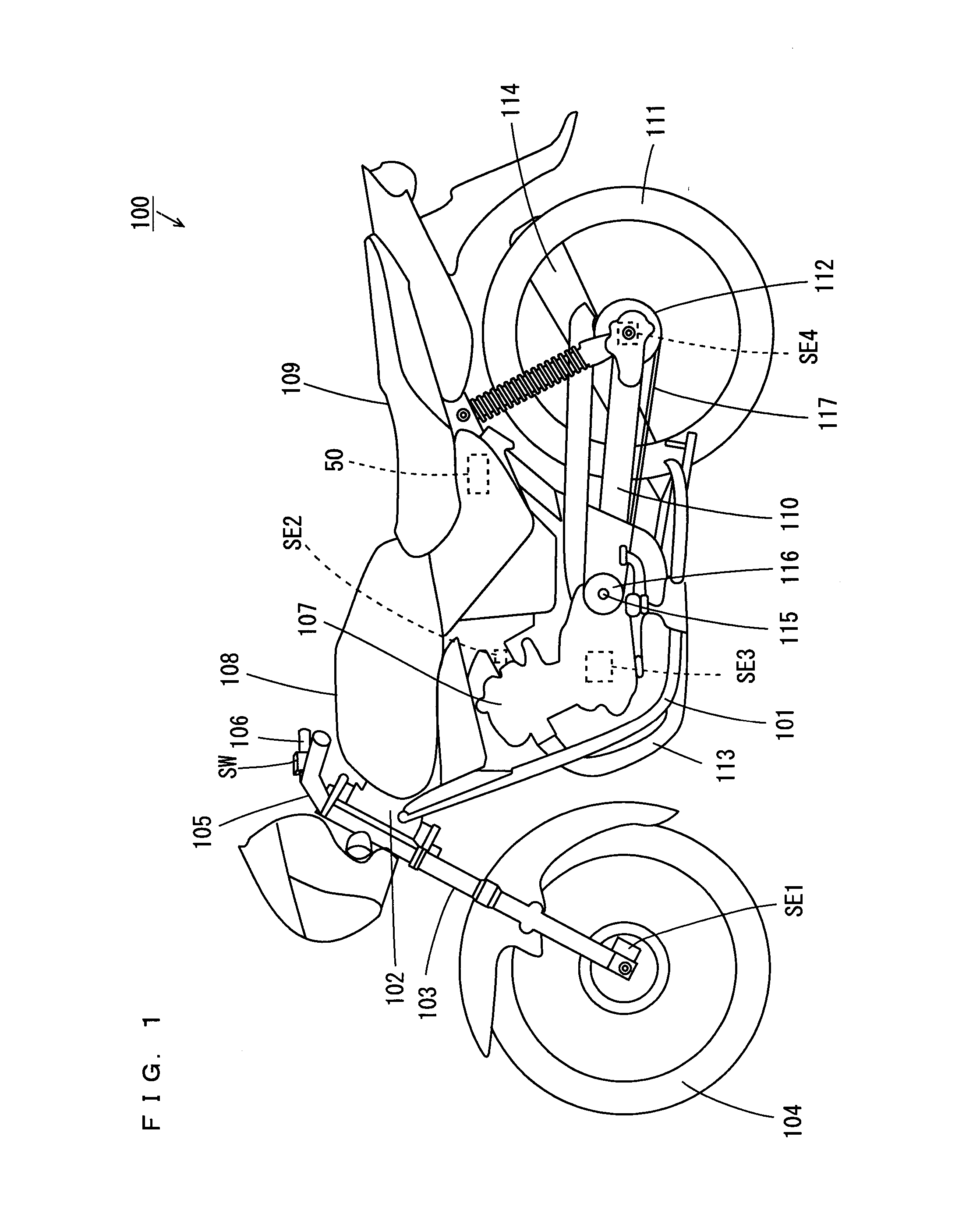

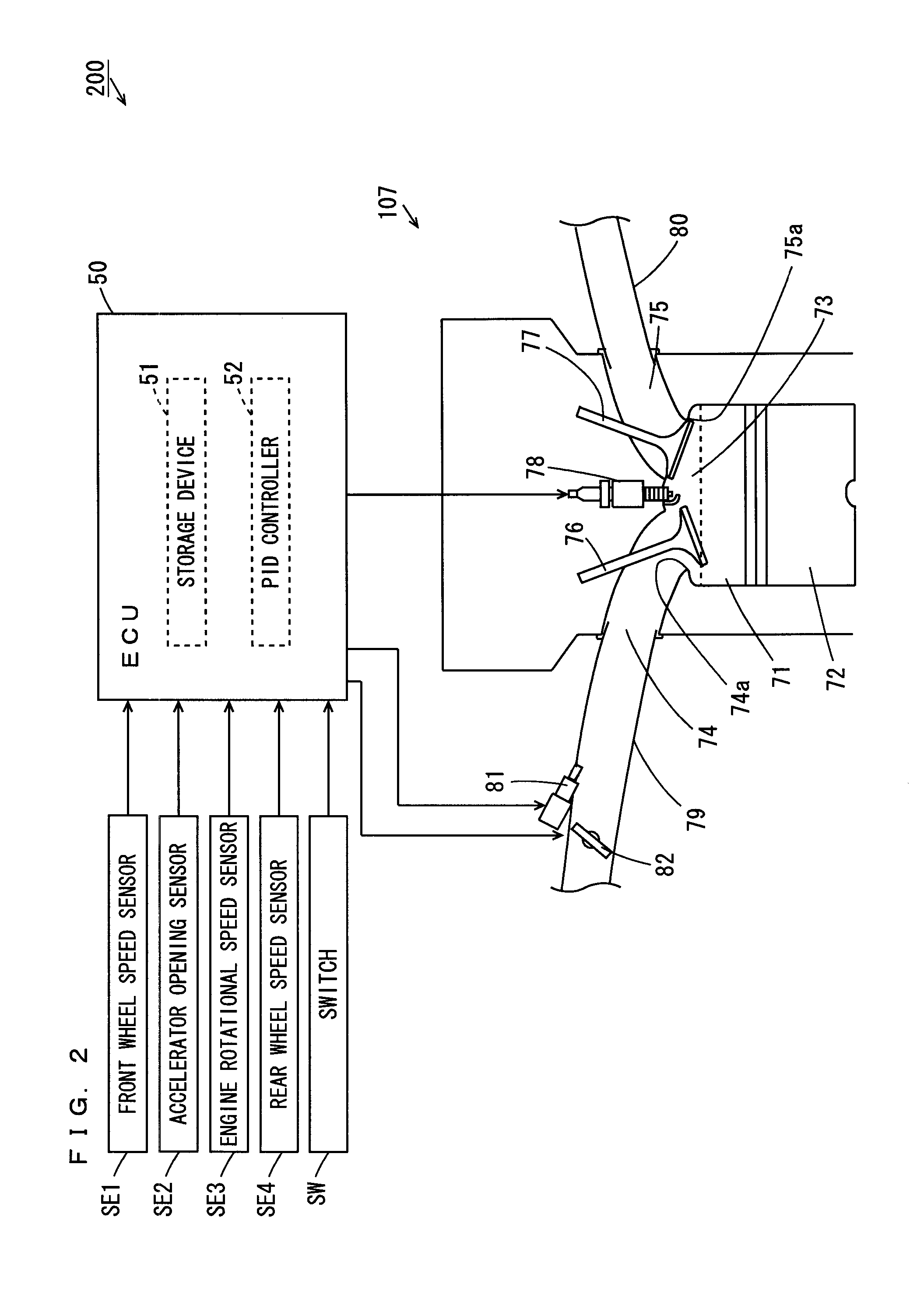

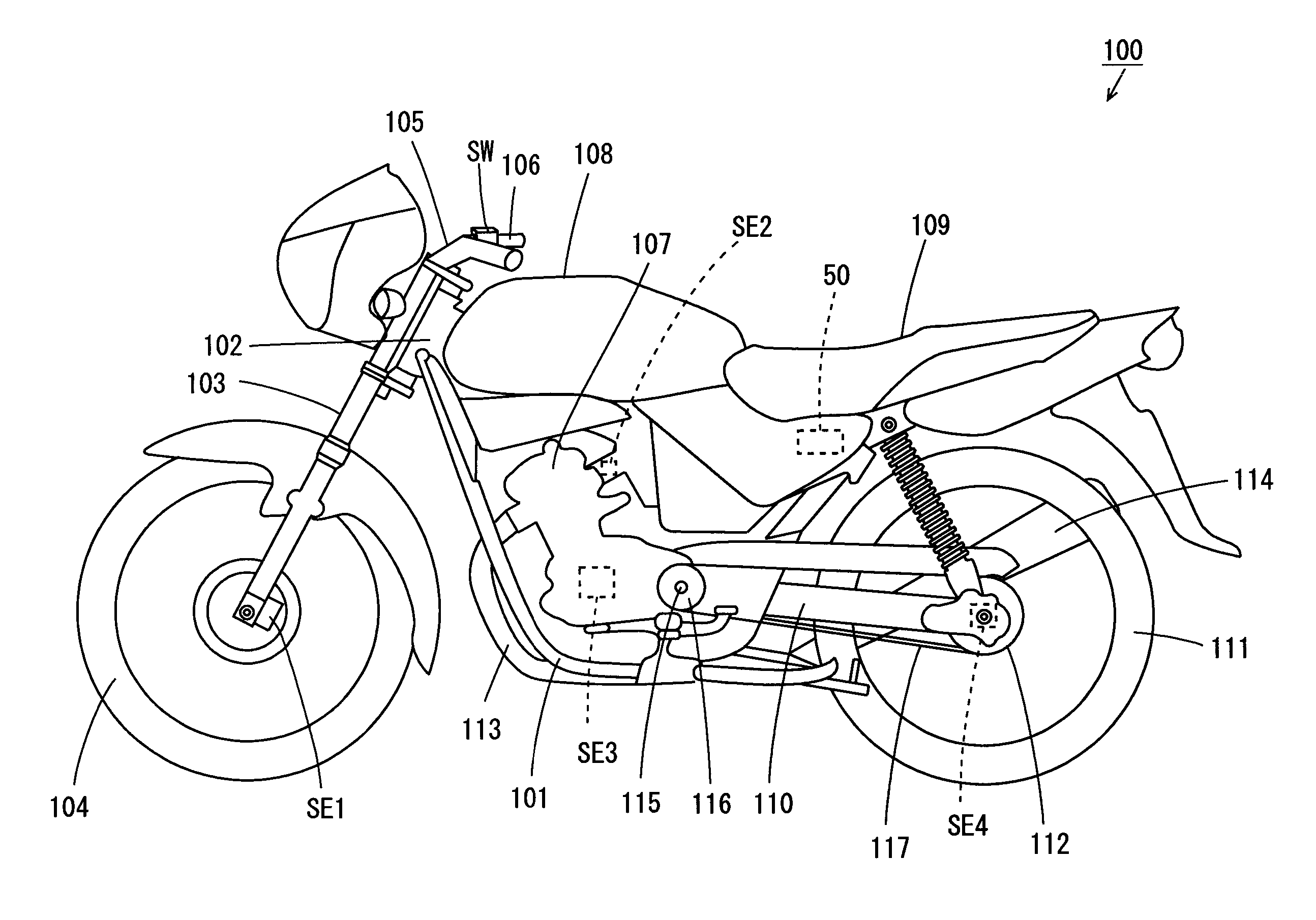

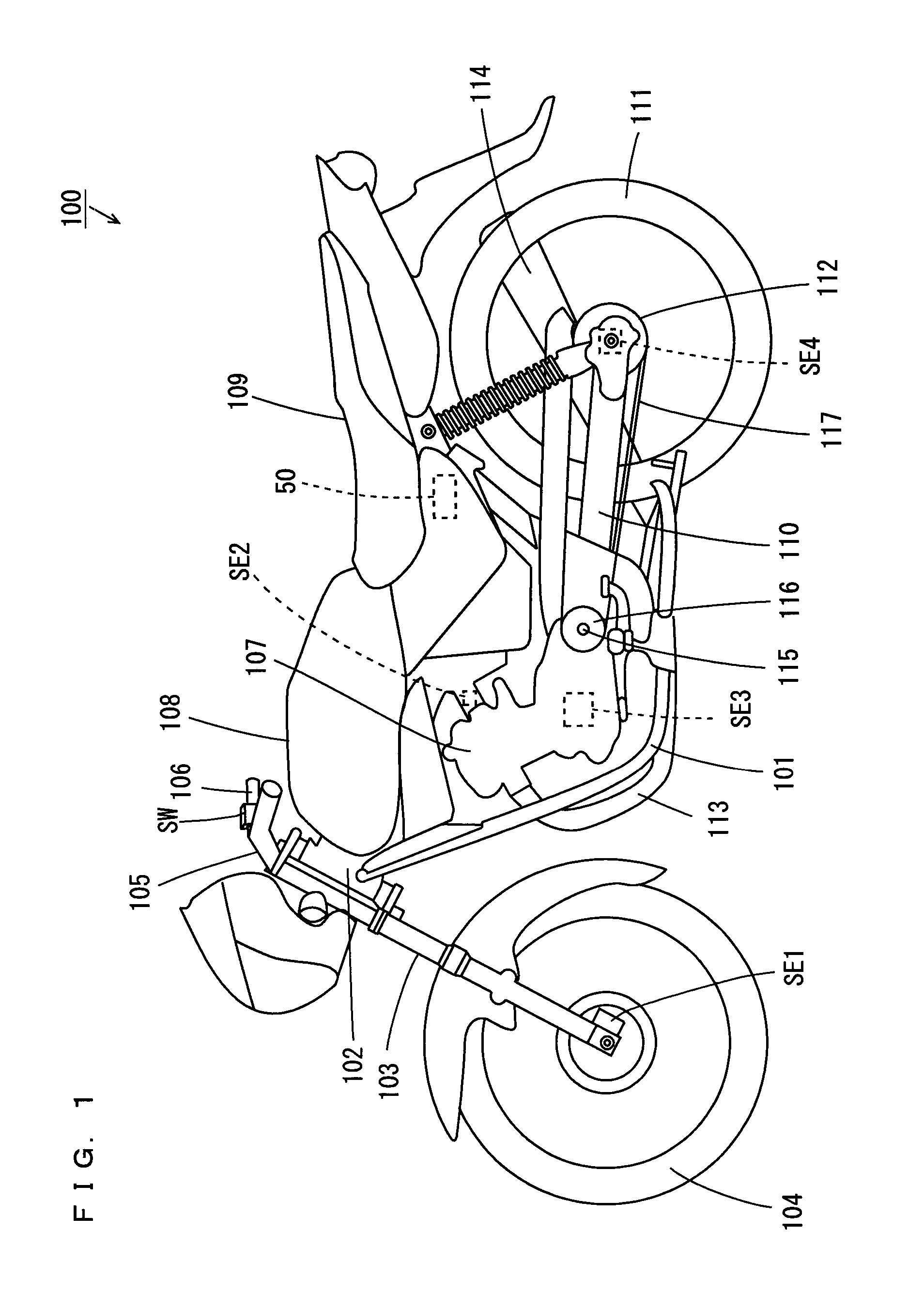

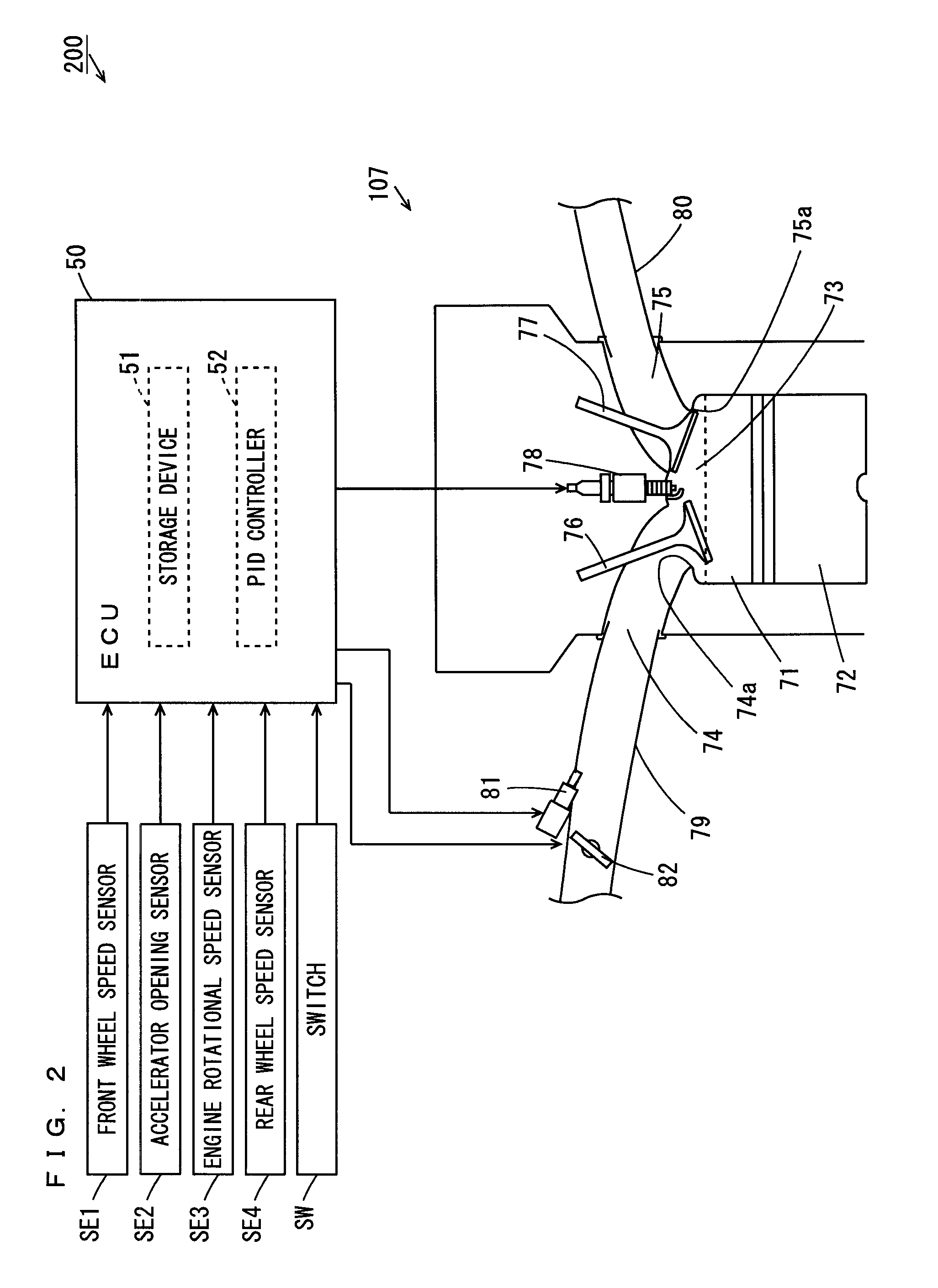

Control system and vehicle including the same

InactiveUS20080105479A1Sure easyEasy to operateDigital data processing detailsSteering initiationsLow speedControl system

A control system for a vehicle includes an ECU, a front wheel speed sensor, a rear wheel speed sensor, and an engine. The ECU detects an actual slip speed and an actual slip ratio of a rear wheel on the basis of respective detected values of a front wheel speed sensor and a rear wheel speed sensor. Slip speed traction control is started when the actual slip speed exceeds a threshold value of a slip speed when a vehicle is at a low speed, and slip ratio traction control is started when the actual slip ratio exceeds a threshold value of a slip ratio when it is at an intermediate or high speed. An output of the engine is adjusted depending on the actual slip speed in the slip speed traction control, while being adjusted depending on the actual slip ratio in the slip ratio traction control.

Owner:YAMAHA MOTOR CO LTD

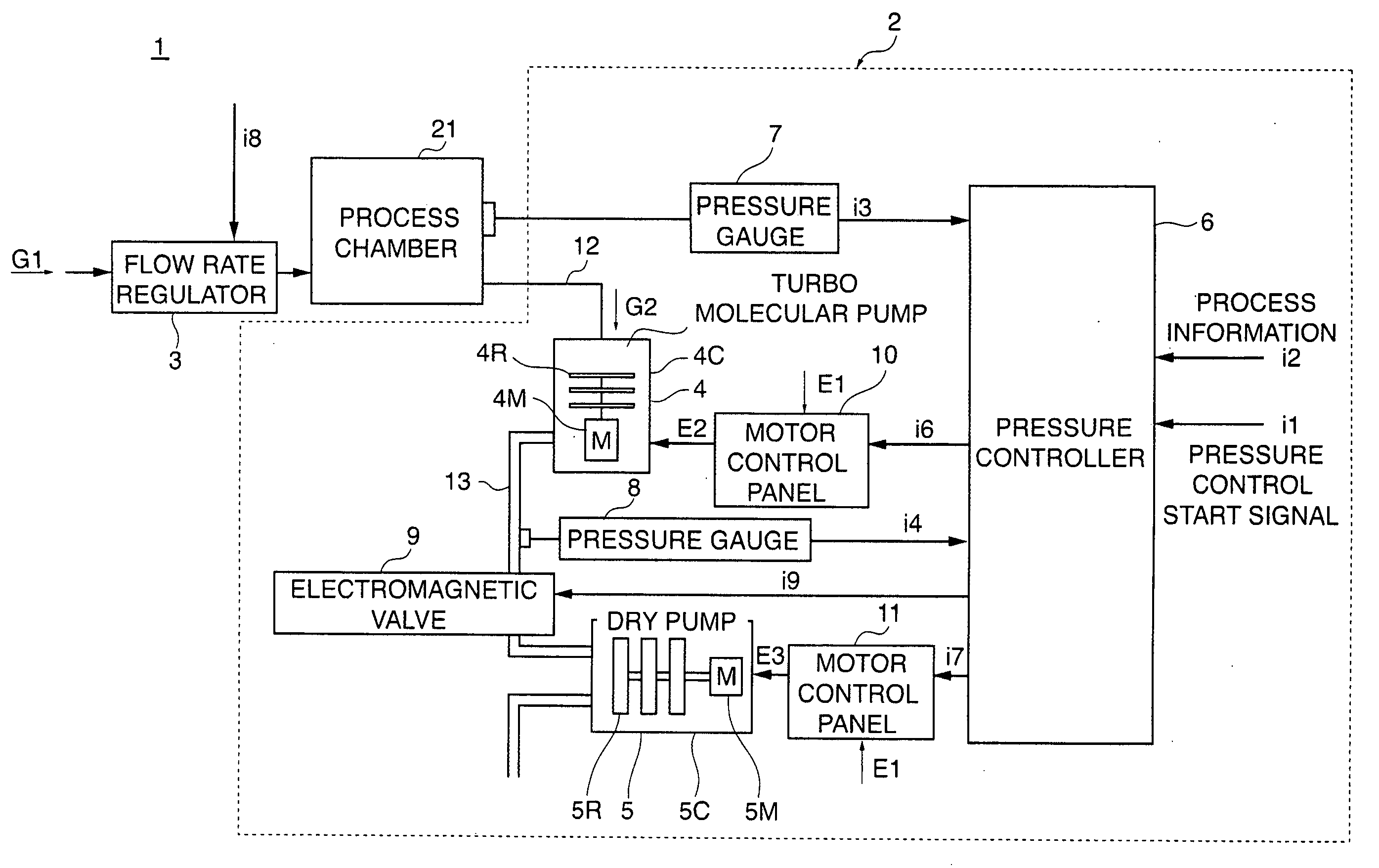

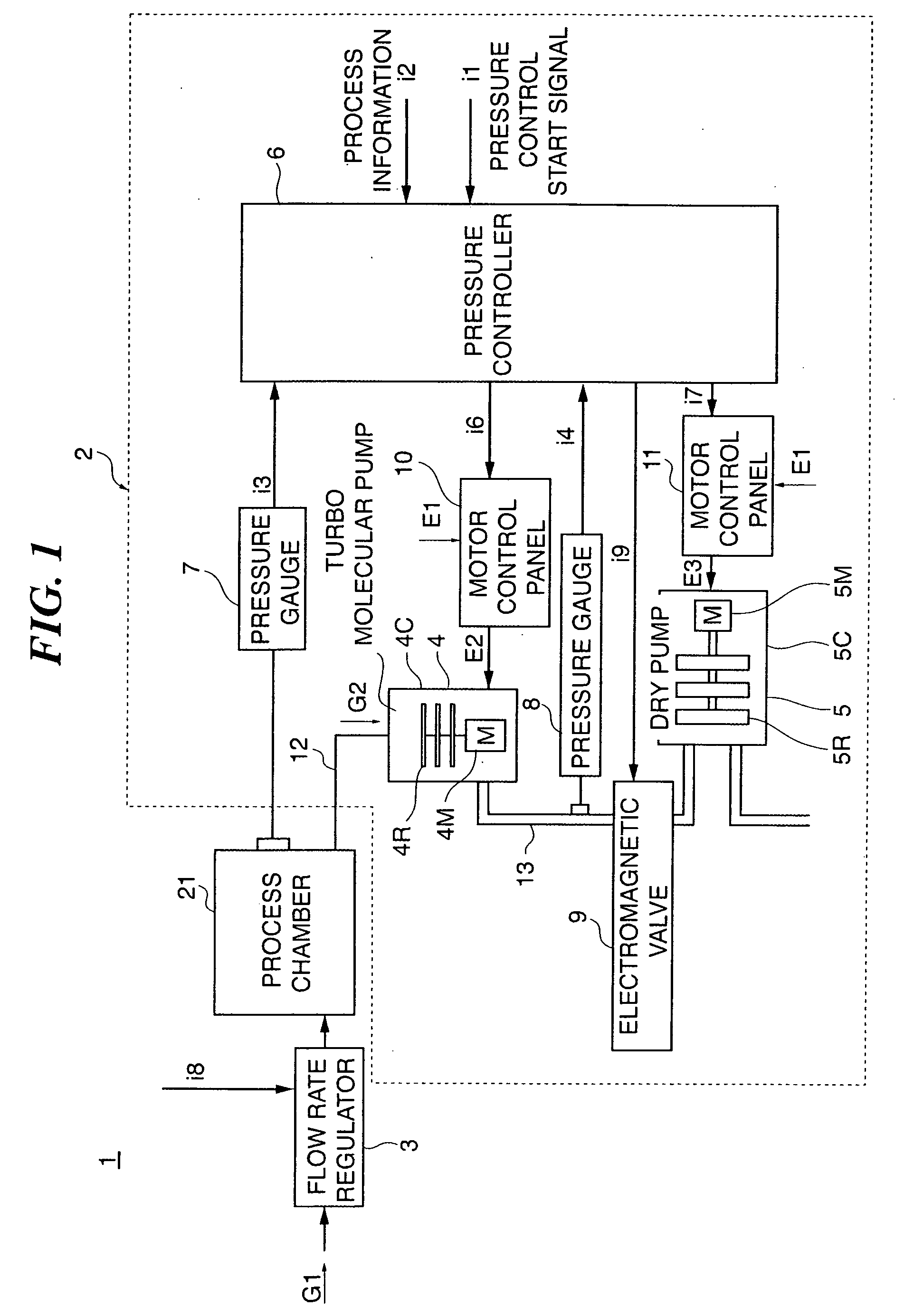

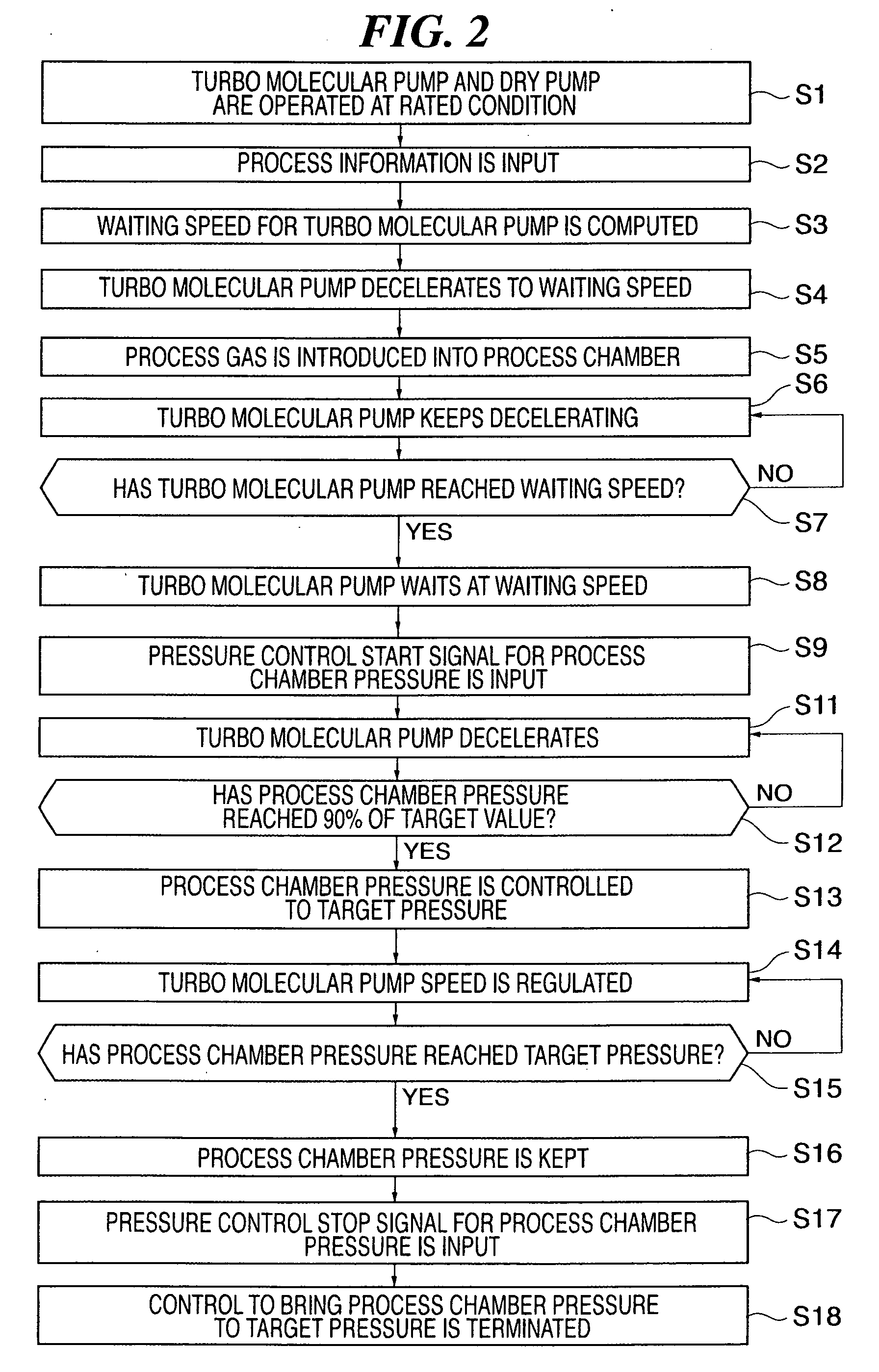

Vacuum evacuation device and method, and substrate processing apparatus and method

InactiveUS20070048145A1Appropriate speedSuitable for processingEfficient regulation technologiesPump controlProcess engineeringProcess information

A vacuum evacuation device 2 of the invention comprises a vacuum pump 4,5 for exhausting a gas G2 in a process chamber 21 into which a process gas G1 is introduced and in which a process reaction is performed, to form a vacuum in said process chamber 21; and a control means 6 for performing a first control that regulates the rotational speed of said vacuum pump 4,5 such that a pressure condition in said process chamber 21 reaches a pressure condition suitable for said process reaction during said process reaction, wherein said control means 6 calculates a specified rotational speed for said vacuum pump 4,5 based on process information related to said process reaction, and performs a second control that brings said vacuum pump 4,5 to said specified rotational speed before said first control. The vacuum evacuation device 2 is capable of bringing the pressure in a process chamber 21 to the target pressure in a short period without a vacuum pump 4,5 being overloaded, regardless of the process reaction condition.

