Patents

Literature

31results about How to "Play a pore-forming role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

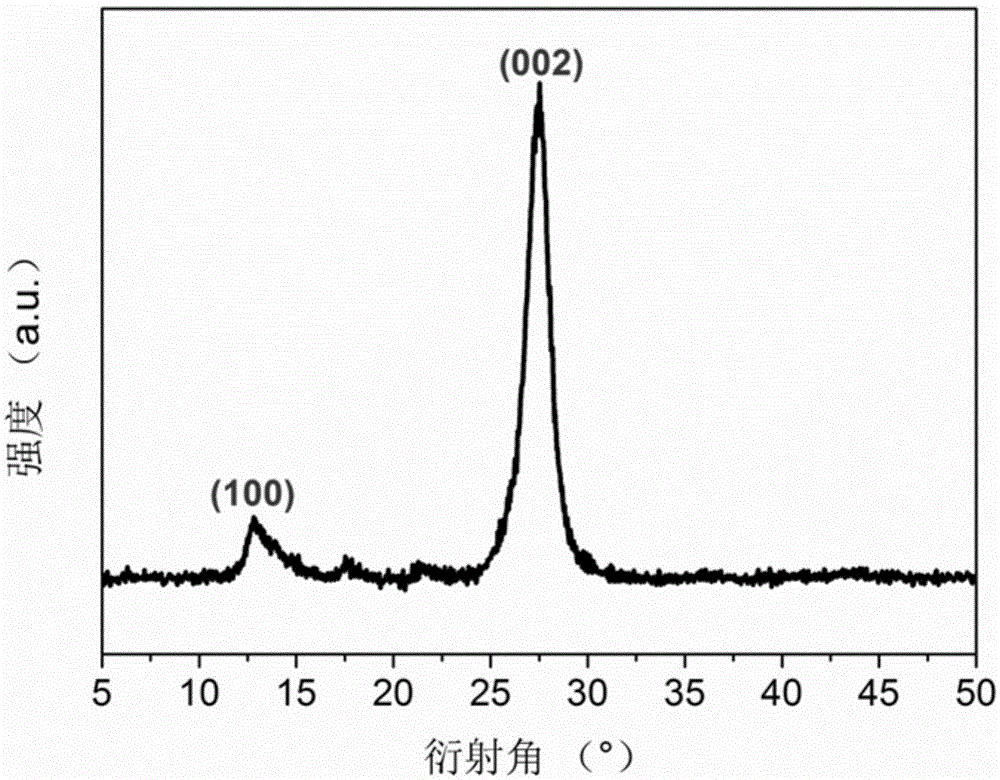

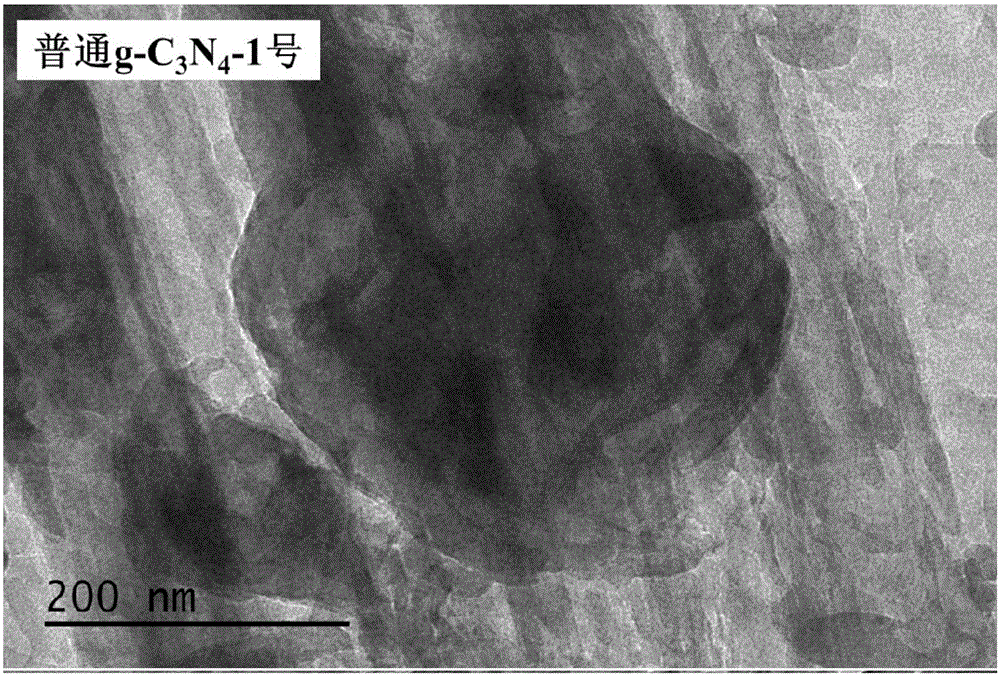

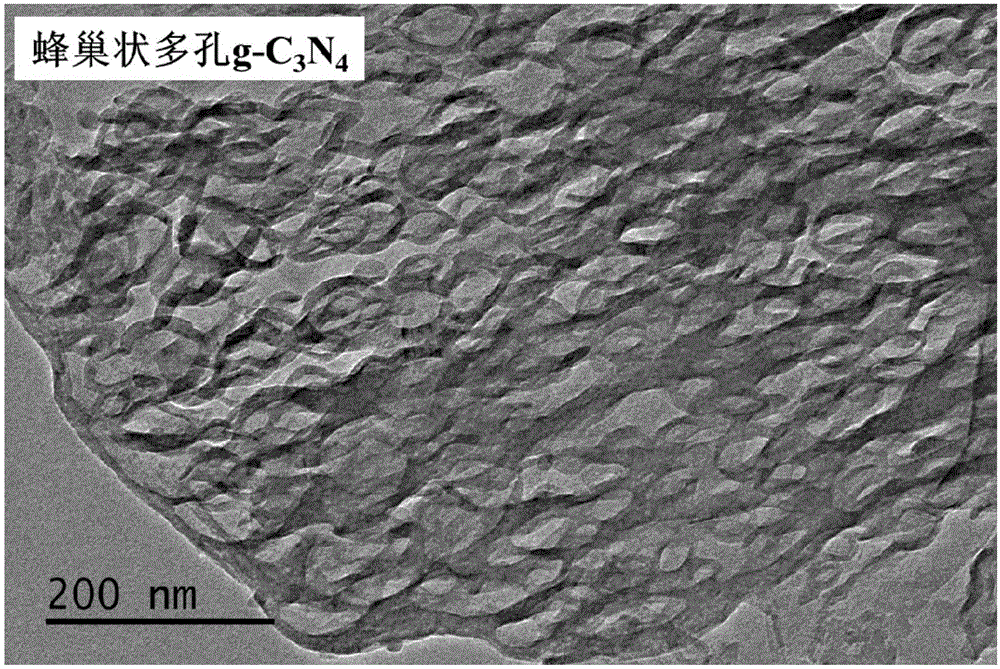

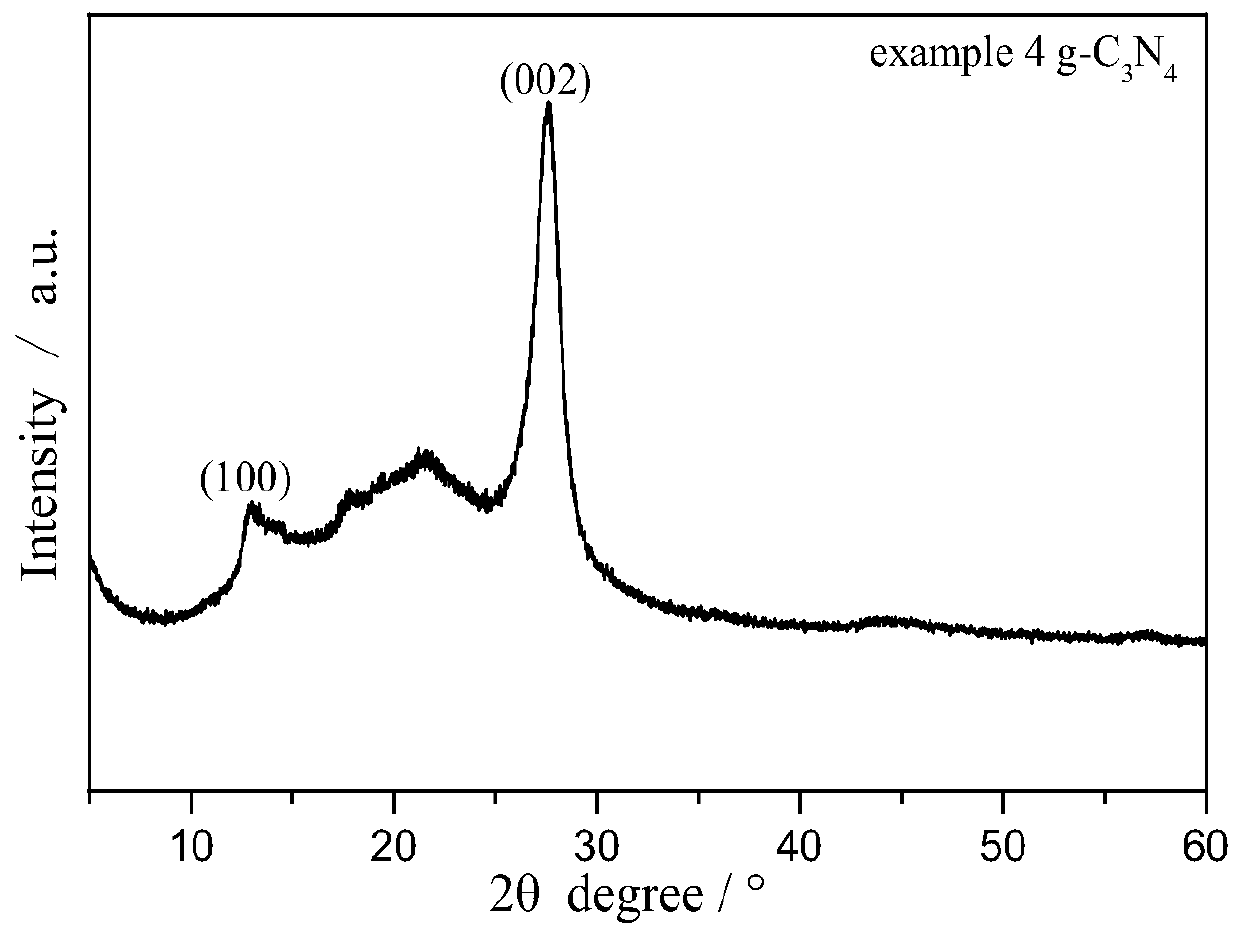

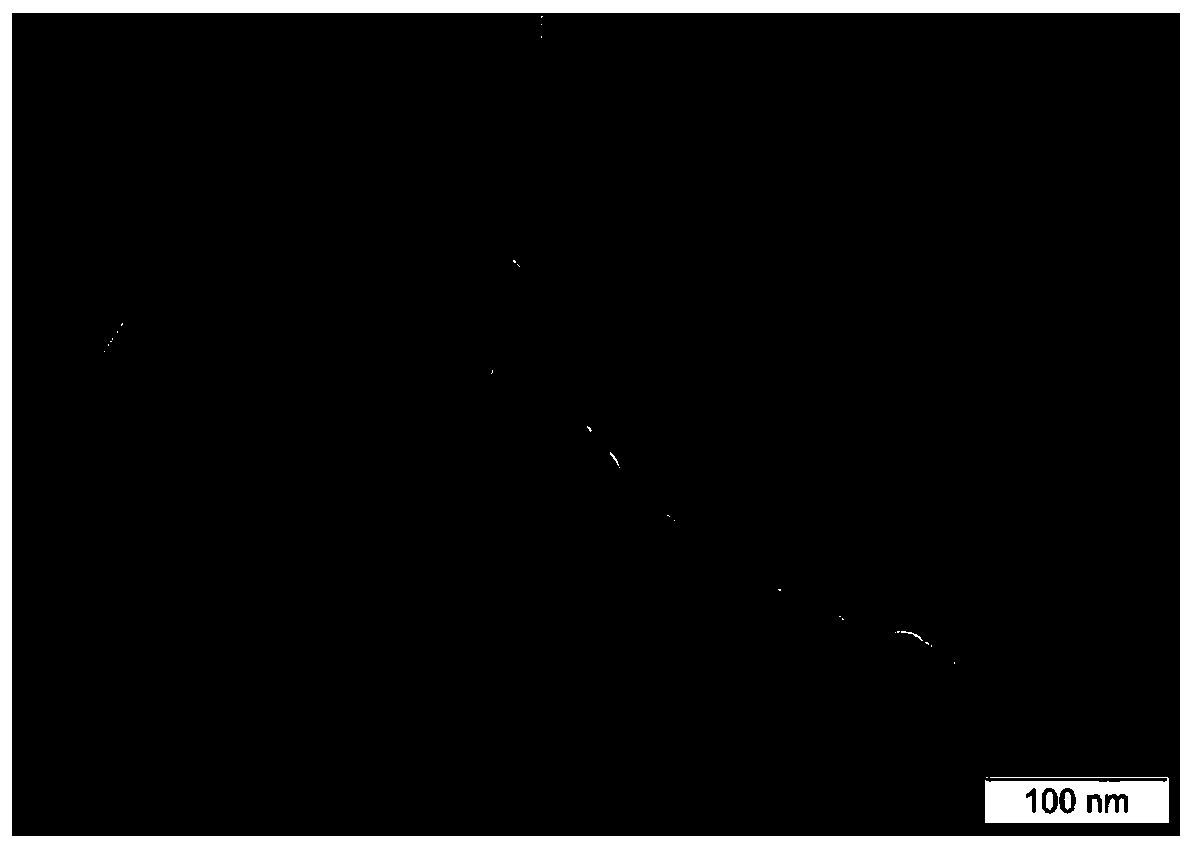

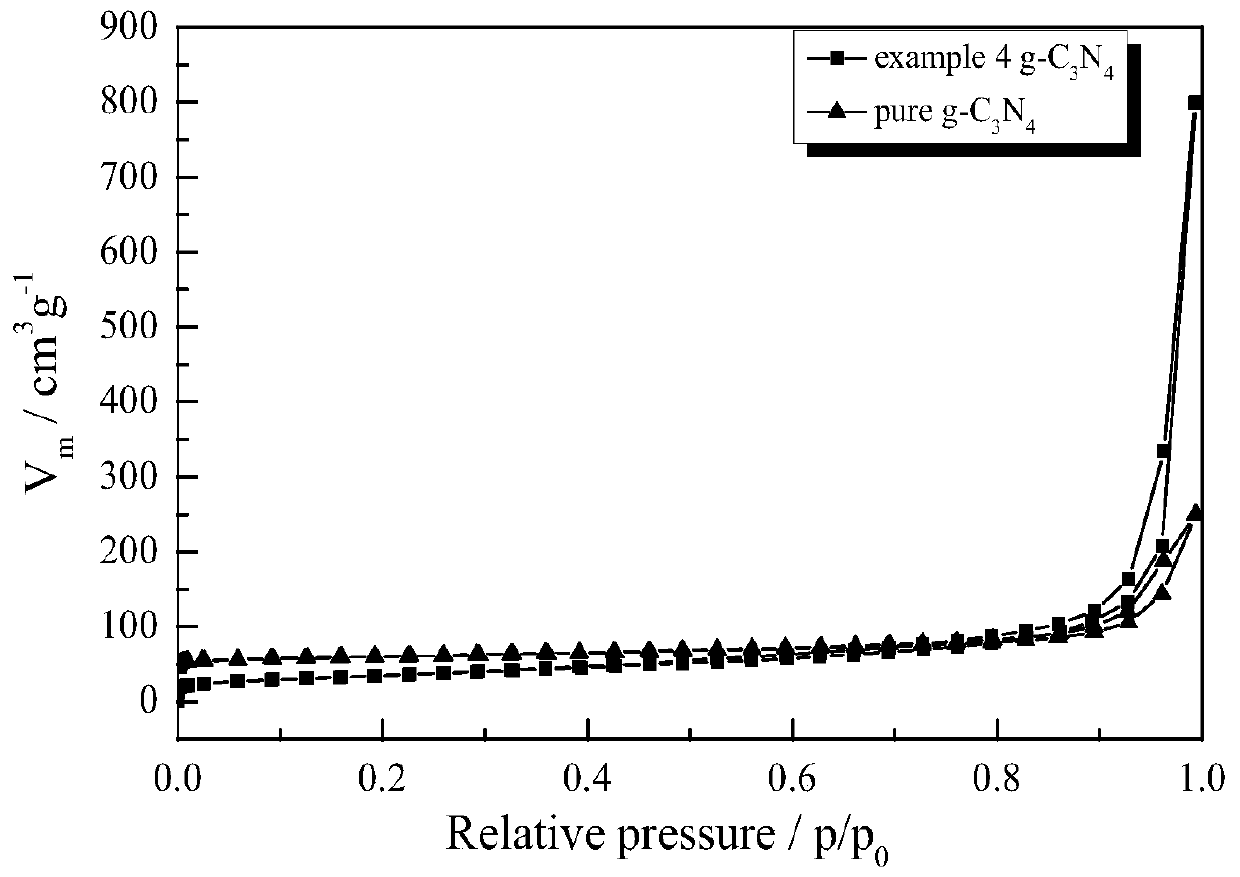

Graphite-phase carbon nitride (g-C3N4) material and preparation method and application thereof

ActiveCN105126893APlay a pore-forming roleAppropriate speedPhysical/chemical process catalystsWater/sewage treatment by irradiationCalcinationMaterials science

The invention relates to a method for preparing a graphite-phase carbon nitride (g-C3N4) material. The method includes the steps that a carbon nitride precursor and ammonium salt are evenly mixed, and then calcination is conducted so that the porous g-C3N4 material can be obtained. The ammonium salt is any one of ammonium base salts capable of generating ammonia gas through thermal decomposition or is the combination of at least two of the ammonium base salts. In the preparation process of the g-C3N4 material, the ammonium salt is added into the carbon nitride precursor to be mixed. In the high-temperature calcining process, the ammonium salt is subjected to pyrogenic decomposition to generate gas, a pore-forming effect on the g-C3N4 material is achieved, and the cellular porous g-C3N4 material is obtained. In the preparation process of the g-C3N4 material, template agents are not used, and thus the method is simple, efficient and environmentally friendly; the prepared g-C3N4 material is high in photocatalytic activity and can be used in the pollution control processes such as exhaust gas and wastewater treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

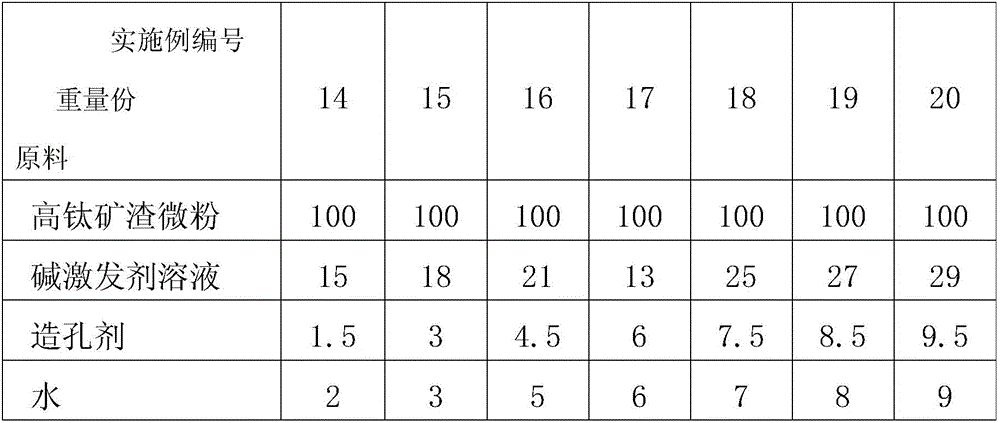

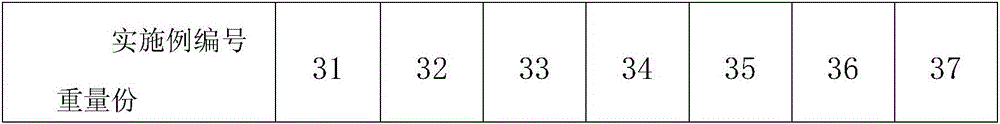

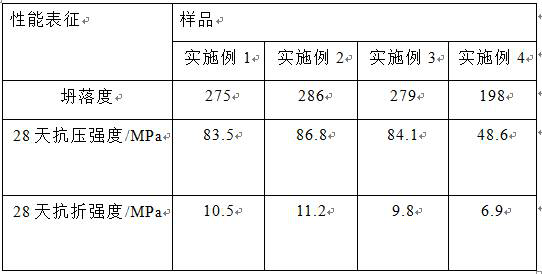

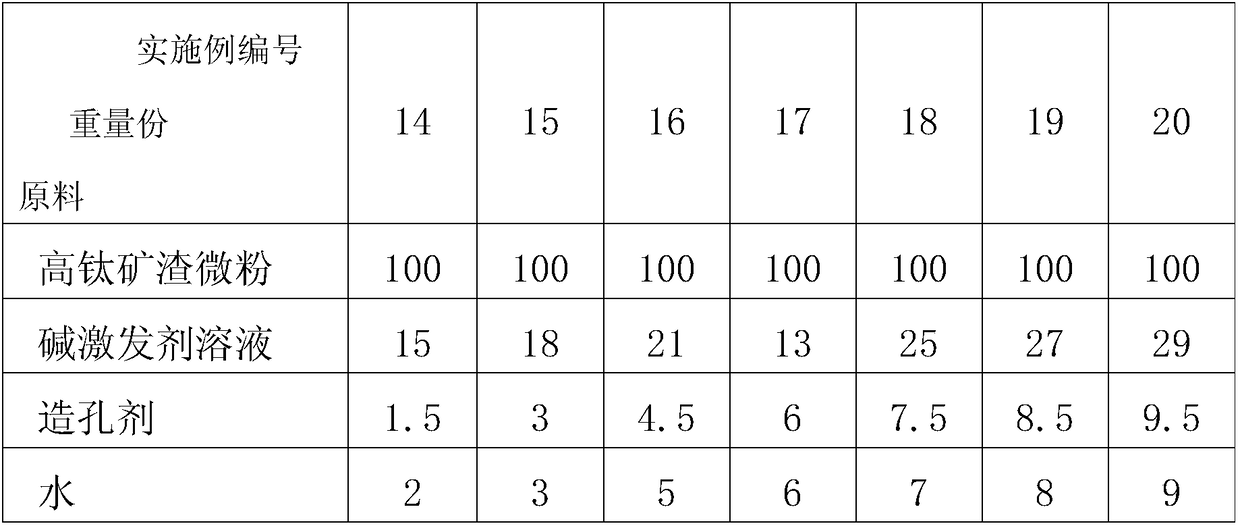

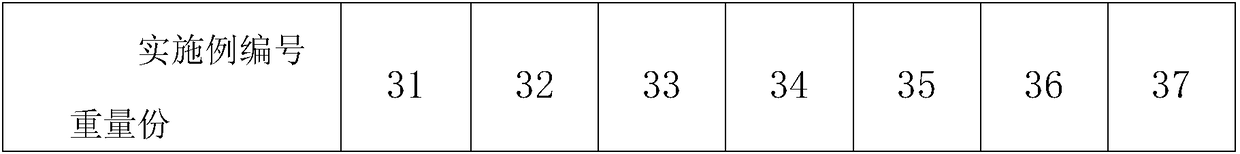

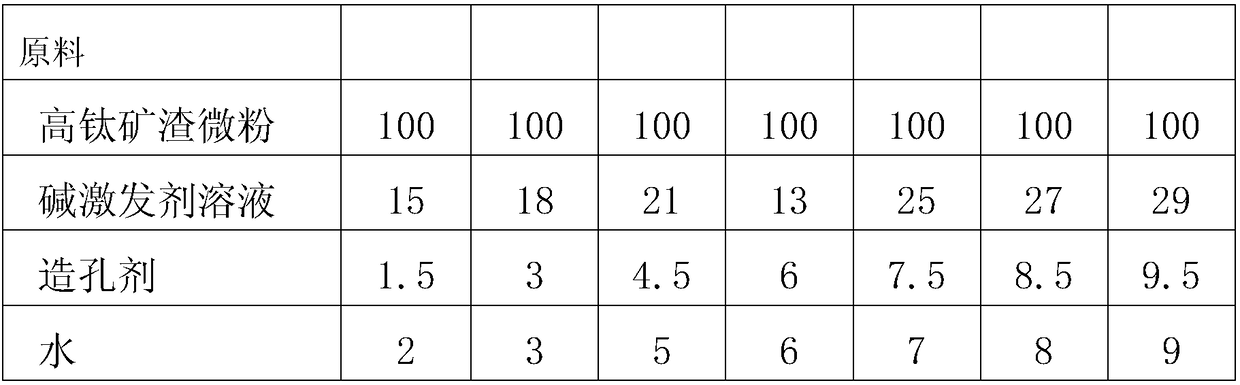

Alkali-activated high-titanium slag baking-free haycite and preparation method thereof

