Batch preparation method for titanium-based air suction element with high porosity

A high-porosity, mass-produced technology, applied in chemical instruments and methods, other chemical processes, metal processing equipment, etc., can solve the problems of titanium-based non-evaporable getter comprehensive performance and mass production capacity gap, and achieve product stability Good performance, low preparation cost and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

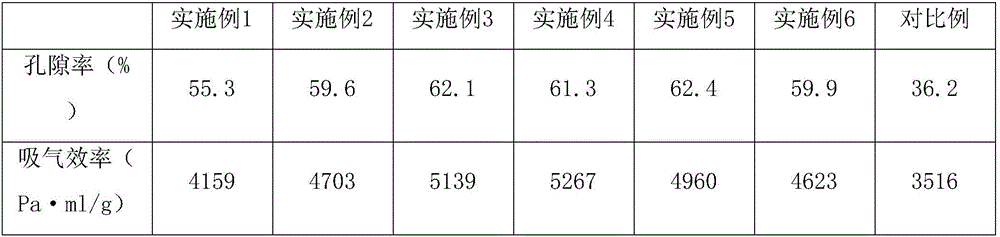

Examples

Embodiment 1

[0027] (1) Under the condition of argon protection, according to the weight ratio of 9:1, the volume ratio of titanium powder with a particle size of 25 μm and an average particle size of 45 μm is 1:1:1:1 Molybdenum powder, zirconium vanadium iron powder , the mixture of zirconium aluminum powder and zirconium nickel powder is mixed for 24h until uniform, and the titanium-based raw material is obtained.

[0028] (2) Under the protection of argon, in parts by weight, 19 parts of titanium-based raw materials and 1 part of ammonium bicarbonate with a particle size of 20 μm are uniformly mixed, and 19 parts of organic binder are added, and mixed for 2 hours in total. Stop for 0.5h for 5 minutes to form injection feed, the organic binder is a mixture of paraffin wax, high-density polyethylene, polypropylene and stearic acid, wherein the mass percentage of paraffin wax is 70%, and the mass percentage of high-density polyethylene is 10% , the mass percentage of polypropylene is 10%, ...

Embodiment 2

[0033] (1) Under the condition of argon protection, according to the weight ratio of 7:3, the volume ratio of titanium powder with a particle size of 45 μm and an average particle size of 45 μm is 1:1:1:1 Molybdenum powder, zirconium vanadium iron powder , the mixture of zirconium aluminum powder and zirconium nickel powder is mixed for 24h until uniform, and the titanium-based raw material is obtained.

[0034] (2) Under the protection of argon, by weight, 4 parts of titanium-based raw materials and 1 part of ammonium bicarbonate with a particle size of 25 μm are uniformly mixed, and 1 part of organic binder is added, and mixed for 2 hours in total. Stop for 0.5h for 5 minutes to form injection feed, the organic binder is a mixture of paraffin wax, high-density polyethylene, polypropylene and stearic acid, wherein the mass percentage of paraffin wax is 70%, and the mass percentage of high-density polyethylene is 10% , the mass percentage of polypropylene is 10%, and the balan...

Embodiment 3

[0039] (1) Under the condition of argon protection, according to the weight ratio of 4:1, the volume ratio of titanium powder with a particle size of 30 μm and an average particle size of 45 μm is 1:1:1:1 Molybdenum powder, zirconium vanadium iron powder , the mixture of zirconium aluminum powder and zirconium nickel powder is mixed for 24h until uniform, and the titanium-based raw material is obtained.

[0040](2) Under argon protection, in parts by weight, mix 1 part of titanium-based raw material with 1 part of ammonium bicarbonate with a particle size of 23 μm, add 1 part of organic binder, and mix for 2 hours in total. Stop for 0.5h for 5 minutes to form injection feeding, the organic binder is a mixture of paraffin wax, high-density polyethylene, polypropylene and stearic acid, wherein the mass percentage of paraffin wax is 40%, and the mass percentage of high-density polyethylene is 20% , the mass percentage of polypropylene is 20%, and the balance is stearic acid.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com