Owner:EBARA CORP

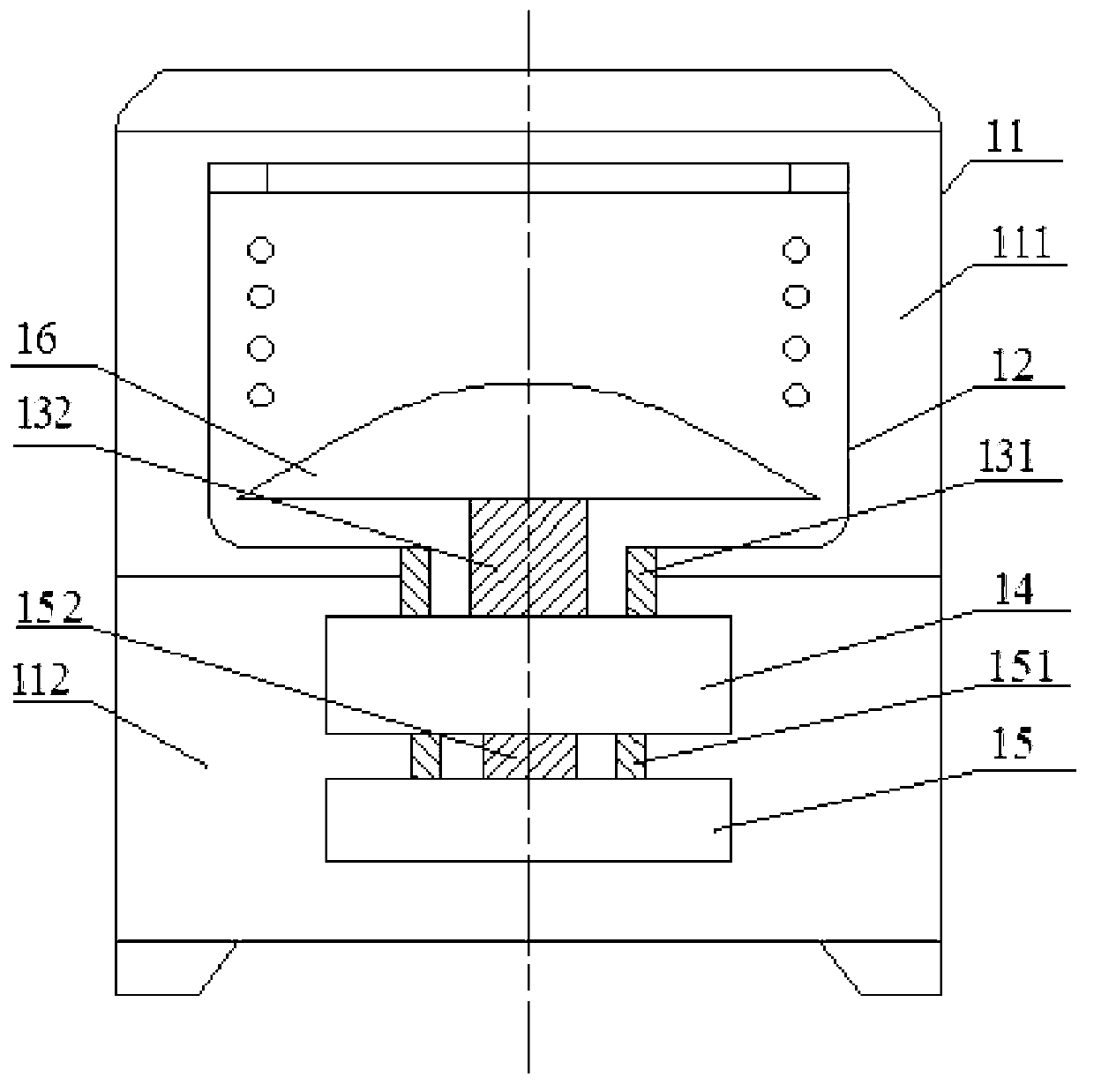

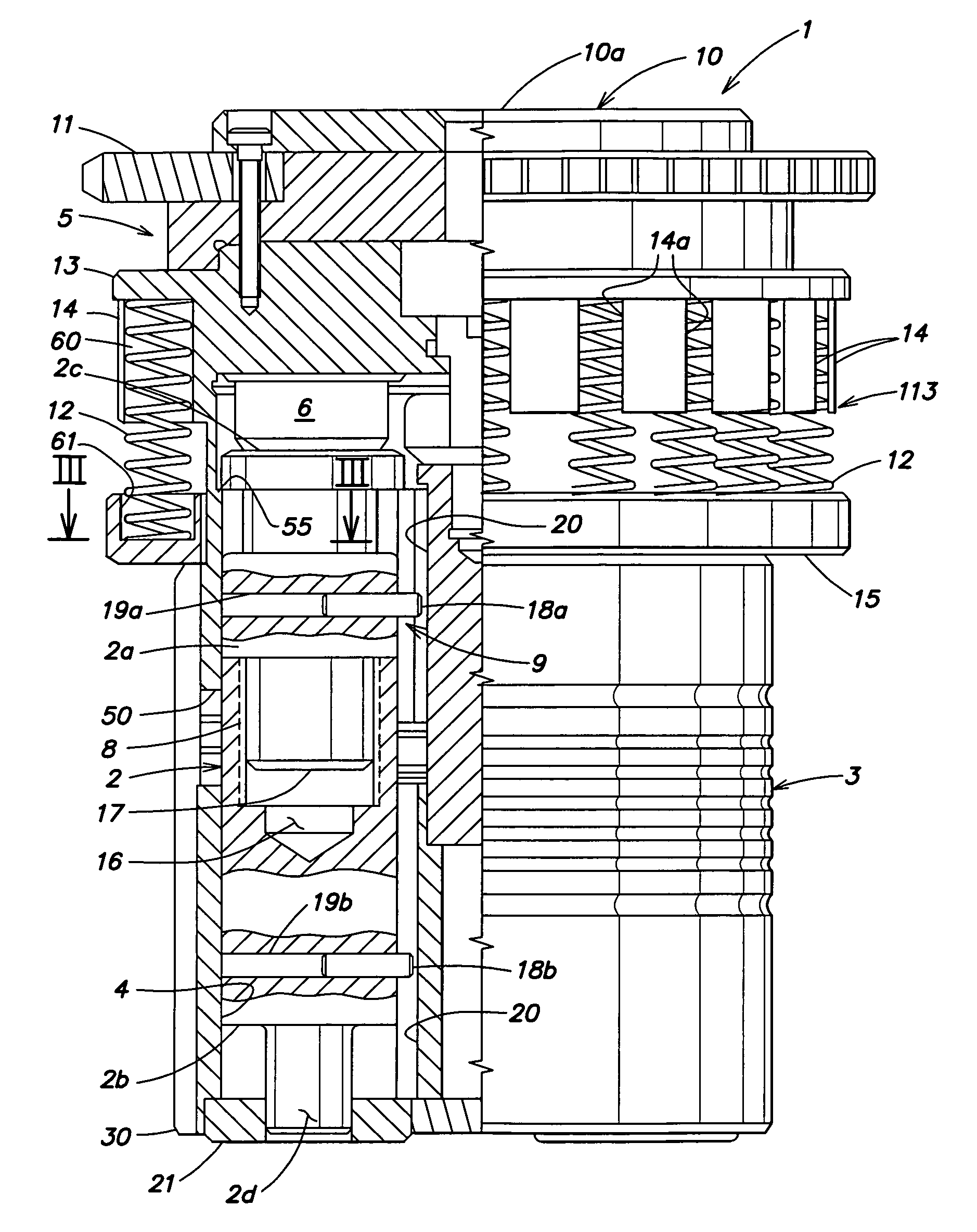

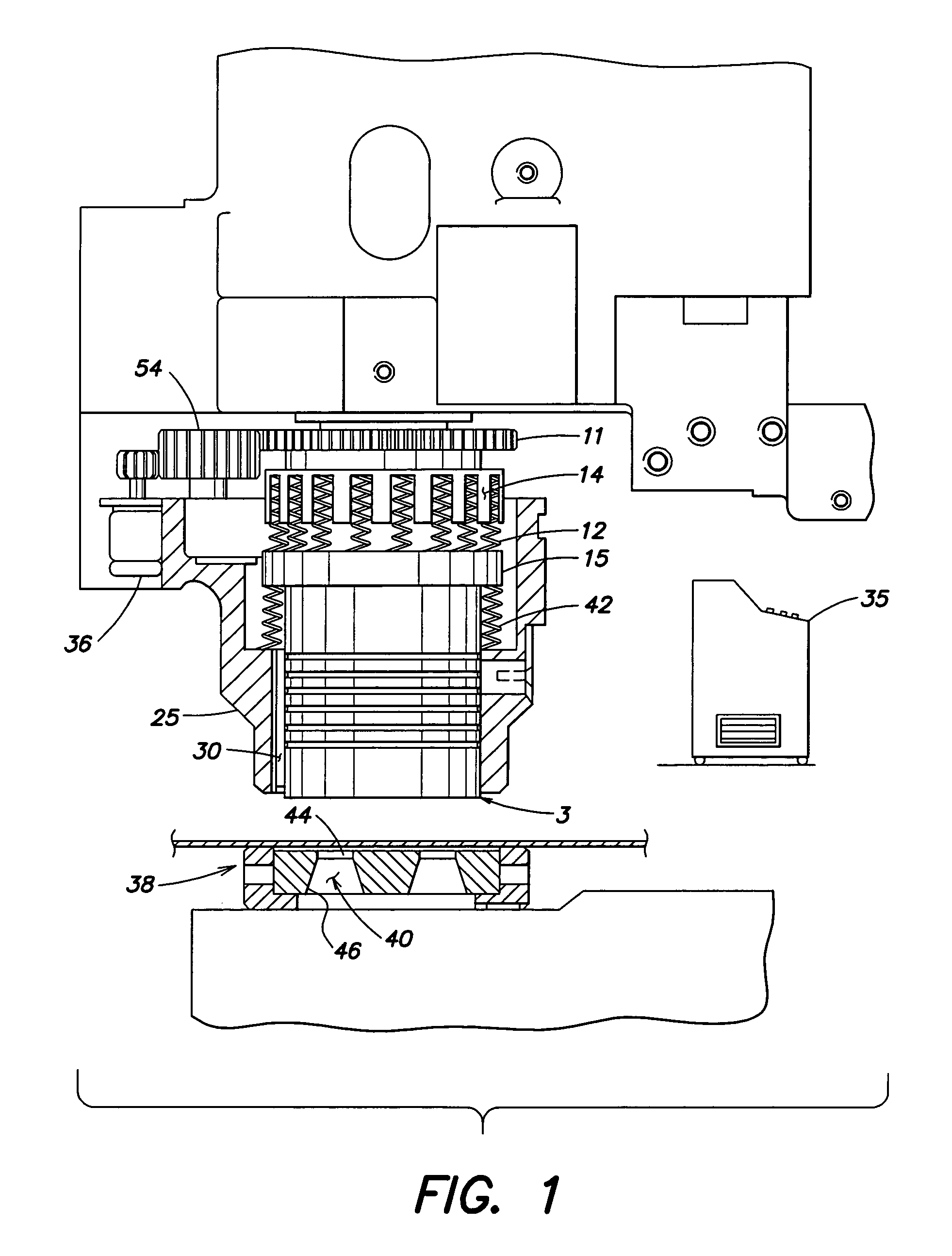

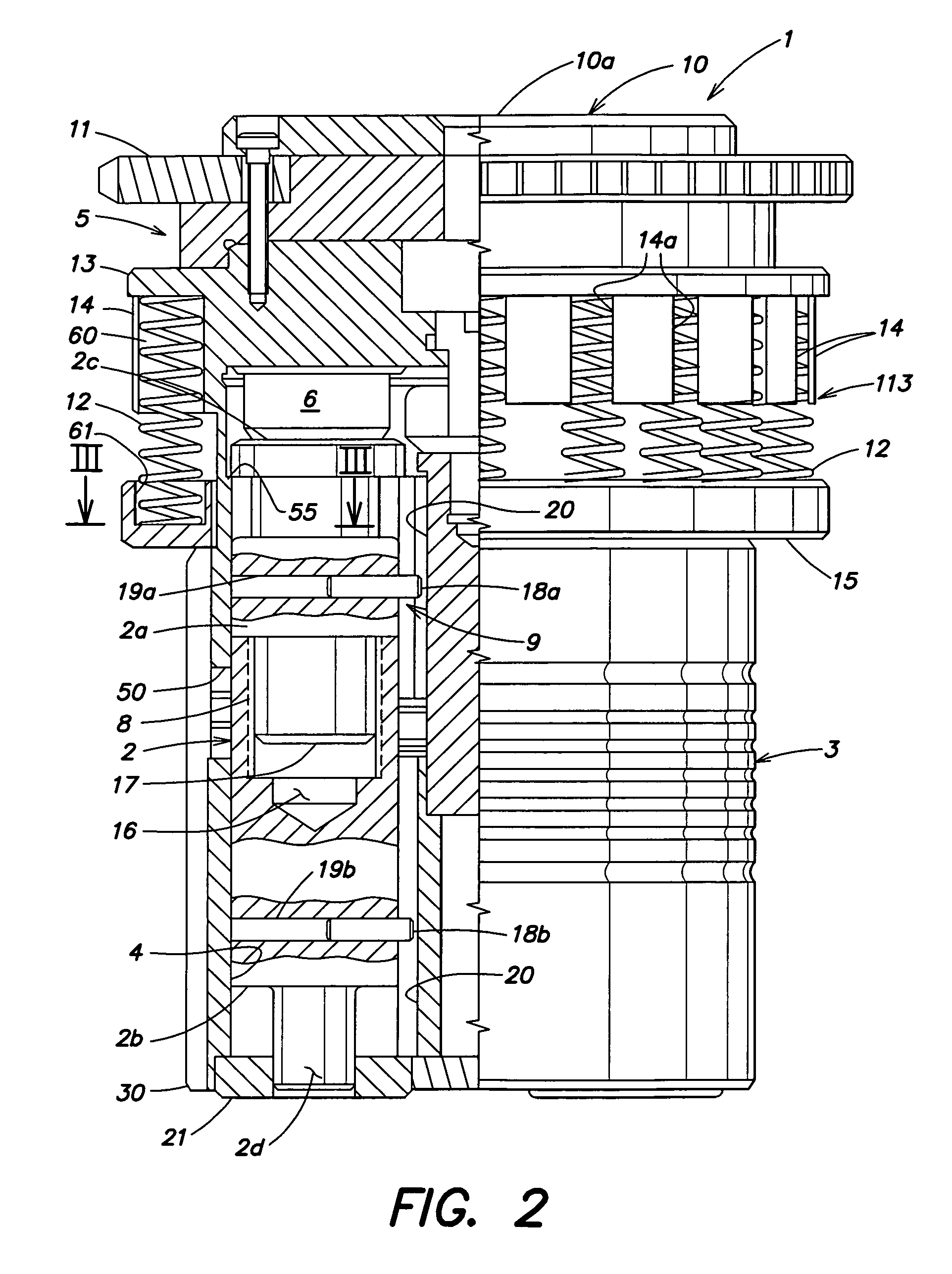

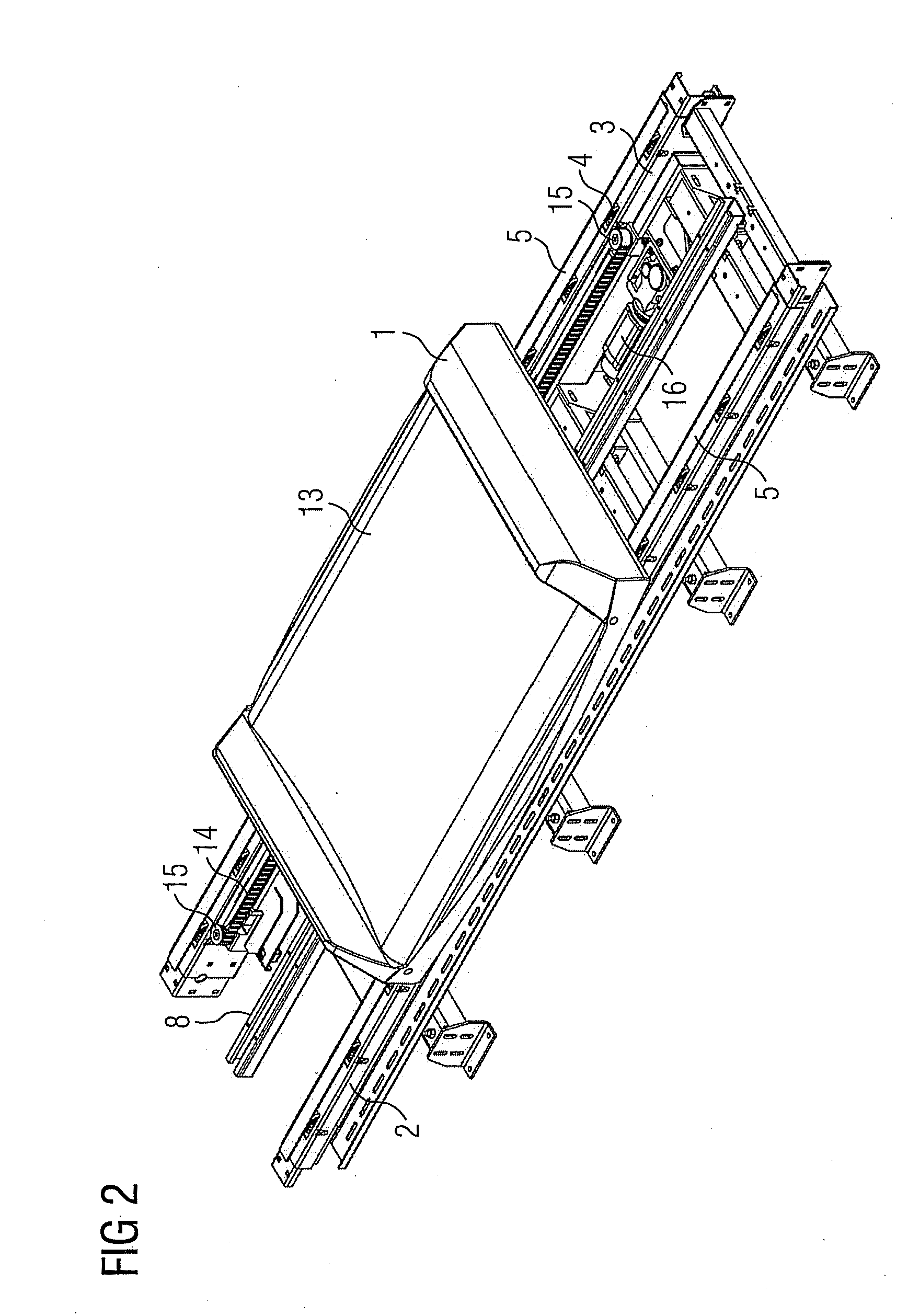

Quick-extraction punch-holder adapter for converting punching machines from a single-punch to a multiple-punch configuration

InactiveUS7032812B2Reliable wayEliminate needShaping toolsDigitally marking record carriersTool holderEngineering

A punching machine comprising at least one punching head including a support body having a first end delimiting a peripheral shoulder, a second end, and at least two parallel seats being angularly spaced from one another and extending through said support body from said first end to said second end; a punching tool holder slibably mounted in at least one of said seats; a multiplicity of removable resilient means angularly spaced from one another, each having a first end resting on said peripheral shoulder and a second end facing away from said peripheral shoulder; an annular cap member arranged in front and spaced from said peripheral shoulder and designed to abut against said second end of said resilient means; a rotor member mounted for rotation on said annular cap member and having an inner face thereof facing towards said punching tool holder; a sliding member projecting from said inner face and arranged to slide onto said punching tool holder when said rotor member rotates; and driving means designed to stepwise drive said rotor member, whereby locating said sliding member onto a pre-selected punching tool holder.

Owner:EUROMAC SPA

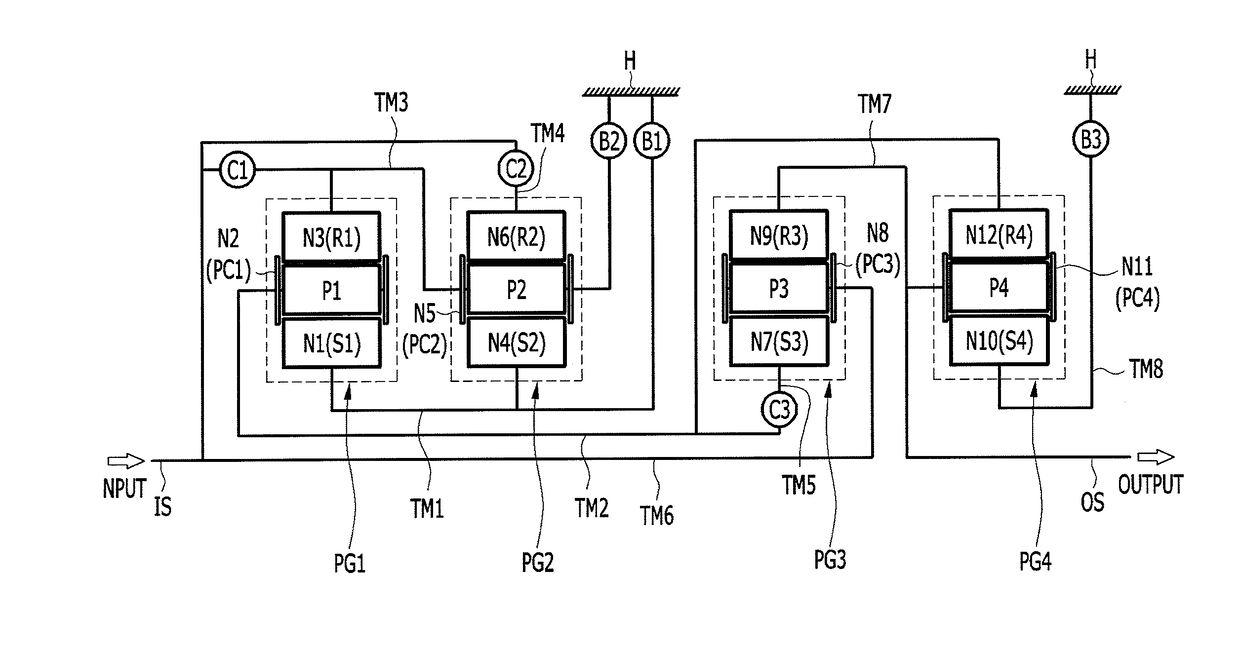

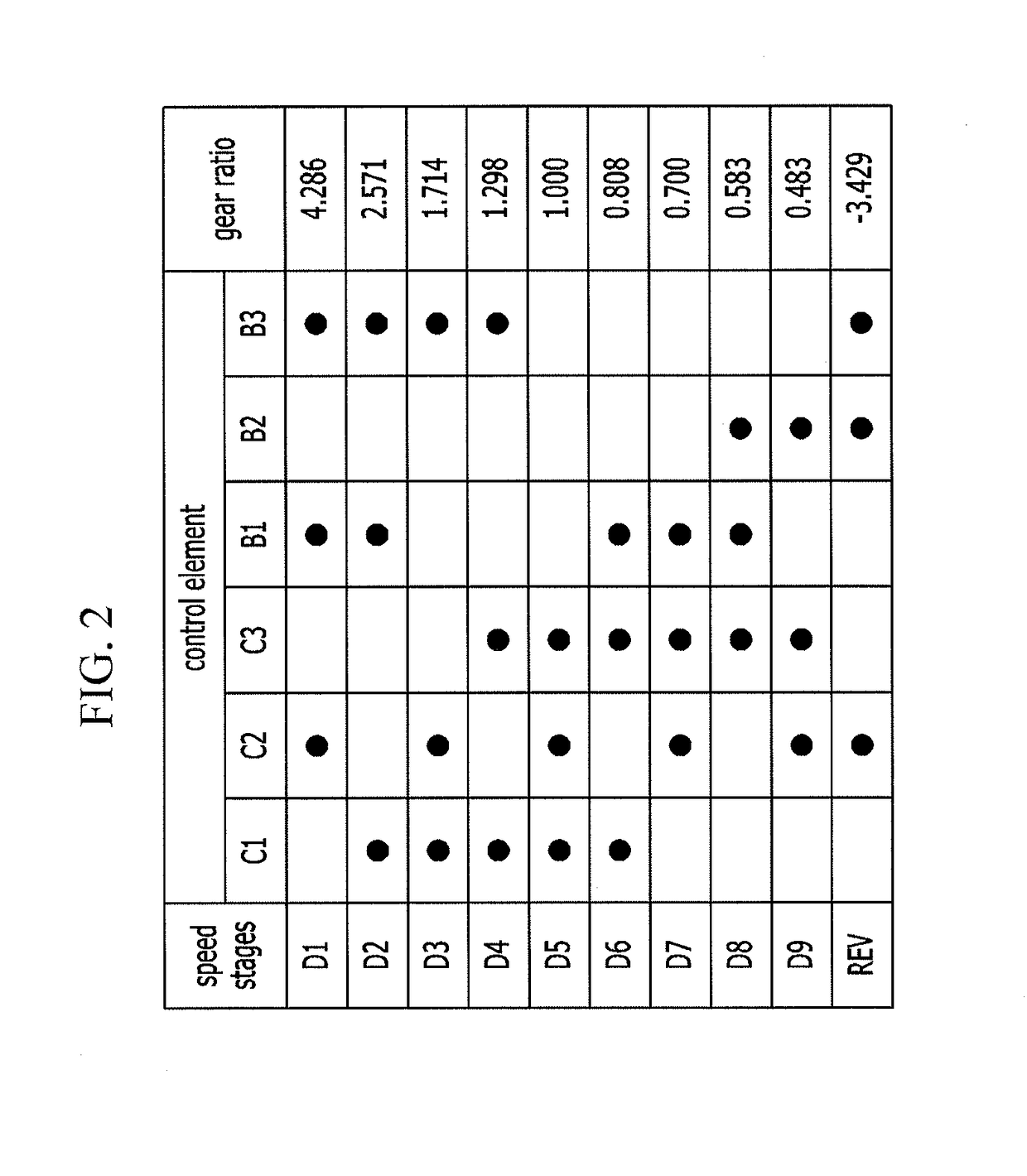

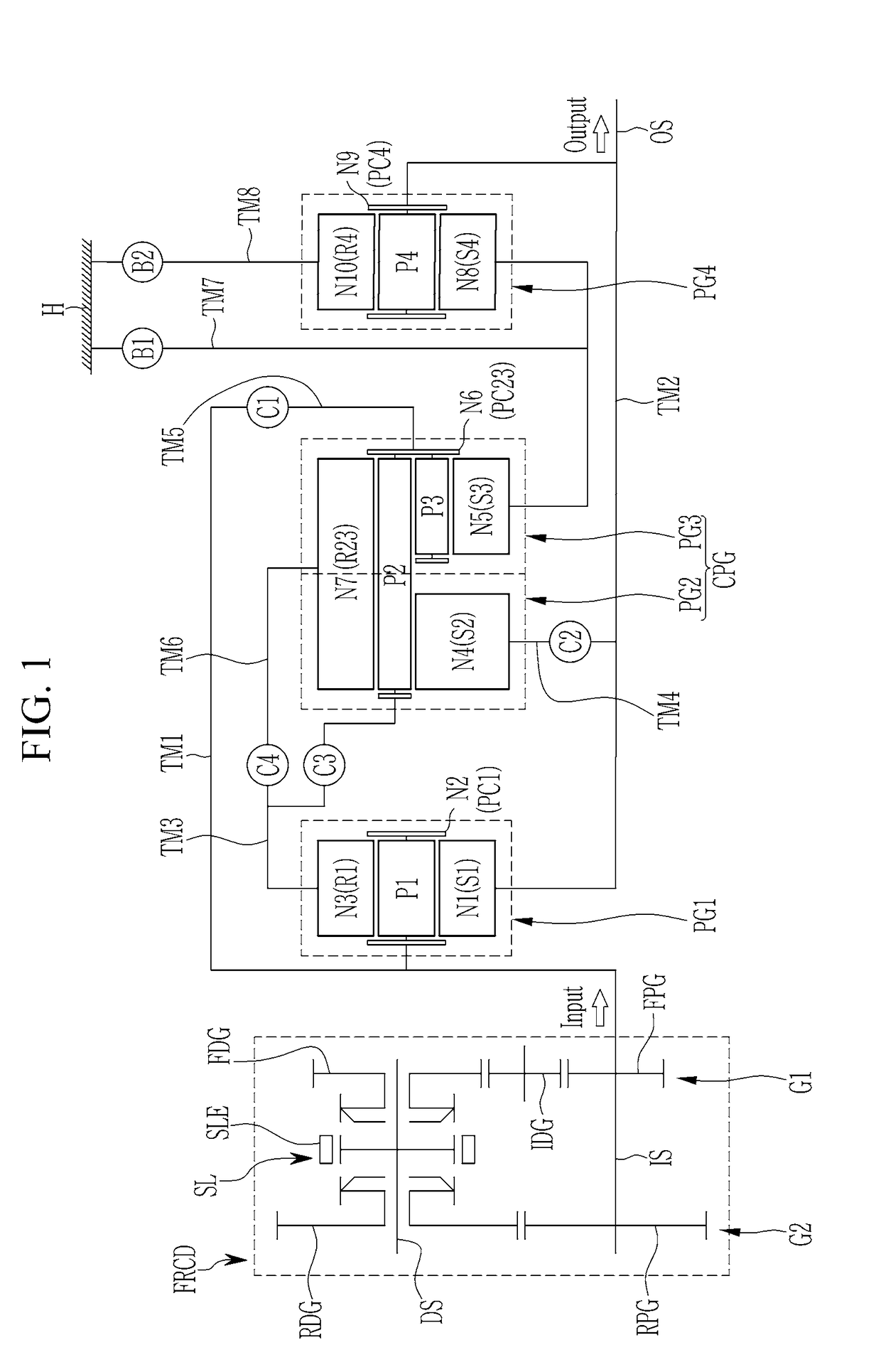

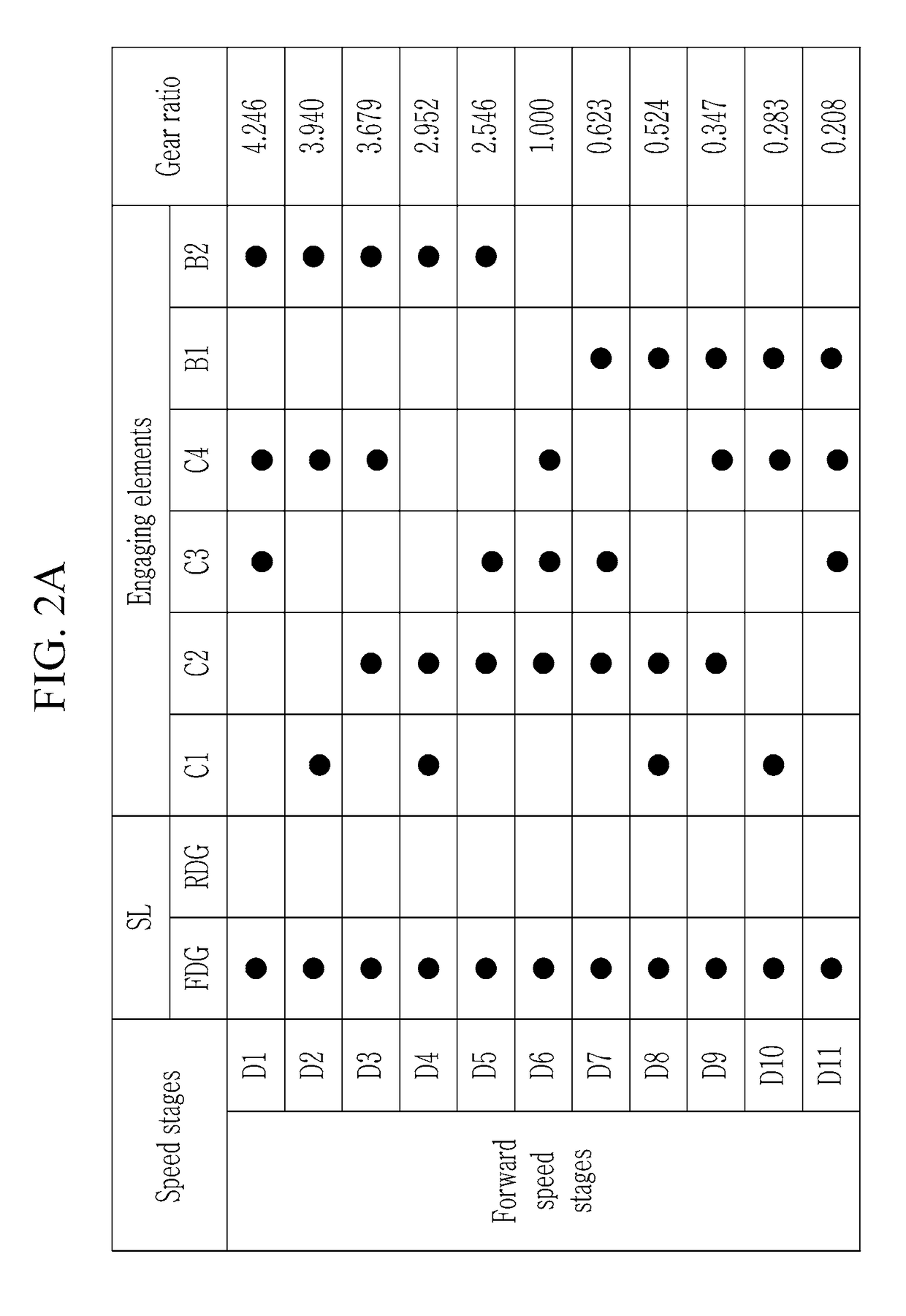

Planetary gear train of automatic transmission for vehicle

ActiveUS20180003269A1Improve fuel economyImproving power delivery performanceToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for a vehicle may include an input shaft receiving torque of an engine, an output shaft outputting torque, a first planetary gear set, a second planetary gear set, a third planetary gear set, a fourth planetary gear set, a first shaft, a second shaft, a third shaft, a fourth shaft, a fifth shaft selectively connectable to the second shaft, a sixth shaft connected to the input shaft, and selectively connectable to each of the third shaft and the fourth shaft, a seventh shaft connected to the output shaft, and an eighth shaft.