The invention discloses alkali-activated high-titanium slag baking-free haycite which is characterized by being prepared by mixing 100 weight parts of high-titanium slag micro powder, 12.5 to 30 weight parts of an alkali-activator, 0.5 to 10 weight parts of a pore forming substance and 0 to 10 weight parts of water. A preparation method of the alkali-activated high-titanium slag baking-free haycite comprises the following steps: putting the high-titanium slag micro powder into a disk granulator for stirring, so as to form a uniformly dispersed powder body; adding the pore forming substance, the water and the alkali-activator solution in sequence, and performing stirring, granulation and forming to obtain a blank, wherein the alkali-activator solution is water glass; maintaining the blank under a natural environment condition for 28 days, so as to obtain the alkali-activated high-titanium slag baking-free haycite. By the adoption of the preparation method for preparing the alkali-activated high-titanium slag baking-free haycite, high-temperature baking is not needed; a large mixing amount of the high-titanium slag micro powder can be used, so that a product is light in mass and high in strength; the alkali-activated high-titanium slag baking-free haycite has the characteristics of simple process, low cost, energy conservation, low carbon, environment friendliness and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Composite SiO2 aerogel heat-insulation felt pad and preparation method

The invention discloses a composite SiO2 aerogel heat-insulation felt pad and its preparation method. The felt pad is composed of, by weight, 60-80 parts of a SiO2 aerogel material, 10-25 parts of a fibrous material, 10-15 parts of water or a bonding resin material, 1*10<-4>-4 parts of a catalyst and 1*10<-2>-2 parts of a structure control agent. The felt pad has high flexibility and strength and low thermal conductivity, and never looks powdery. According to the preparation method of the felt pad, molding of the aerogel felt pad or sheet material is realized through a hot compression molding process on the precondition of keeping properties of SiO2 aerogel unchanged. By the preparation method, preparation time is shortened, and production efficiency is greatly raised.

Owner:纳诚(邢台)新材料科技有限公司

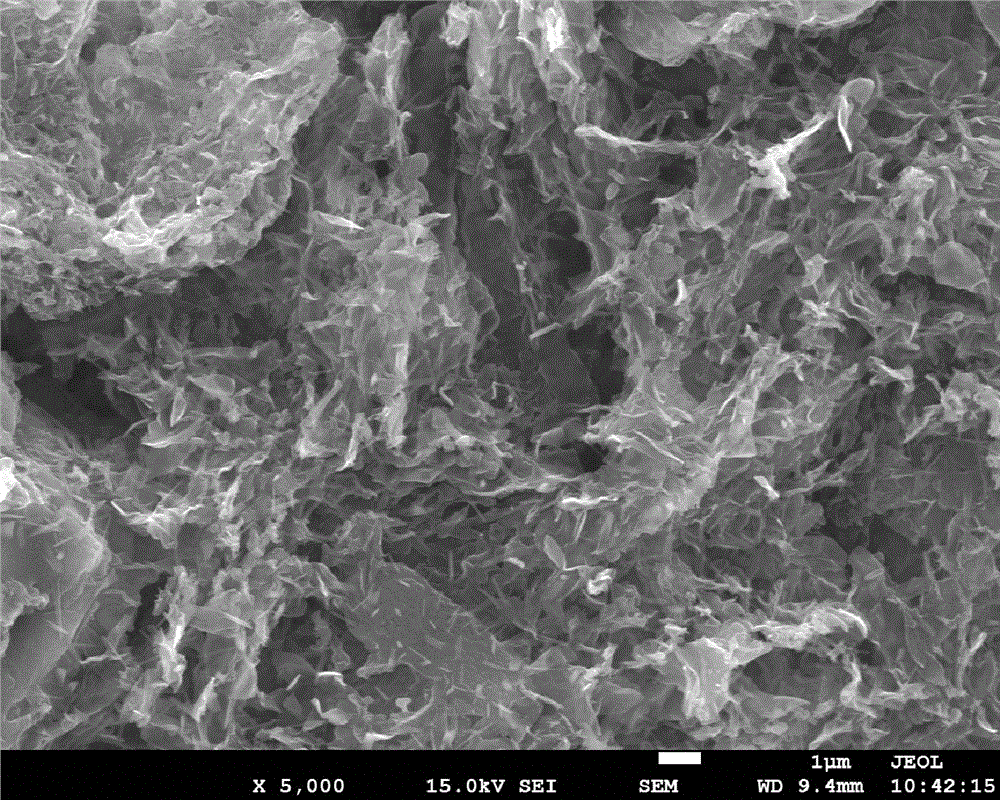

Method for preparing nano flaky nitrogen-containing porous carbon material

InactiveCN104437373AUnique shapeWell developed pore structureSugar derivativesOther chemical processesCellulosePorous carbon

