Preparation method of gas phase fluorination catalyst

A technology for phase fluorination catalysts and fluorination catalysts, which is applied in the field of preparation of fluorination catalysts, and can solve the problems of frequent regeneration and activation, reduced specific surface area, and low activity of fluorination catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

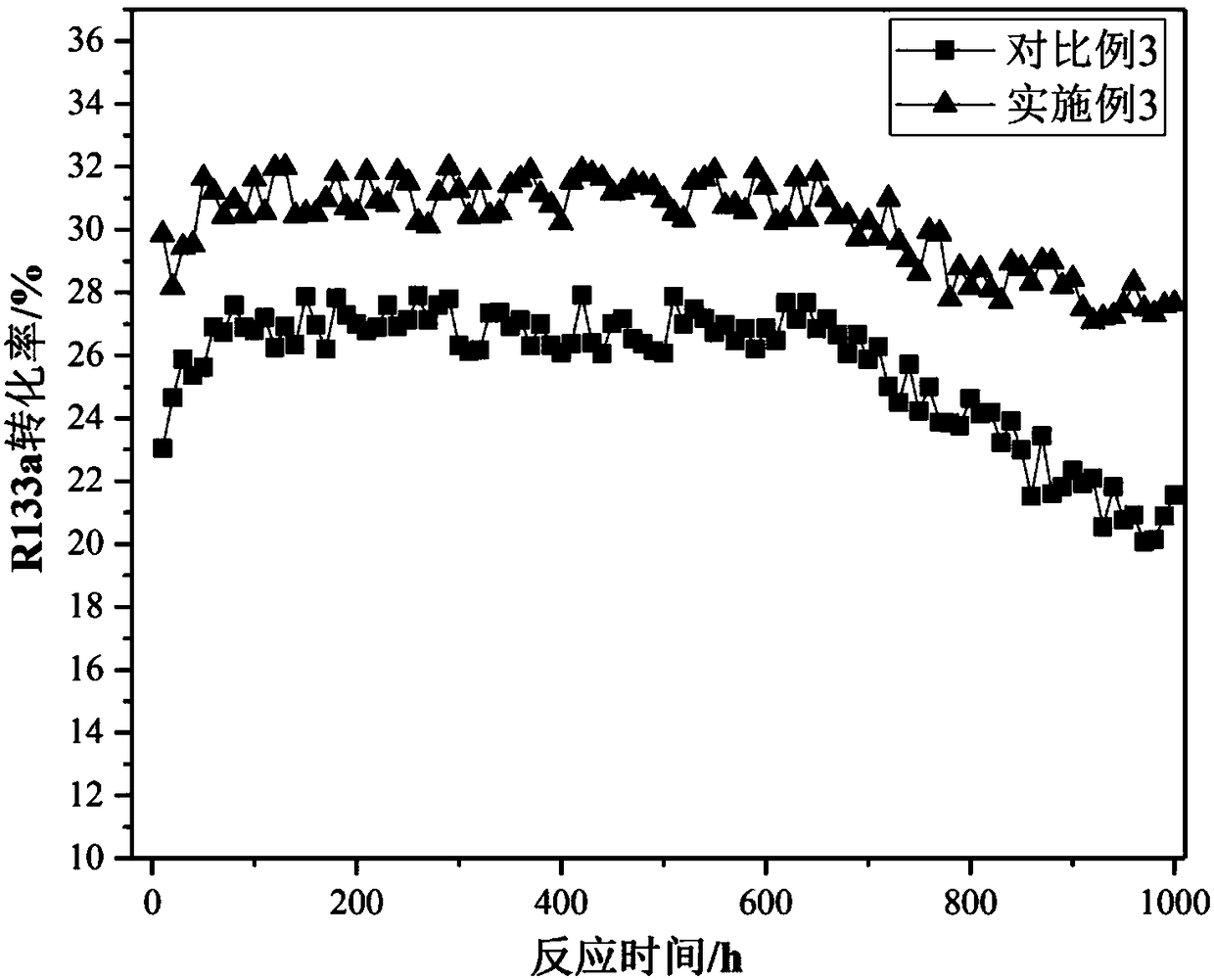

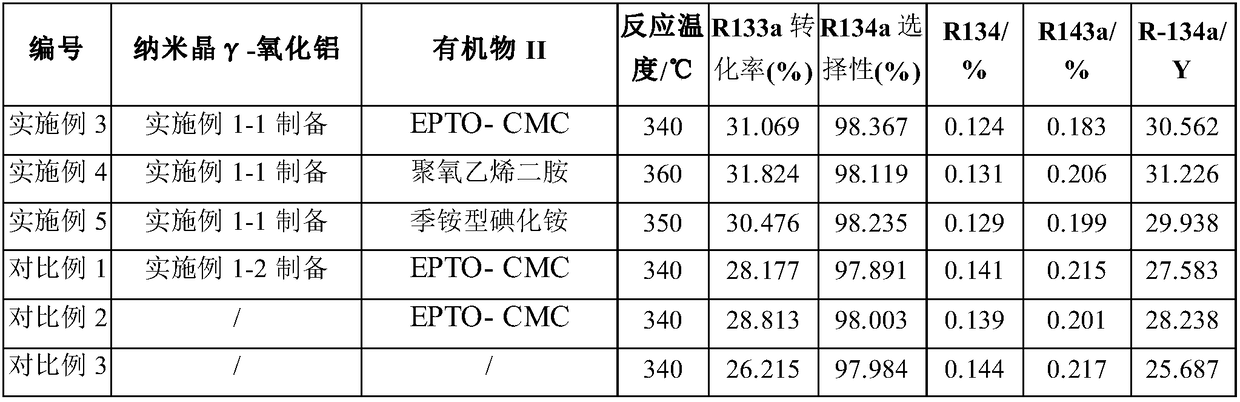

Examples

Embodiment 1-1

[0071] The preparation of embodiment 1-1 nanocrystalline γ-alumina powder

[0072] 25.03g Al(NO 3 ) 3 9H 2 O, 1.35g MgCl 2 , 0.21gLaCl 3 1. 1g of organic matter I (0.26g of isopropanol + 0.56g of tartaric acid + 0.18g of glucose) was dissolved in 500mL of ethanol solvent, refluxed at 80°C for 2h, then added dropwise with ammonium carbonate aqueous solution for 10min, and then maintained the reaction Crystallize at high temperature for 12 hours to obtain a liquid sol, then vacuum dry the liquid sol at 110°C for 12 hours to obtain a solid gel, and finally roast at 550°C for 3 hours to obtain nanocrystalline γ-alumina powder, which is used as a carrier for future use.

Embodiment 1-2

[0073] The preparation of embodiment 1-2 nanocrystalline gamma-alumina powder