Owner:HYUNDAI MOTOR CO LTD

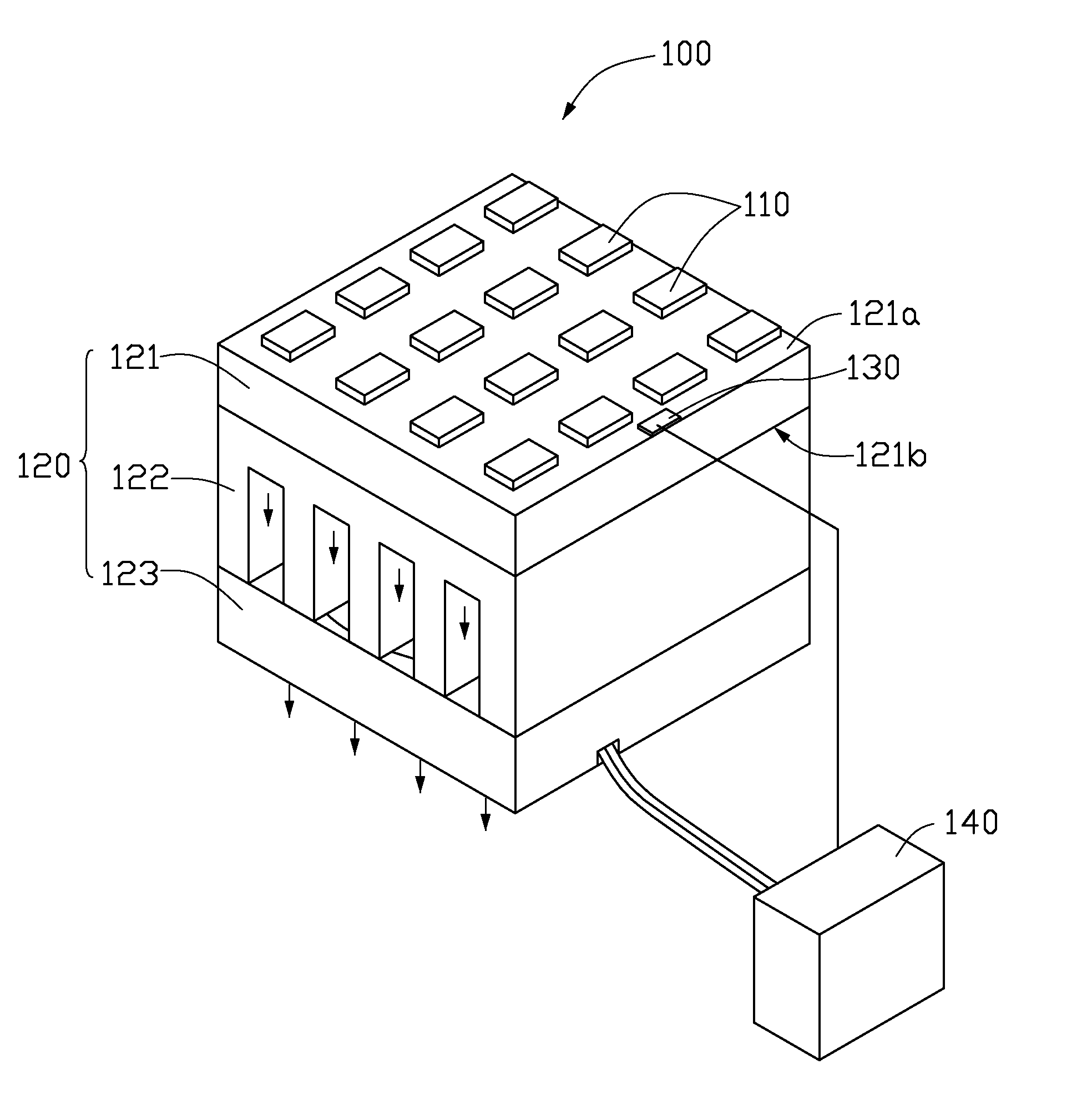

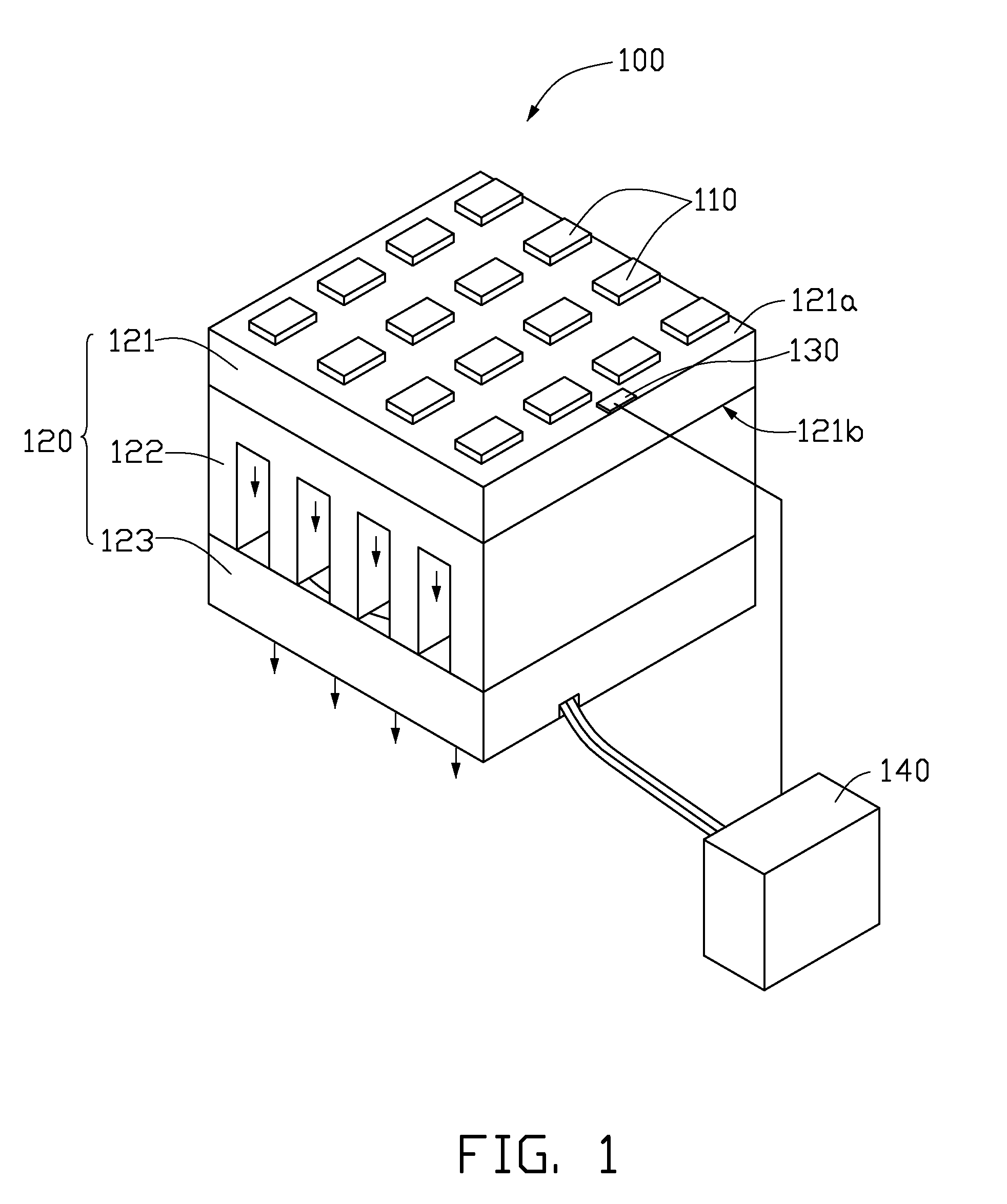

LED illuminantor and heat-dissipating method thereof

InactiveUS20090184619A1Appropriate speedPoint-like light sourceLighting support devicesWorking temperatureEngineering

A heat-dissipating method of a light emitting diode illuminator includes the following steps. First, the light emitting diode illuminator is provided and includes a light emitting diode, a fan apparatus, a temperature sensor and a controller. The controller is electrically connected with the fan and the temperature sensor. Second, a predetermined working temperature of the light emitting diode is defined in the controller. Third, a working temperature of the light emitting diode is sensed using the temperature sensor, and a signal of the working temperature is transmitted to the controller. Fourth, the working temperature sensed by the temperature sensor is compared with the predetermined working temperature in the controller, and the fan is adjusted by the controller to work at a suitable speed.