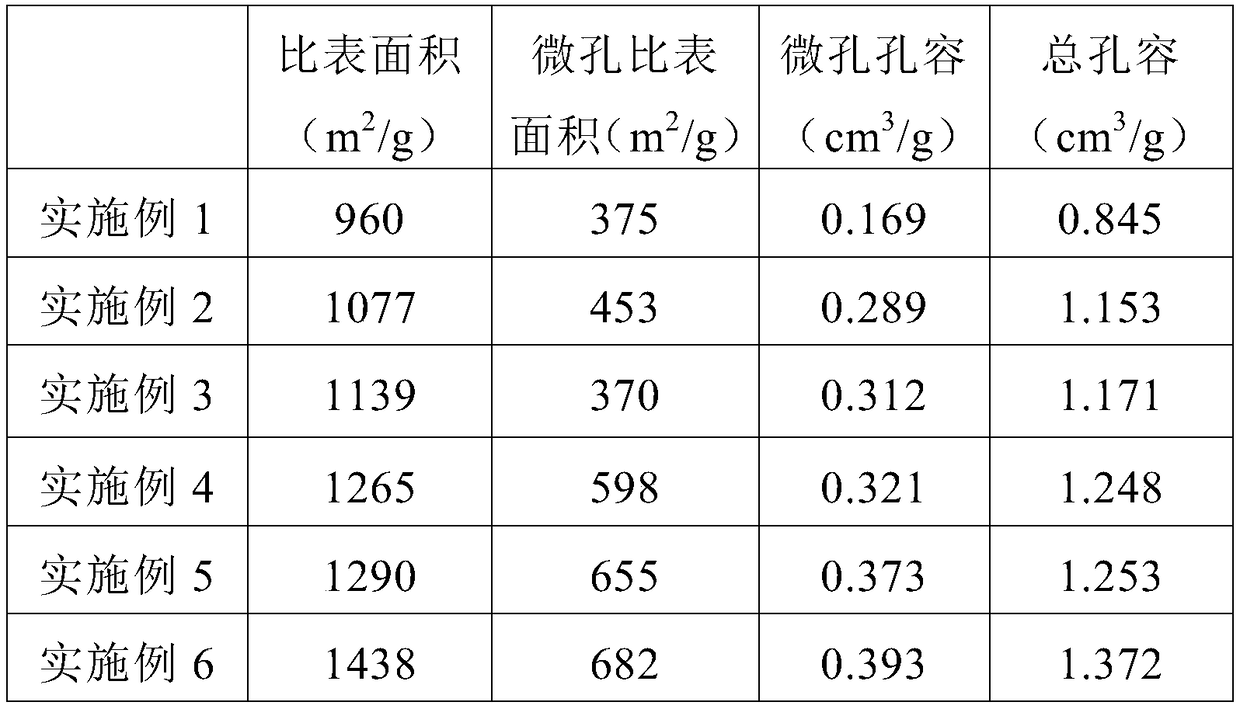

The invention discloses a method for preparing a nano flaky nitrogen-containing porous carbon material. The method comprises the following steps: dissolving alkali and a water soluble amino-containing compound in water, adding cellulose or a derivative of the cellulose, mixing and drying to obtain a crystalline complex of the alkali and the water soluble amino-containing compound wrapped with the cellulose or the derivative of the cellulose, carbonizing the crystalline complex under the nitrogen protection, and washing a carbonized product to obtain the nano flaky nitrogen-containing porous carbon material. By changing proportion of the alkali and the water soluble amino-containing compound to the cellulose or the derivative of the cellulose, the specific surface area, the pore structure and the nitrogen of the nano flaky nitrogen-containing porous carbon material and the thickness of the nano flake can be adjusted, so that the nano flaky nitrogen-containing porous carbon material with the thickness of 10-100 nm, the specific surface area of 800-2000 m<2> / g, the pore volume of 0.50-1.50 cm<3> / g, and the nitrogen content of 1-8wt% can be obtained.

Owner:ZHONGBEI UNIV +1

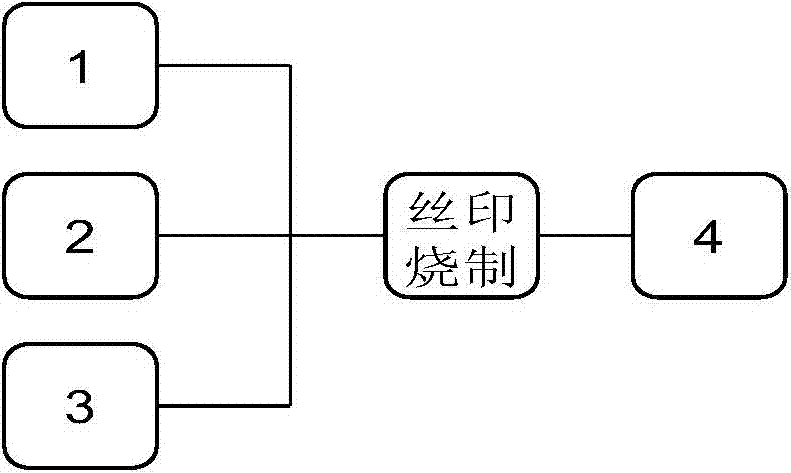

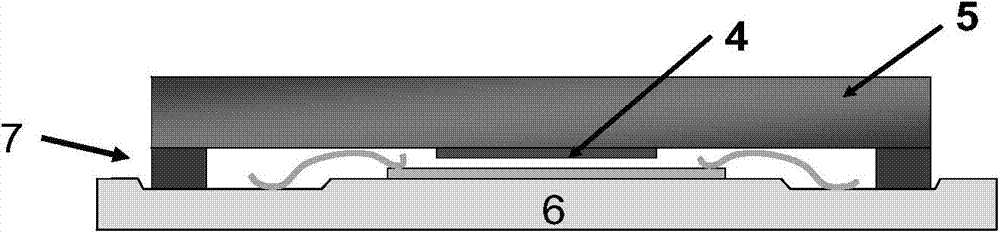

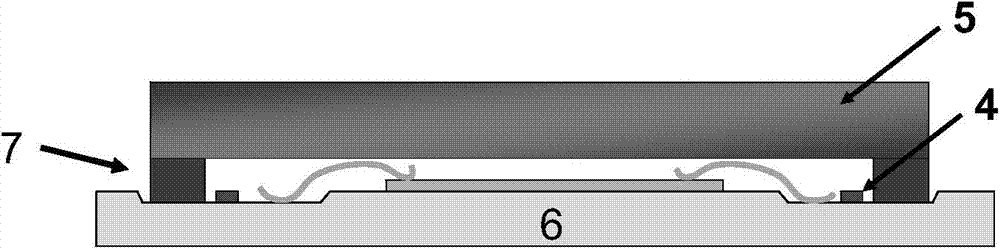

MEMS component with composite getter layer and preparation method thereof

InactiveCN104743502AStir wellPlay a pore-forming roleDecorative surface effectsSolid-state devicesRare earthGetter

The invention discloses an MEMS component with a composite getter layer and a preparation method thereof. The method comprises the following steps: mixing three components including non-evapotranspiration getter material powder, an organic bonding agent and rear earth oxide; carrying out silk-screening a cover plate material or a tubular shell material of the MEMS component with a composite getter layer with the thickness of 10-400 microns by utilizing a 40-300-mesh screen; and carrying out vacuum sintering at 350-400 DEG C so as to prepare the MEMS component with the composite getter layer. The component can be conveniently prepared on a plurality of internal components of the MEMS device simultaneously when the vacuum degree of a seal chamber is maintained, the structure is simple, the use reliability of the MEMS device can be improved, the service life of the MEMS device can be prolonged by absorbing vapor and residual gas in the internal chamber after vacuum packaging.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Insulation and heat dissipation material for electric heater shell and preparation method of insulation and heat dissipation material

InactiveCN108250629AGood heat dissipation and insulation performanceNot easily deformedRosinAntistatic agent

The invention discloses an insulation and heat dissipation material for an electric heater shell and a preparation method of the insulation and heat dissipation material, and relates to the technicalfield of insulation materials. The insulation and heat dissipation material is prepared from the following raw materials in parts: 44 to 46 parts of polyvinyl chloride, 24 to 26 parts of ABS (Acrylonitrile Butadiene Styrene) resin, 24 to 26 parts of polyethylene glycol terephthalate, 19 to 21 parts of polyimide, 15 to 20 parts of tourmaline-graphene composite powder, 10 to 15 parts of carbon fiber, 4 to 6 parts of rosin, 4 to 6 parts of lithium-based bentonite, 3 to 5 parts of zinc ethylphenyl dithiocarbamate, 3 to 5 parts of halogen flame retardant, 2 to 4 parts of anti-aging agent, 1 to 3 parts of antistatic agent, 1 to 3 parts of stabilizer and an appropriate amount of deionized water. The insulation and heat dissipation material disclosed by the invention has good heat dissipation andinsulation properties, and is not easy to deform and high in stability.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Lightweight concrete material and preparation method thereof

The invention relates to a lightweight concrete material and a preparation method thereof, and belongs to the technical field of building materials. According to the technical scheme, the surface of ceramsite is coated with a composite elastomer material to form effective elastic load, so that the mechanical strength of the material is effectively improved, meanwhile, the stress of internal pores of the concrete material can be effectively improved through elastic particles, and the mechanical property of the concrete material is improved from another angle; and according to the technical scheme, the coated porous ceramsite material is used as a modified base material, the roundness of the surface of the base material filled in the concrete material is increased along with the effective load of base particles, the angular coating of the surface is gradually reduced, and the nano sol material is substituted into the concrete, so that the compactness of the concrete is increased, and the mechanical strength of the material is further improved.

Owner:成都翎渠杉建筑科技有限公司

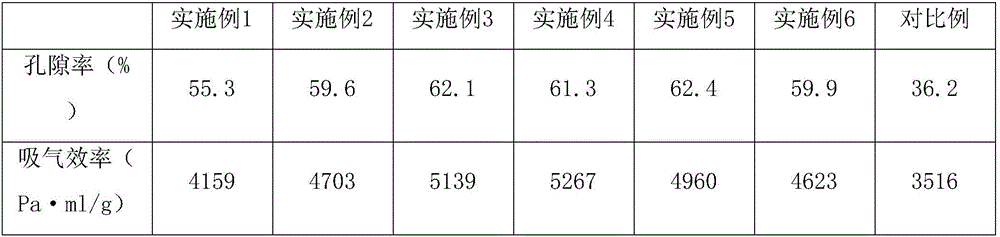

Batch preparation method for titanium-based air suction element with high porosity

InactiveCN106735175AControl shapeReduce porosityOther chemical processesTransportation and packagingPorosityTrichloroethylene

The invention provides a batch preparation method for a titanium-based air suction element with the high porosity. The preparation method comprises the following steps that under the condition of argon protection, titanium powder and a mixture of molybdenum powder, zirconium ferrovanadium powder, zirconium aluminum powder and zirconium nickel powder are evenly mixed, and a titanium-based raw material is obtained; under inert gas protection, the titanium-based raw material and ammonium bicarbonate are evenly mixed, an organic binder bond is added, and an injecting feedstock is formed; the feedstock is deposited on modified metal wires, subjected to forming through isostatic cool pressing and taken out after pressure relief and demoulding, and a blank is formed; under a vacuum state, the blank is stored in trichloro ethylene to be subjected to chemical degreasing treatment and then taken out for cooling, and a chemical degreasing blank is obtained; and the chemical degreasing blank is subjected to high-temperature sintering in a vacuum sintering furnace, cooled and taken out of the vacuum sintering furnace, and then the high-porosity titanium-based air suction element with the porosity being higher than 50% is obtained. According to the titanium-based air suction element with the high porosity, a preparation technique is simple and easy to operate, and the air suction element is high in porosity, good in manipulative performance and excellent in air suction performance.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

Preparation method of graphite-phase carbon nitride with large specific surface area

InactiveCN110560127APlay a pore-forming roleAvoid accumulationPhysical/chemical process catalystsWater/sewage treatment by irradiationAir atmosphereMolten state

The invention belongs to the field of visible light catalytic materials, and particularly relates to a method for preparing a large-specific-surface-area graphite-phase carbon nitride material by utilizing a low-melting-point precursor and carrying out low-temperature heat treatment on the precursor in a roasting process. The preparation method comprises the following steps: (1) putting a nitrogen-containing precursor into a three-necked flask, putting the three-necked flask filled with the nitrogen-containing precursor into an oil bath pot after the temperature of the oil bath pot reaches themelting point of the nitrogen-containing precursor, and heating and stirring to enable the nitrogen-containing precursor to be in a molten state; (2) heating to keep a molten state, taking out the three-neck flask, and cooling and crystallizing the nitrogen-containing precursor at the molten state at room temperature; and (3) grinding the crystallized nitrogen-containing precursor into powder, putting the powder into a crucible, putting the crucible into a muffle furnace, carrying out programmed heating, and roasting in an air atmosphere to obtain a target product. The method has the advantages of simple process, environmental protection, low cost, high purity of the target product, and high catalytic performance.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

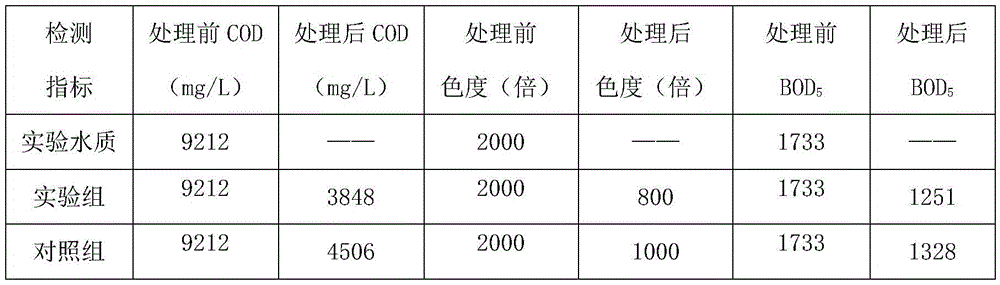

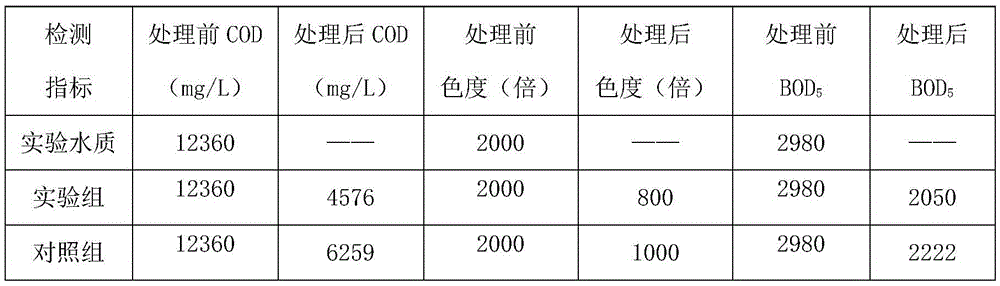

A kind of multi-element catalytic micro-electrolysis filler and its preparation method and application

ActiveCN104628091BIncrease potential differenceQuick responseWater treatment compoundsWater/sewage treatment apparatusIron powderWastewater

The invention discloses multi-element catalytic microelectrolysis packing as well as a preparation method and application thereof, and belongs to the field of wastewater treatment. The multi-element catalytic microelectrolysis packing is mainly prepared from iron powder, aluminum powder, dried carbon powder, copper powder, zinc powder, kieselguhr, ammonium chloride and sodium tetraborate through steps of weighing, uniform mixing, forming, drying and roasting, cooling and the like. When the multi-element catalytic microelectrolysis packing is used in sewage treatment, the biodegradability of wastewater is remarkably improved, and the packing is not easy to cake, not easy to passivate, long in service life, convenient and rapid to fill and simple to maintain.

