Water pump device for electric appliances

a technology for electric appliances and water pumps, which is applied in the direction of lighting and heating apparatus, heating types, separation processes, etc., can solve the problems of increasing assembly cost and difficulty, not compact, and alternating current of power supplies that must be converted into direct current, so as to avoid any accidents and get easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

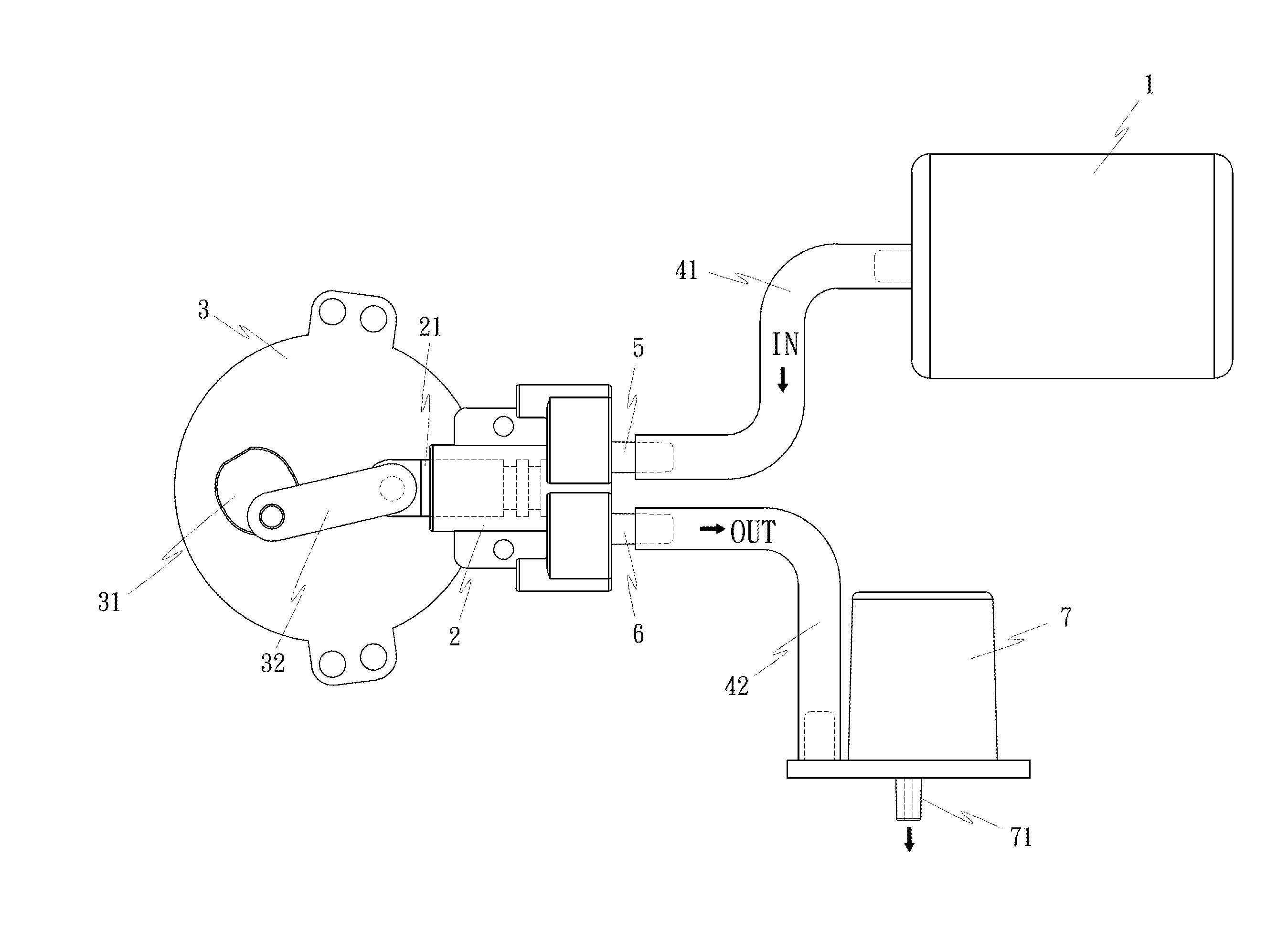