Owner:FOXSEMICON INTEGRATED TECH INC

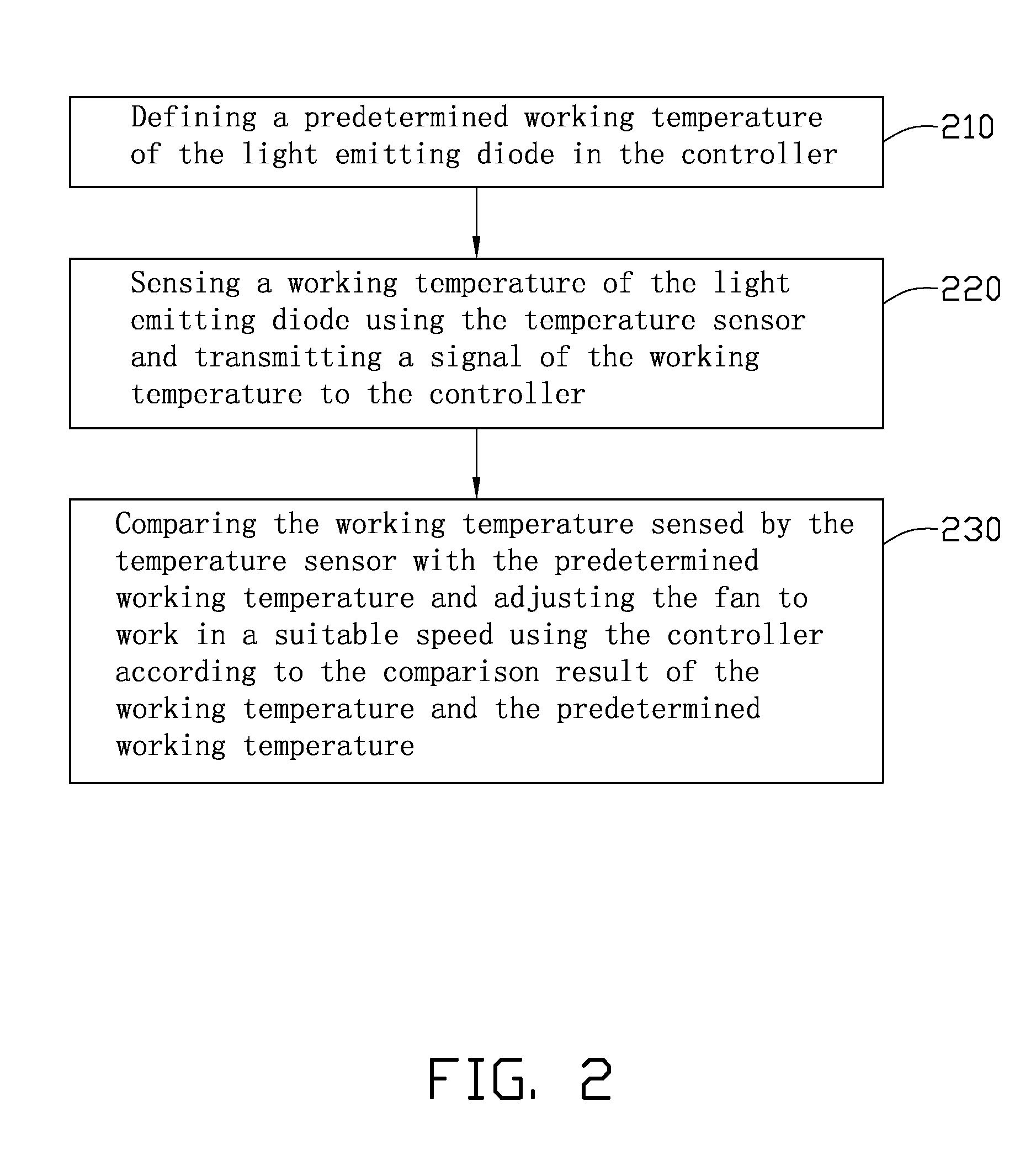

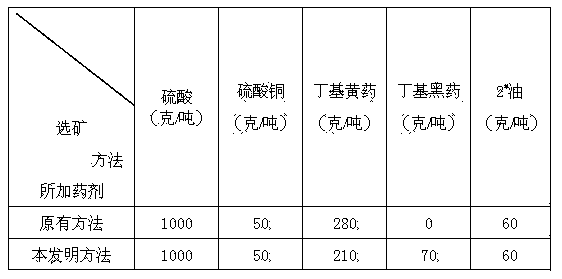

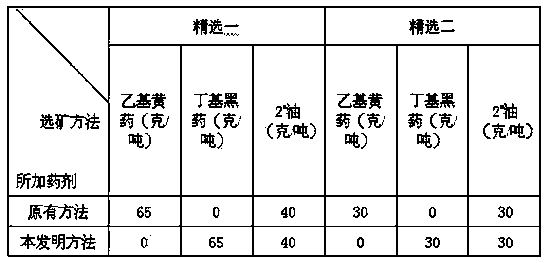

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

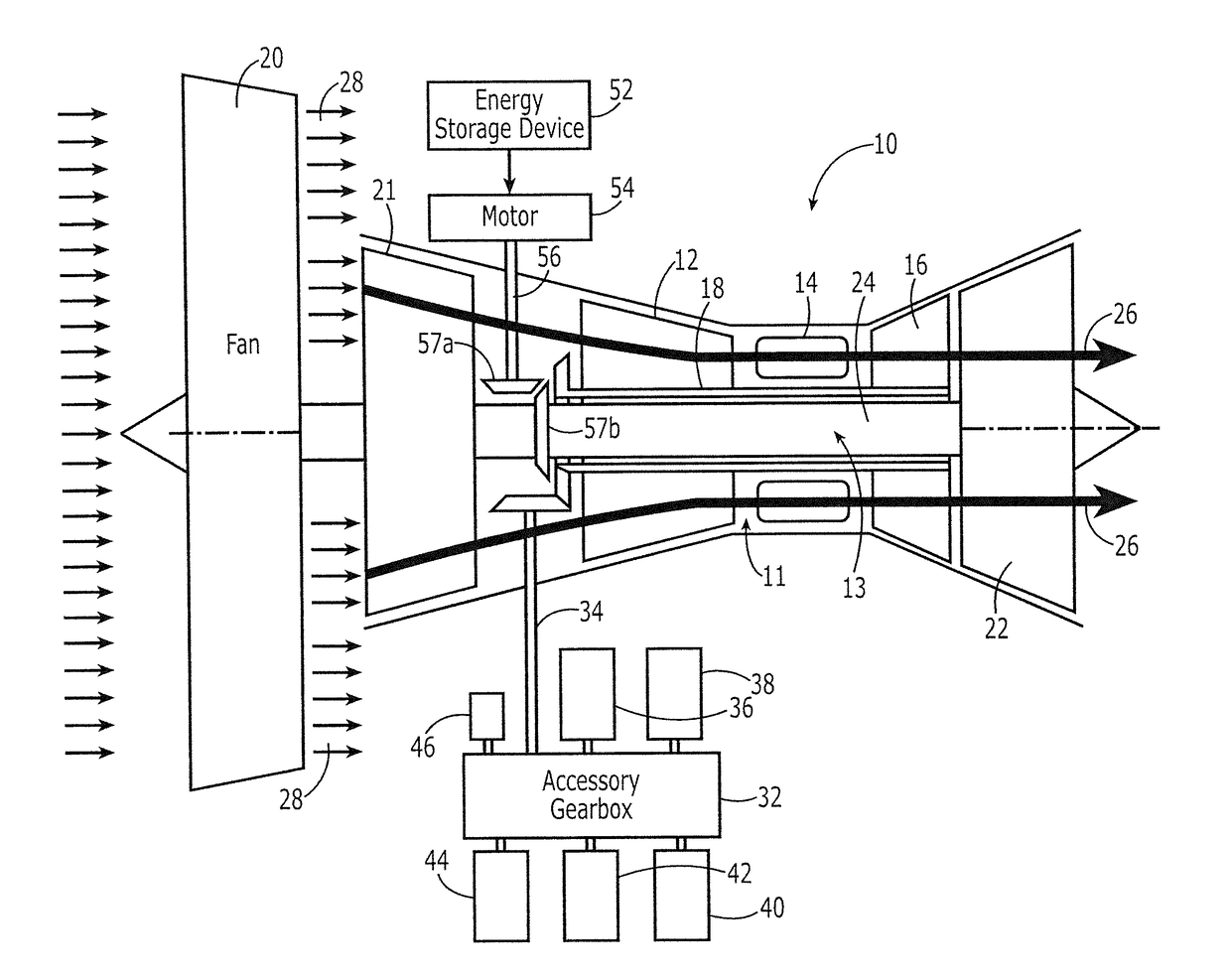

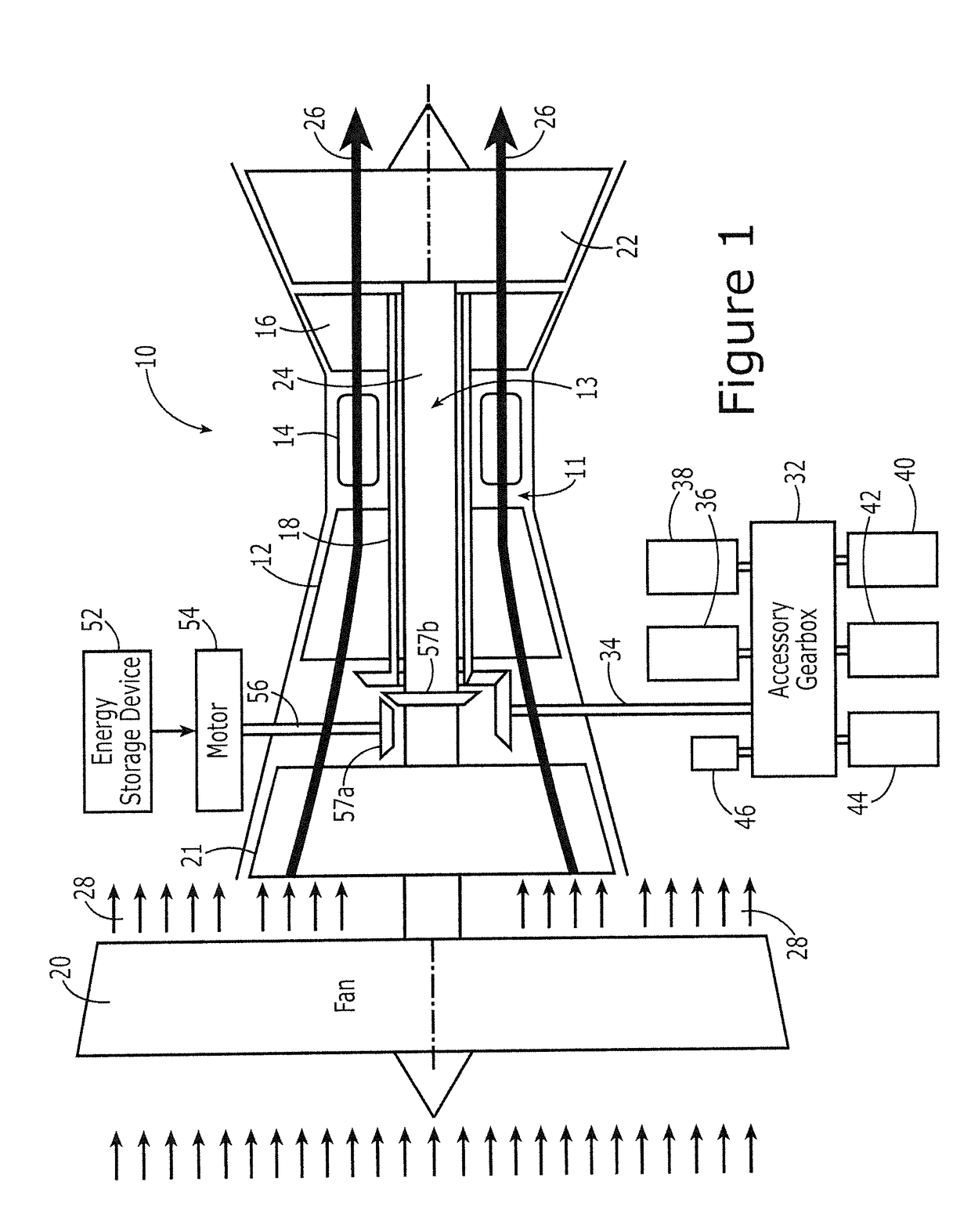

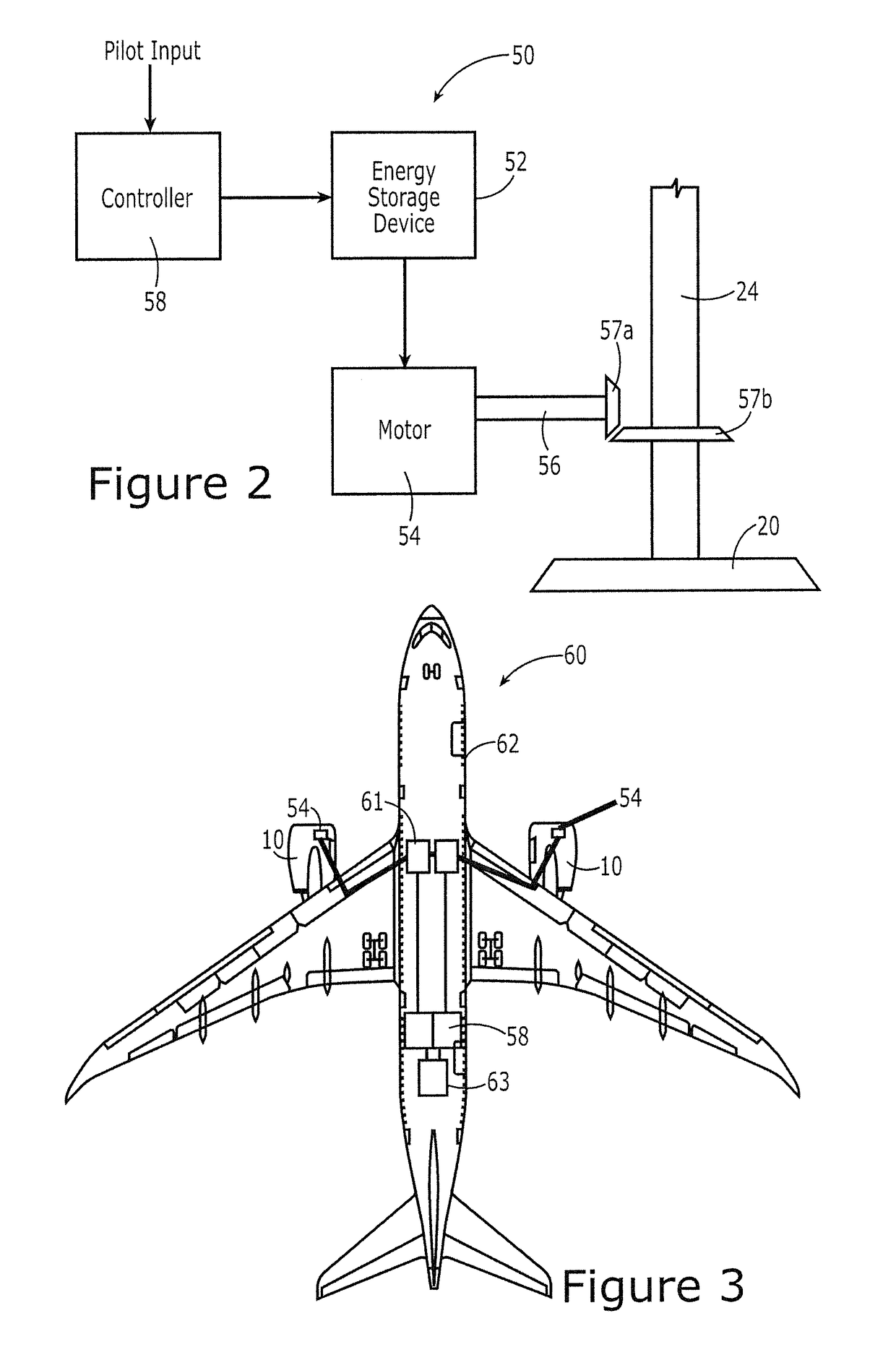

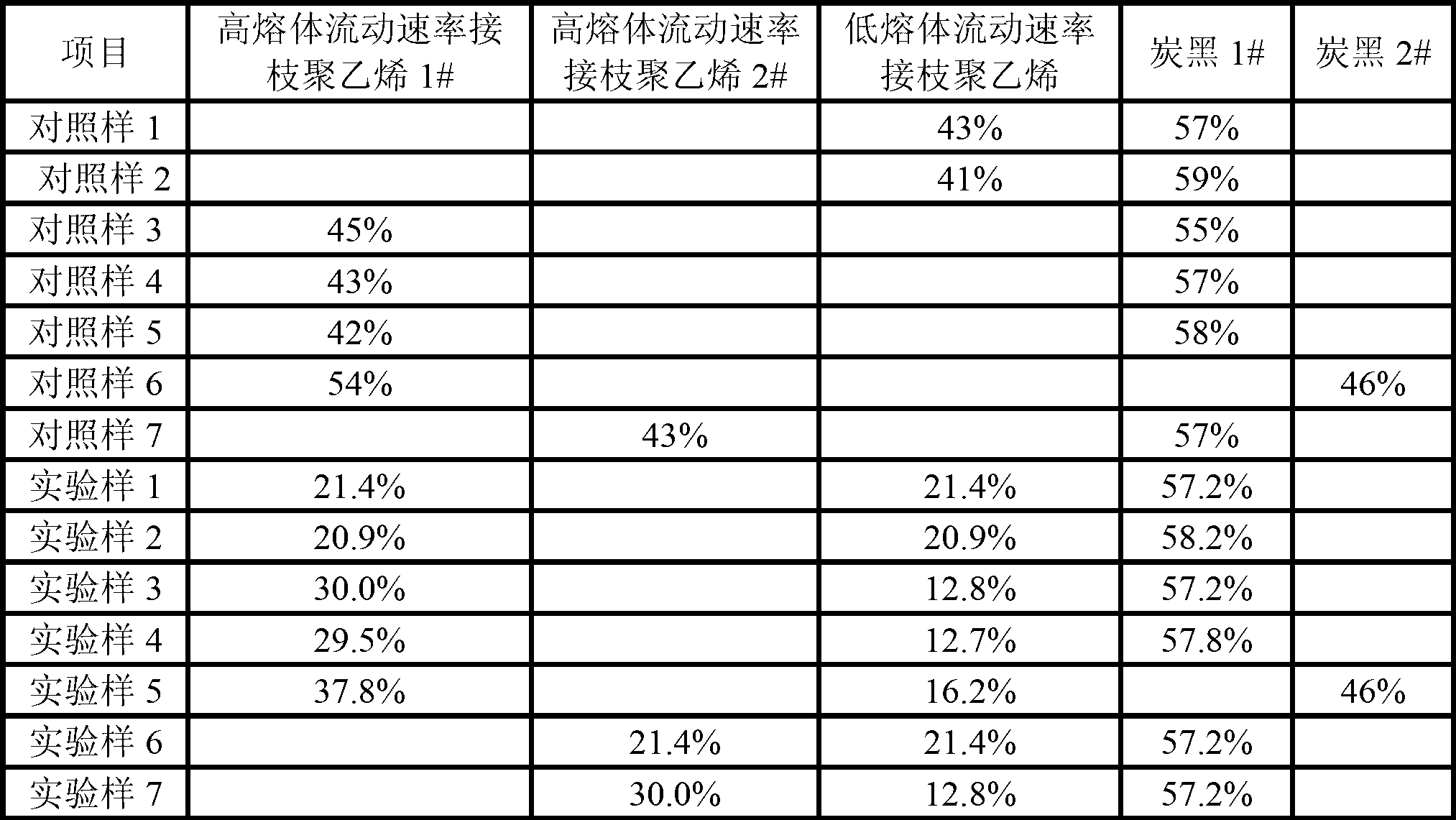

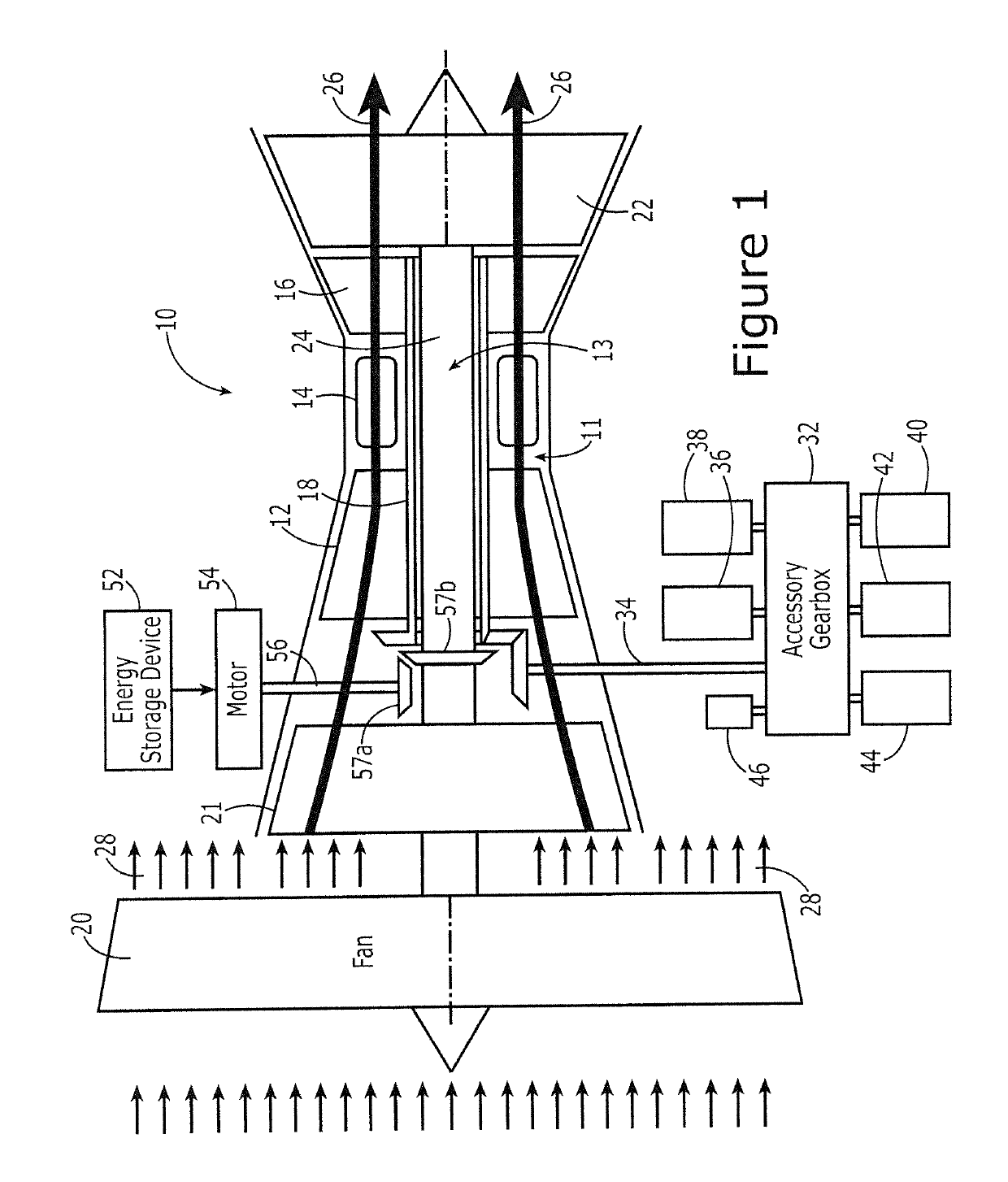

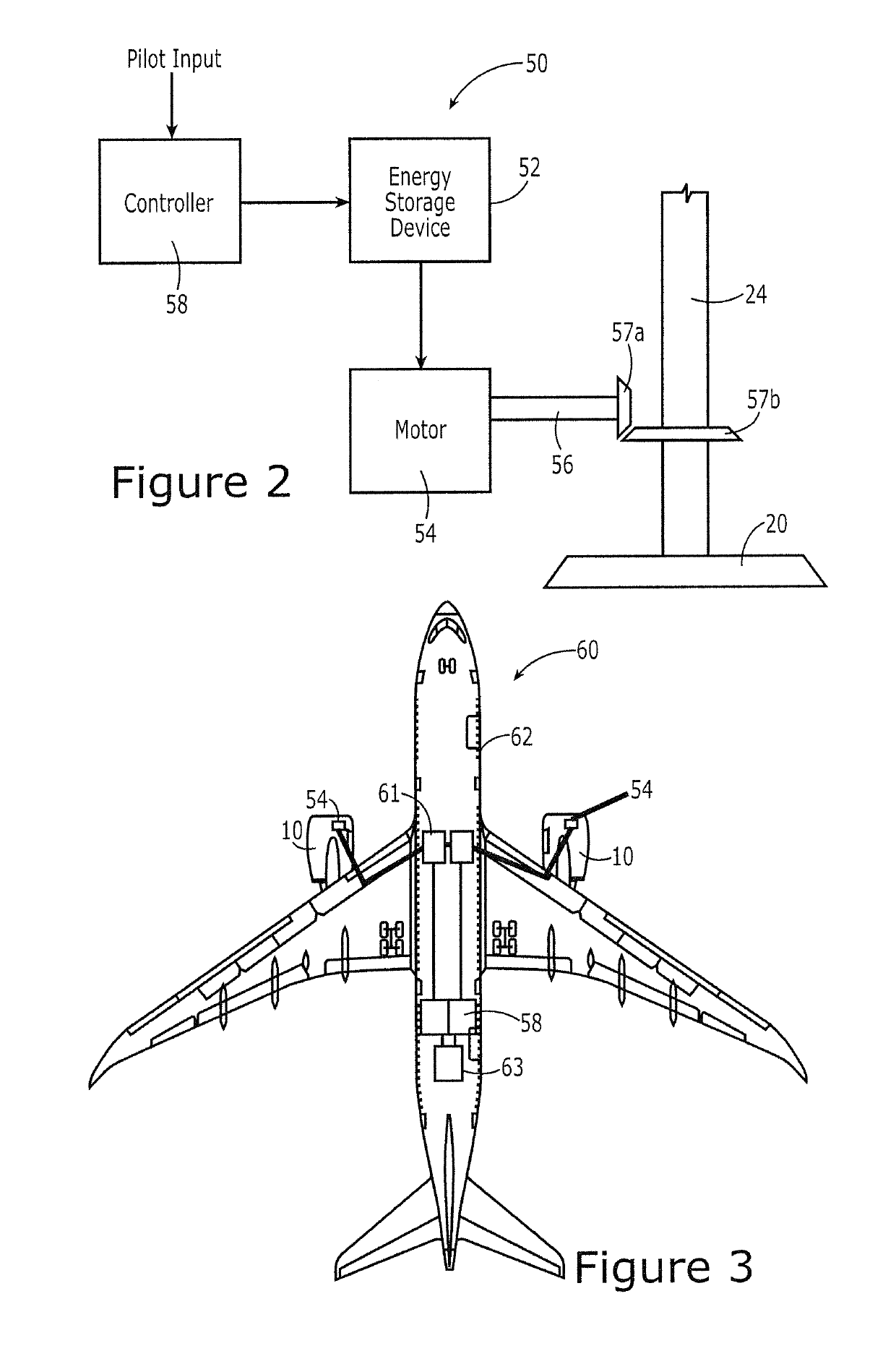

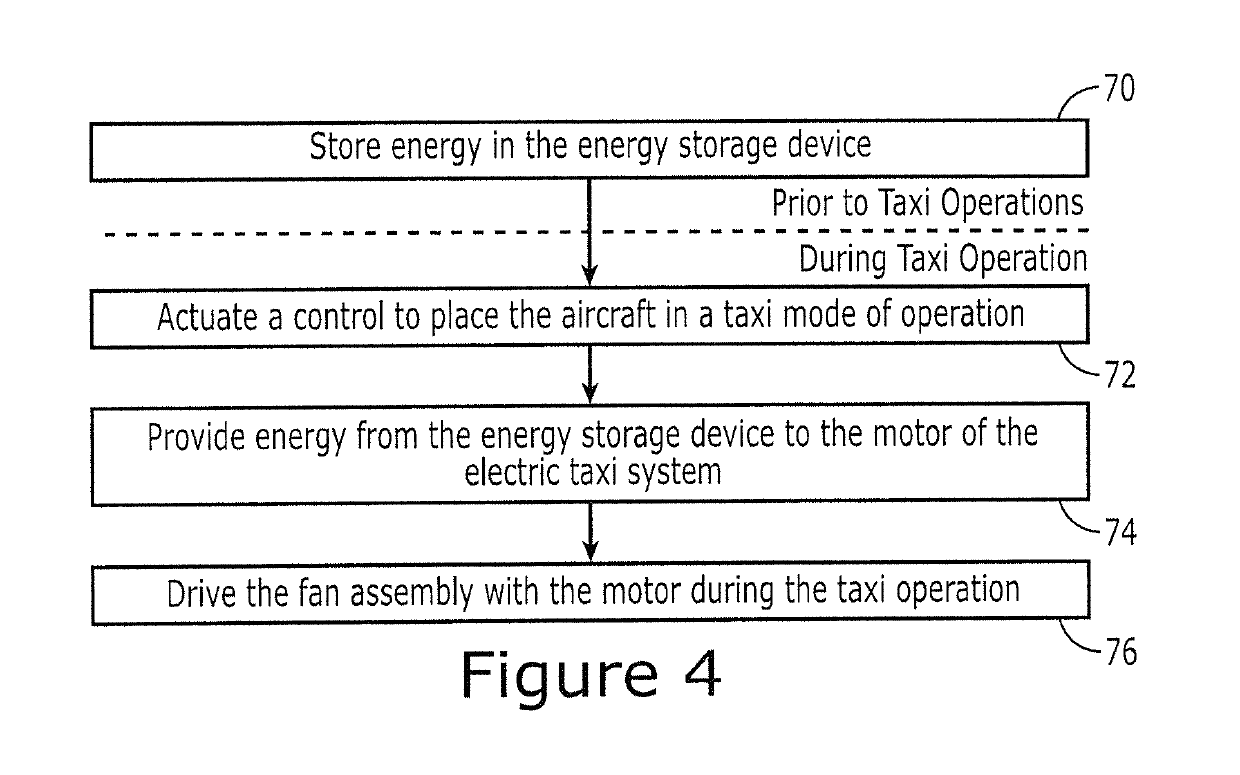

Aircraft engine and associated method for driving the fan with the low pressure shaft during taxi operations

ActiveUS20170190441A1Increase consumptionWeight increasePower installationsEnergy efficient operational measuresCombustorHigh pressure

An aircraft engine, an electric taxi system and a corresponding method are provided to facilitate taxiing without operation of the core gas turbine engine by driving the fan assembly with the electric taxi system during taxi operations. An aircraft engine is provided that includes a core gas turbine engine including a compressor, a combustor and a high pressure turbine. The aircraft engine also includes a fan assembly coupled to the core gas turbine engine. The aircraft engine further includes an electric taxi system coupled to the fan assembly. The electric taxi system includes an energy storage device and a motor responsive to energy provided by the energy storage device. The motor is coupled to the fan assembly and is configured to drive the fan assembly during taxi operations.

Owner:THE BOEING CO

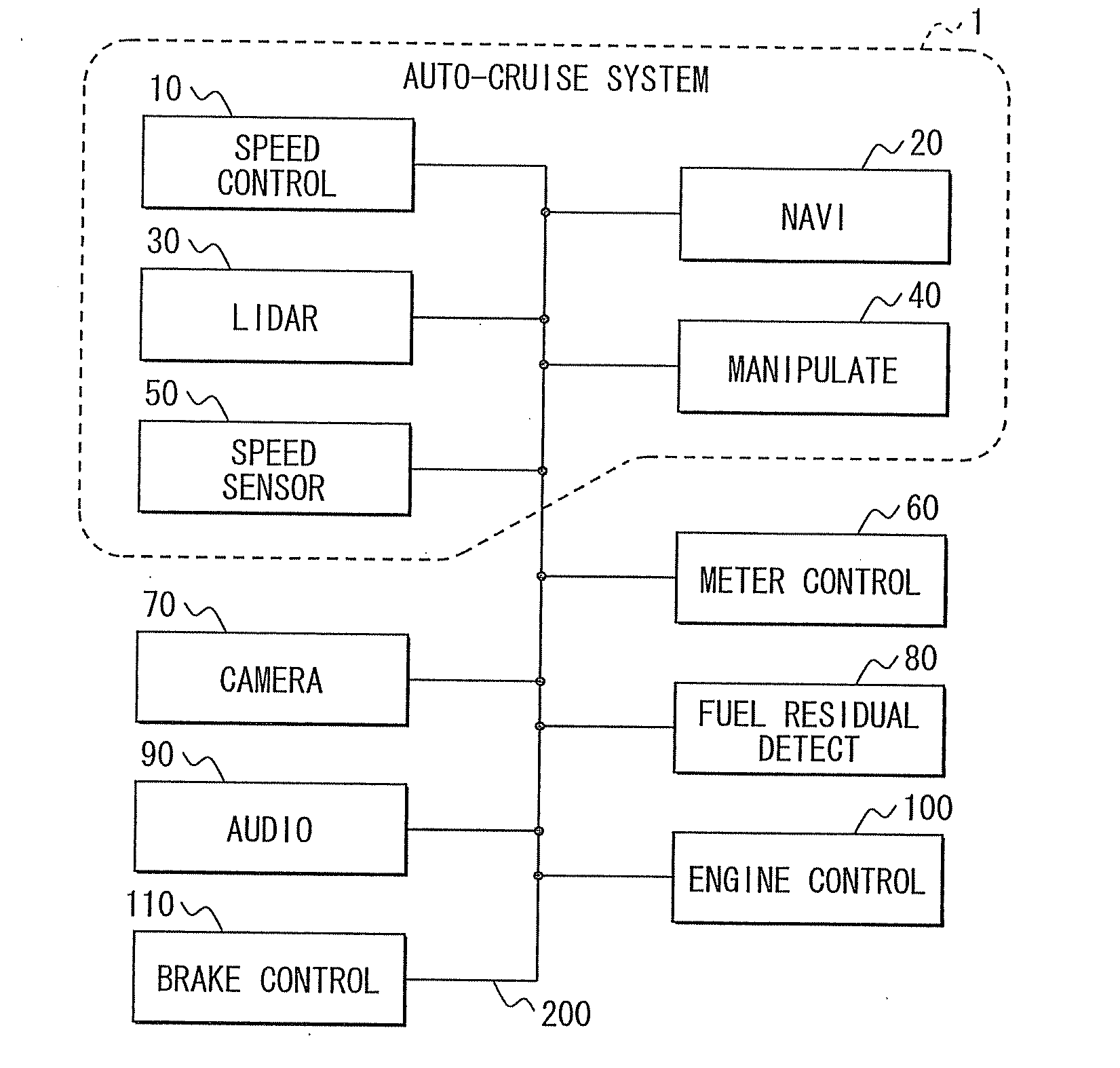

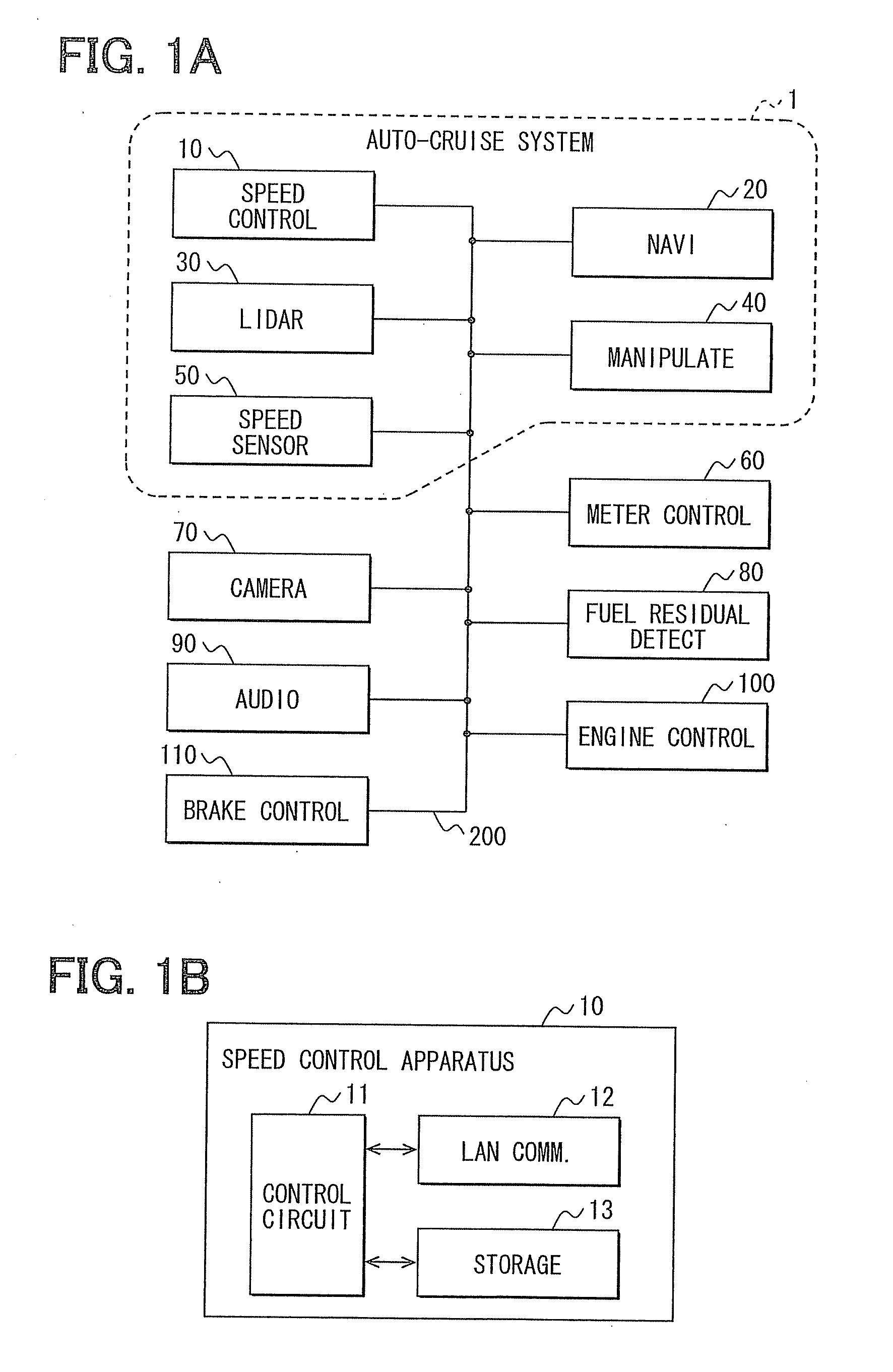

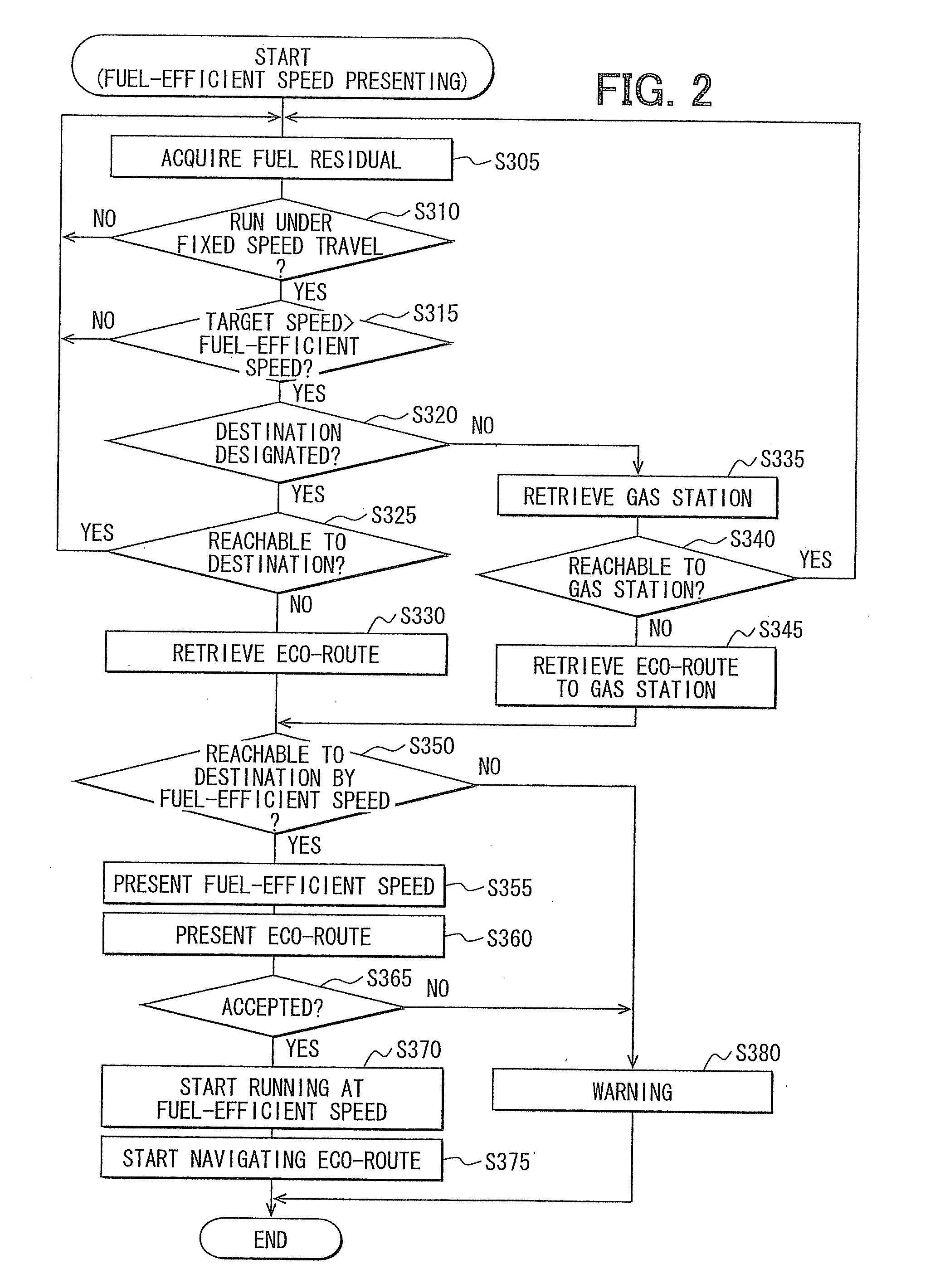

Vehicle speed control system

InactiveUS20120123657A1Driving by auto-cruise more smoothlyDrive stabilityInstruments for road network navigationVehicle fittingsSpeed control systemMarine navigation

A subject vehicle runs under a fixed speed travel at a target speed by an auto-cruise system. When it is determined that the subject vehicle cannot arrive at a destination using a present residual fuel quantity, a navigation apparatus is caused to retrieve an eco-route. It is then determined whether the subject vehicle can arrive at the destination by running the eco-route at a fuel-efficient speed which can consume fuel efficiently using the present residual fuel quantity. When it is determined that the subject vehicle can arrive, the fuel-efficient speed is presented as a recommended speed. Thus, a driver of the subject vehicle is urged to designate the fuel-efficient speed as a new target speed for the auto-cruise control.

Owner:DENSO CORP

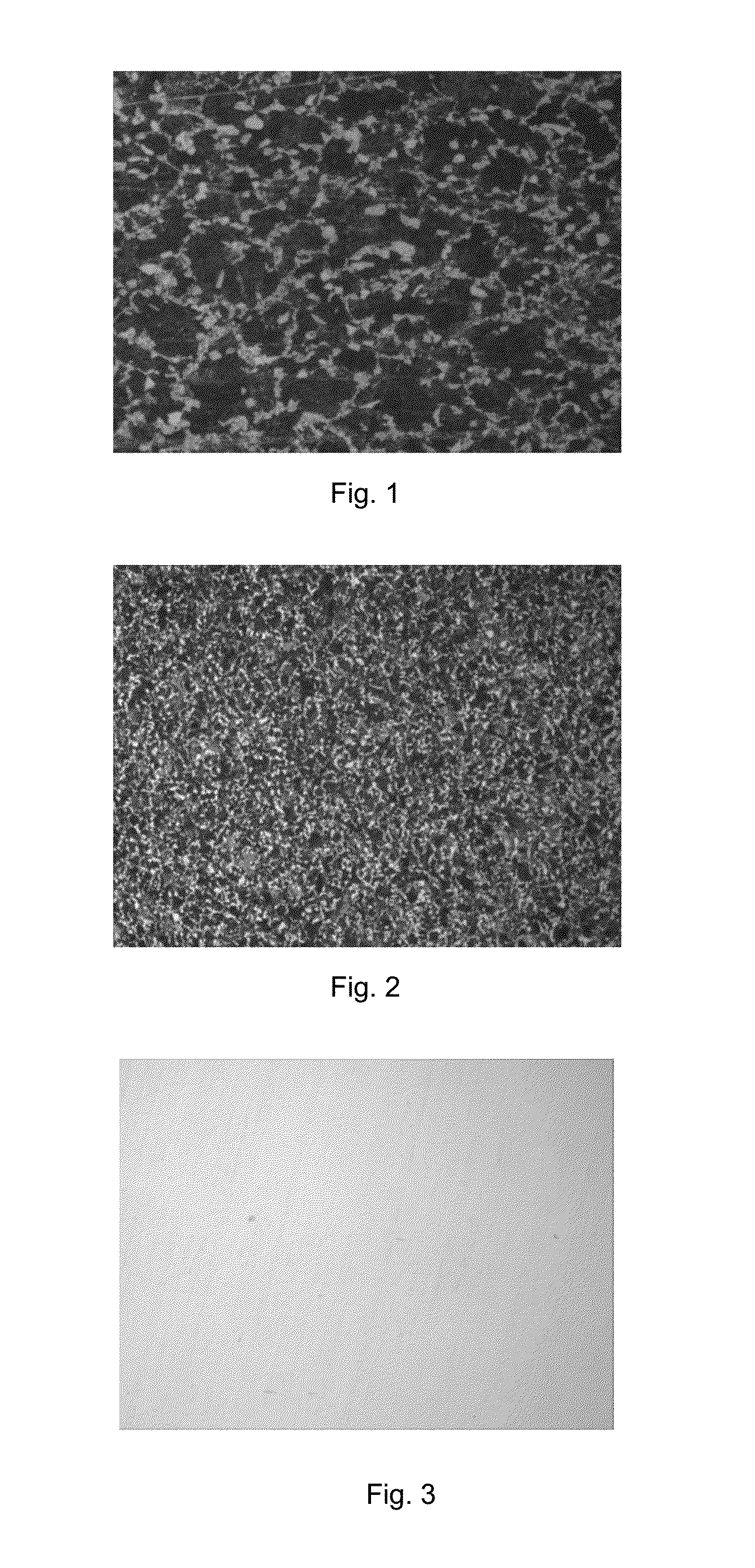

High-activity graphite-phase carbon nitride material and preparation method thereof

InactiveCN107252701AReduce compoundingImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationReactive site

The invention belongs to the technical field of material preparation and photocatalysis, and discloses a high-activity graphite-phase carbon nitride material and a preparation method thereof. The preparation method comprises the following steps: forming a self-generated gas atmosphere a gas generated from a precursor by pyrolysis in the high-temperature calcining process under the control on an inert gas, and guiding synthesis of a carbon nitride material, thereby obtaining a flaky porous graphite-phase carbon nitride material. According to the preparation method, after the inert gas is not introduced any longer, a self-generated gas generated from the precursor is relatively uniform at different parts, and the carbon nitride material prepared with the preparation method is uniform in morphology and relatively good in crystal form; due to the escape of the self-generated gas, the material is effectively pored, and thus the specific surface area and the active sites of the material are increased; due to the self-generated gas atmosphere, the polymerization degree of the precursor is reduced, and the obtained carbon nitride material has a relatively large amount of unpolymerized amino or imino groups. The preparation method disclosed by the invention is simple, efficient and low in cost, and the carbon nitride material prepared with the preparation method is excellent in photocatalysis activity and very good in practicability.