Owner:徐艳萍

Method for preparing lower volume fraction porous silicon carbide ceramic body

InactiveCN102875151AGuaranteed StrengthGuarantee the strength of the gel body at room temperatureCarbide siliconGraphite

The invention discloses a method for preparing a lower volume fraction porous silicon carbide ceramic body. According to the method, water in an acrylamide gel system formed by adopting a conventional ceramic gel injection molding process is replaced by silica sol to form a silica sol-acrylamide double gel network system. A gel blank is enabled to have a certain strength by controlling the ratio of the silica sol to acrylamide and adding graphite powder with a certain proportion in slurry; and meanwhile, by using a silica sol-gel network left by removing the gel, the blank is enabled to have a certain strength and the requirement of late infiltration metal on the strength of the blank body can be met. Due to the adoption of the graphite powder in the slurry, the setting phenomenon of carborundum particles due to low viscosity caused by overlow volume fraction in the gel process can be effectively avoided and the graphite powder can be burnt out in the air in the late stage of gel removal. According to the method, the porous silicon carbide ceramic body with the volume fraction being 15-45 percent, the strength being over 3MPa and the closed porosity being smaller than 0.5 percent can be prepared with lower cost.

Owner:UNIV OF SCI & TECH BEIJING

Bioactive water capable of reducing blood pressure, blood fat and blood sugar, and production technology thereof

InactiveCN108928972APromote formationHigh yieldWater/sewage treatment by irradiationMetabolism disorderActivated carbon filtrationBlood pressure

The invention discloses a bioactive water capable of reducing the blood pressure, the blood fat and the blood sugar, and a production technology thereof. The production technology of the bioactive water capable of reducing the blood pressure, the blood fat and the blood sugar comprises the following steps: (1) taking of spring water in a natural water source; (2) quartz sand filtration; and (3) activated carbon filtration. The bioactive water capable of reducing the blood pressure, the blood fat and the blood sugar can effectively improve the clinical symptoms of patients suffering from hypertension, hyperlipidemia and hyperglycemia, can be taken for a long term to regulate the functions of the heart, the brain, the liver and the kidney and the immunity of human bodies and promote the metabolism of the human body and the stability of an environment in the human body, is safe, has no side effects, and is worth promoting and applying.

Owner:李晓军

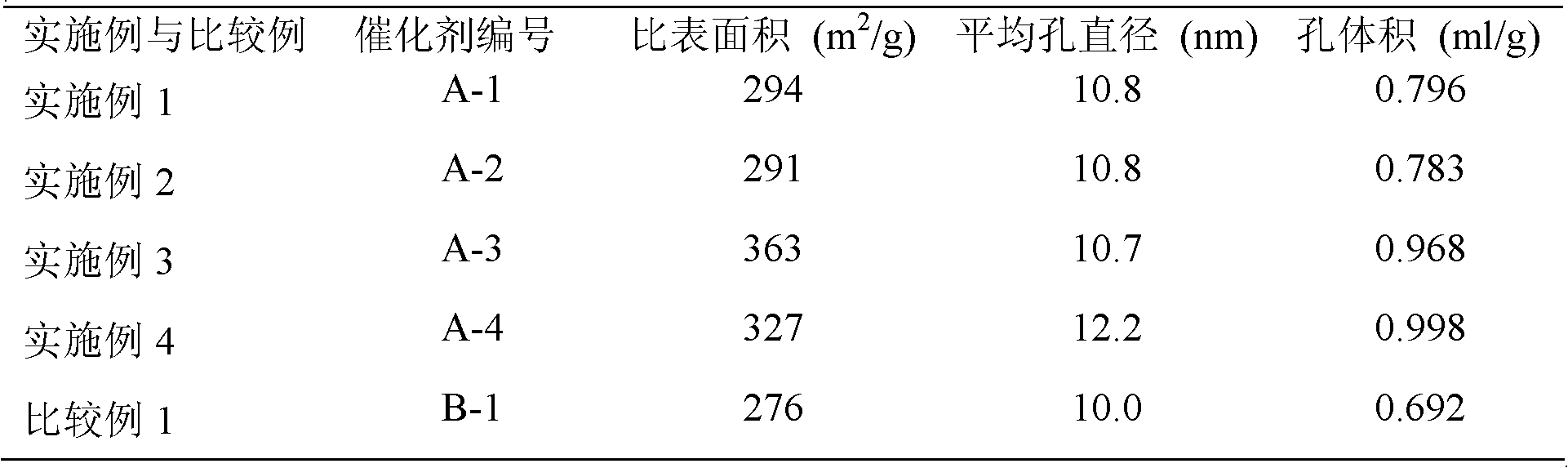

Preparation method of wear-resistant large-pore-volume microspherical silica carrier

InactiveCN105435858AGood adhesionImprove wear resistanceCatalyst carriersWear resistantSilicon dioxide

The invention provides a preparation method of a wear-resistant large-pore-volume microspherical silica carrier. The preparation method comprises the steps: roasting a precipitated silicon dioxide powder or white carbon black with the specific surface area of 250-600 m<2> / g at the temperature of 730-760 DEG C to make the specific surface area reduced to 100-220 m<2> / g; adding water, mixing evenly, and grinding silicon dioxide micro-particles to the average diameter of 2-5 [mu]m; adding acetic acid and ammonium acetate, and performing crystallization treatment at the temperature of 150-180 DEG C; and adding an activated carbon emulsion and acidic silica sol, mixing evenly, performing spray granulation, and roasting the granulation powder at the temperature of 650-720 DEG C. The prepared carrier has proper pore structure including higher specific surface area, pore volume and larger average pore size, has higher mechanical strength, higher wear resistance and higher impact resistance, is suitable for further loading active components, and is used for preparation of a catalyst for fluidized beds.

Owner:钟俊超

a compound sio 2 Airgel thermal insulation felt pad and preparation method thereof

The invention discloses a composite SiO2 aerogel heat-insulation felt pad and its preparation method. The felt pad is composed of, by weight, 60-80 parts of a SiO2 aerogel material, 10-25 parts of a fibrous material, 10-15 parts of water or a bonding resin material, 1*10<-4>-4 parts of a catalyst and 1*10<-2>-2 parts of a structure control agent. The felt pad has high flexibility and strength and low thermal conductivity, and never looks powdery. According to the preparation method of the felt pad, molding of the aerogel felt pad or sheet material is realized through a hot compression molding process on the precondition of keeping properties of SiO2 aerogel unchanged. By the preparation method, preparation time is shortened, and production efficiency is greatly raised.

Owner:纳诚(邢台)新材料科技有限公司

Method for preparing wear-resisting large-pore-volume micro-spherical silicon dioxide carrier

InactiveCN105498853AGood adhesionImprove wear resistanceCatalyst carriersMicroparticleSilicon dioxide

The invention provides a method for preparing a wear-resisting large-pore-volume micro-spherical silicon dioxide carrier. The method comprises the steps that precipitation method silicon dioxide powder or white carbon black with the specific surface area of 250-600 m<2> / g is calcined at the temperature of 730 DEG C to 760 DEG C, the specific surface area of the precipitation method silicon dioxide powder or white carbon black is reduced to 100-220 m<2> / g, and water is added for even mixing; grinding and dispersing are carried out till the average diameter of microparticles ranges from 2 micrometers to 5 micrometers, activated carbon emulsion and a white carbon black emulsus glue solution are added for even mixing, and spray granulation is carried out; pelleted powder is calcined at the temperature of 650 DEG C to 720 DEG C, the micro-spherical silicon dioxide carrier with the average diameter of 50-250 micrometers is prepared, the specific surface area ranges from 60 m<2> / g to 120 m<2> / g, the pore volume ranges from 0.7 ml / g to 1.1 ml / g, and the average pore diameter ranges from 35 nm to 50 nm. High mechanical strength, wear resistance and impact resistance are achieved, and the carrier is suitable for further loading active components and preparing a catalyst for a fluidized bed.

Owner:钟俊超

Preparation method of magnetic hydrogel

InactiveCN110064345AAvoid decompositionPlay a pore-forming roleGel preparationColloidal chemistry detailsIron(II) chloridePolyacrylamide

The invention belongs to the technical field of hydrogel, and particularly relates to a preparation method of magnetic hydrogel. In the preparation process, calcium oxide is taken as a raw material, firstly, the raw material and nanometer titania are heated, then the effect of carbon dioxide is utilized, nano calcium carbonate is formed, and under the effect of an auxiliary agent, the nano calciumcarbonate is continuously combined with the nanometer titania; dispersion performance is added for polyvinylpyrrolidone, then the polyvinylpyrrolidone, ferric chloride and ferrous chloride are mixed,magnetic particles are formed and uniformly distributed on the surfaces of mixed particles at the same time, the crystal form is improved through a guiding agent, and finally, polyacrylamide is formed for wrapping; groups on the surfaces of the particles can be combined with polyacrylamide well, the effect is utilized that the nano calcium carbonate is combined with the nanometer titania, gaps can be formed well for loading the magnetic particles, and by utilizing formation of a nano-substance, the mechanical performance and magnetic performance of the hydrogel can be effectively improved.

Owner:龙升

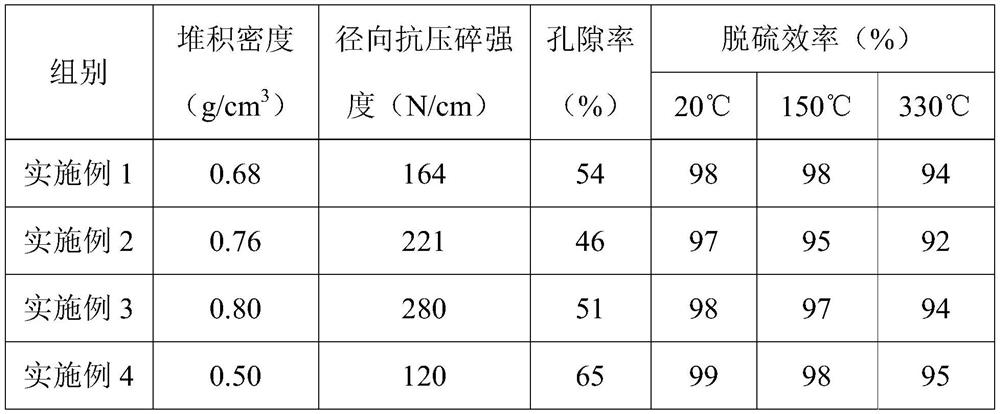

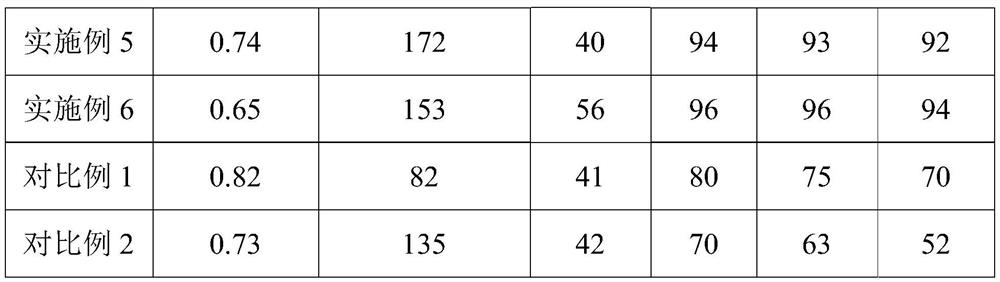

A kind of flue gas desulfurizer and its preparation method and application

ActiveCN111330424BReduce porosityImprove pore structureGas treatmentDispersed particle separationHydration reactionPozzolana

The invention provides a flue gas desulfurizing agent as well as a preparation method and application thereof. The flue gas desulfurizing agent comprises the following raw materials in parts by weight: 30-60 parts of slaked lime powder, 20-60 parts of silica fume, 6-24 parts of a binder and 6-15 parts of crystalline hydrated salt. According to the flue gas desulfurizing agent, active substances inthe slaked lime powder and the silica fume are subjected to a pozzolanic reaction to generate high-strength hydrated silicate; the binder can bind all the raw material components to improve the strength of the flue gas desulfurizing agent; the crystalline hydrated salt plays a pore-forming role by losing crystalline water in the flue gas desulfurizing agent; mutual cooperation of components, theflue gas desulfurizing agent has relatively small stacking density (0.5-0.8 g / cm<3>), relatively high radial crushing strength (120-280 N / cm) and relatively large porosity (40-65%); the desulfurizingagent can be used for a fixed bed reactor or a moving bed reactor, is suitable for purification treatment of SO2-containing industrial flue gas or waste gas at 20-330 DEG C, has relatively high reaction activity, particularly still has relatively high crushing resistance under a relatively high flue gas temperature condition, and is not easy to pulverize and low in bed pressure.

