Seed emulsion of opacifying polymer and preparation process

A technology for covering polymers and polymers, which is applied in the field of seed emulsions and preparation processes of covering polymers, can solve the problems of increasing the VOC content of emulsions, not conforming to the concept of environmental protection, and complicated preparation processes, and achieves increased coating uniformity and reduced Unstable glue or slag problems, the effect of low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

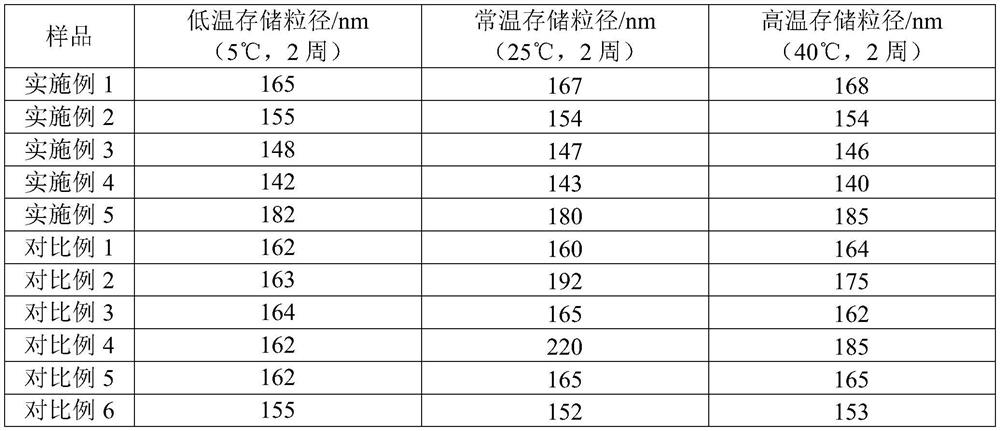

Embodiment 1

[0055] Prepare the masking polymer seed emulsion raw material according to the following recipe:

[0056] 70g of deionized water,

[0057] Methyl methacrylate 20g,

[0058] Methacrylic acid 10g,

[0059] Solvay RHODAPEX TR / 2030-S 1.08g,

[0060] Ethylene glycol dimethacrylate 0.3g,

[0061] Vinyltrimethoxysilane 0.3g,

[0062] Evonik VISOMER Terra C13-MA 0.3g,

[0063] Ammonium persulfate 0.12g,

[0064] Clariant Emulsogen LCN407 0.05g,

[0065] Polyvinyl alcohol 0.01g.

[0066] Prepare the seed emulsion of covering polymer according to the following process:

[0067] 1) Prepare the pre-emulsion: Add 20g of deionized water and 1g of anionic emulsifier (Solvay RHODAPEXTR / 2030-S) into the pre-emulsification kettle under normal temperature and pressure to fully dissolve and mix, and add the formula in turn under stirring A certain amount of methyl methacrylate, methacrylic acid, crosslinking agent (ethylene glycol dimethacrylate), 350rpm high-frequency stirring 15min, ma...

Embodiment 2

[0076] Prepare the masking polymer seed emulsion raw material according to the following recipe:

[0077] 60g of deionized water,

[0078] Methyl methacrylate 22g,

[0079] Methacrylic acid 8g,

[0080] Clariant Emulsion EPA073 1.285g,

[0081] Allyl methacrylate 0.4g,

[0082] Vinyltriethoxysilane 0.1g,

[0083] BASF LMA1214F 0.4g,

[0084] Sodium persulfate 0.115g,

[0085] Solvay ABEX AP470-Z 0.08g,

[0086] Polyvinyl alcohol 0.04g.

[0087] Prepare the seed emulsion of covering polymer according to the following process:

[0088] 1) Prepare the pre-emulsion: under normal temperature and pressure, add 15g of deionized water and 1.2g of anionic emulsifier (Clariant Emulsion EPA073) into the pre-emulsion kettle to fully dissolve and mix. While stirring, add the formula amount of formazan in sequence methyl acrylate, methacrylic acid, crosslinking agent (allyl methacrylate), 350rpm high-frequency stirring for 25min, to make a pre-emulsion;

[0089] 2) Preparation of ...

Embodiment 3

[0097] Prepare the masking polymer seed emulsion raw material according to the following recipe:

[0098] 90g of deionized water,

[0099] Methyl methacrylate 18g,

[0100] methacrylic acid 12g,

[0101] Solvay ABEX 8018R 0.92g,

[0102] Trimethylolpropane trimethacrylate 0.2g,

[0103] γ-methacryloxypropyltrimethoxysilane 0.4g,

[0104] Evonik VISIOMER Terra C17.4-MA 0.2g,

[0105] Potassium persulfate 0.12g,

[0106] Clariant Emulsogen LCN407 0.03g,

[0107] Polyvinyl alcohol 0.07g.

[0108] Prepare the seed emulsion of covering polymer according to the following process:

[0109] 1) Prepare the pre-emulsion: under normal temperature and pressure, add 22g of deionized water and 0.8g of anionic emulsifier (Solvay ABEX8018R) into the pre-emulsification kettle to fully dissolve and mix, and add the formula amount of formazan in sequence under stirring methyl acrylate, methacrylic acid, crosslinking agent (trimethylolpropane trimethacrylate), 350rpm high-frequency stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com