Owner:CHINA WEST NORMAL UNIVERSITY

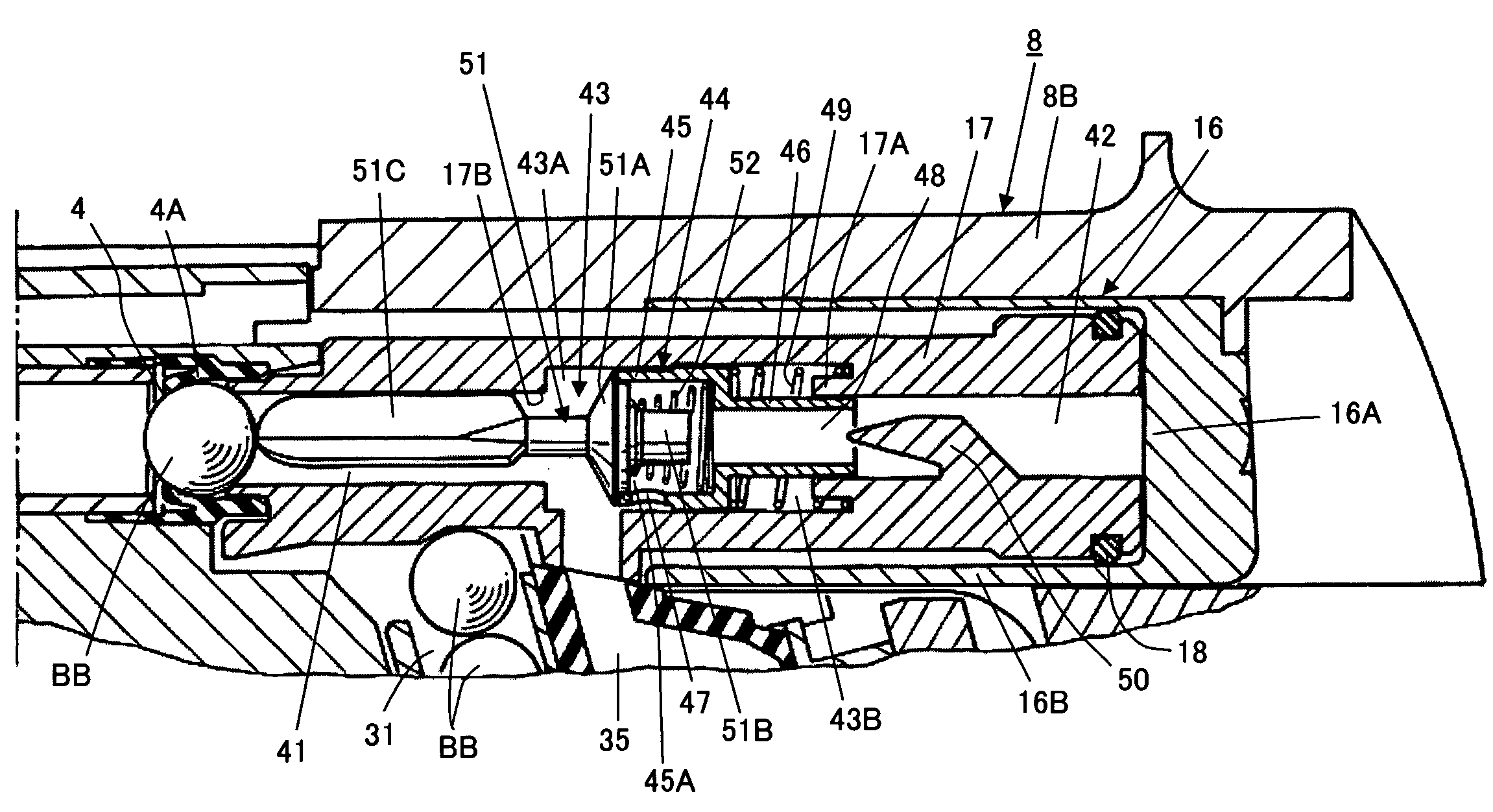

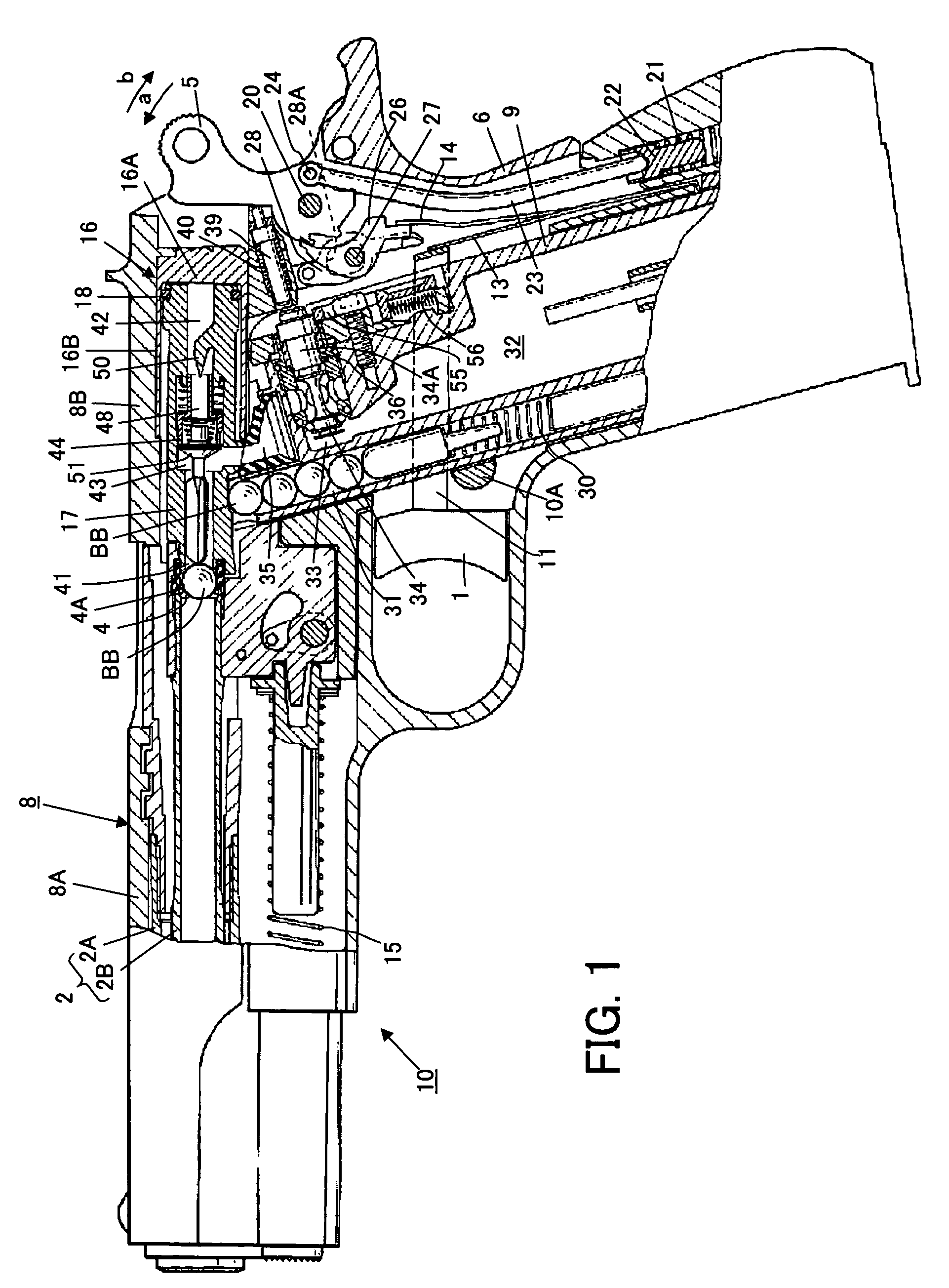

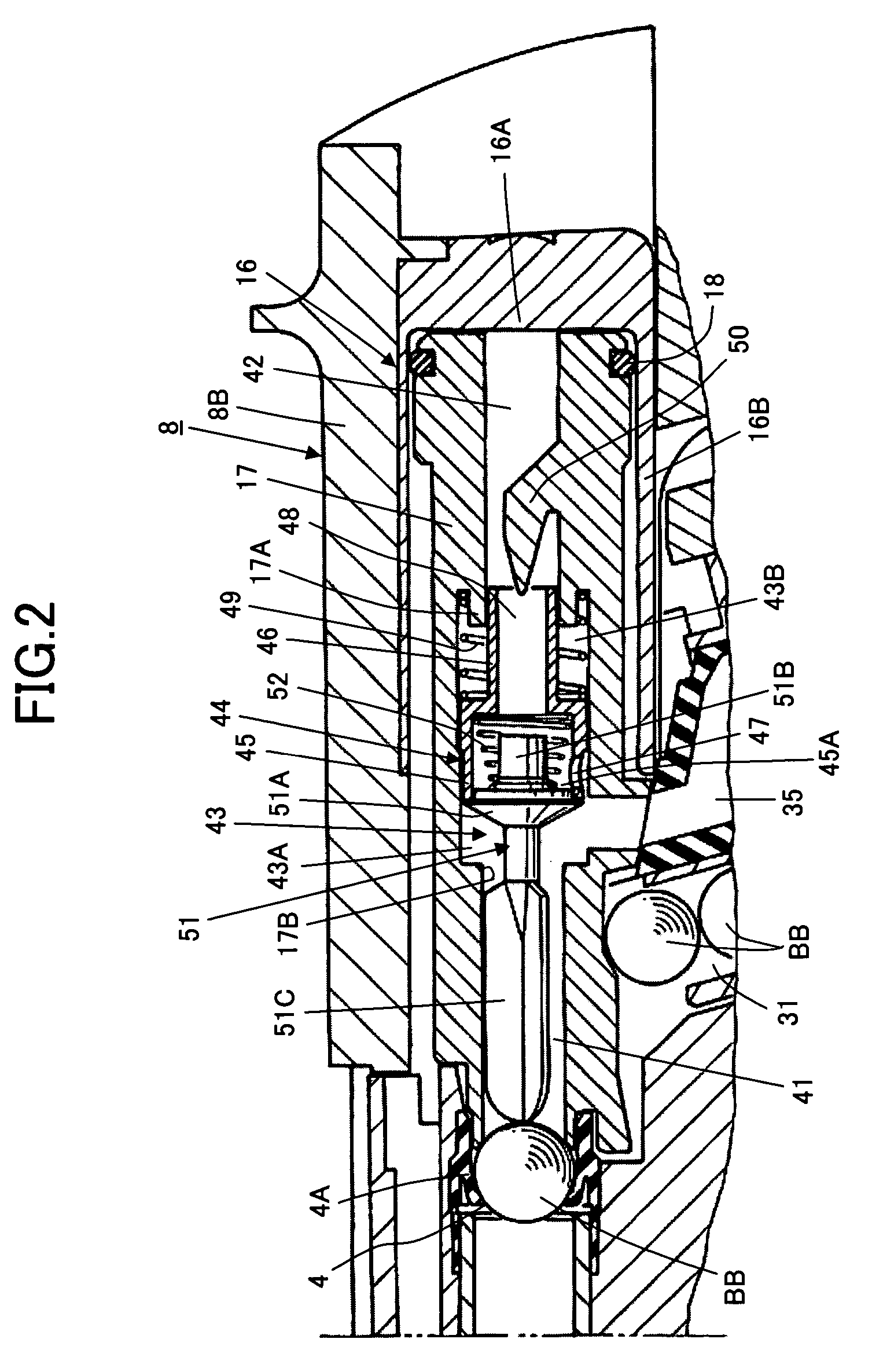

Gas powered toy gun

A gas powered toy gun comprises a gas supplying portion from which a gas leading passage extends, a valve for controlling the gas leading passage to be open and closed selectively, a slider provided to be movable to a barrel portion connected with a bullet holding chamber and provided with a pressure receiving portion for moving backward in order to supply the bullet holding chamber with a sham bullet, a movable member having an inner space formed therein and provided to be movable in the slider so as to be put selectively in a first state wherein the inner space is coupled with the gas leading passage and in a second state wherein the inner space is removed from the gas leading passage for guiding gas flowing through the gas leading passage to the bullet holding chamber through the inner space so that the sham bullet put in the bullet holding chamber is shot with pressure of gas acting thereon and for guiding further the gas flowing through the gas leading passage to the pressure receiving portion through the inner space so that the slider is moved backward with pressure of gas acting on the pressure receiving portion, and gas flow adjusting means provided in the inner space formed in the movable member for adjusting the amount of gas flowing through the inner space to the pressure receiving portion in response to pressure of gas led into the inner space.

Owner:WESTERN ARMS

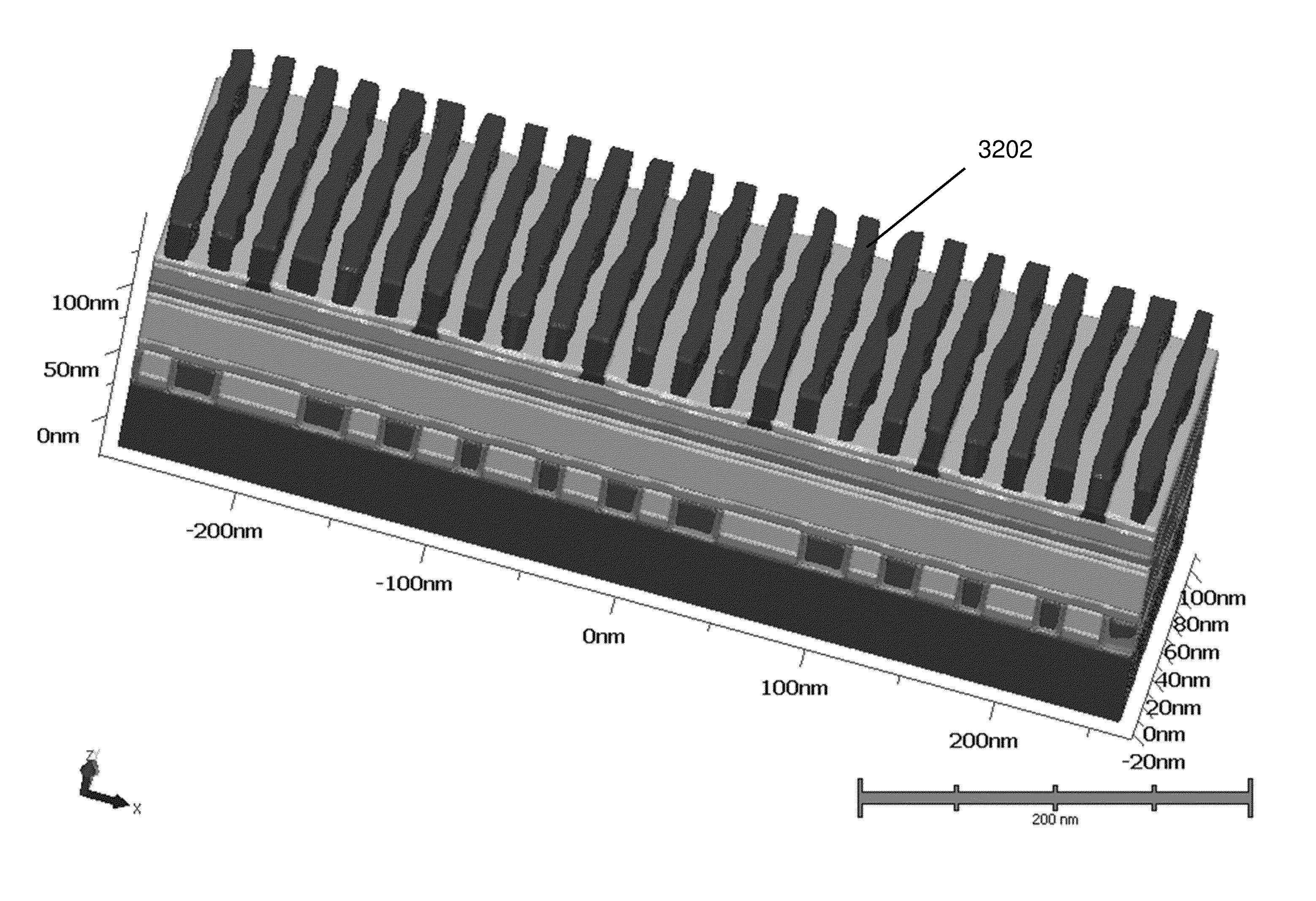

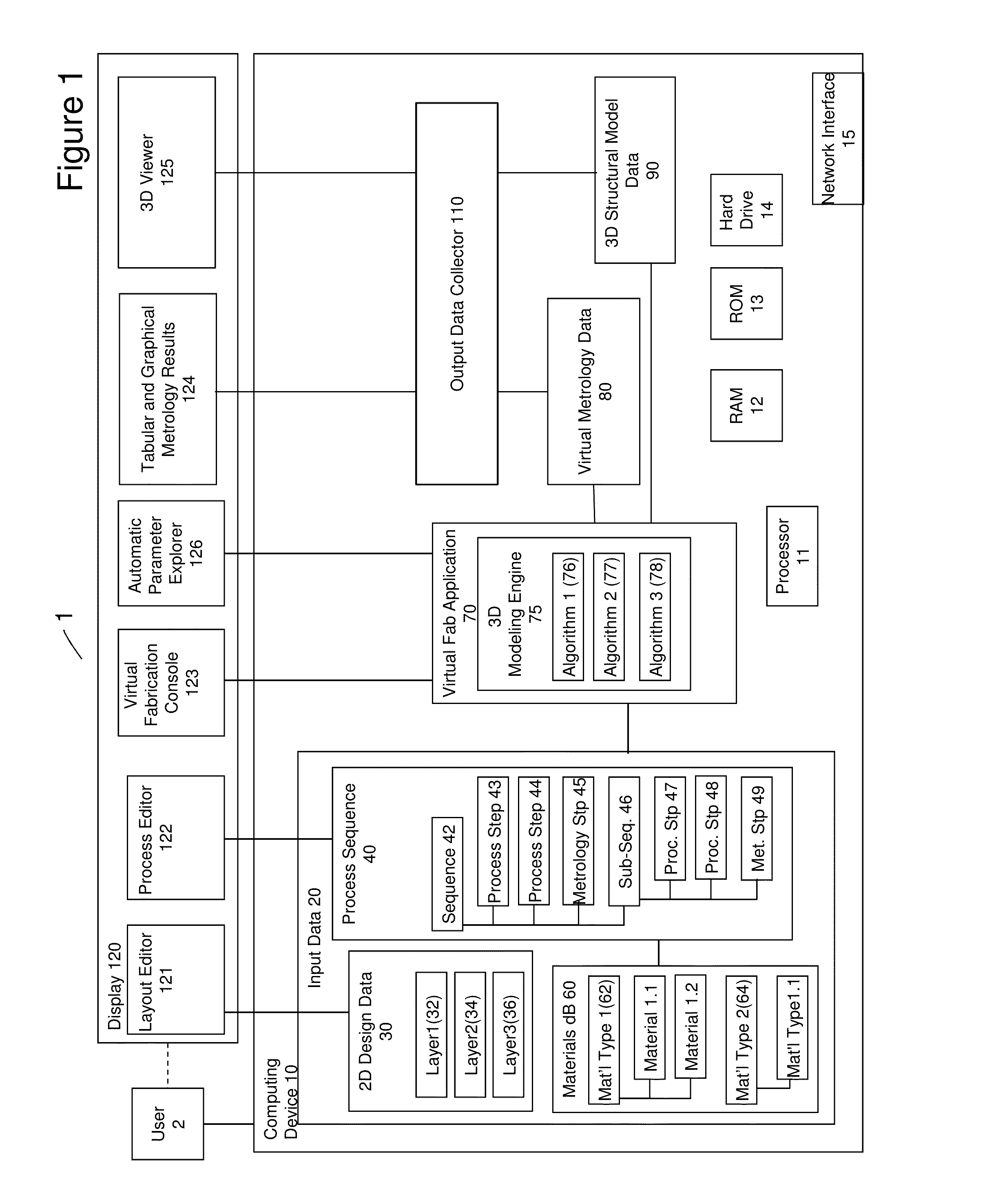

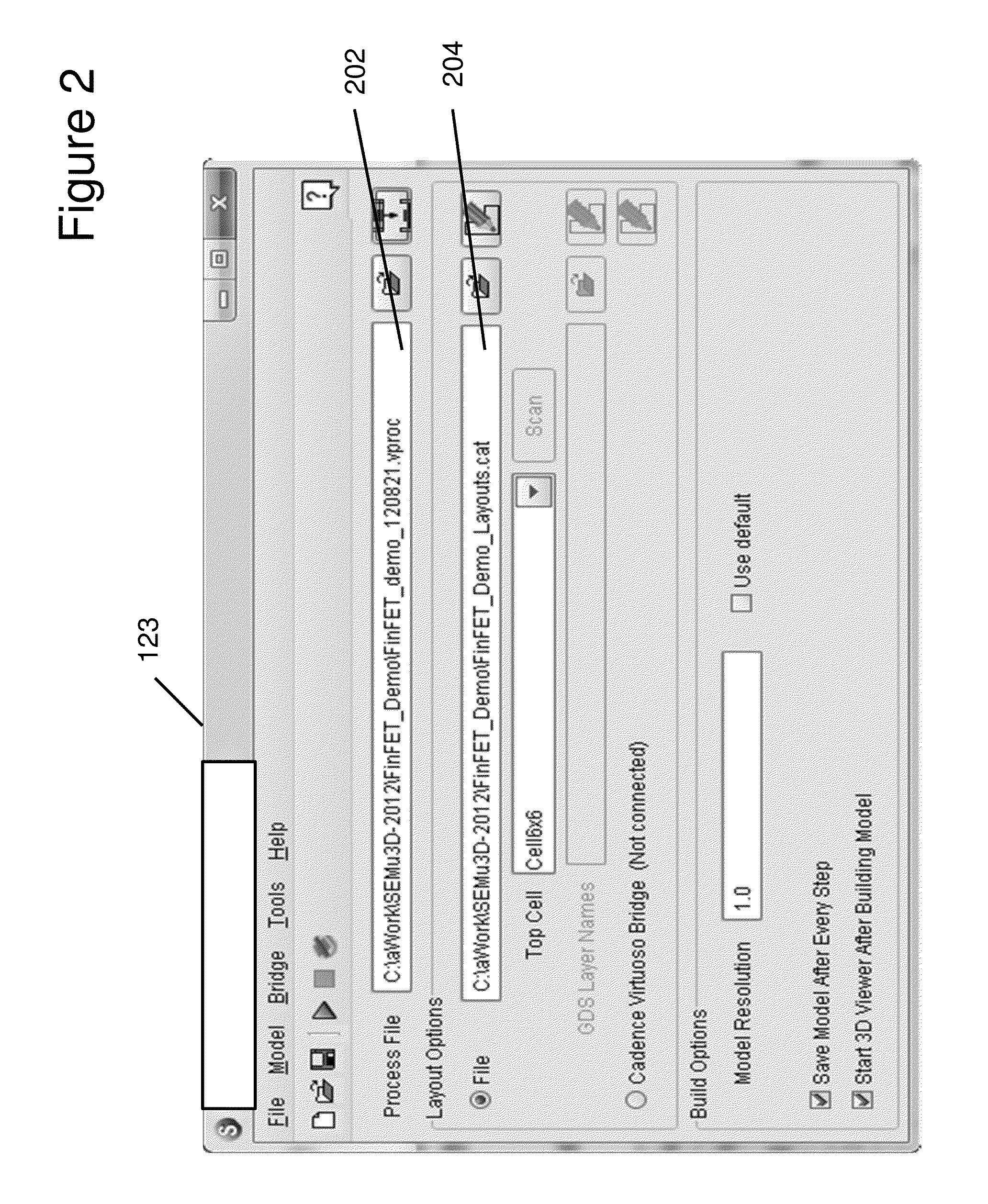

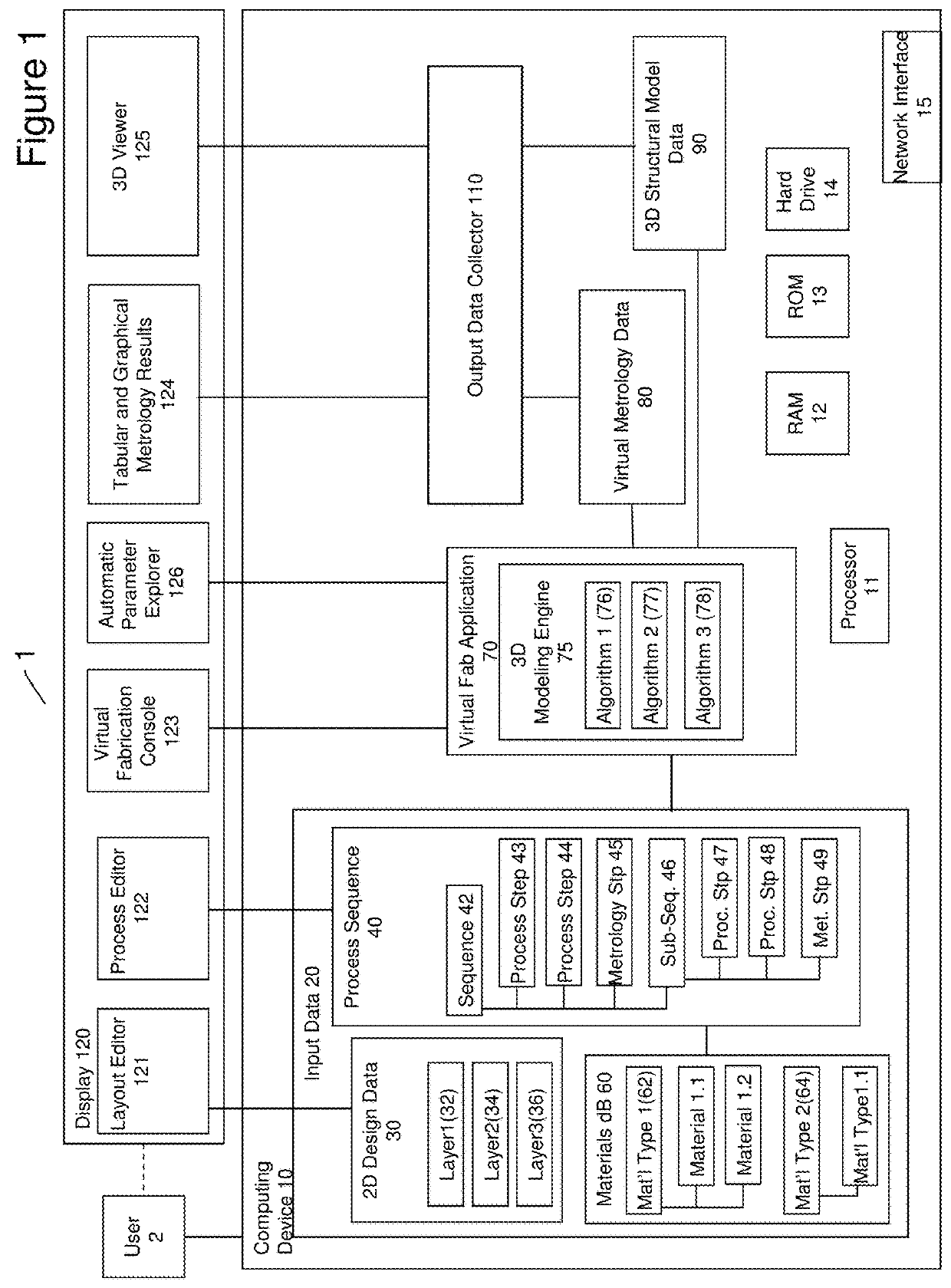

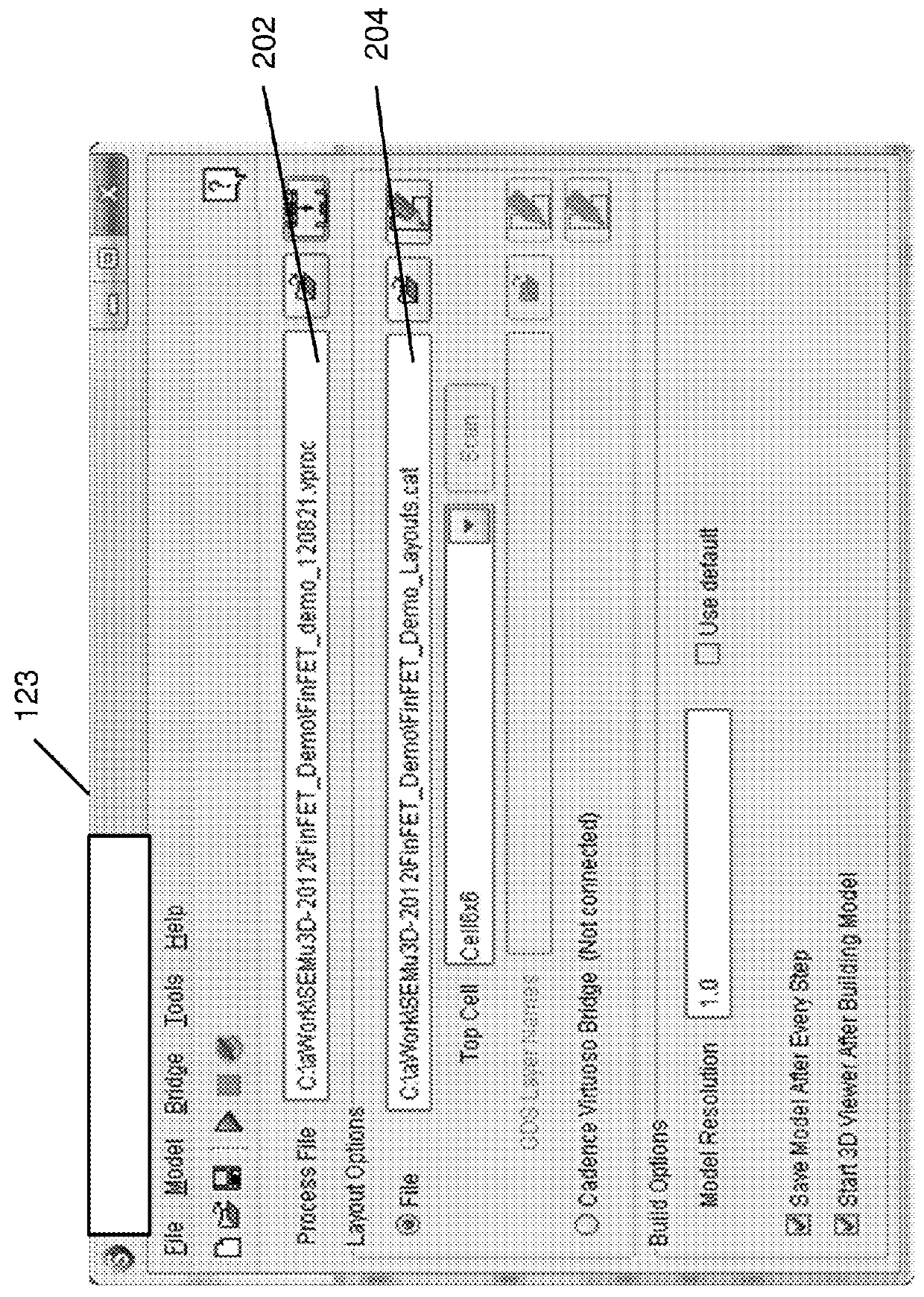

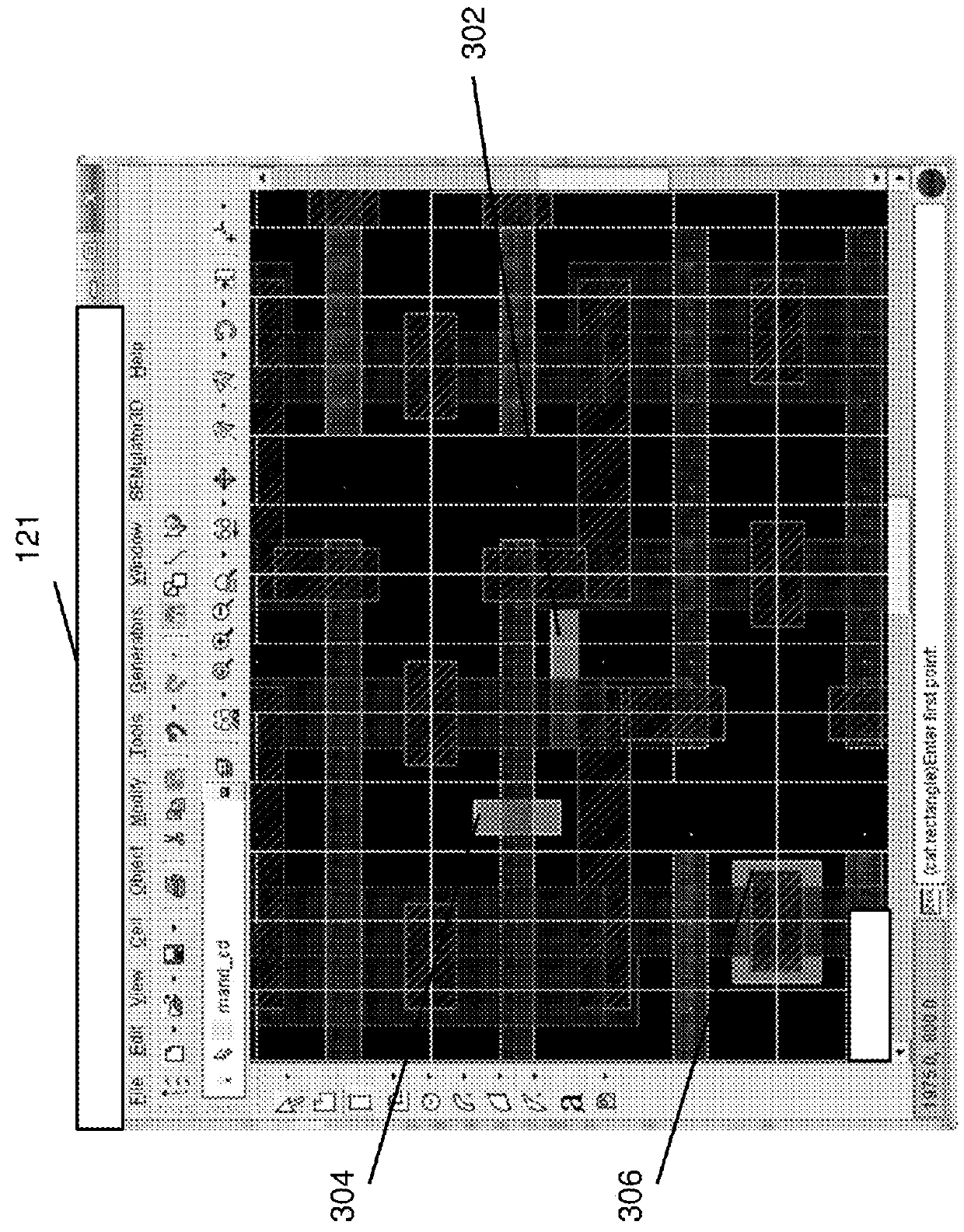

System and method for performing directed self-assembly in a 3-d virtual fabrication environment

ActiveUS20160217233A1Appropriate speedProgramme controlPhotomechanical apparatusEngineeringDirected self assembly

The modeling of a DSA step within a virtual fabrication process sequence for a semiconductor device structure is discussed. A 3D model is created by the virtual fabrication that represents and depicts the possible variation that can result from applying the DSA step as part of the larger fabrication sequence for the semiconductor device structure of interest. Embodiments capture the relevant behavior caused by polymer segregation into separate domains thereby allowing the modeling of the DSA step to take place with a speed appropriate for a virtual fabrication flow.