Owner:北京予知环境工程有限公司

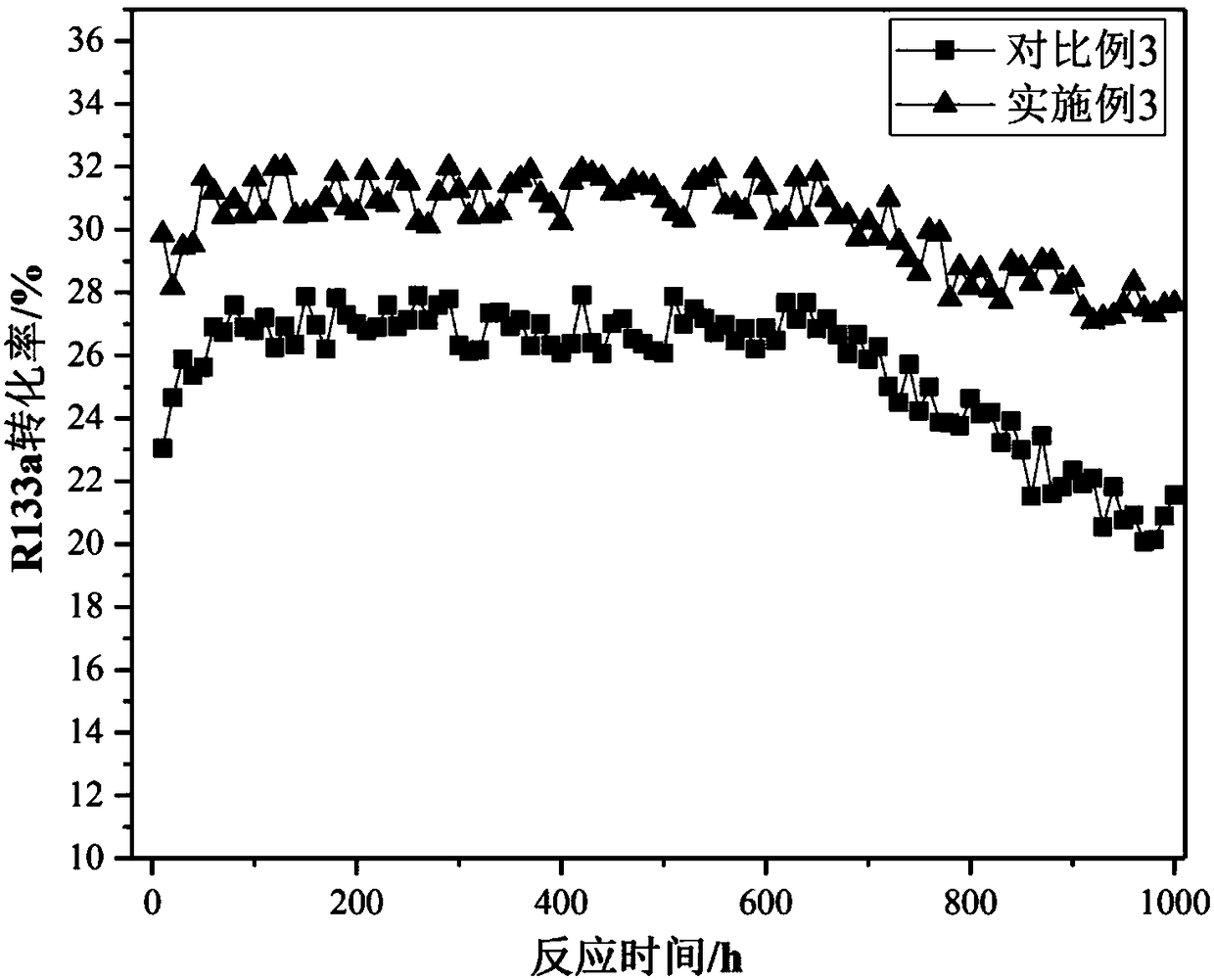

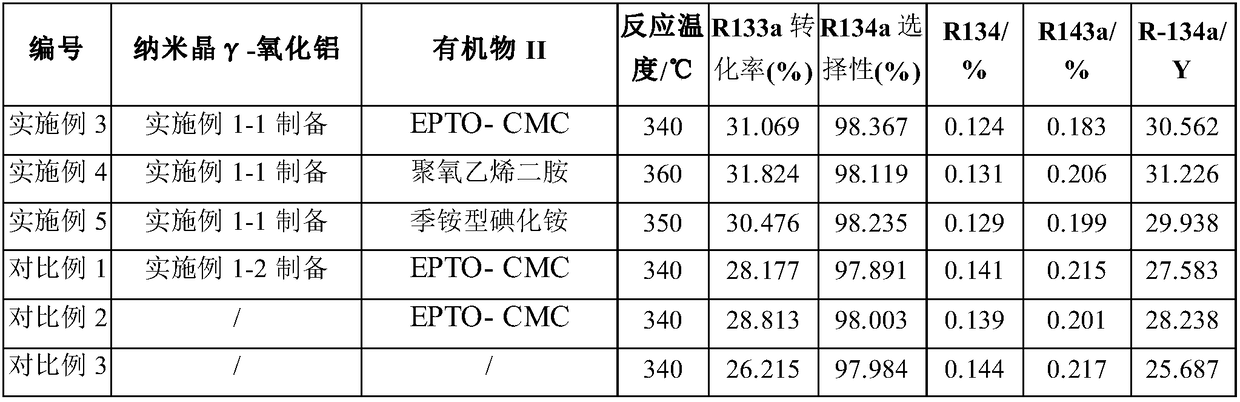

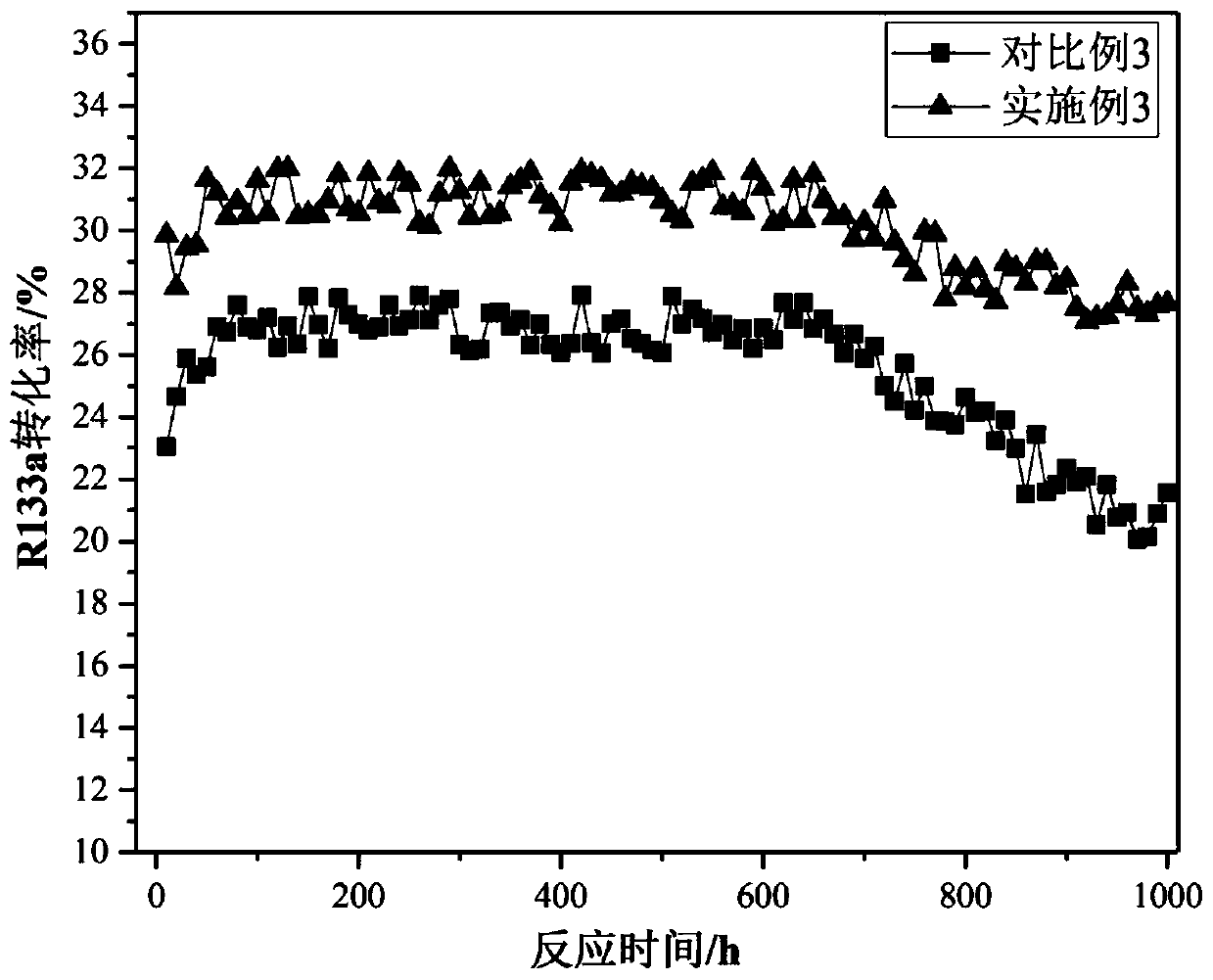

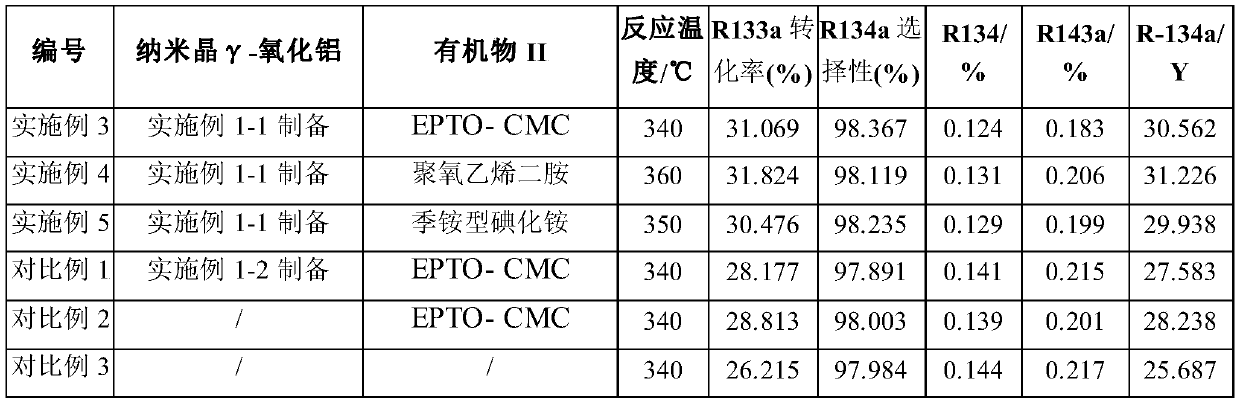

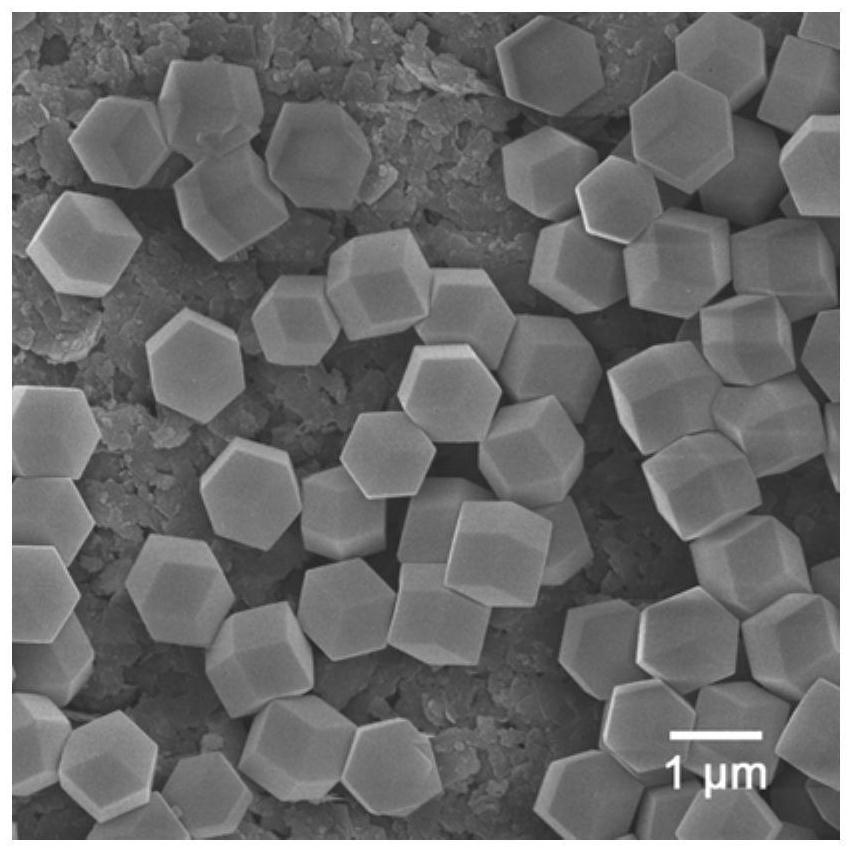

Preparation method of gas phase fluorination catalyst

ActiveCN108057435APrevent agglomeration rateReduce the probability of collapsePreparation by halogen replacementCatalyst activation/preparationGas phaseGraphite

The invention relates to a preparation method of a gas phase fluorination catalyst. The preparation method comprises the following steps: evenly mixing nano crystal gamma-alumina powder, amorphous chrome oxide powder, an organic matter II, and graphite, pressing and moulding the mixture to obtain a precursor of the gas phase fluorination catalyst; and finally fluorinating the precursor to obtain the gas phase fluorination catalyst. The nano crystal gamma-alumina powder is prepared by a water containing gel-sol method, and an organic matter I is added. The organic matter I and the organic matter II can be heated, decomposed, and volatilized to generate pores so that after fluorination, obtained gas phase fluorination catalyst still has a large specific surface area, high activity, and highstability, and the preparation method is especially suitable for the preparation of a R134a product.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