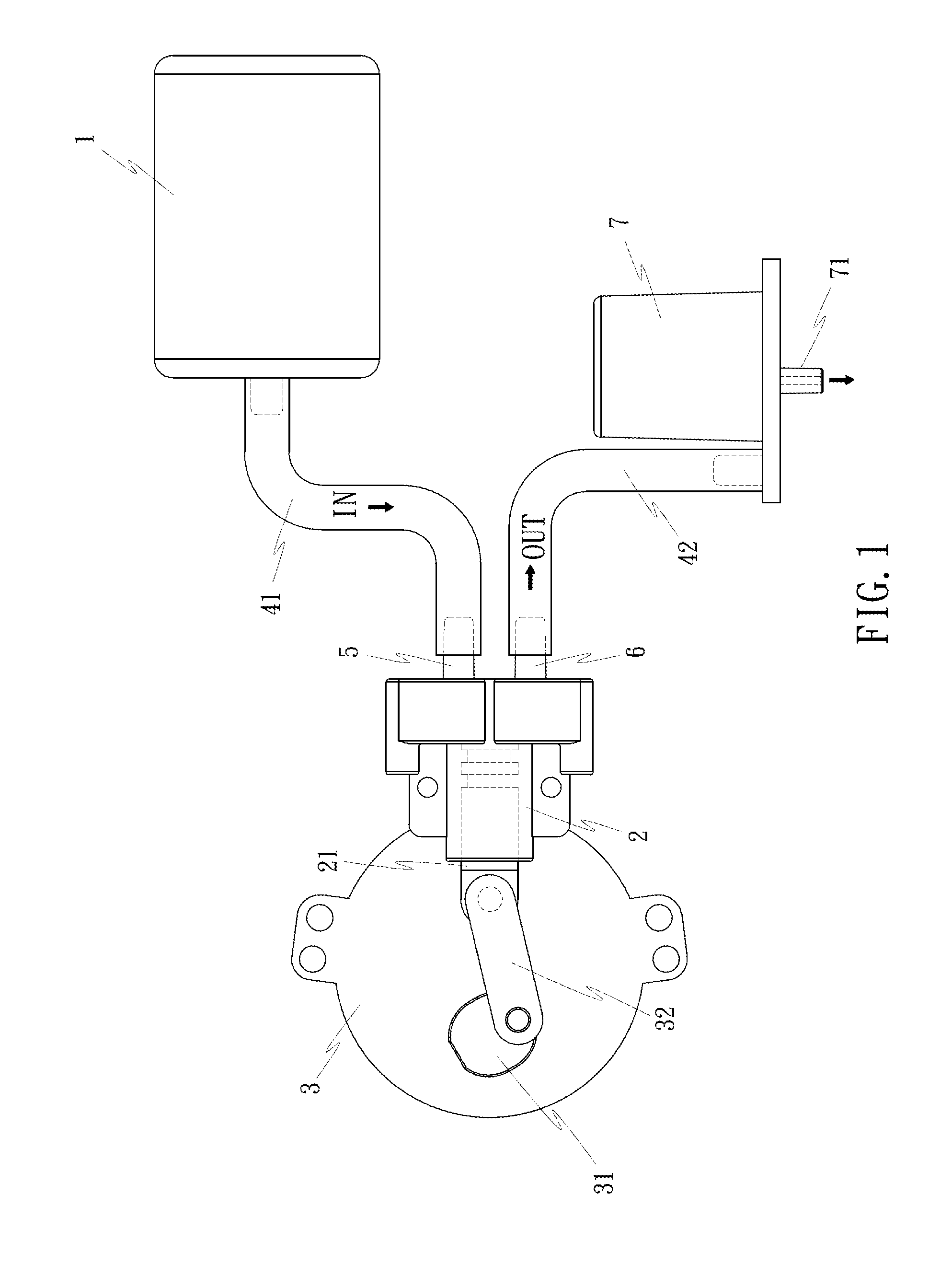

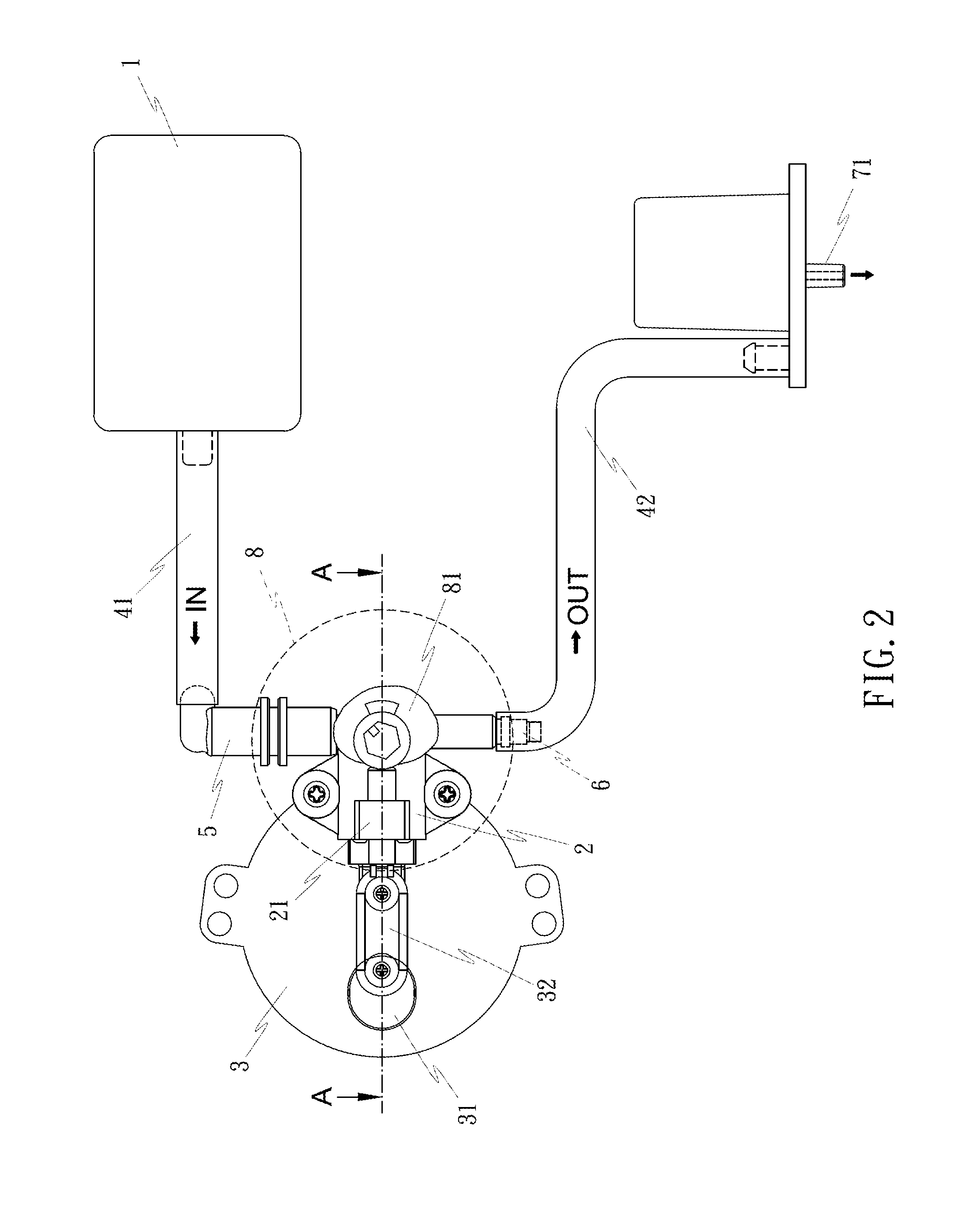

[0016]As shown in FIG. 1, the water pump device for electric appliances according to a preferred embodiment of the present invention comprises a water container 1, a piston cylinder 2, and an AC synchronous motor 3.

[0017]The water container 1 is used to store water. An inlet pipe 41 is connected between the water container 1 and an inlet end of the piston cylinder 2. A clockwise check valve 5 is provided between the inlet pipe 41 and the inlet end of the piston cylinder 2.

[0018]The piston cylinder 2 comprises a piston 21 therein. The piston 21 is driven by the AC synchronous motor 3. The piston cylinder 2 has an outlet end which is connected with an outlet pipe 42. A counterclockwise check valve 6 is provided between the outlet pipe 42 and the outlet end of the piston cylinder 2. Another end of the outlet pipe 42 is connected to a heating member 7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com