Owner:COVENTOR

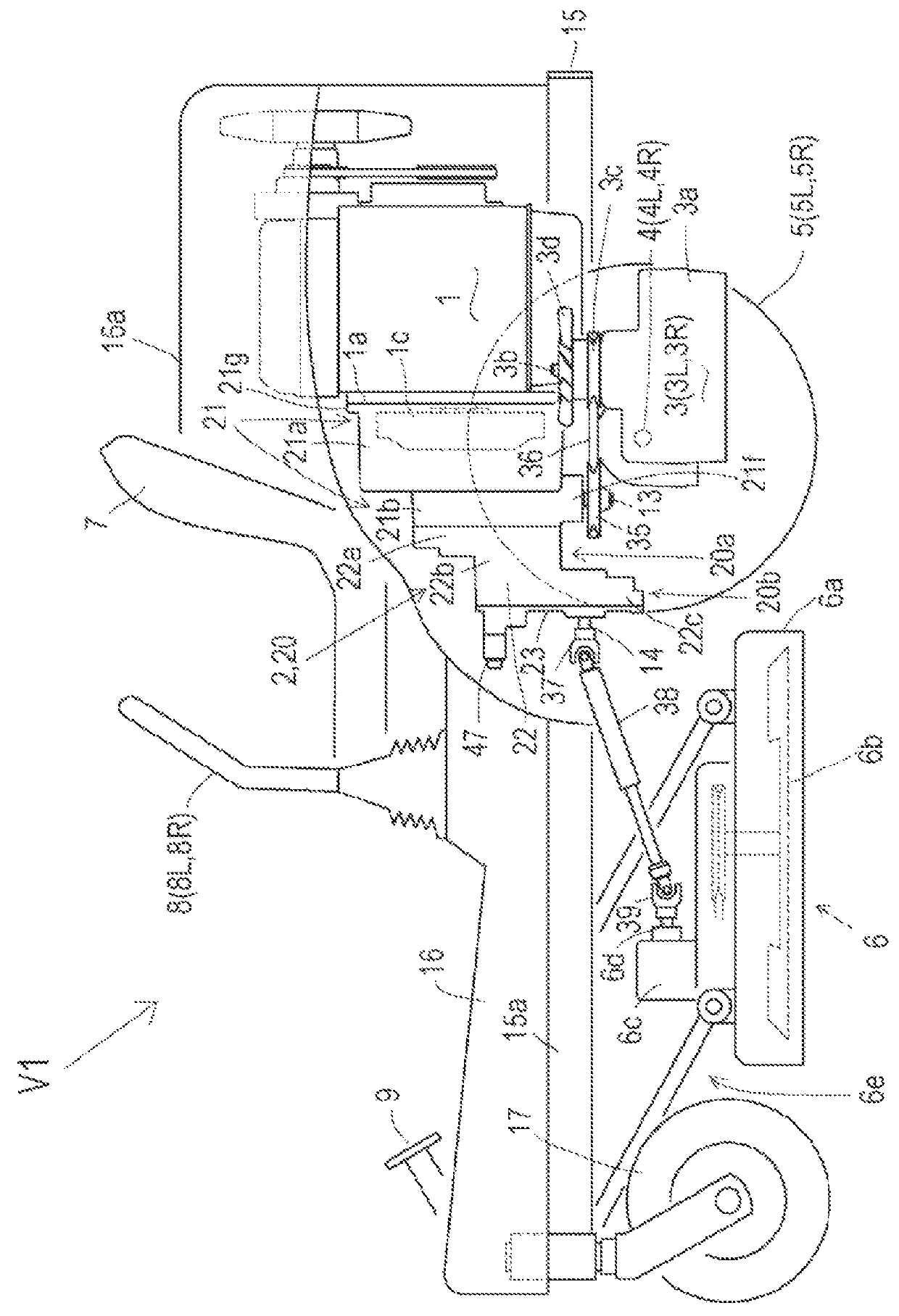

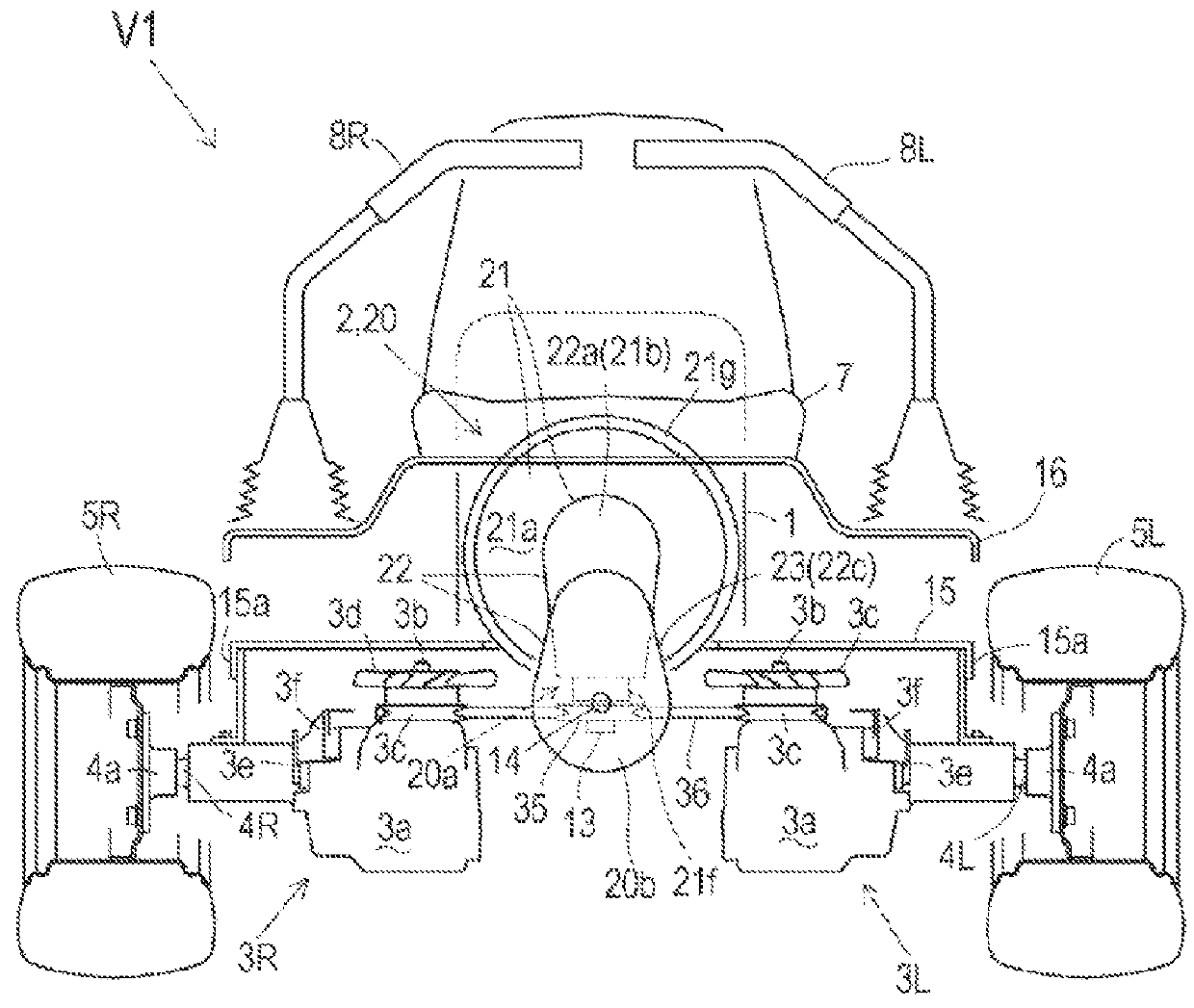

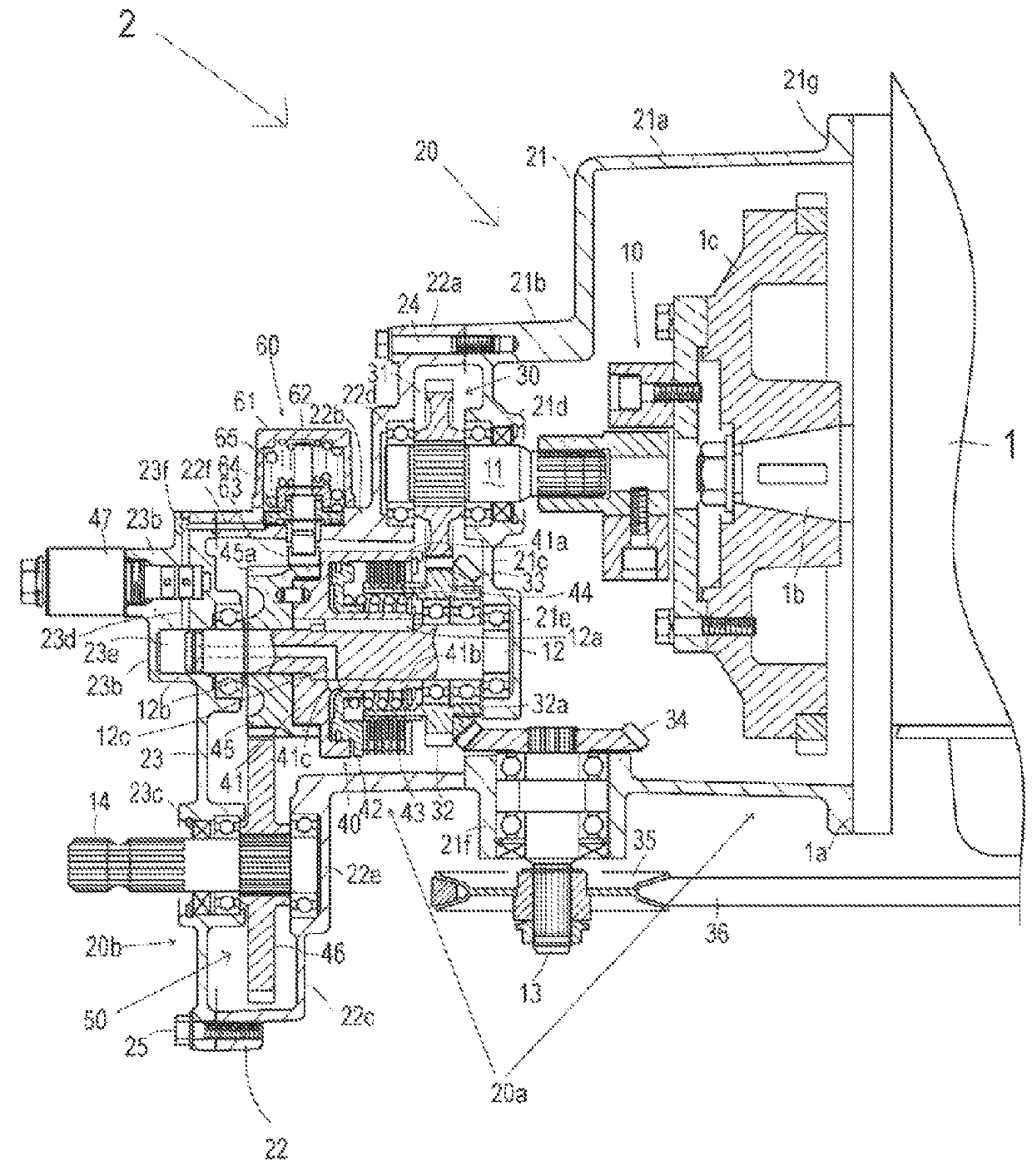

Transmission for working vehicle

A transmission for a working vehicle equipped with an engine having a horizontal engine output shaft, pair of transaxles for driving right and left drive wheels at variable speeds, and working device comprises a horizontal input shaft, output shaft, first gear train, horizontal PTO shaft, second gear train, PTO clutch and casing. An axial end of the input shaft connects to a flywheel of the engine. The output shaft drivingly connects to the transaxles. The first gear train transmits power from the input shaft to the output shaft. The PTO shaft extends parallel to the input shaft, and is provided with a universal joint connected to the working device. The second gear train transmits power from the input shaft to the PTO shaft via the PTO clutch. The casing supports the input and output shafts and incorporates the first and second gear trains and the PTO clutch.

Owner:KANZAKI KOKYUKOKI MFG

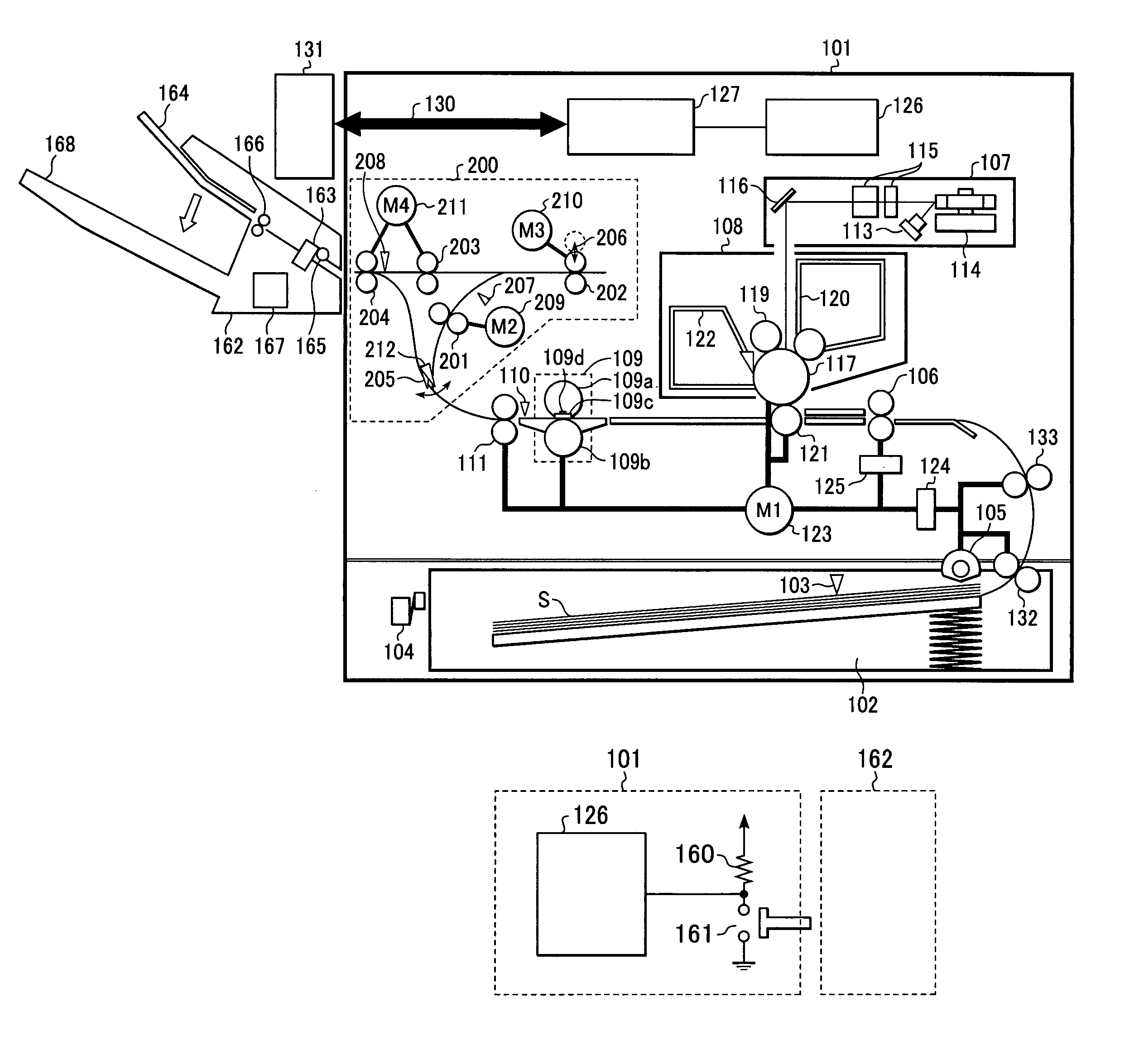

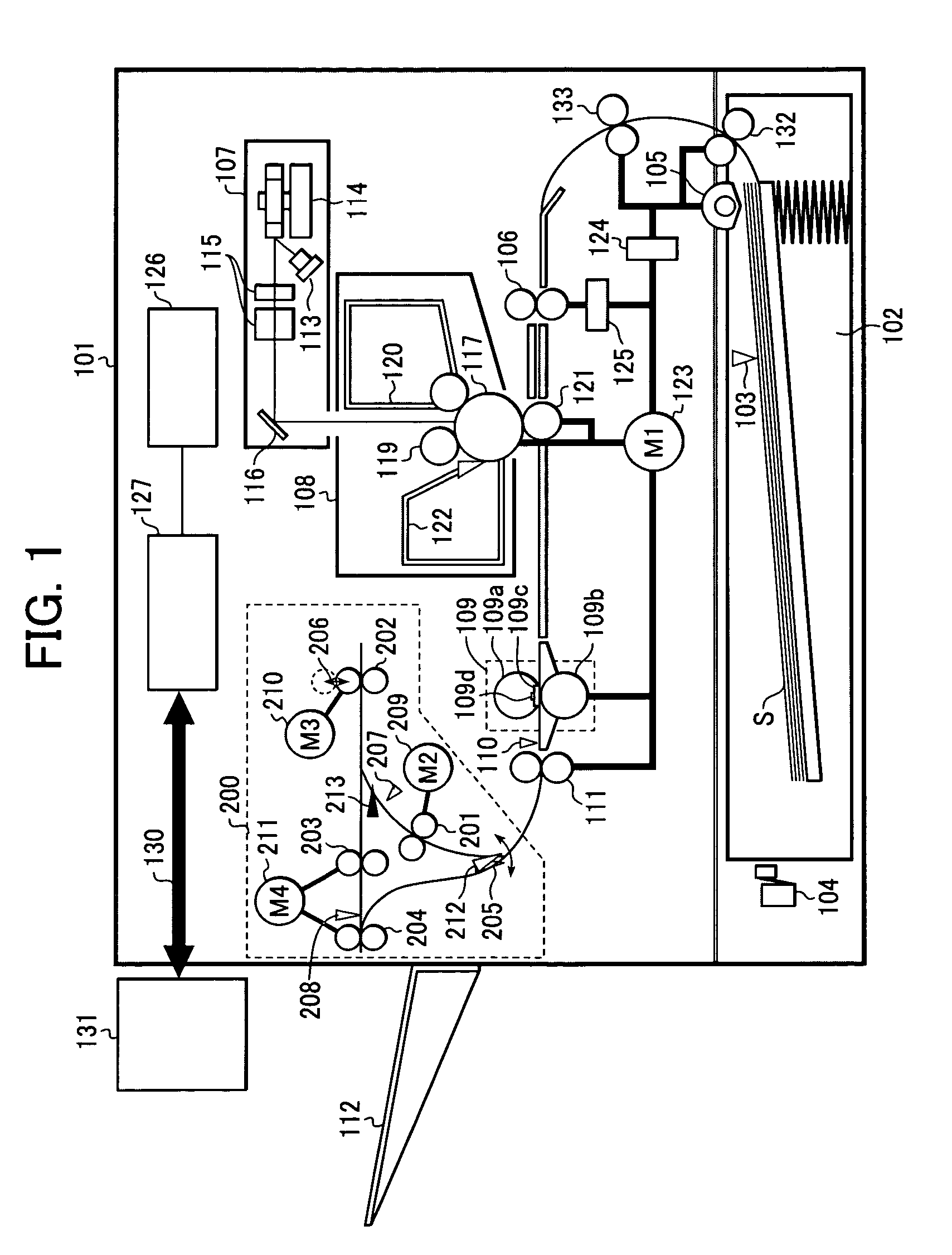

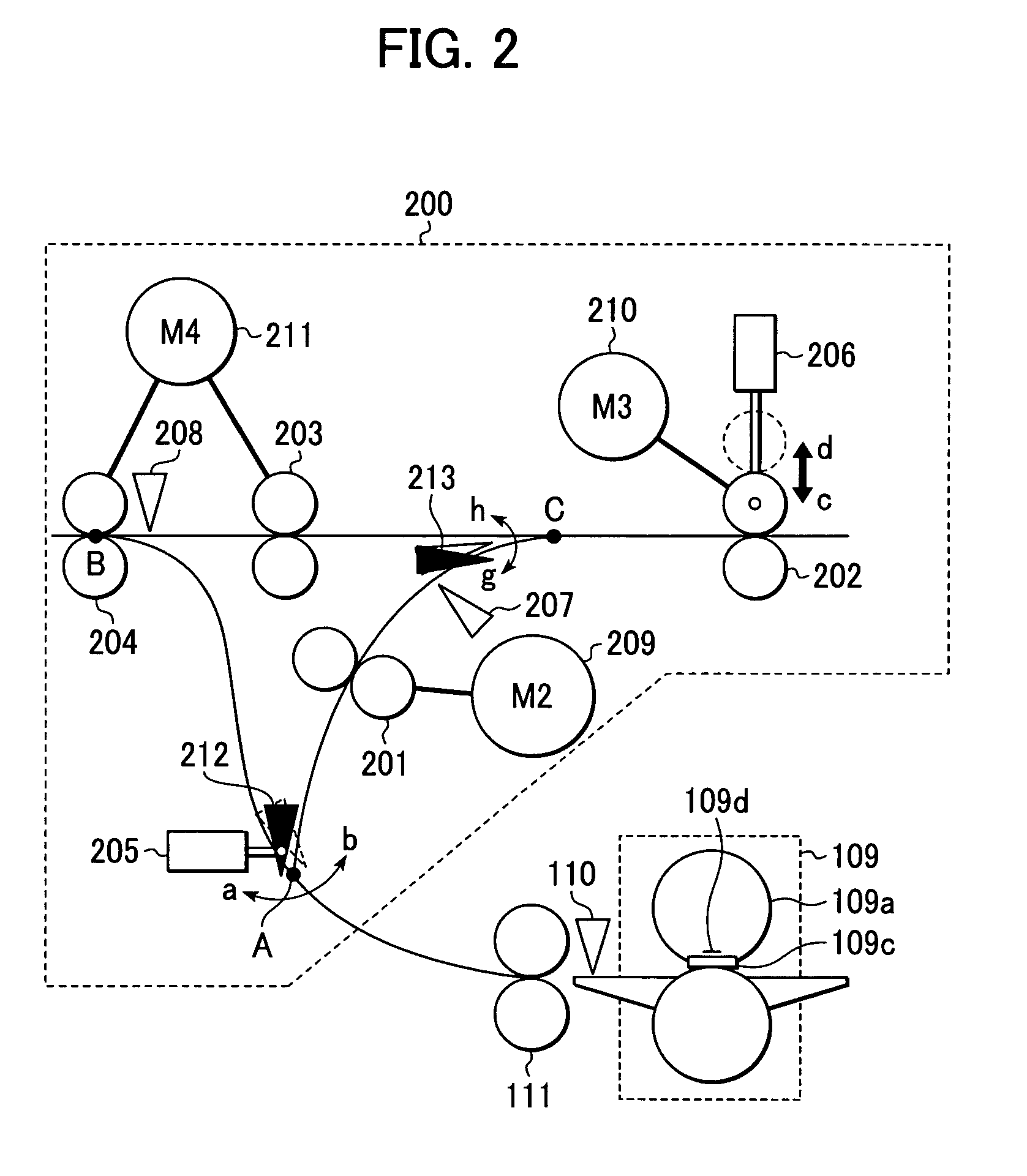

Image forming apparatus to which a sheet discharge device can be detachably mounted

ActiveUS7146113B2Sacrificing suitable stackingShorten the timeElectrographic process apparatusOther printing apparatusImage formationPath switching

An image forming apparatus is provided which includes an image formation unit for forming images on a recording medium; a first transporting path for discharging a recording medium to a sheet discharge device; a longer second transporting path for reversing the transportation direction of the recording medium; a transporting path switching unit for switching between the first transporting path or the second transporting path; a setting unit for setting the discharge speed for discharging the recording medium from the first and second transporting paths to a recording sheet stacking unit, and also setting the reverse transportation speed; and a determining unit for determining whether or not the sheet discharge device has been connected to the image forming apparatus; wherein the setting unit sets a first discharge speed slower than the reverse transportation speed in the event that the sheet discharge device has not been connected, and otherwise sets a faster second discharge speed.

Owner:CANON KK

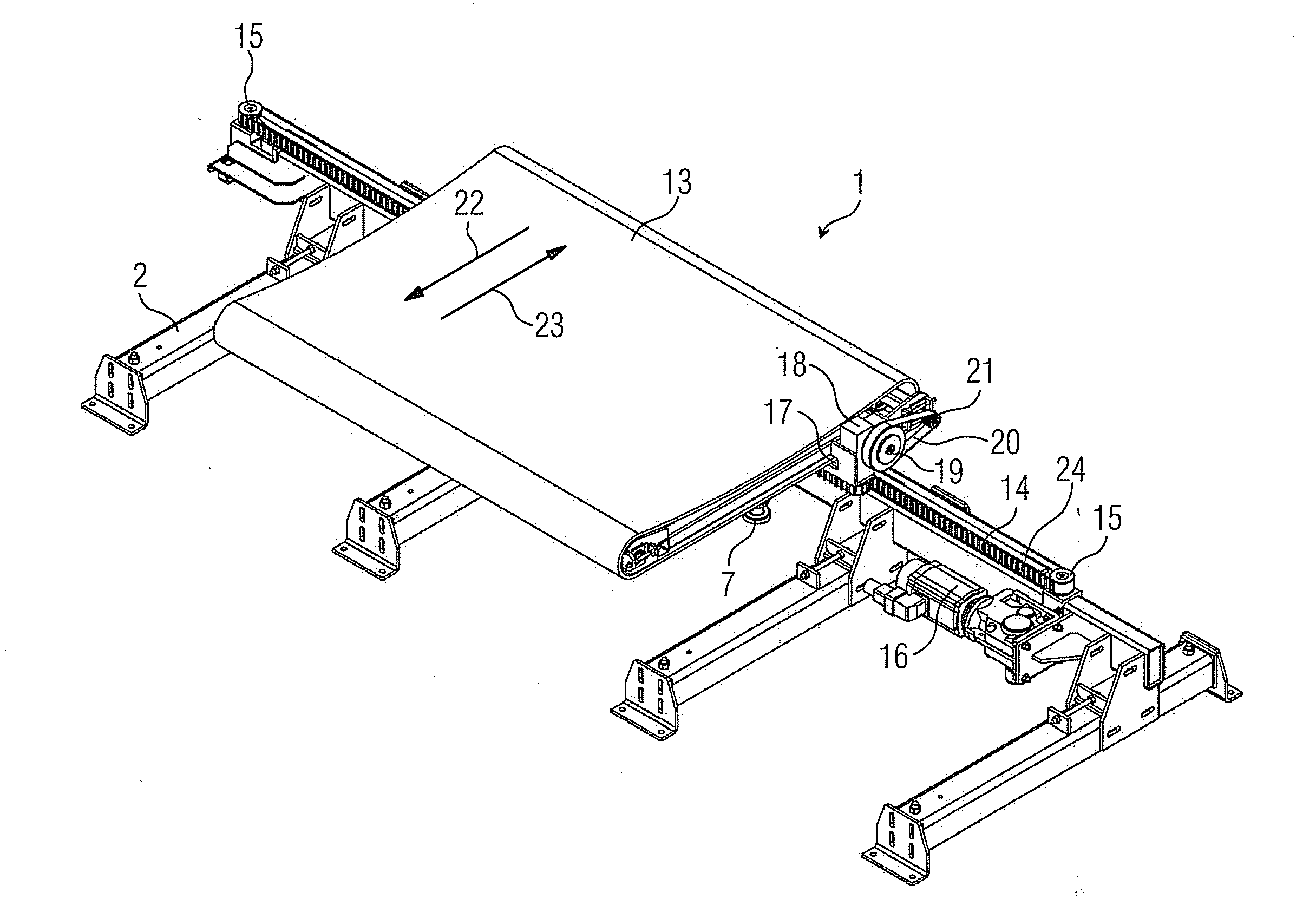

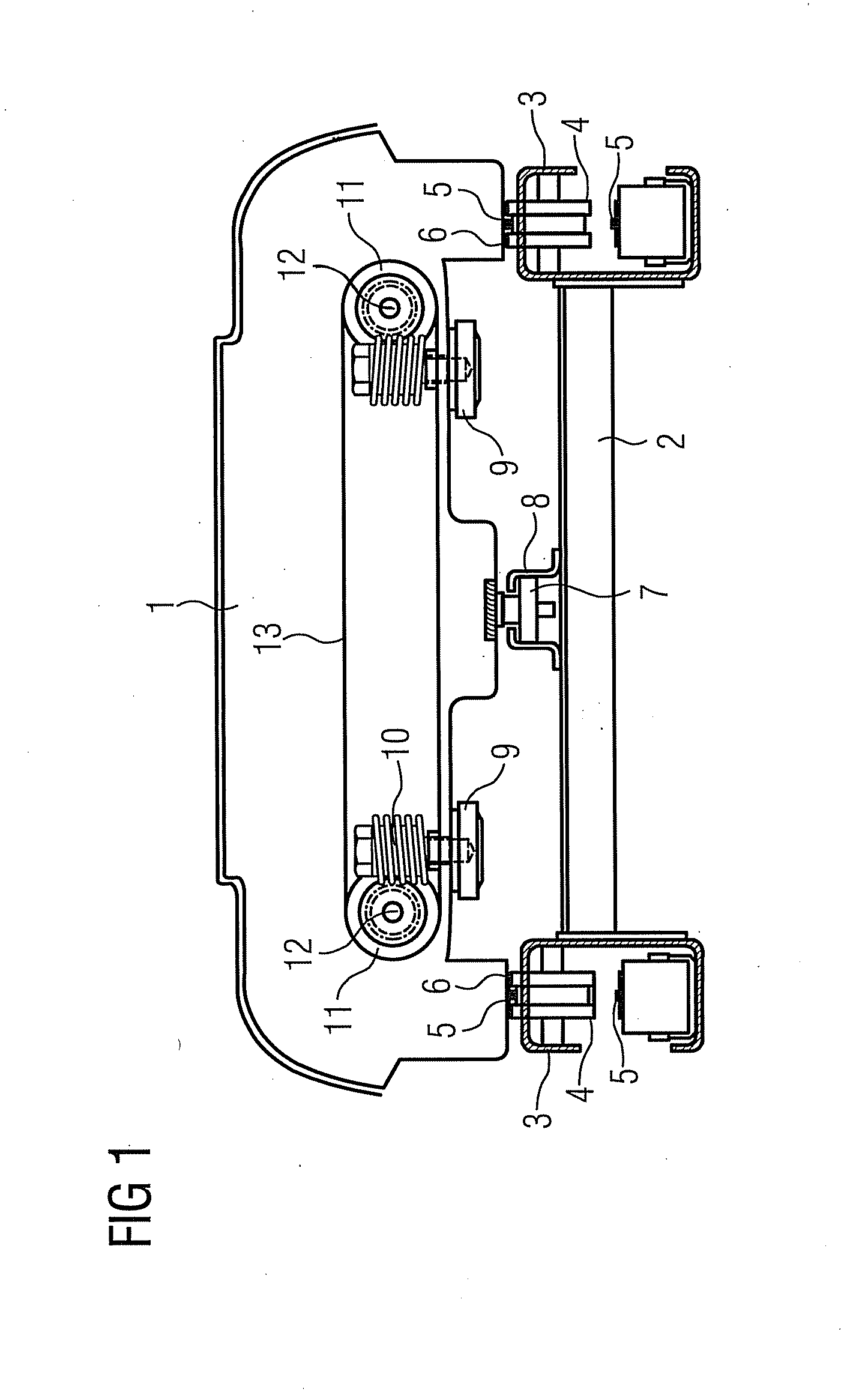

Container for Transporting Piece Goods, Particularly Pieces of Luggage

A loading and unloading station for a container that transports piece goods, particularly pieces of luggage on a conveyor belt is provided. The upper part of the container receiving the piece goods is formed by a storage surface for the piece goods, the surface including an continuous carrying belt spanning the lower part of the container and capable of bearing a load, the carrying belt is arranged transversely to the transport direction of the container and drivably guided around a plurality of deflection rollers provided on both sides of the container. A method for transporting piece goods on a conveyor track including supporting and guide elements for the container is also provided.