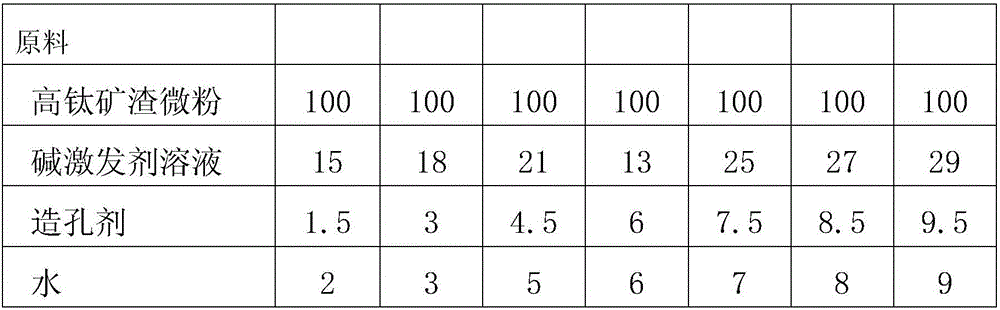

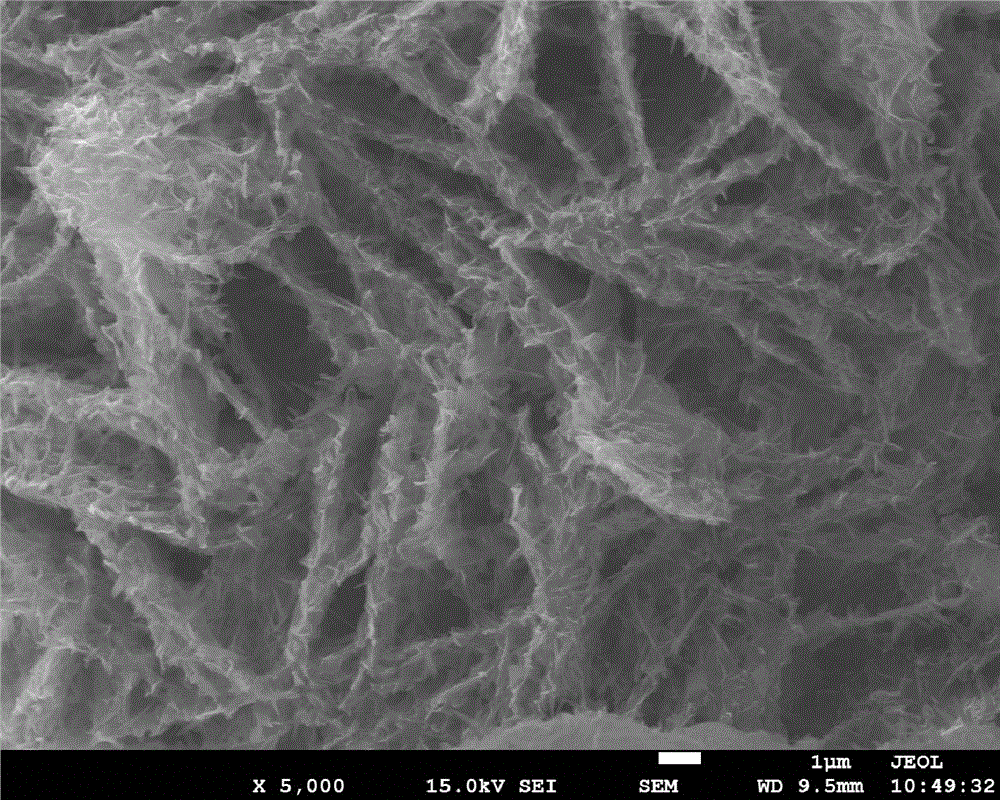

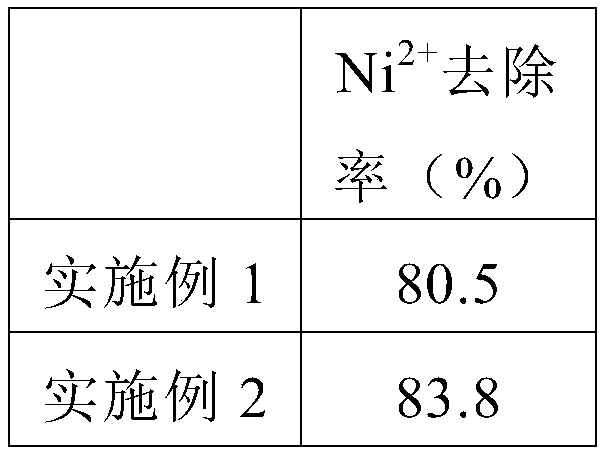

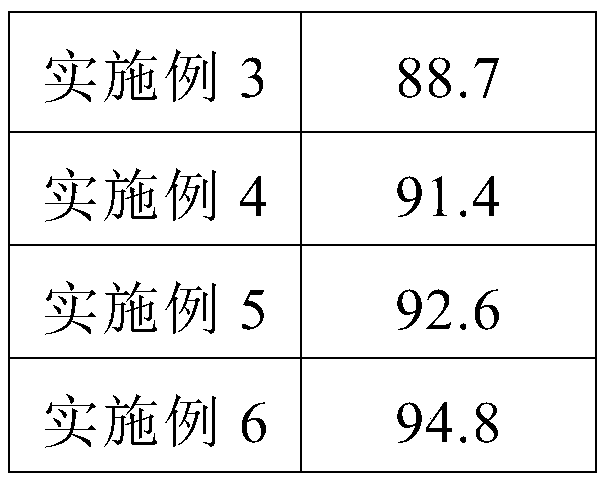

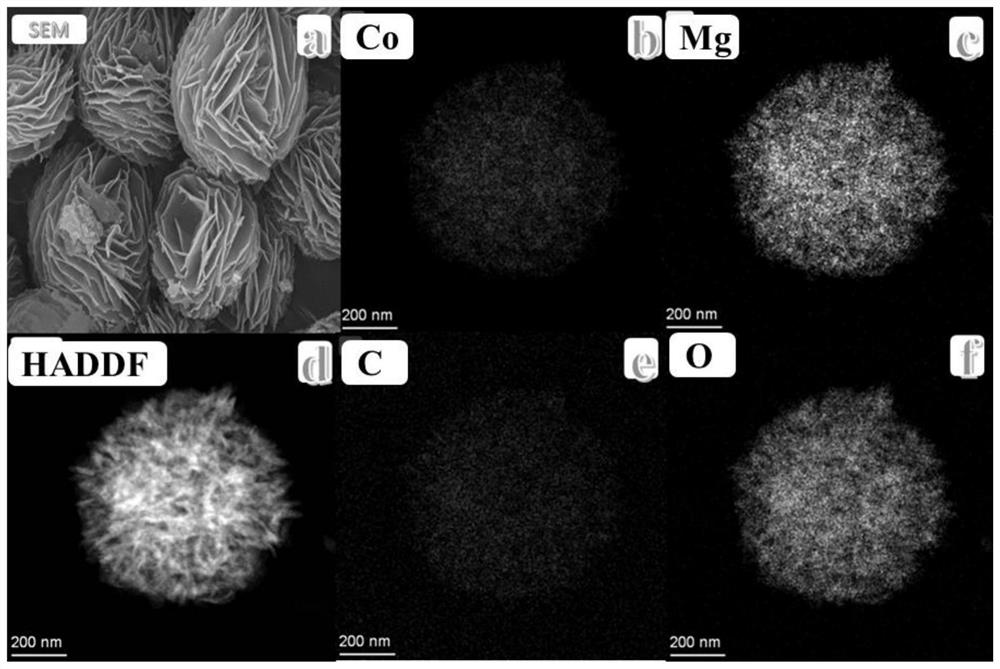

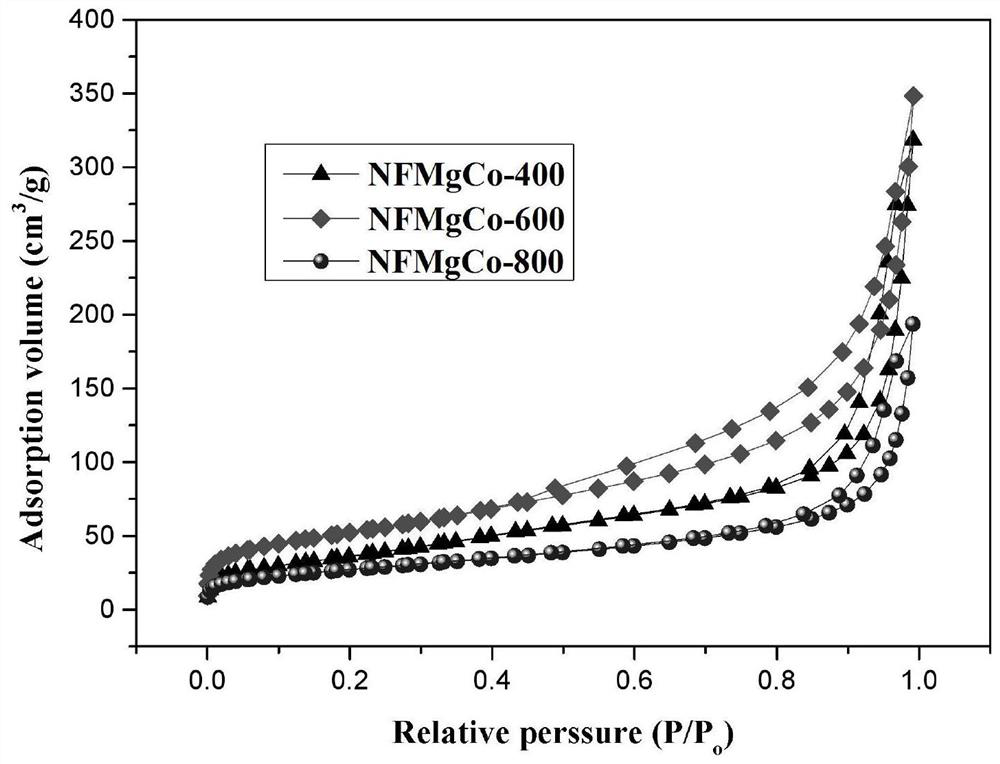

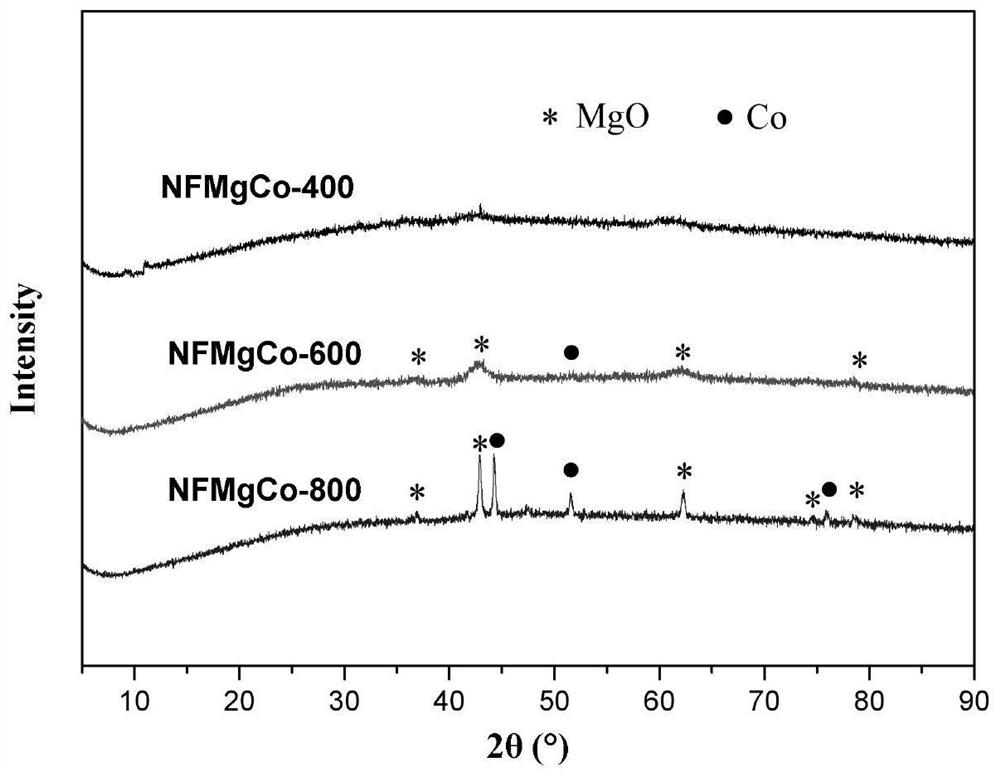

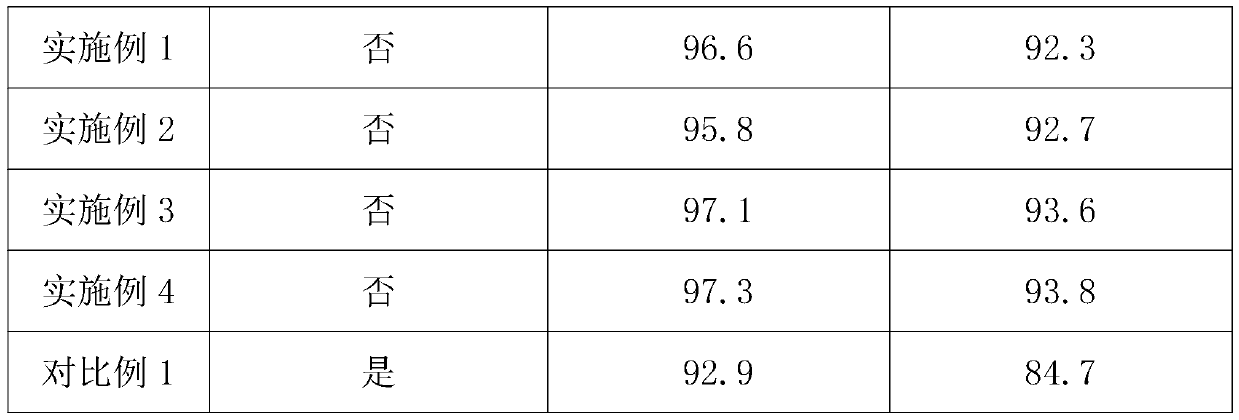

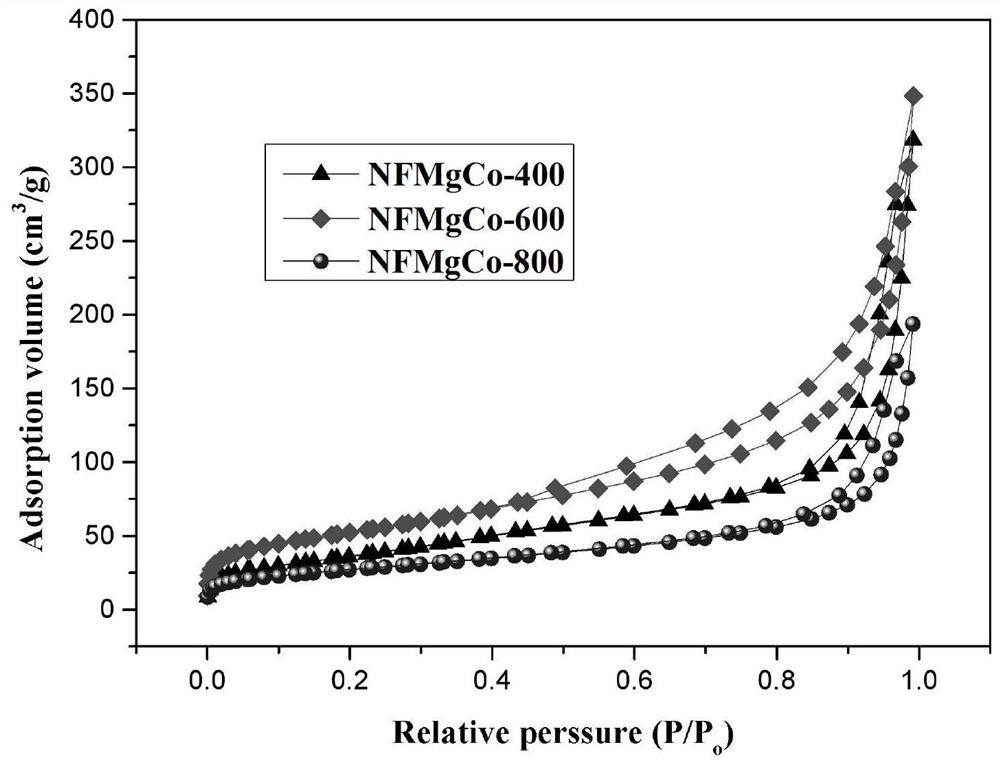

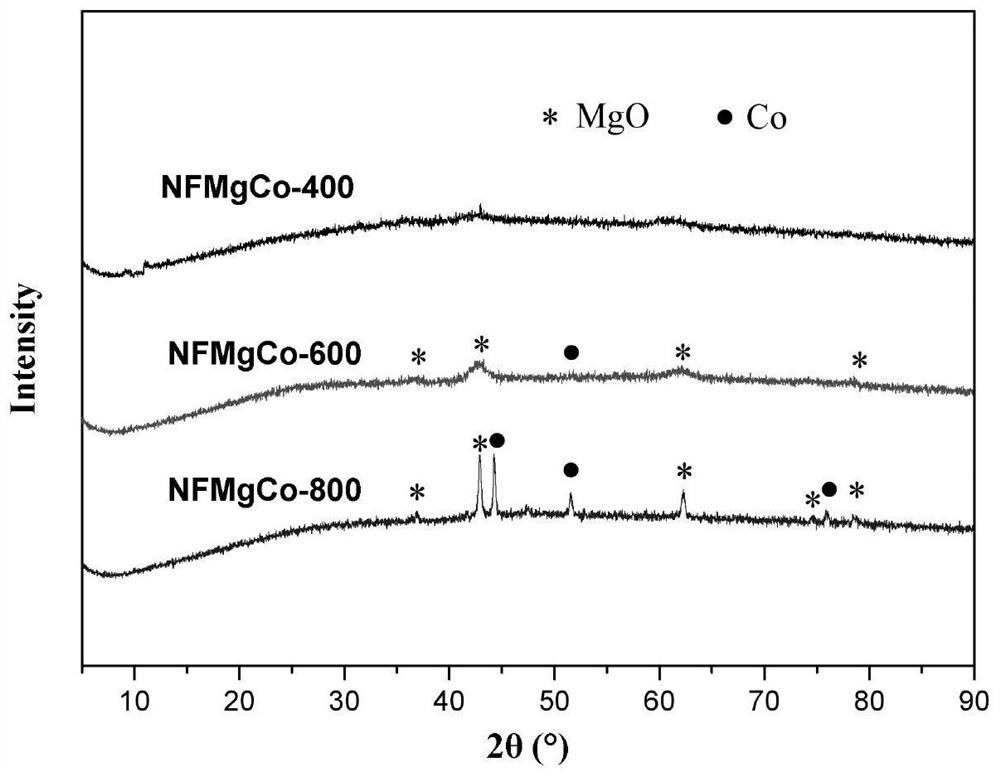

Magnetic MgO nanoflower phosphate adsorbent, preparation method and application thereof

ActiveCN111889064ALarge specific surface areaFast adsorption rateWater treatment parameter controlOther chemical processesO-Phosphoric AcidPhosphate

The invention provides a magnetic MgO nanoflower phosphate adsorbent, a preparation method and application thereof, and belongs to the technical field of adsorbents. The preparation method provided bythe invention comprises the following steps: mixing polyvinylpyrrolidone, ethylene glycol, ammonia water, magnesium acetate and cobalt acetate, carrying out a solvothermal reaction on the obtained mixed solution, and separating to obtain a solid product; and calcining the solid product to obtain a magnetic MgO nanoflower phosphate adsorbent, wherein the calcination temperature is 600 to 900 DEG C. The adsorbent prepared by the method provided by the invention has a porous lamellar flower-shaped structure, wherein the specific surface area is up to 209 m<2> / g, the effective adsorption sites are uniformly distributed in the flower-like lamellas, and the effective adsorption sites are rich due to the lamellar flower-like structure, so that the adsorbent has high adsorption selectivity, wid pH application range and high phosphorus adsorption rate under the interference of numerous anions, and the orthophosphate adsorption capacity is as high as 230.5 mg / g.

Owner:NANKAI UNIV

A kind of preparation method of gas phase fluorination catalyst

ActiveCN108057435BPrevent agglomeration rateReduce the probability of collapsePreparation by halogen replacementCatalyst activation/preparationPtru catalystGraphite

The invention relates to a method for preparing a gas-phase fluorination catalyst, which includes: uniformly mixing nanocrystalline γ-alumina powder, amorphous chromium oxide powder, organic matter II and graphite, and pressing into tablets to obtain a gas-phase fluorination catalyst precursor; The gas phase fluorination catalyst precursor is fluorinated to obtain the gas phase fluorination catalyst. Among them, nanocrystalline γ-alumina powder is prepared by a hydrogel-sol method, and organic matter I is added. The organic matter I and organic matter II can be thermally decomposed and volatilized to form pores, so that the resulting gas-phase fluorination catalyst still has a high specific surface area after fluorination, exhibits high activity and high stability, and is particularly suitable for R134a products. preparation.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

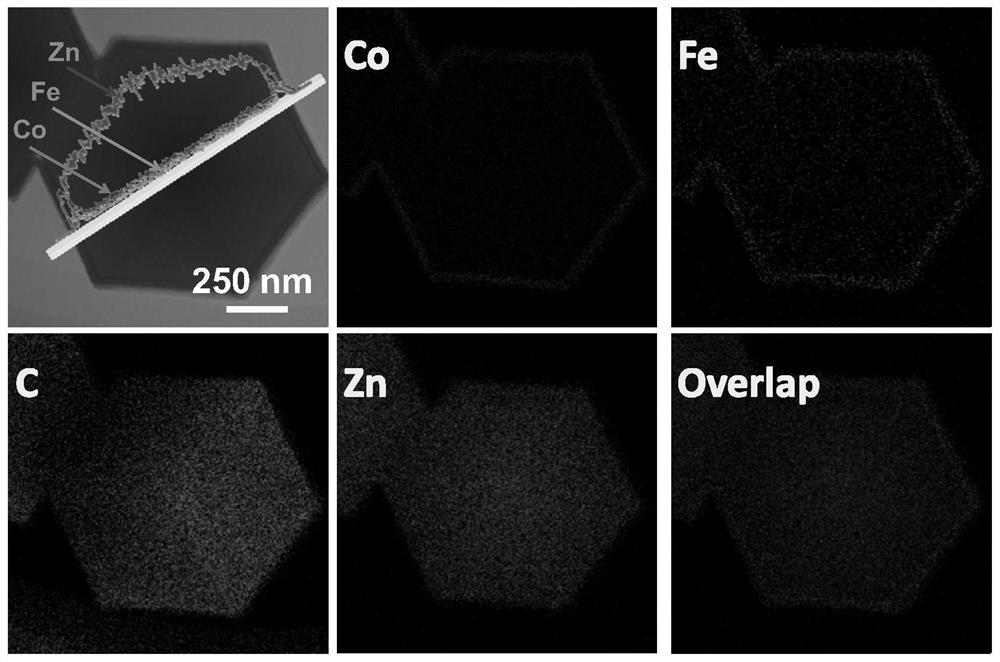

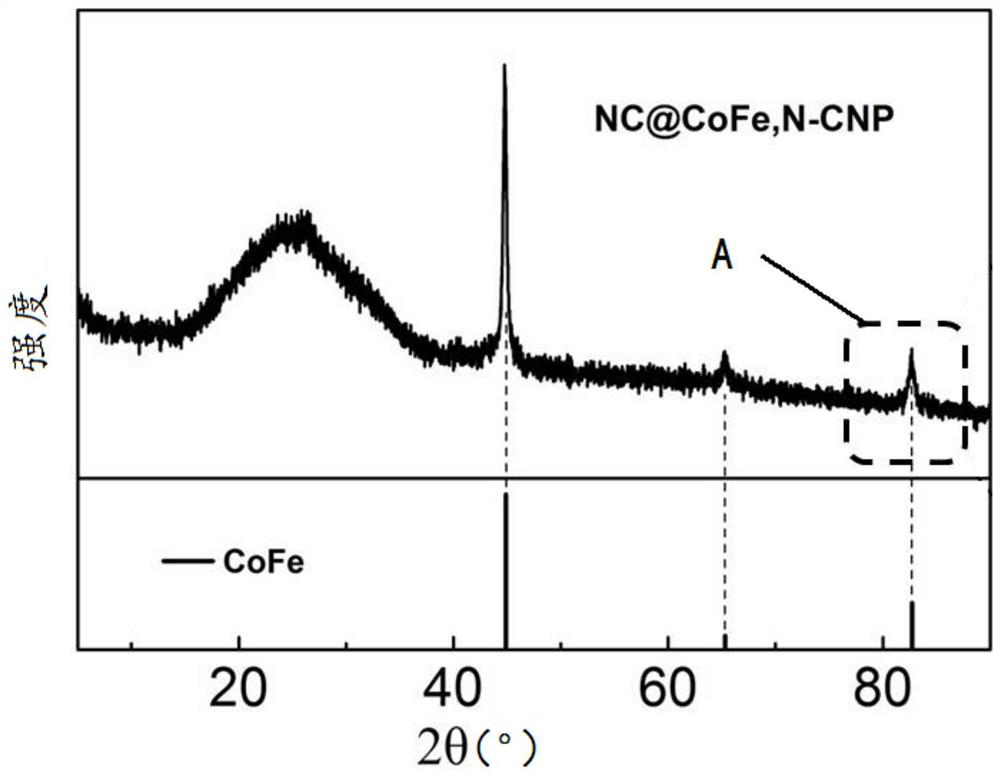

A kind of cobalt-iron alloy, nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application

ActiveCN111697239BGuaranteed stabilityAvoid entrapment problemsCell electrodesFuel cellsPtru catalystPhysical chemistry

The invention relates to a cobalt-iron alloy and nitrogen co-doped carbon oxygen reduction catalyst. The precursor of the catalyst is a core-shell structure, wherein the core of the precursor is a material with pore-forming and supporting functions, and the shell of the precursor is Fe, Co-ZIF, the shell of the catalyst is an iron-cobalt alloy. The core of the precursor as a support can ensure the stability of the core-shell structure and avoid the problem of catalyst active sites being embedded due to the collapse of the structure during the pyrolysis process. The hierarchical pore structure that is favorable for mass transfer can also promote the uniform dispersion of metal ions in the shell during the pyrolysis process; the shell uses the synergistic catalytic effect of CoFe alloy and active site N to greatly improve the catalytic activity of oxygen reduction; bimetallic iron Co-doped with cobalt and co-doped with nitrogen in the ZIF shell, the metal and nitrogen are spaced apart, which can promote the uniform dispersion of metal particles after high temperature pyrolysis.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Regeneration method of hydrogenation catalyst

