Preparation method of wear-resistant large-pore-volume microspherical silica carrier

A technology of spherical silica and large pore volume, used in catalyst supports, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of reducing the mechanical strength and wear resistance of the carrier, the wear resistance of the carrier cannot be greatly improved, and the sintering Poor performance and other problems, to achieve the effect of stable catalytic reaction performance, not easy to break, and good sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 1000g of calcined silica powder A, put it into a mixing tank, add 3000g of deionized water, start stirring and beating, after the dispersion is uniform, use a homogenizer to grind and disperse to the average particle diameter of 5um, transfer to an autoclave, add 200g of acetic acid, acetic acid Ammonium 50g sizing liquid pH value to 3.5, crystallization treatment at 150°C for 40hrs, cooling to 60°C, the specific surface area of silica particles was measured to be 122m 2 / g; add 2000g activated carbon emulsion M (containing activated carbon 200g, the average diameter of activated carbon microparticles is 1.5um), mix well after stirring for 10 minutes, add 600g acidic silica sol D (SiO mass concentration 30%, Na 2 (00.06%, colloidal average diameter 10nm), mix after stirring 10 minutes, pump into the centrifugal spray granulator that has been preheated to 200 ℃ of working temperature and carry out granulation and adjust the rotating speed of feed pump and centrifug...

Embodiment 2

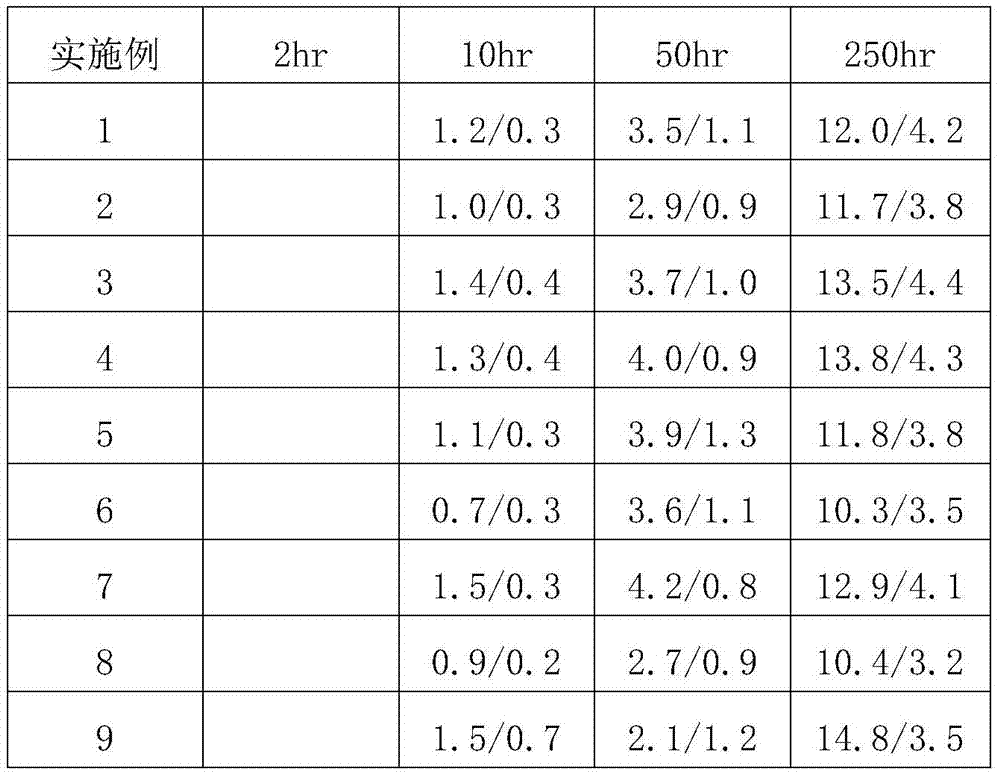

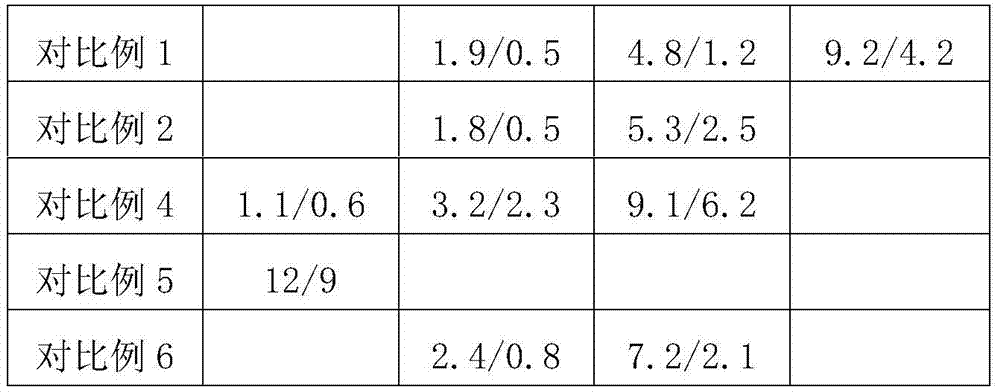

[0042] The other half of the granulated micropowder in Example 1 was calcined at 720° C. for 3 hours to obtain the microspherical silica carrier with large pore volume of the present invention. The average diameter of the measured carrier is 213um, the sphericity is good, and the strength is good; the specific surface area is 100m 2 / g, the pore volume is 0.90ml / g, and the average pore diameter is 39nm; the measured wear rate and fragmentation rate are relatively low, see the data listed in the table below for details.

Embodiment 3

[0044] Take 1000g of calcined silica powder B, put it into the mixing tank, add 3000g of deionized water, start stirring and beating, after the dispersion is uniform, use a homogenizer to grind and disperse to the average particle diameter of 5um, transfer to the autoclave, add 200g of acetic acid, acetic acid Ammonium 100g sizing liquid pH value to 4.0, crystallization treatment at 165°C for 20hrs, cooling to 60°C, measured specific surface area of silica particles 102m 2 / g, add 2500g activated carbon emulsion M (containing activated carbon 250g, the average diameter of activated carbon microparticles is 1.5um), mix well after stirring for 10 minutes, add 1200g acidic silica sol E (silica mass concentration 20%, Na 2 (00.10%, colloidal average diameter 20nm), mix after stirring 10 minutes, pump into the centrifugal spray granulator that has been preheated to 240 ℃ of working temperature and carry out granulation and adjust the rotating speed of feed pump and centrifuge, mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com