Owner:SIEMENS AG

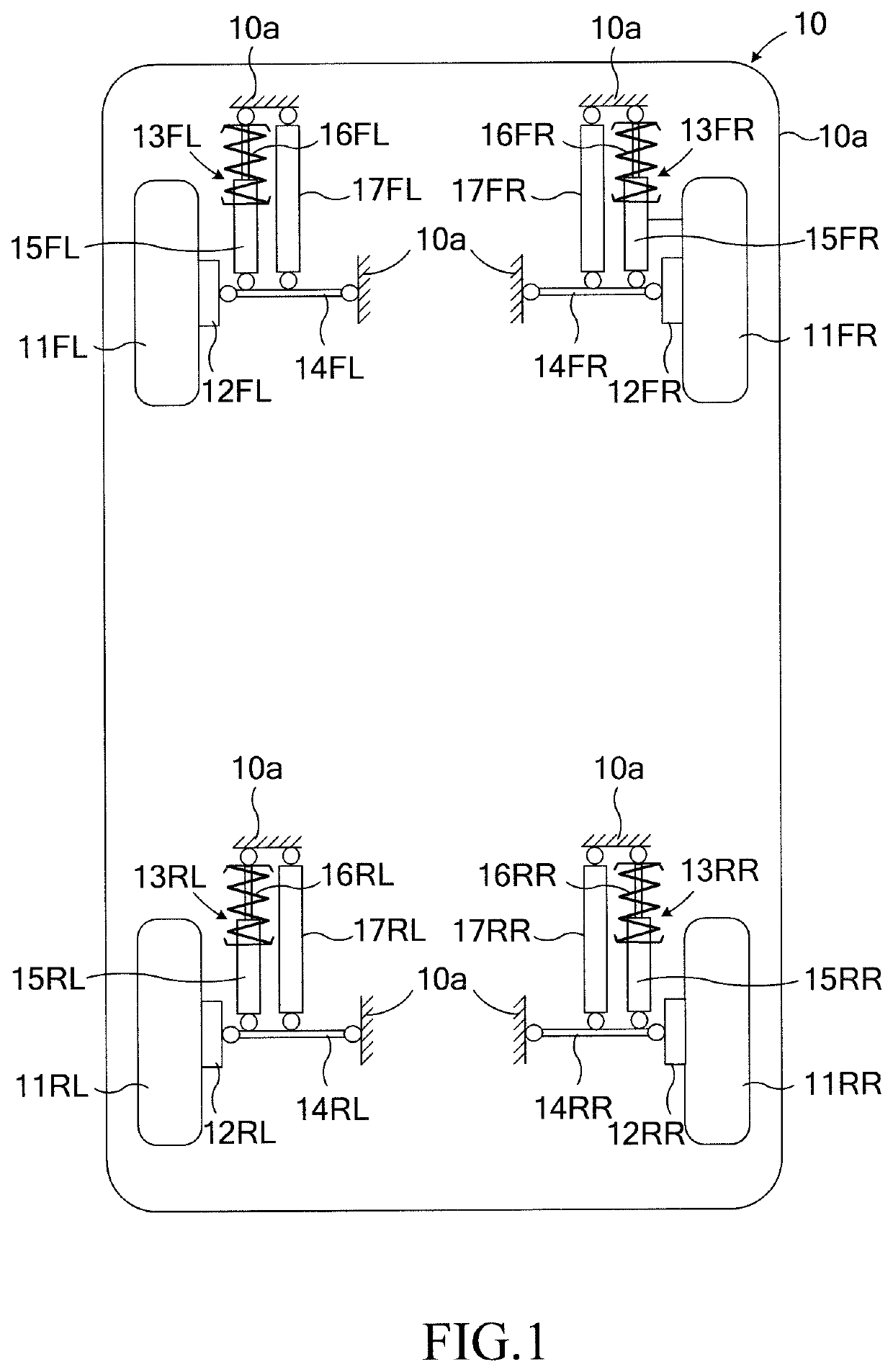

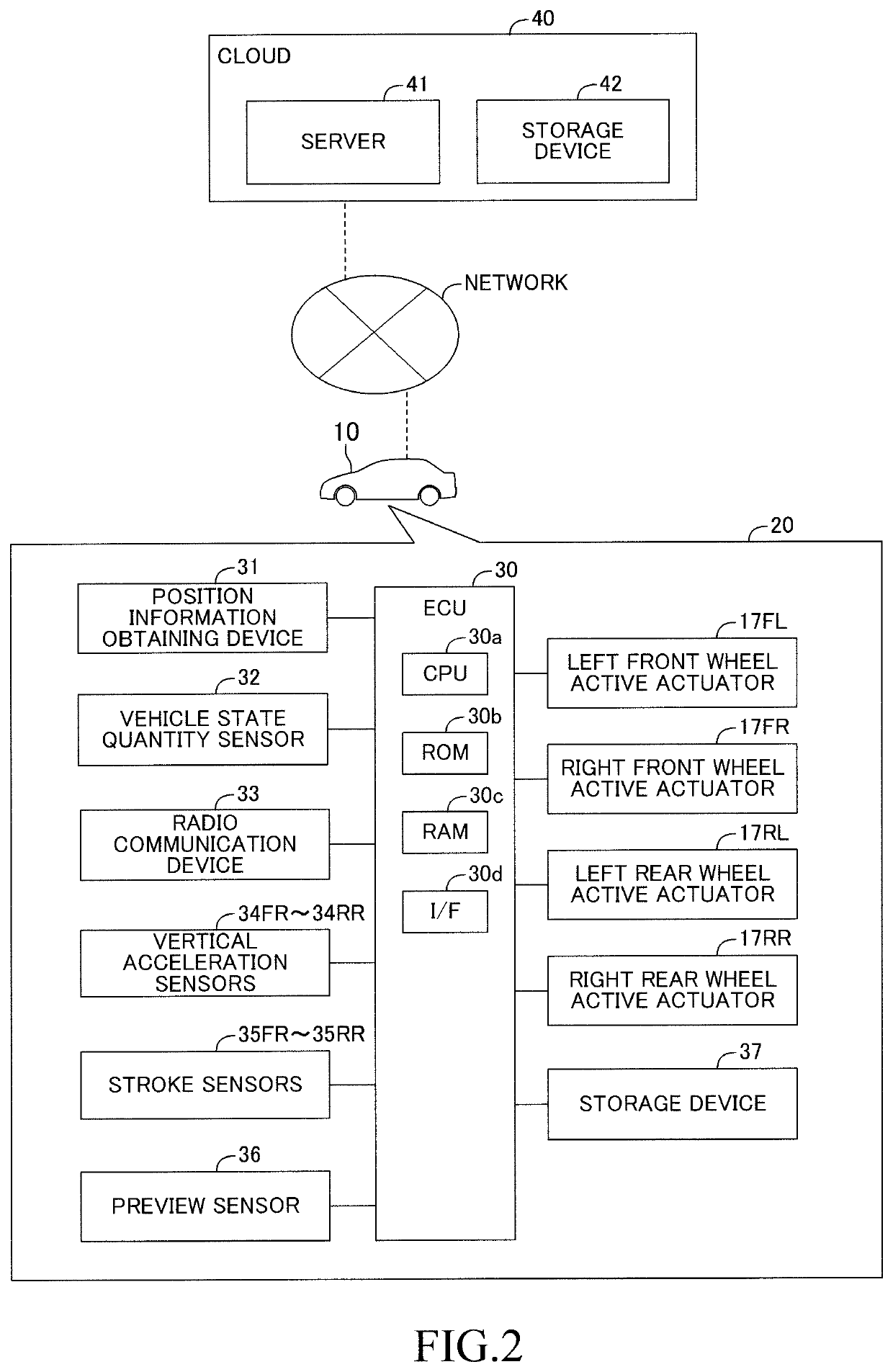

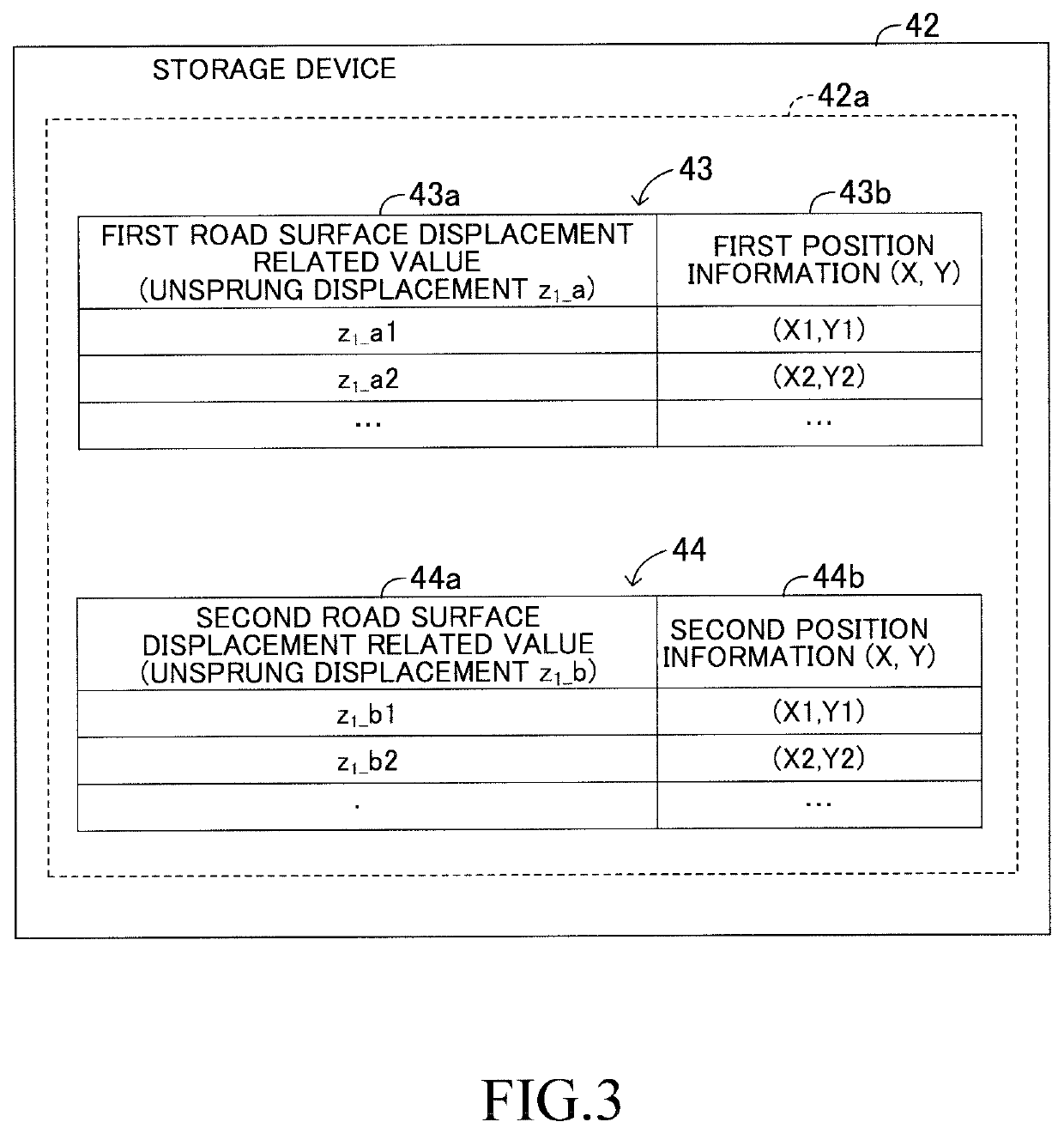

Vibration damping control apparatus

PendingUS20220111695A1Small scaleReduce the possibilityResilient suspensionsVehicle springsTarget controlClassical mechanics

A vibration damping control apparatus of a vehicle executes preview vibration damping control for controlling a control force generating apparatus on the basis of a final target control force including a first target control force computed by using preview information. When the vibration damping control apparatus determines that the probability that a road surface condition has changed after a past point in time is high, the vibration damping control apparatus executes particular control for setting the magnitude of the first target control force to become smaller.

Owner:TOYOTA JIDOSHA KK

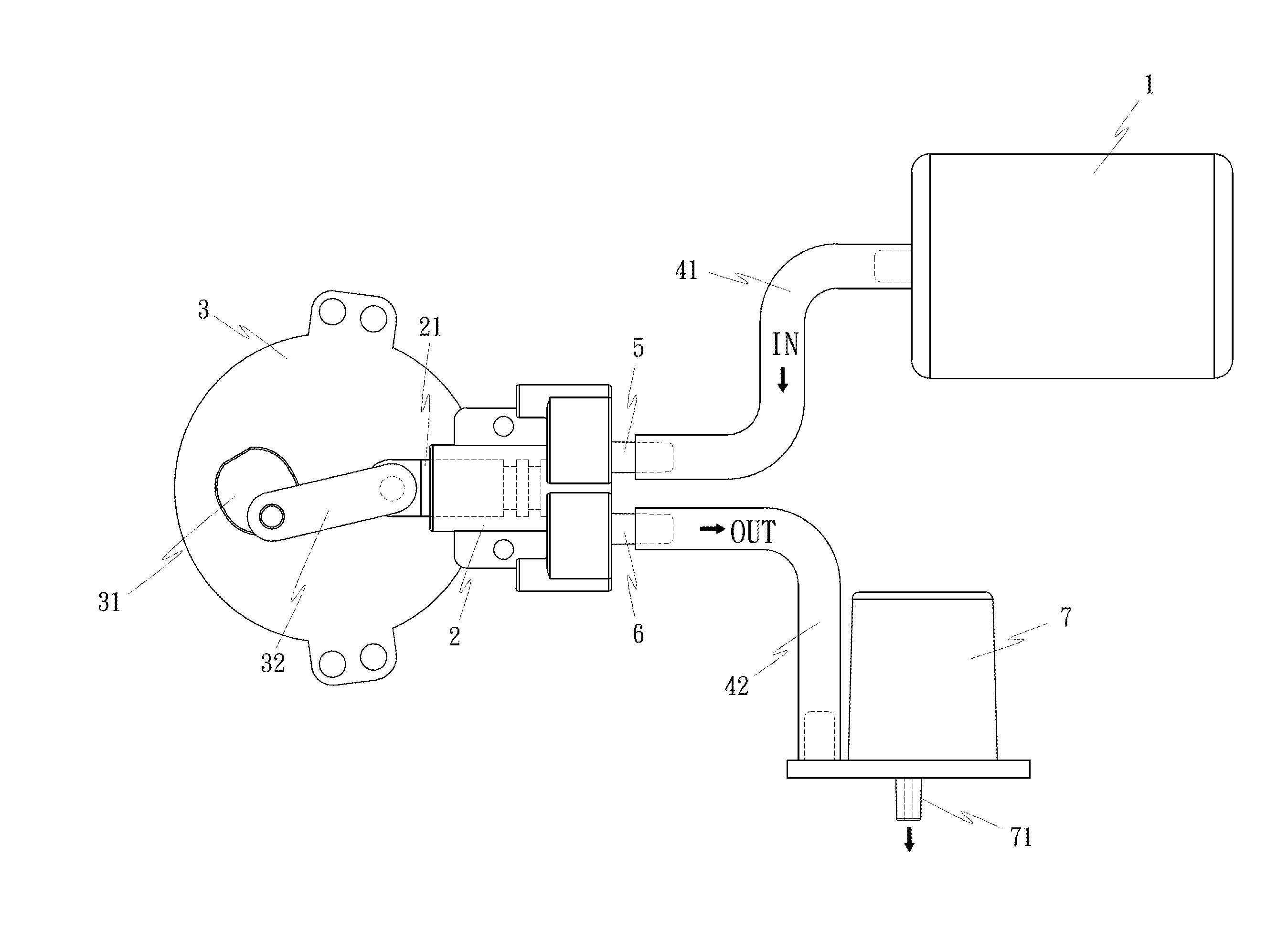

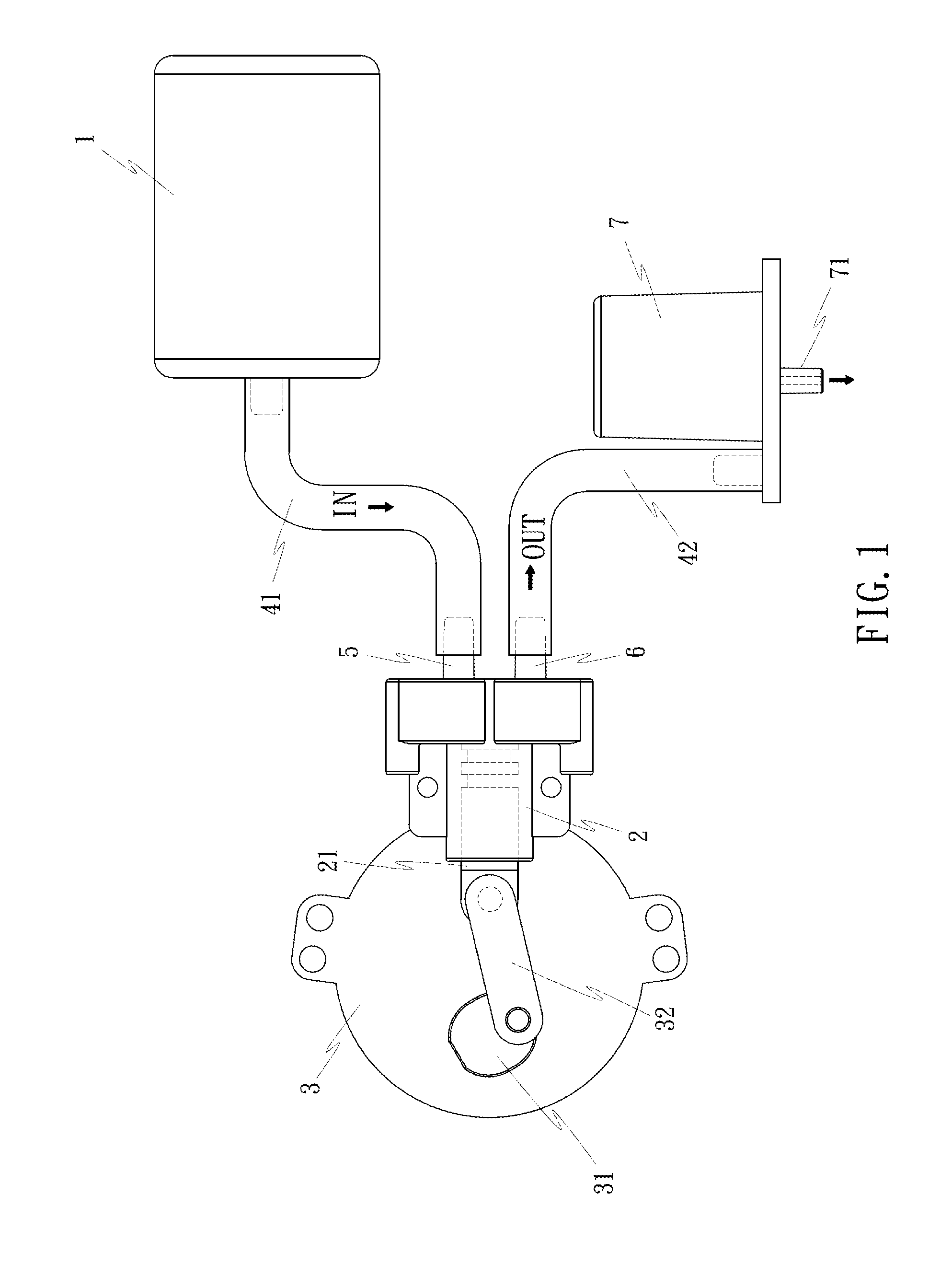

Water pump device for electric appliances

InactiveUS20130163968A1Easy to getAvoid accidentsSteam generation heating methodsSpray nozzlesSynchronous motorReciprocating motion

A water pump device for electric appliances includes a water container, a piston cylinder, and an AC synchronous motor. The piston cylinder includes a piston. The AC synchronous motor drives the piston to reciprocate. The water container supplies water through reciprocation of the piston driven by the AC synchronous motor. The water in the water container enters the piston cylinder for pressurization. The pressurized water enters a heating member of a steam generator to output high temperature and high pressure steam. The water pump device further includes a steam adjustment knob between the clockwise check valve and the piston cylinder. The steam adjustment knob can be turned to drive a cam which is used to change the movement route of the piston, so that the volume of the pressurized water can be adjusted for desired high temperature and high pressure steam.

Owner:HSU CHIH KAO

Control system and vehicle including the same

InactiveUS7753156B2Sure easyEasy to operateDigital data processing detailsSteering initiationsLow speedWheel speed sensor

A control system for a vehicle includes an ECU, a front wheel speed sensor, a rear wheel speed sensor, and an engine. The ECU detects an actual slip speed and an actual slip ratio of a rear wheel on the basis of respective detected values of a front wheel speed sensor and a rear wheel speed sensor. Slip speed traction control is started when the actual slip speed exceeds a threshold value of a slip speed when a vehicle is at a low speed, and slip ratio traction control is started when the actual slip ratio exceeds a threshold value of a slip ratio when it is at an intermediate or high speed. An output of the engine is adjusted depending on the actual slip speed in the slip speed traction control, while being adjusted depending on the actual slip ratio in the slip ratio traction control.

Owner:YAMAHA MOTOR CO LTD

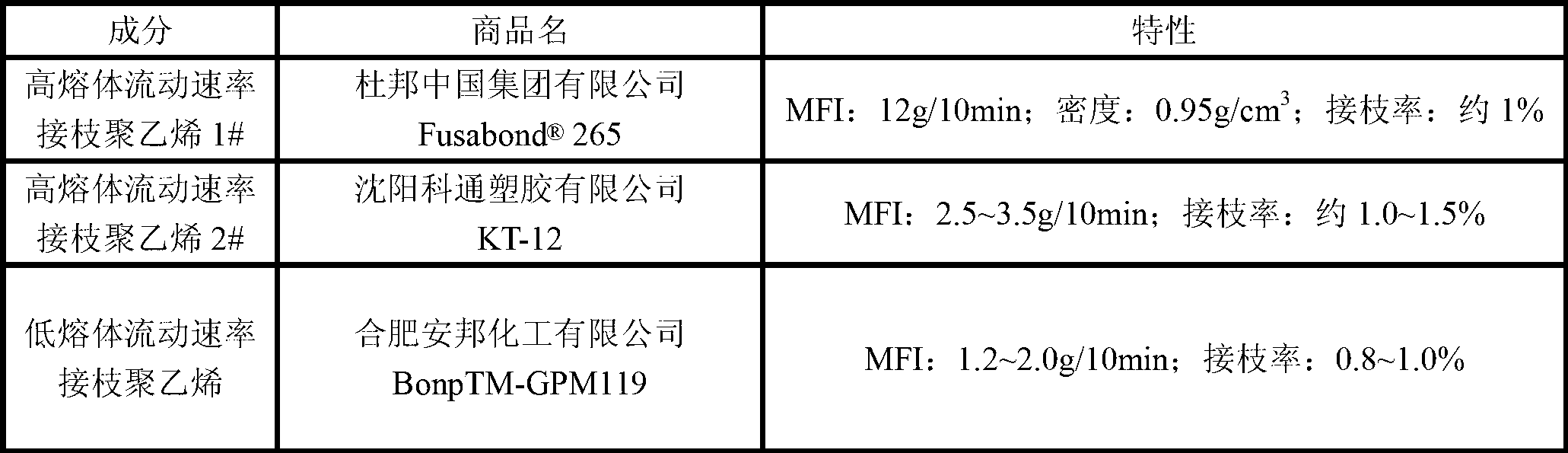

Novel positive-temperature-coefficient thermistor element core layer material and application thereof

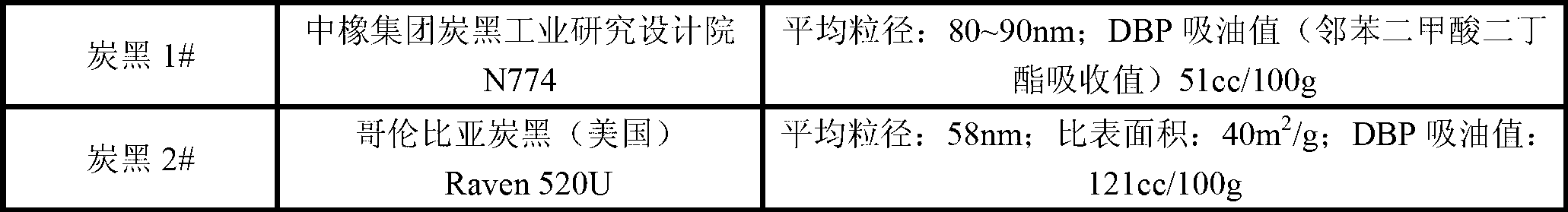

ActiveCN103013019AAppropriate temperatureAppropriate speedPositive temperature coefficient thermistorsMaleic anhydridePolypropylene

The invention relates to the field of thermistors, and particularly relates to a positive-temperature-coefficient thermistor element core material and a preparation method thereof. The positive-temperature-coefficient thermistor element core material disclosed by the invention is prepared from the following raw material constituents: 41-54wt% of a polymer base material and 46-59 wt% of a conductive filler; the polymer base material is formed by mixing a graft polymer with a high melt flow rate with a graft polymer with a low melt flow rate; and the graft polymer is selected from one or the combination of more than two of graft polyolefin, graft polyolefin copolymer and graft polyolefin derivative, and the graft group of the graft polymer is a polar group. According to the invention, by using two types of maleic anhydride-grafted high-density polypropylene with different melt flow rates together, processing performance can be improved, room-temperature resistivity can be reduced and production efficiency can be increased; and the two types of maleic anhydride-grafted high-density polypropylene is prepared into an annular positive-temperature-coefficient thermistor element which is good in electrical performance, high in PTC (positive-temperature-coefficient) strength and the like.

Owner:SHANGHAI KETER POLYMER MATERIAL

Aircraft engine and associated method for driving the fan with the low pressure shaft during taxi operations

ActiveUS10336461B2Increase consumptionWeight increasePower installationsEnergy efficient operational measuresCombustorHigh pressure

An aircraft engine, an electric taxi system and a corresponding method are provided to facilitate taxiing without operation of the core gas turbine engine by driving the fan assembly with the electric taxi system during taxi operations. An aircraft engine is provided that includes a core gas turbine engine including a compressor, a combustor and a high pressure turbine. The aircraft engine also includes a fan assembly coupled to the core gas turbine engine. The aircraft engine further includes an electric taxi system coupled to the fan assembly. The electric taxi system includes an energy storage device and a motor responsive to energy provided by the energy storage device. The motor is coupled to the fan assembly and is configured to drive the fan assembly during taxi operations.