ActiveCN114130409AImprove hydrodesulfurization activityEliminate interactionHeterogenous catalyst chemical elementsCatalyst regeneration/reactivationPtru catalystOrganic chemistry

The invention provides a regeneration method of a hydrogenation catalyst. The method comprises the following steps: (1) mixing inactivated hydrogenation catalysts A1 and A2, soaking the mixture in a solvent, and carrying out ultrasonic treatment to obtain a catalyst B and a mixed material mixed with black powder; (2) recovering the catalyst B, and filtering the mixed material mixed with the black powder to obtain powder C; (3) grinding the catalyst B into powder, screening to obtain catalyst powder D, and forming, drying and roasting to obtain a regenerated carrier; and (4) dissolving the powder C in diesel oil, dipping on a regenerated carrier, and drying to obtain the regenerated hydrogenation catalyst. According to the method, active metal components do not need to be additionally supplemented, the desulfurization performance of the regenerated catalyst is good, the dosage of a vulcanizing agent can be reduced, the vulcanizing time can be shortened, and the obtained regenerated hydrogenation catalyst has good physicochemical properties and activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkali-activated high-titanium slag unfired ceramsite and preparation method thereof

The invention discloses alkali-activated high-titanium slag baking-free haycite which is characterized by being prepared by mixing 100 weight parts of high-titanium slag micro powder, 12.5 to 30 weight parts of an alkali-activator, 0.5 to 10 weight parts of a pore forming substance and 0 to 10 weight parts of water. A preparation method of the alkali-activated high-titanium slag baking-free haycite comprises the following steps: putting the high-titanium slag micro powder into a disk granulator for stirring, so as to form a uniformly dispersed powder body; adding the pore forming substance, the water and the alkali-activator solution in sequence, and performing stirring, granulation and forming to obtain a blank, wherein the alkali-activator solution is water glass; maintaining the blank under a natural environment condition for 28 days, so as to obtain the alkali-activated high-titanium slag baking-free haycite. By the adoption of the preparation method for preparing the alkali-activated high-titanium slag baking-free haycite, high-temperature baking is not needed; a large mixing amount of the high-titanium slag micro powder can be used, so that a product is light in mass and high in strength; the alkali-activated high-titanium slag baking-free haycite has the characteristics of simple process, low cost, energy conservation, low carbon, environment friendliness and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of wear-resistant large-pore-volume microspherical silica carrier

The invention provides a preparation method of a wear-resistant large-pore-volume microspherical silica carrier. The preparation method comprises the steps: roasting precipitated silica powder or white carbon black with the specific surface area of 250-600 m<2> / g at the temperature of 730-760 DEG C, and making the specific surface area reduced to 100-220 m<2> / g; adding water to the precipitated silica powder or white carbon black, adding an acid, adjusting the pH to 2-3, grinding and dispersing until the diameters of micro particles are all 1 [mu]m or less, adding the roasted silica powder, grinding and dispersing until the average diameter of micro particles is 2-5 [mu]m, adding an activated carbon emulsion, mixing evenly, carrying out spray granulation, roasting at the temperature of 650-720 DEG C, and thus obtaining the microspherical carrier with the average diameter of 50-250 [mu]m, the specific surface area of 80-200 m<2> / g, the pore volume of 0.7-1.1 ml / g, and the average pore diameter of 20-40 nm. The prepared microspherical silica carrier has the advantages of wear resistance and impact resistance, and is suitable for preparation of a catalyst for a fluidized bed.