[0074] 25.03g Al(NO 3 ) 3 9H 2 O was dissolved in 500mL ethanol solvent, refluxed at 80°C for 2h, then ammonium carbonate aqueous solution was added dropwise for 10min, and then crystallized at the reaction temperature for 12h to obtain a liquid sol, and then the liquid sol was vacuum-dried at 110°C After 12 hours, a solid gel was obtained, and finally the nanocrystalline γ-alumina powder was obtained by roasting at 550°C for 3 hours.

Embodiment 2

[0075] The preparation of embodiment 2 amorphous chromium oxide powder

[0076] Weigh 50.02g CrCl 3 ·6H 2 O, 1.85gMgCl 2 , 2.81g AlCl 3 , 1.53gZnCl 3 , 0.21g LaCl 3 , 2.49g organic matter I (0.68g ethanol+1.42g citric acid+0.39g sucrose) was dissolved in 900mL deionized water to obtain a mixed salt solution, the mixed salt solution was mixed with ammonia water until the solution pH=10, filtered and washed with water to obtain a sample, The sample was dried in an oven at 110°C for 6 hours, and then transferred to a roasting furnace. 2 Roast at a high temperature of 350°C for 3 hours in the atmosphere, crush and sieve the calcined sample to obtain amorphous chromium oxide powder for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com