Owner:THE BOEING CO

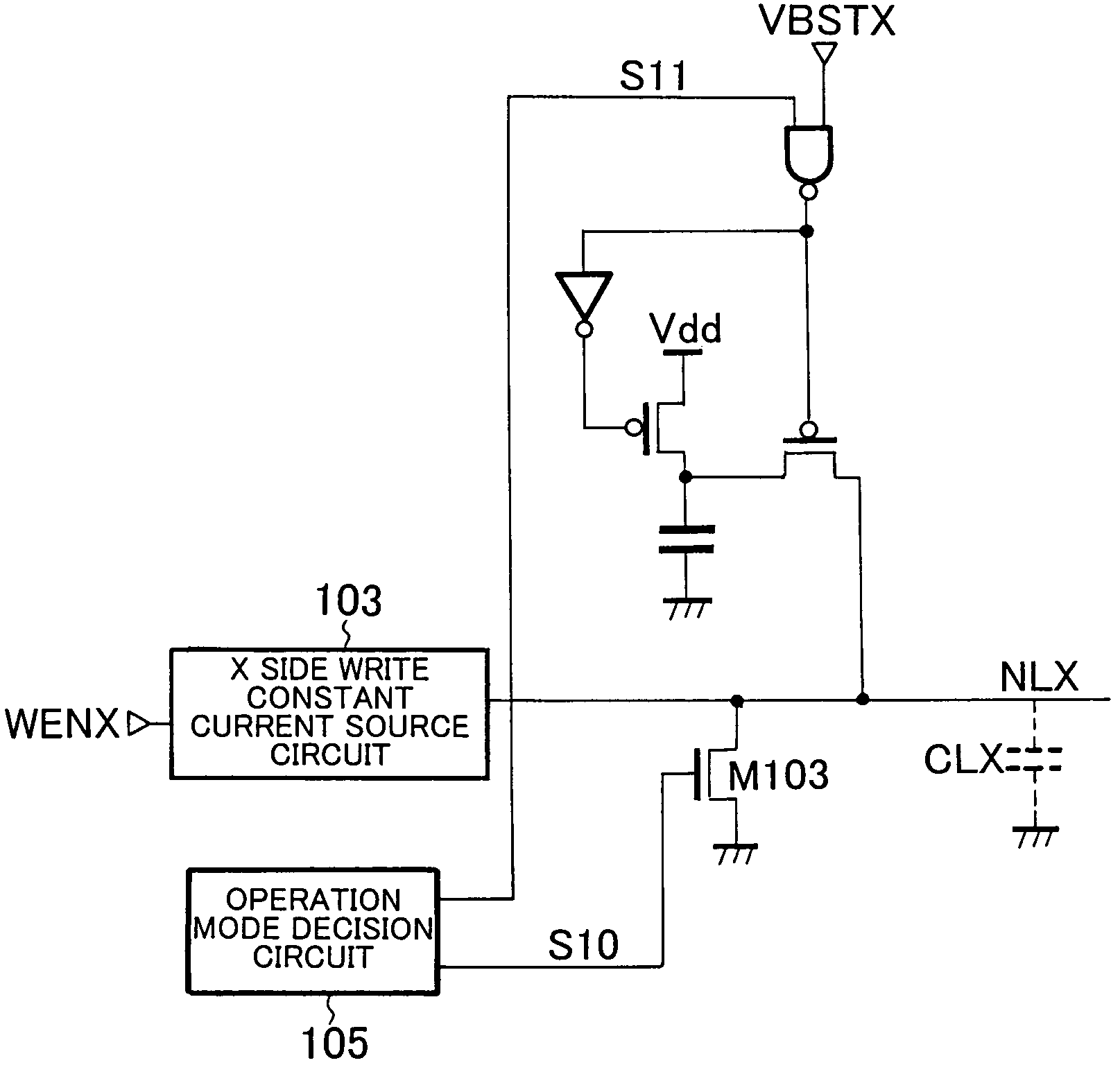

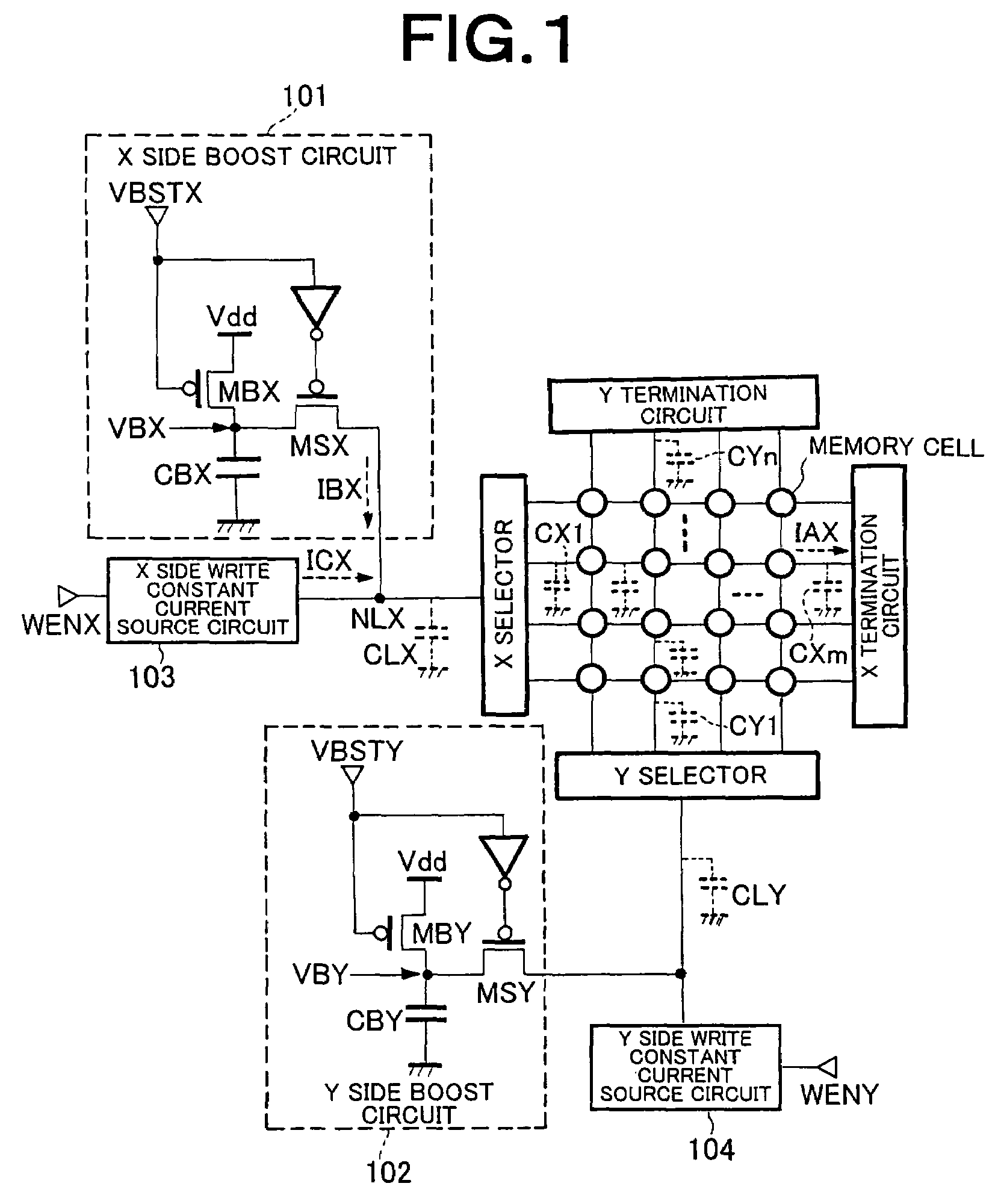

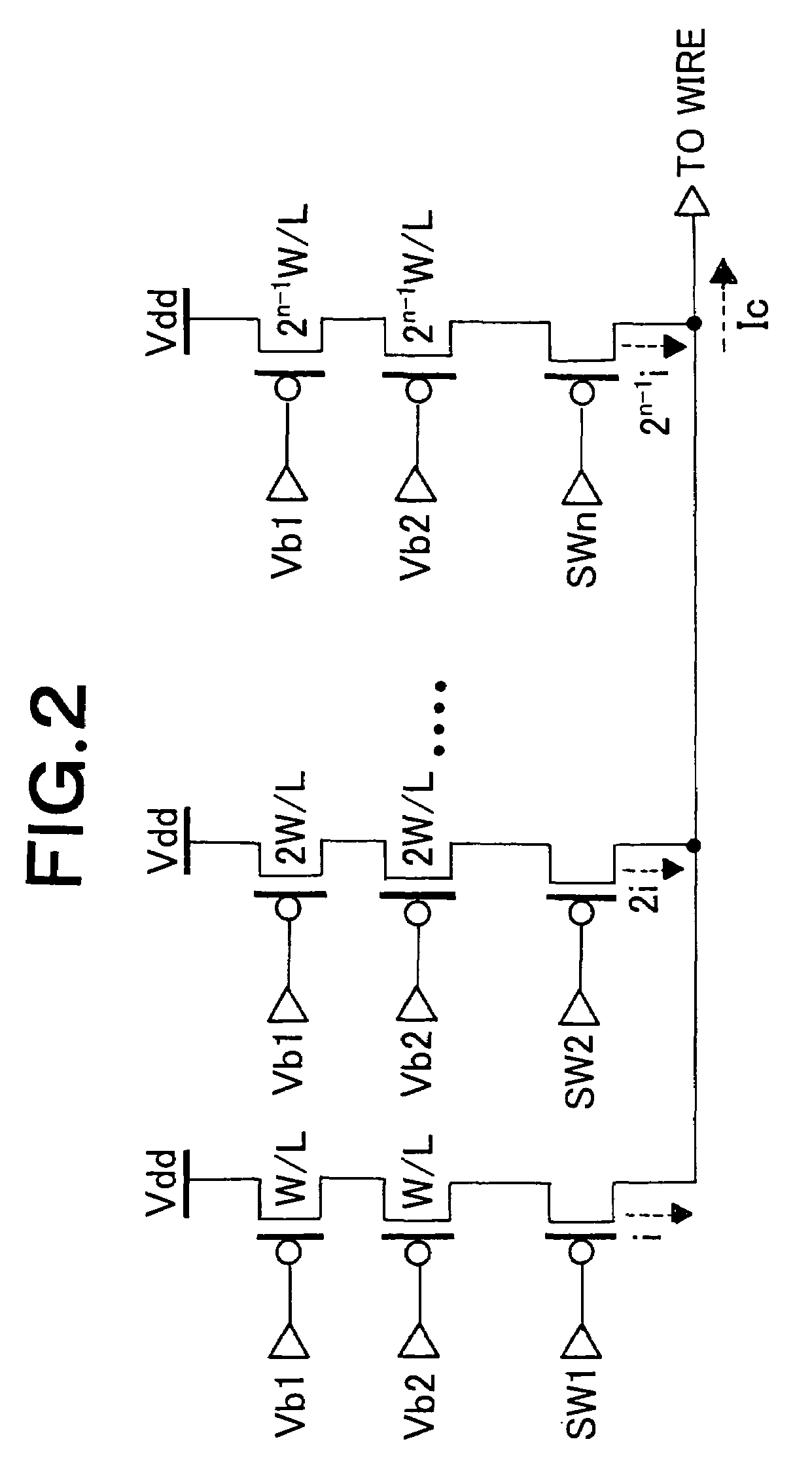

Semiconductor storage apparatus

ActiveUS7301829B2Minimize impactWrite current flow in a short timeDigital storageParasitic capacitanceHemt circuits

A semiconductor memory device in which information is written into a storage element by flowing current. The semiconductor memory device has a shortened write speed and reduced power consumption by preventing parasitic capacitors from prolonging the time required for a write current to reach a predetermined value. The semiconductor memory device includes storage elements for storing information, a constant current source for writing information into the storage element by flowing current, and a boost circuit for charging parasitic capacitors by a time when an amount of a current flowed by the constant current source reaches an amount of a current required to write information into the storage element, at a predetermined position related to the storage element.

Owner:NEC CORP

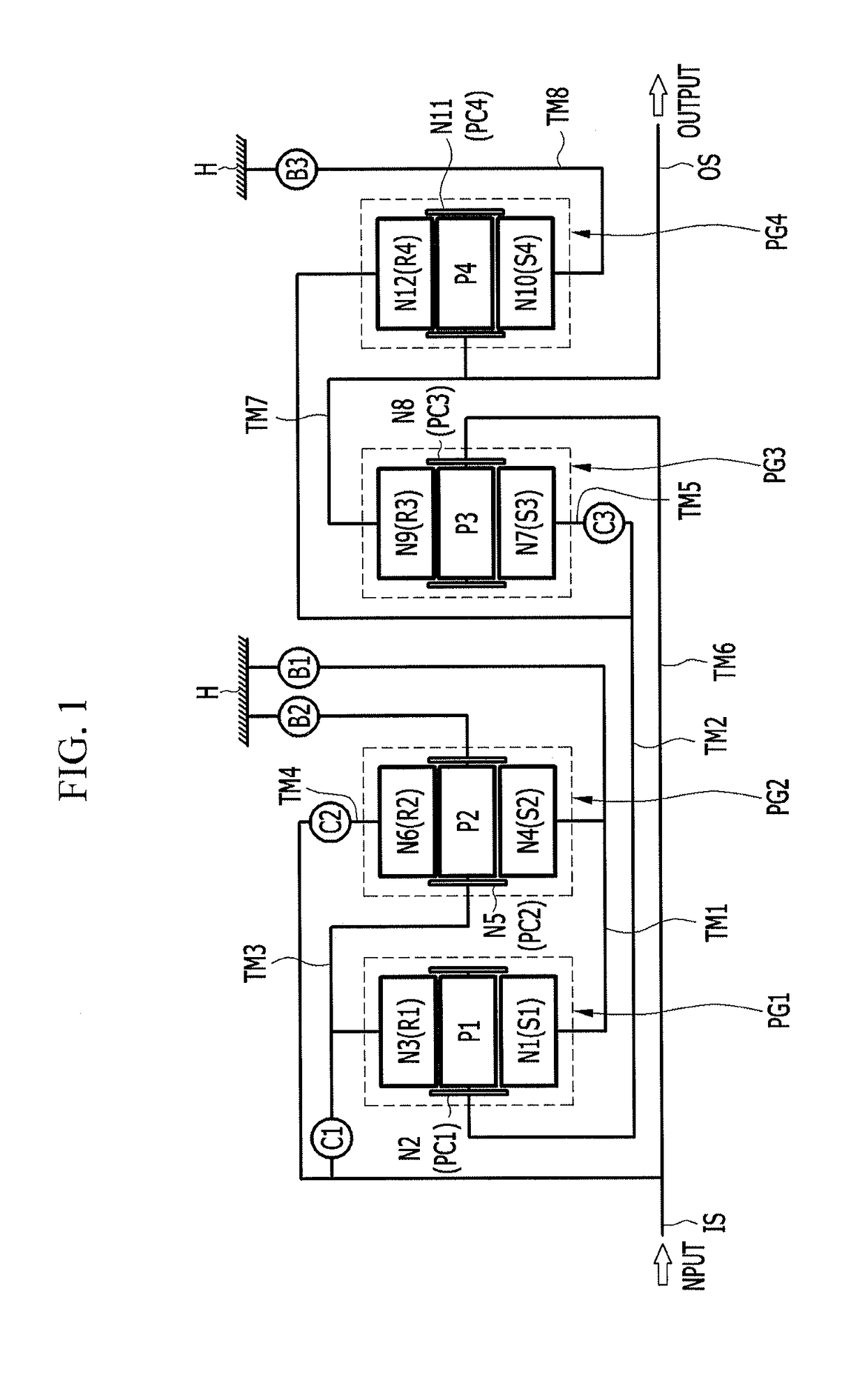

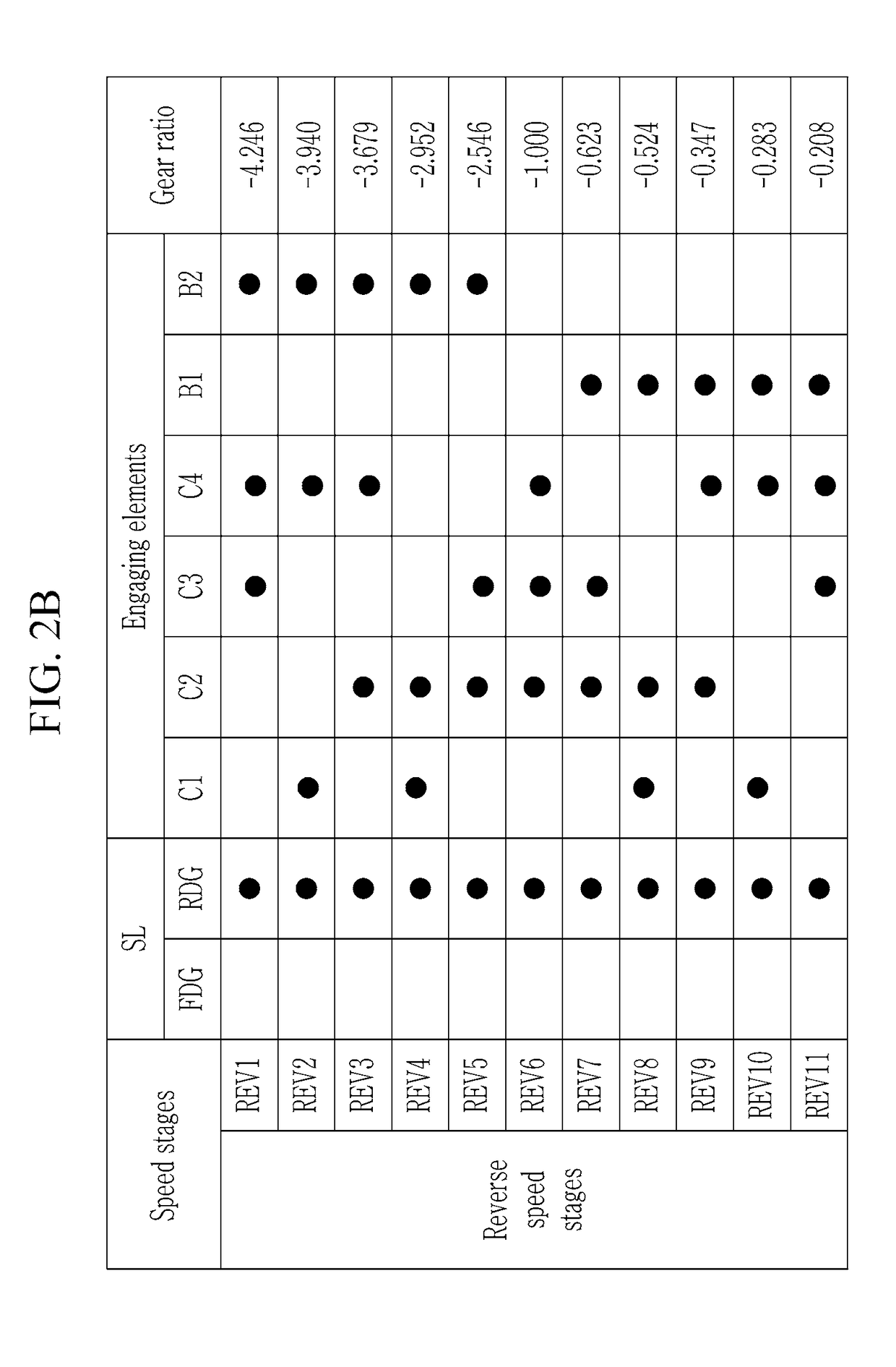

Planetary gear train of automatic transmission for vehicle

ActiveUS20190085959A1Improve fuel economyImproving power delivery performanceToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for a vehicle may include: an input shaft receiving torque of an engine; an output shaft outputting torque; a direction changer disposed on an input shaft side and transmitting the torque of the engine to the input shaft with or without change of rotation direction, or disposed on an output shaft side and outputting the torque of the output shaft with or without change of rotation direction; a first planetary gear set including first, second and third rotation elements; a compound planetary gear set including fourth, fifth, sixth, and seventh rotation elements by combining second and third planetary gear sets; a fourth planetary gear set including eighth, ninth, and tenth rotation elements.

Owner:HYUNDAI MOTOR CO LTD +1

Non quenched and tempered steel and manufacturing process thereof

InactiveUS20160208358A1Quality improvementEnsure uniformityCrucible furnacesHeat treatment process controlCore temperatureMechanical property

A non quenched and tempered steel and manufacturing process thereof. The process comprises a cooling step after the finish rolling step; and the process utilizes alternate intense cooling and moderate cooling. The intense cooling can ensure the surface temperature of the steel to decrease rapidly; and the moderate cooling allows the core temperature of the steel to dissipate gradually to the surface; a further intense cooling is carried out to allow rapid heat dissipation. The intense cooling and the moderate cooling can be carried out alternately several times according to practical requirement. A water cooling mode combining intense cooling and moderate cooling allows the core temperature and the surface temperature of the steel to become the same within a short time, and thus ensures the uniformity of the mechanical properties of the steel and improves the production efficiency.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

System and method for performing directed self-assembly in a 3-D virtual fabrication environment

ActiveUS9965577B2Appropriate speedProgramme controlComputer controlEngineeringDirected self assembly

The modeling of a DSA step within a virtual fabrication process sequence for a semiconductor device structure is discussed. A 3D model is created by the virtual fabrication that represents and depicts the possible variation that can result from applying the DSA step as part of the larger fabrication sequence for the semiconductor device structure of interest. Embodiments capture the relevant behavior caused by polymer segregation into separate domains thereby allowing the modeling of the DSA step to take place with a speed appropriate for a virtual fabrication flow.

Owner:COVENTOR

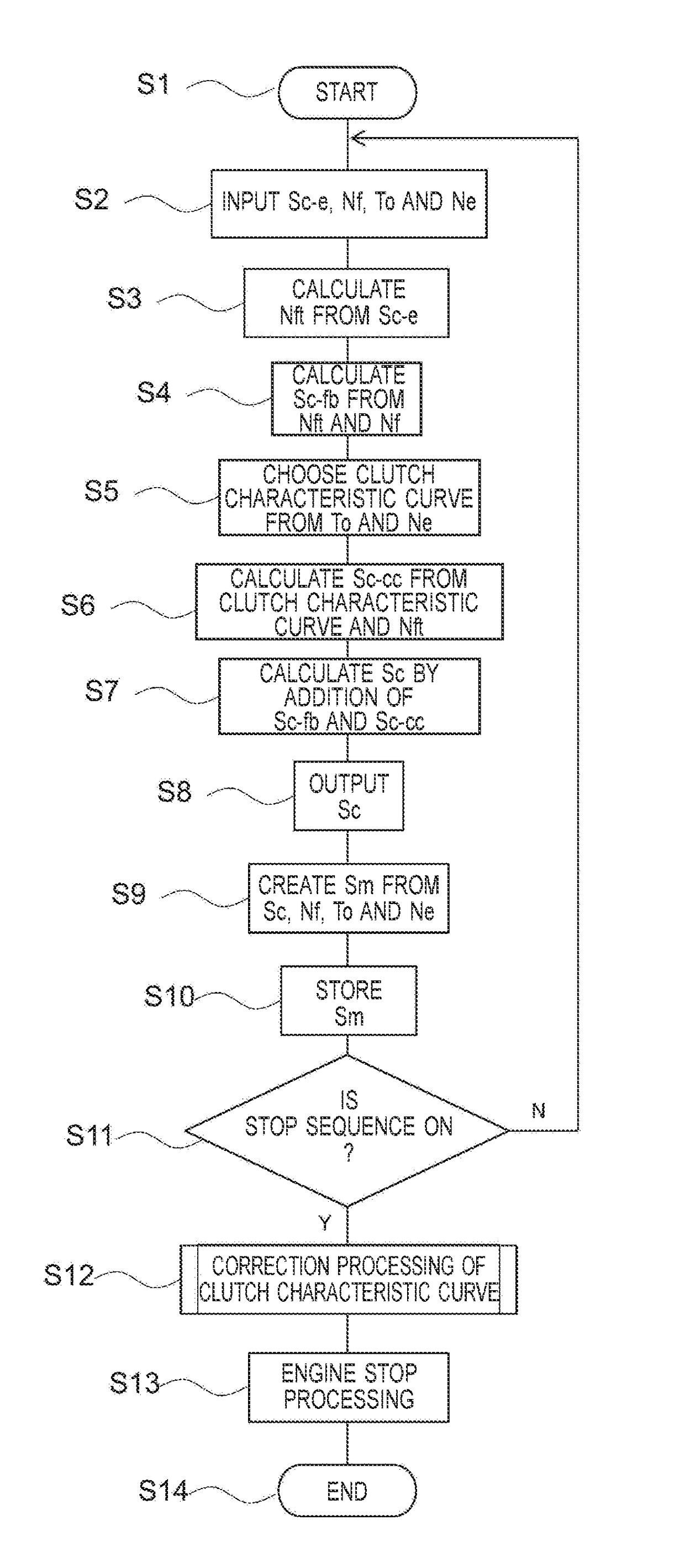

Clutch control device for work machine

ActiveUS20180087587A1Appropriate speedClutchesTemperature control using plurality of sensorsClutch controlControl signal

Provided is a clutch control device for a work machine capable of controlling a fan to an appropriate rotational speed. In the clutch control device for the work machine, a controller includes a target fan rotational speed calculation module that calculates a target fan rotational speed for the fan, a clutch characteristic curve storage module that stores a plurality of clutch characteristic curves, a clutch command calculation module that outputs with reference to a clutch characteristic curve a first clutch control signal corresponding to the target fan rotational speed, a feedback control module that output a second clutch control signal based on the difference between the target fan rotational speed and an actual fan rotational speed, and an adder that adds the first clutch control signal and the second clutch control signal to output a third clutch control signal.

Owner:NIHON KENKI CO LTD

Non quenched and tempered steel and manufacturing process thereof

InactiveUS20160230247A1Disadvantageous effectHigh purityTemperature control deviceWork treatment devicesCore temperatureMechanical property

A non quenched and tempered steel and manufacturing process thereof. The process comprises a cooling step after the finish rolling step; and the process utilizes alternate intense cooling and moderate cooling. The intense cooling can ensure the surface temperature of the steel to decrease rapidly; and the moderate cooling allows the core temperature of the steel to dissipate gradually to the surface; a further intense cooling is carried out to allow rapid heat dissipation. The intense cooling and the moderate cooling can be carried out alternately several times according to practical requirement. A water cooling mode combining intense cooling and moderate cooling allows the core temperature and the surface temperature of the steel to become the same within a short time, and thus ensures the uniformity of the mechanical properties of the steel and improves the production efficiency.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

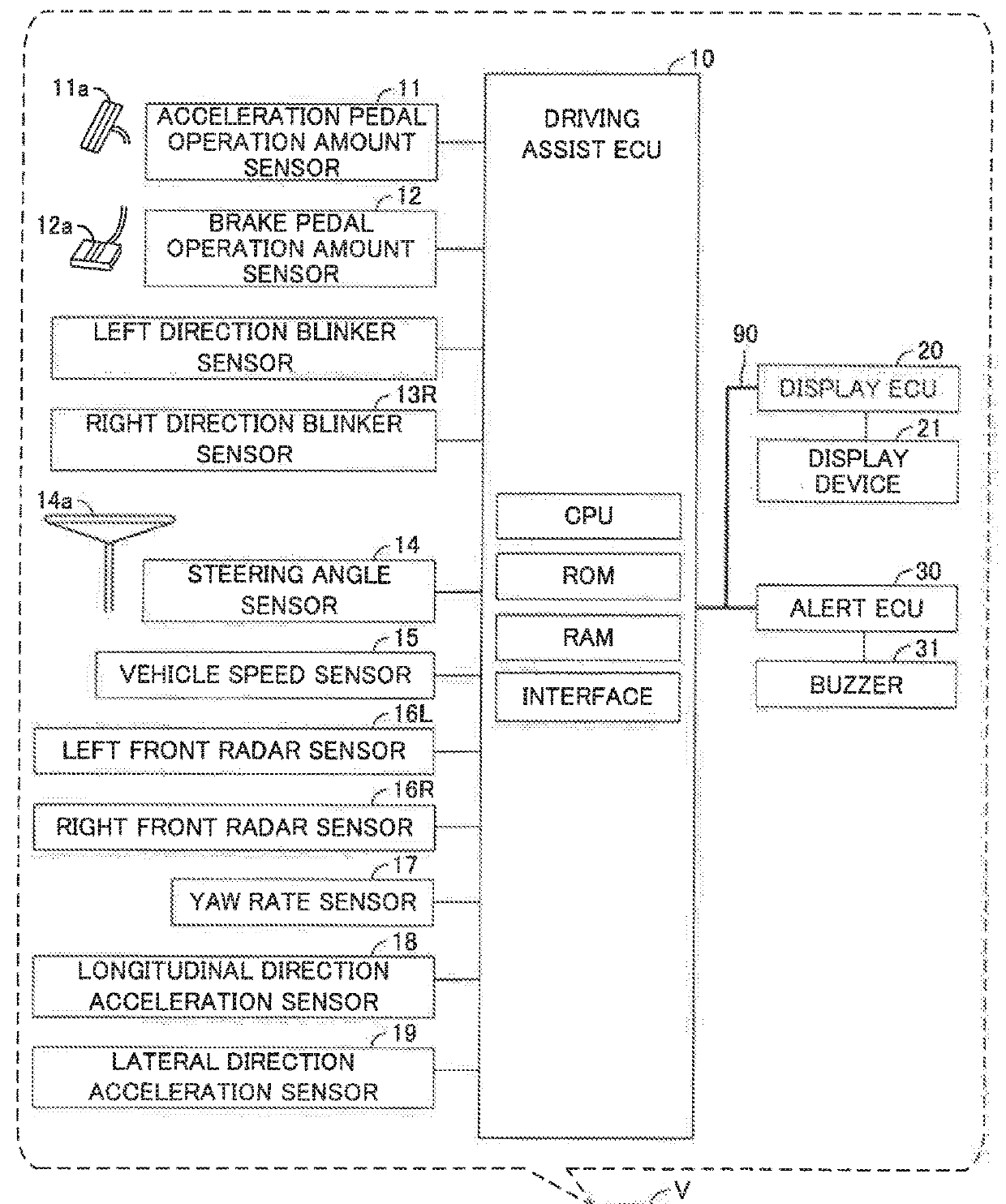

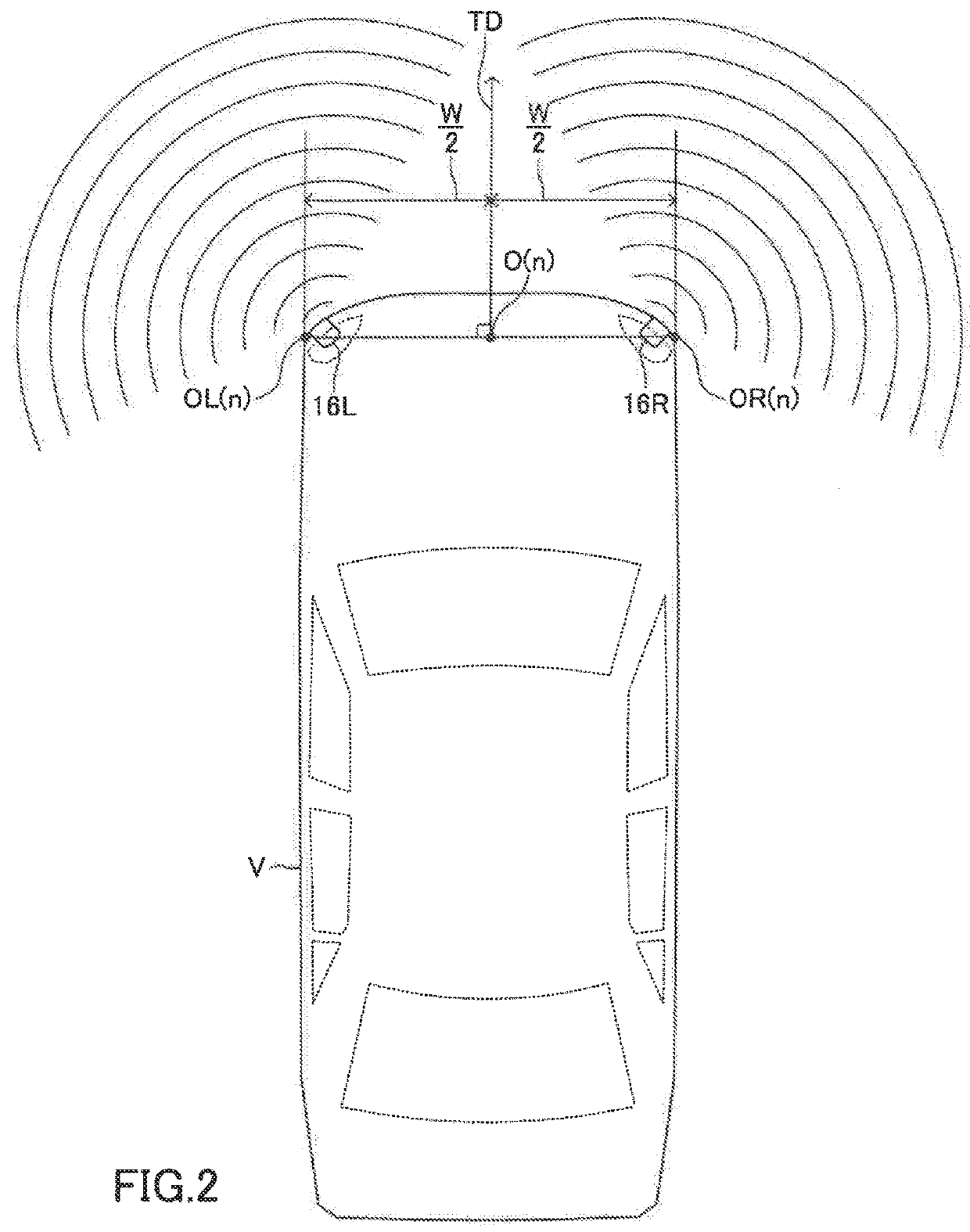

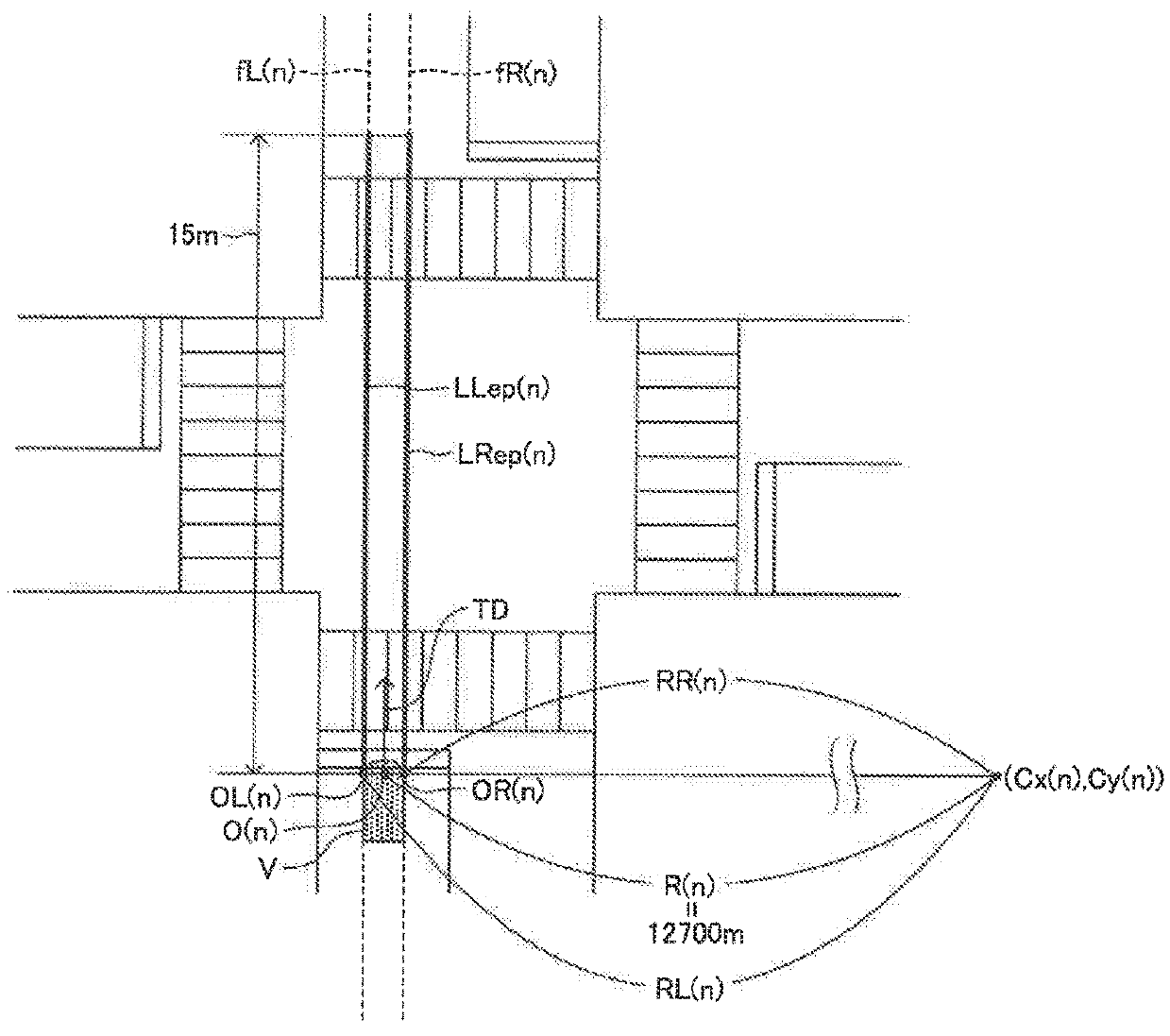

Driving assist apparatus of vehicle

ActiveUS20180178841A1Easy to understandAppropriate speedAnti-collision systemsVehicle sub-unit featuresEngineeringTurning radius

A driving assist apparatus of a vehicle of the invention sets a predicted route predicted for the vehicle to move and performs an attention operation to a driver when a time predicted for the vehicle to reach a point where a moving object crosses the predicted route is smaller than or equal to a threshold time. The apparatus predicts a radius of a route predicted for the vehicle to move as a left turn radius when the vehicle turns left and sets a route curved along an arc having the left turn radius as the predicted route. The apparatus predicts the radius of the route predicted for the vehicle to move as a right turn radius when the vehicle turns right and sets the route curved along the arc having the right turn radius as the predicted route.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com