Owner:钟俊超

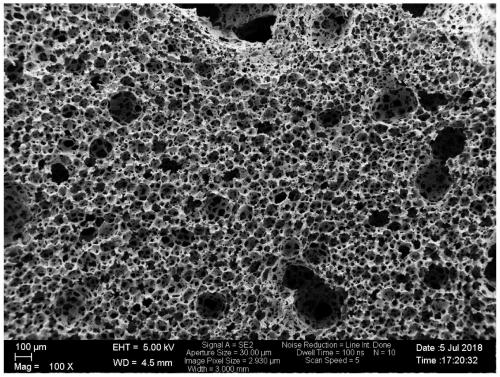

A method for preparing foamed ceramics with connected pore walls by using hollow microspheres

The invention discloses a method utilizing hollow micro-spheres to prepare foamed ceramic provided with communicated hole walls. The method comprises the following steps that ceramic powder and hollowmicro-spheres are used as raw materials to prepare water-based slurry with the total solid phase content of 20%-50% by weight. A surface active agent is added in the slurry to conduct hydrophobization modification on the ceramic powder. Slurry foaming is performed in a mechanical stirring mode to obtain ceramic grains and foam cooperatively stable with the hollow micro-spheres, and sintering is performed to obtain the foamed ceramic provided with communicated hole walls after foam drying. The hollow micro-spheres embedded into the hole walls play a hole formation effect through sintering treatment. Therefore, the prepared foam structure has a highly pored structure and can be applied to the fields such as adsorption, catalysis and filtration.

Owner:北京华圻生态科技有限公司

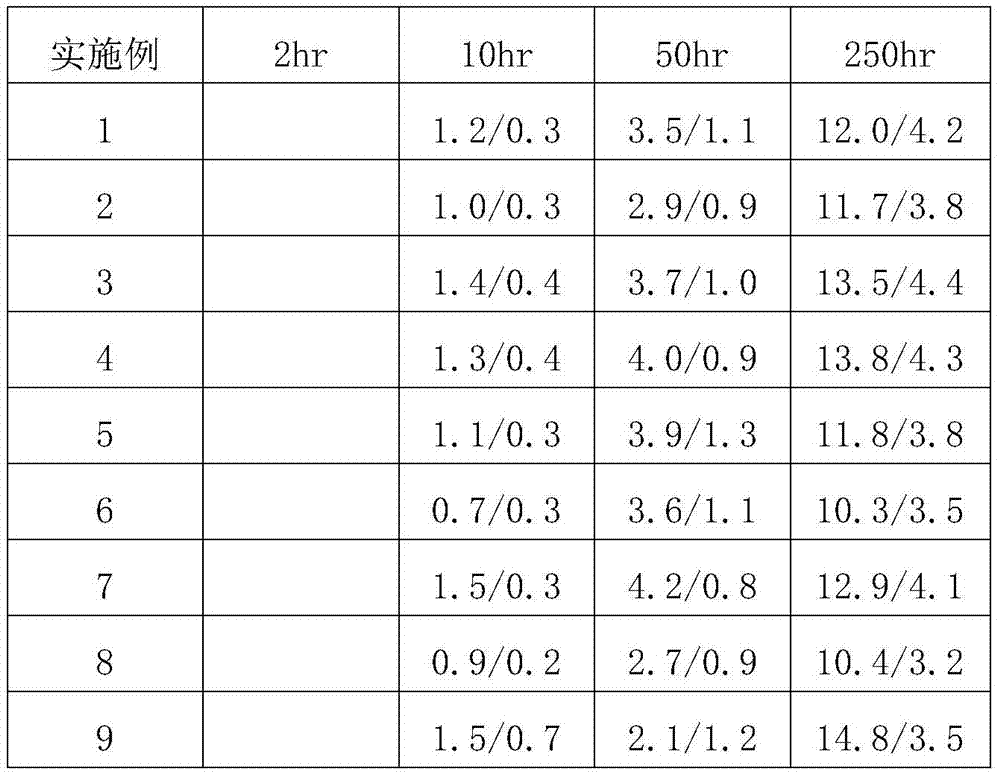

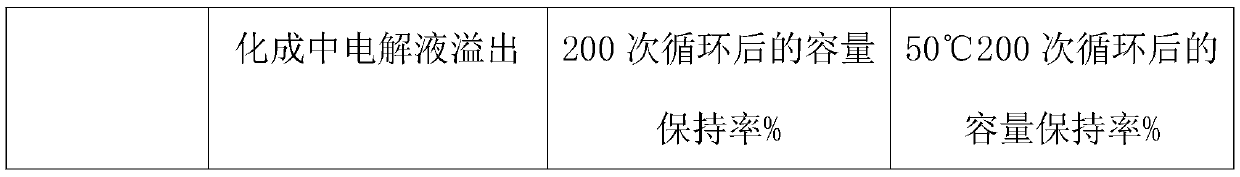

A kind of formation process of lithium ion battery

ActiveCN109256592BImprove cycle performanceAvoid negative effectsFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryLithium-ion battery

The invention provides a lithium ion battery formation process, which includes the control of liquid injection, atmosphere, pressure, temperature and formation current and voltage during the formation process, so as to promote the formation of dense SEI on the electrode surface of the lithium ion battery film, improve the cycle life and capacity retention of the battery.

Owner:星恒电源(滁州)有限公司

Regeneration method of hydrogenation catalyst

PendingCN114130418AWide range of applicationsImprove catalyst performanceCatalyst regeneration/reactivationHydrocarbon oils treatmentChemistryEngineering

The invention provides a regeneration method of a hydrogenation catalyst. The method comprises the following steps: (1) mixing inactivated hydrogenation catalysts A1 and A2, soaking the mixture in a solvent, and carrying out ultrasonic treatment to obtain a catalyst B and a mixed material mixed with black powder; (2) recovering the catalyst B, and filtering the mixed material mixed with the black powder to obtain powder C; (3) grinding the catalyst B into powder, and screening to obtain catalyst powder D; forming, drying and roasting the catalyst powder D to obtain a regenerated carrier; (4) dissolving the powder C in liquid paraffin, and stirring; and then dipping on a regenerated carrier, cooling, carbonizing, and carrying out hydro-thermal treatment to obtain the regenerated hydrogenation catalyst. According to the method, active metal components do not need to be additionally supplemented, the desulfurization performance of the regenerated catalyst is good, the dosage of a vulcanizing agent can be reduced, the vulcanizing time can be shortened, and the obtained regenerated hydrogenation catalyst has a reasonable pore structure, strength and metal distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of magnetic mgo nano flower phosphate adsorbent and its preparation method and application

ActiveCN111889064BPlay a pore-forming roleLarge specific surface areaWater treatment parameter controlOther chemical processesO-Phosphoric AcidPhosphate

Owner:NANKAI UNIV

Regeneration method of hydrogenation catalyst

ActiveCN113000073AEliminate interactionQuality improvementCatalyst regeneration/reactivationChemical recyclingPtru catalystMaterials science

The invention provides a regeneration method of a hydrogenation catalyst. The method comprises the following steps: (1) immersing an inactivated hydrogenation catalyst A in a solvent, carrying out ultrasonic treatment to obtain a catalyst B and a mixed material mixed with black powder, recovering the catalyst B, and filtering the mixed material mixed with the black powder to obtain powder C; (2) grinding the catalyst B into powder, and screening to obtain catalyst powder D; (3) forming, drying and roasting the catalyst powder D to obtain a regenerated carrier; and (4) dissolving the powder C obtained in the step (1) in diesel oil, dipping on a regenerated carrier, and drying to obtain the regenerated hydrogenation catalyst. According to the method disclosed by the invention, additional supplement of active metal components is not needed, interaction between the carrier and metal molybdenum is basically eliminated in the preparation process of the catalyst, and uniform dispersion of molybdenum sulfide can also be realized, so that the obtained regenerated hydrogenation catalyst has relatively good physicochemical properties and activity. And the use amount of the vulcanizing agent can be reduced and the vulcanizing time can be shortened at the start-up stage of the industrial device.

Owner:CHINA PETROLEUM & CHEM CORP +1

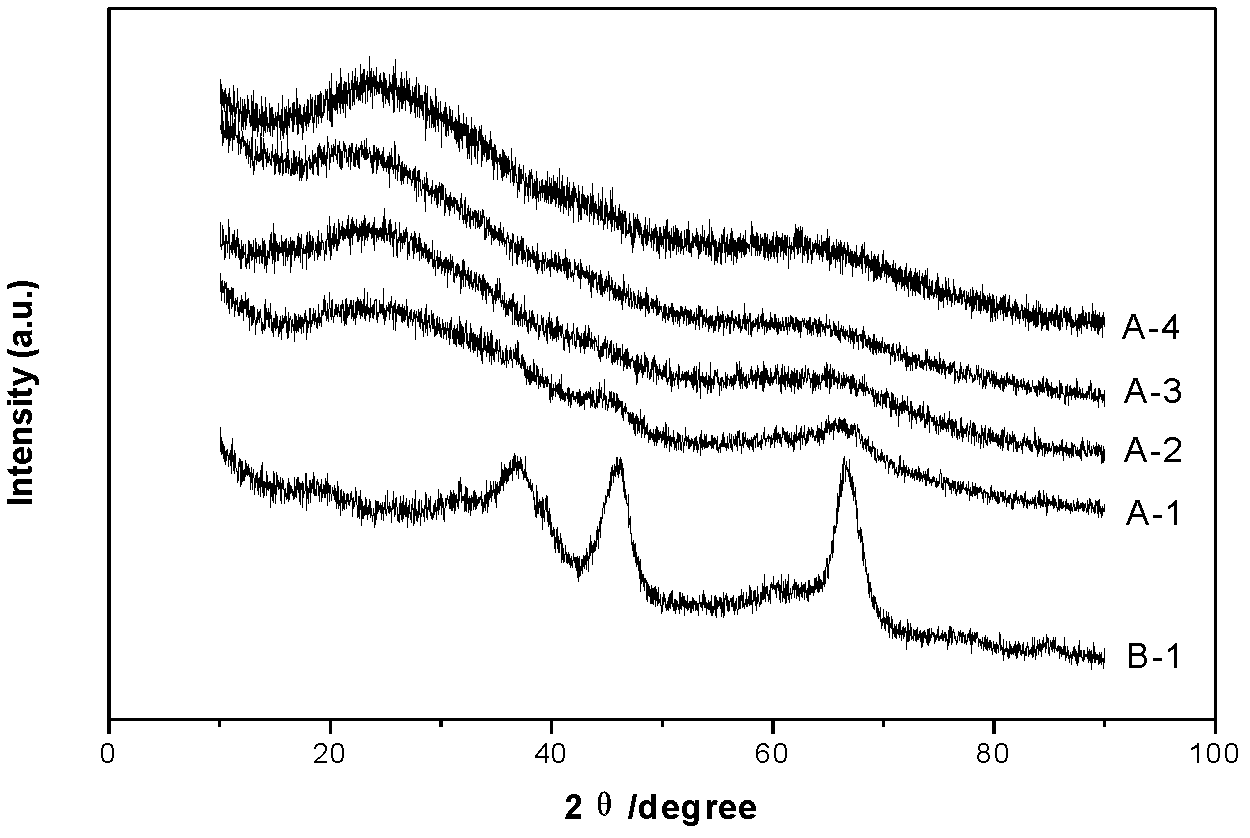

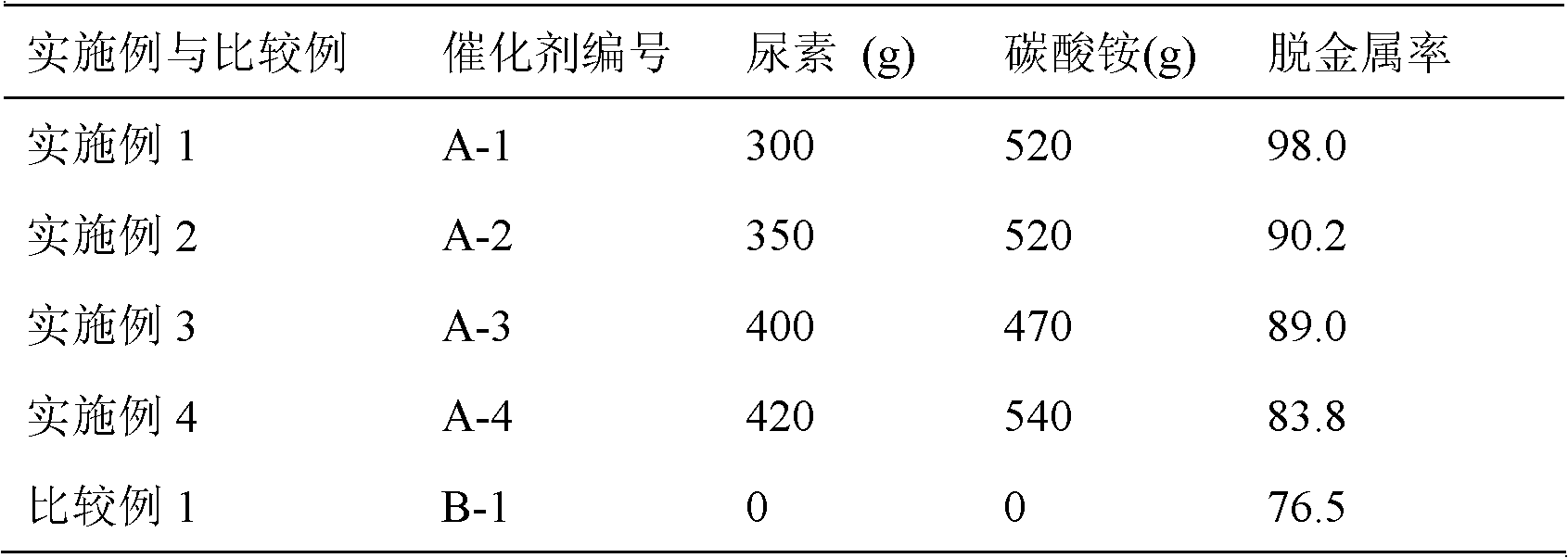

Preparation method of hydrogenation demetallization catalyst

InactiveCN102600858BTunable interactionHigh hydrodemetallization activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsMetal catalystAmmonium carbonate

The invention provides a preparation method of a hydrogenation demetallization catalyst, relates to a catalyst, and provides a preparation method of the hydrogenation demetallization catalyst, which is simple in preparing process, short in preparing period short and higher hydrogenation demetallization activity of prepared catalyst. The hydrogenation demetallization catalyst is prepared by the steps of: dissolving aluminum chloride hexahydrate grains in water, and then sequentially adding ammonium molybdate and basic nickel carbonate to obtain a solution A; then adding urea to the solution A for dissolving to obtain a solution B; adding ammonium carbonate to the solution B to generate gel; and aging the gel, drying and calcining.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com