MEMS component with composite getter layer and preparation method thereof

A technology of getters and components, applied in the direction of electrical components, coatings, electric solid devices, etc., can solve the problems of internal vacuum degree reliability attenuation, lack of space for getters, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

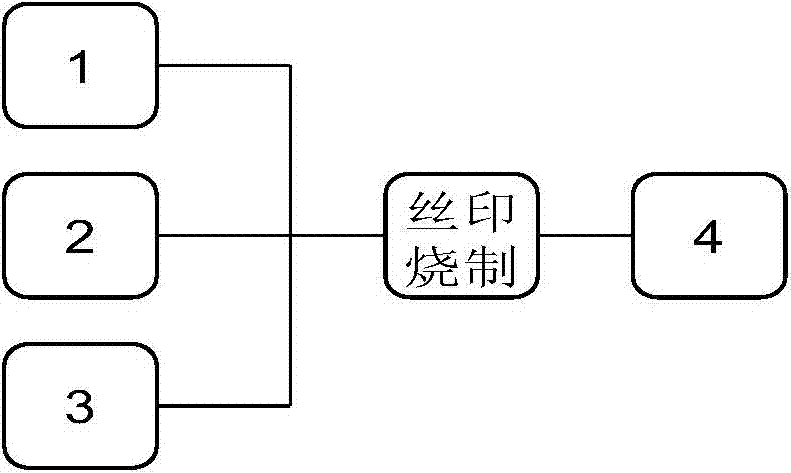

[0030] The process of preparing MEMS components with composite getter layers is as follows figure 1 As shown, the specific operation is as follows:

[0031] A. Mix the three components of ferro-zirconium vanadium getter powder (55wt%), organic binder (40wt%) and niobium oxide (5wt%); the organic binder is ethyl cellulose, silane The mixed solution of the joint agent and terpineol, the weight ratio of the three is 5%: 10%: 85%.

[0032] B. Use a 200-mesh polyester screen to screen-print a composite getter layer with a thickness of 95 microns on the Kovar cover plate of the MEMS device;

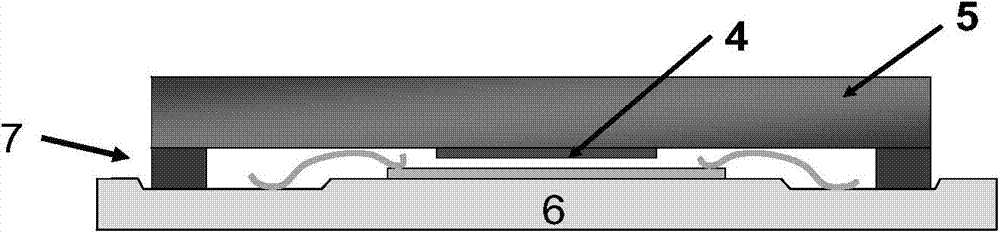

[0033] C. Vacuum firing the MEMS device prepared in step B at 450° C. for 1 hour to prepare a MEMS component with a composite getter layer. MEMS component structure such as figure 2 As shown, the composite getter layer 4 is attached to the cover plate 5 of the MEMS device.

[0034] The fired cover plate with the composite getter layer was kept at a temperature of 300° C. for 1 hour to cond...

Embodiment 2

[0037] Adopt the technical process identical with embodiment 1, concrete operations are as follows:

[0038] A. Mix the three components of ferro-zirconium vanadium getter powder (40wt%), organic binder (50wt%) and cerium oxide (10wt%); the organic binder is ethyl cellulose, silane The mixed solution of the joint agent and terpineol, the weight ratio of the three is 10%: 15%: 75%.

[0039] B. use 300 purpose polyester screens to screen-print a composite getter layer with a thickness of 40 microns on the ceramic shell of the MEMS device;

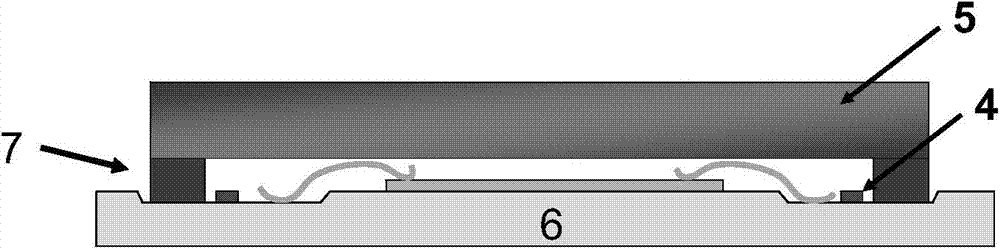

[0040] C. Vacuum firing the MEMS device prepared in step B at 450° C. for 1.5 hours to prepare a MEMS component with a composite getter layer. MEMS component structure such as image 3 As shown, the composite getter layer 4 is attached to the ceramic package 6 of the MEMS device.

[0041] The fired cover plate with the composite getter layer was kept at a temperature of 300° C. for 1 hour to conduct the getter activation test. The result ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com