Preparation method of hydrogenation demetallization catalyst

A hydrodemetallization and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of heavy oil processing process being greatly affected, shorten the preparation cycle and simplify the preparation process , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

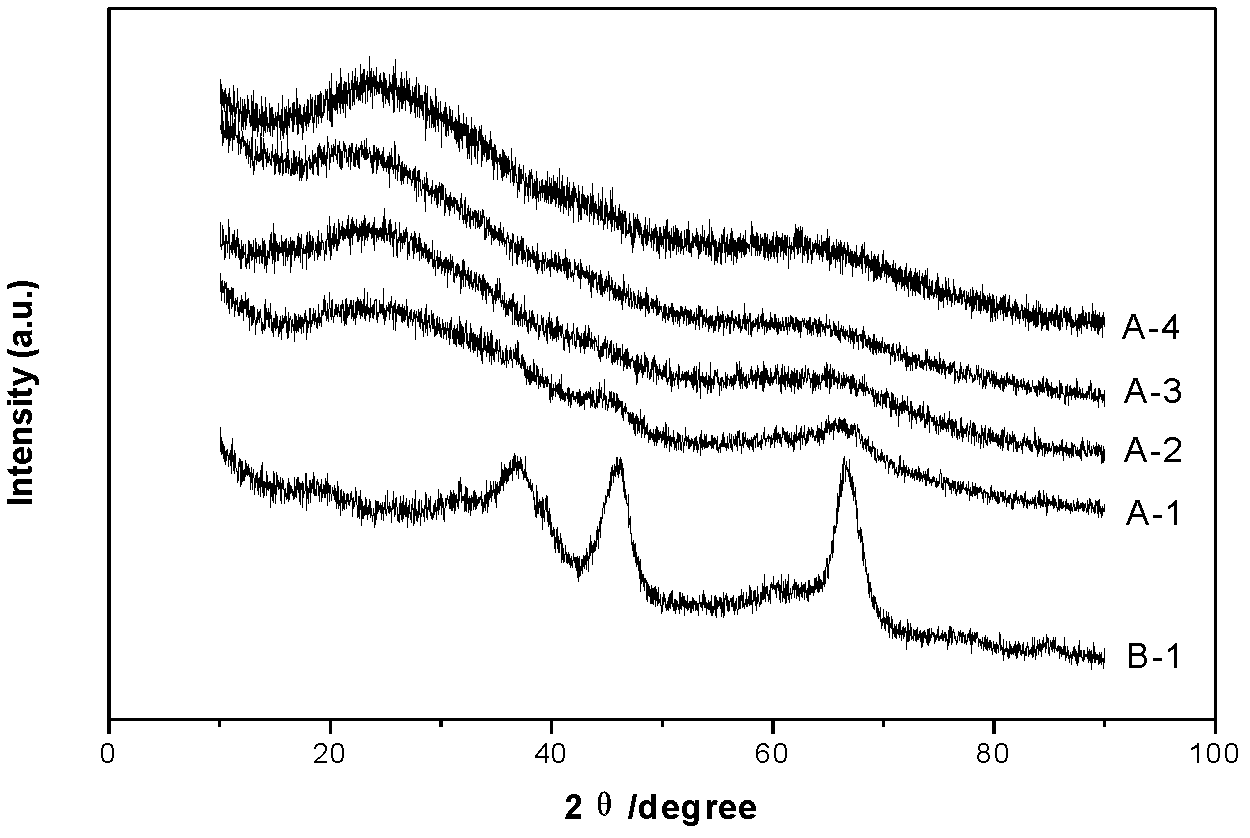

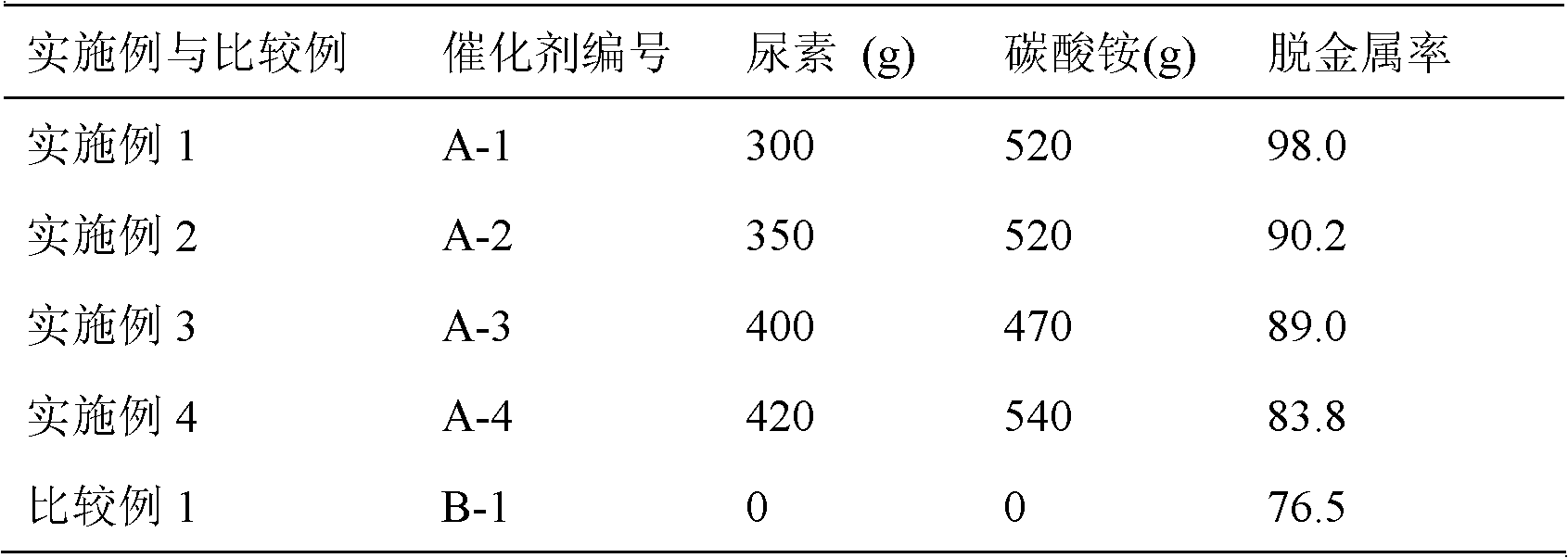

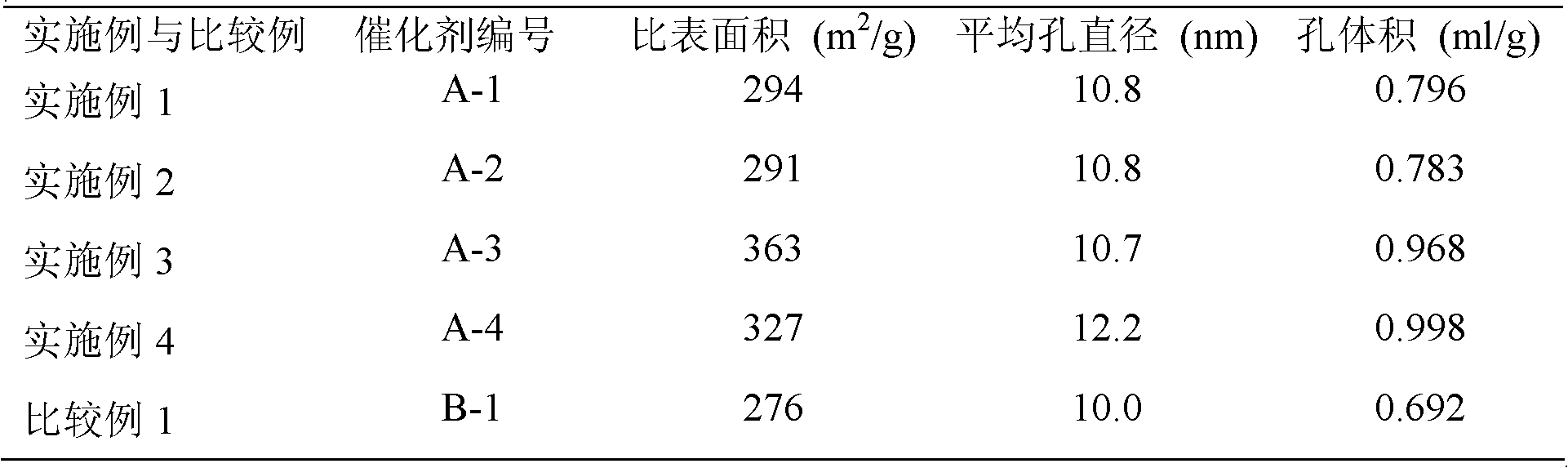

[0017] Example 1: Weigh 98g of aluminum chloride hexahydrate in a beaker, add 100mL of deionized water, stir in a constant temperature water bath at 80°C until completely dissolved, add 1.85g of ammonium molybdate and 1.9g of basic nickel carbonate successively under stirring , after completely dissolving, add 300g of urea, add ammonium carbonate gradually under stirring until gelatinous, the dosage is 52g, aging at 25°C for 12h, drying at 80°C for 12h, and calcining at 500°C for 3h in a muffle furnace to obtain the catalyst. Gained supported hydrodemetallization catalyst contains NiO 5.0%, MoO 3 7.5%, and the resulting catalyst was labeled A-1. See Table 1 for additive addition and hydrodemetallization activity, see Table 2 for the physical properties of the prepared catalyst, and see Table 2 for the X-ray powder diffraction spectrum. figure 1 .

Embodiment 2

[0018] Embodiment 2: Similar to Embodiment 1, the difference is that the urea is changed to 350g, the ammonium carbonate consumption is still 520g, and the resulting catalyst is marked as A-2. See Table 1 for additive addition and hydrodemetallization activity, see Table 2 for the physical properties of the prepared catalyst, and see Table 2 for the X-ray powder diffraction spectrum. figure 1 .

Embodiment 3

[0019] Embodiment 3: similar to Example 1, the difference is that the urea is changed to 400g, the ammonium carbonate consumption is 470g, and the resulting catalyst is marked as A-3. See Table 1 for additive addition and hydrodemetallization activity, see Table 2 for the physical properties of the prepared catalyst, and see Table 2 for the X-ray powder diffraction spectrum. figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com