Spinning position, air spinning machine and method for producing yarn

A technology of open-end spinning and yarn, which is applied in the field of spinning stations and open-end spinning machines, can solve the problems of weakening yarn properties such as yarn stability and influence, and achieve the effect of expanding application fields and application possibilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

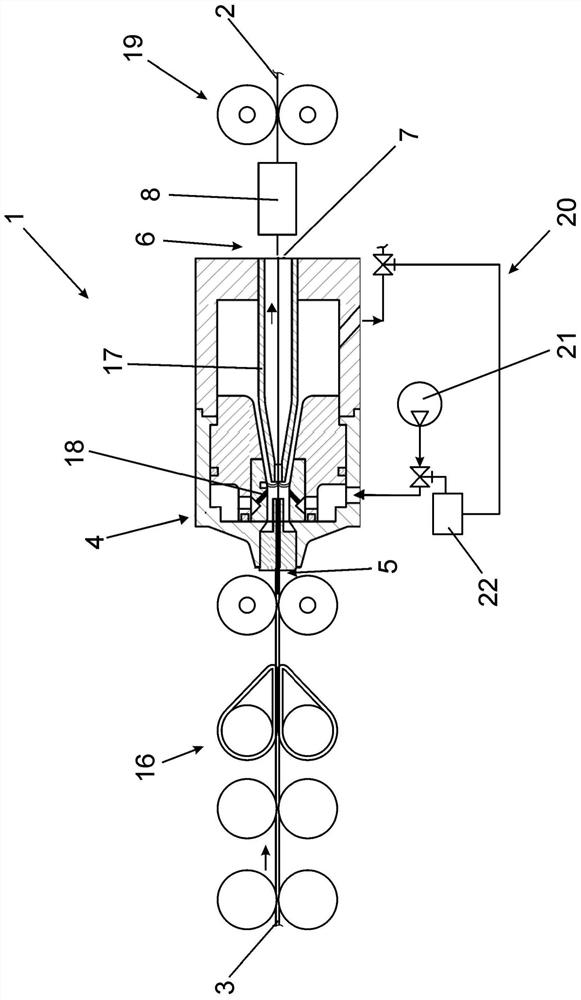

[0059] In air spinning machines such as figure 1 In the spinning station 1 shown, a fiber sliver 3 is fed to an air spinning nozzle 4 and spun there to form a yarn 2 . To this end, the fiber sliver 3 is first drafted by means of the drafting device 16 and then fed to the rotor spinning nozzle 4 via the inlet 5 . In the region of the air spinning nozzle 4 there is a blowing nozzle 18 which turns the outer fibers of the fiber sliver 3 around the fibers in the center of the fiber sliver 3 and thus forms the yarn 2 by means of the yarn former 17 . For this purpose, the spinning station 1 has a compressed air system 20 comprising a compressed air source 21 and a control device 22 .

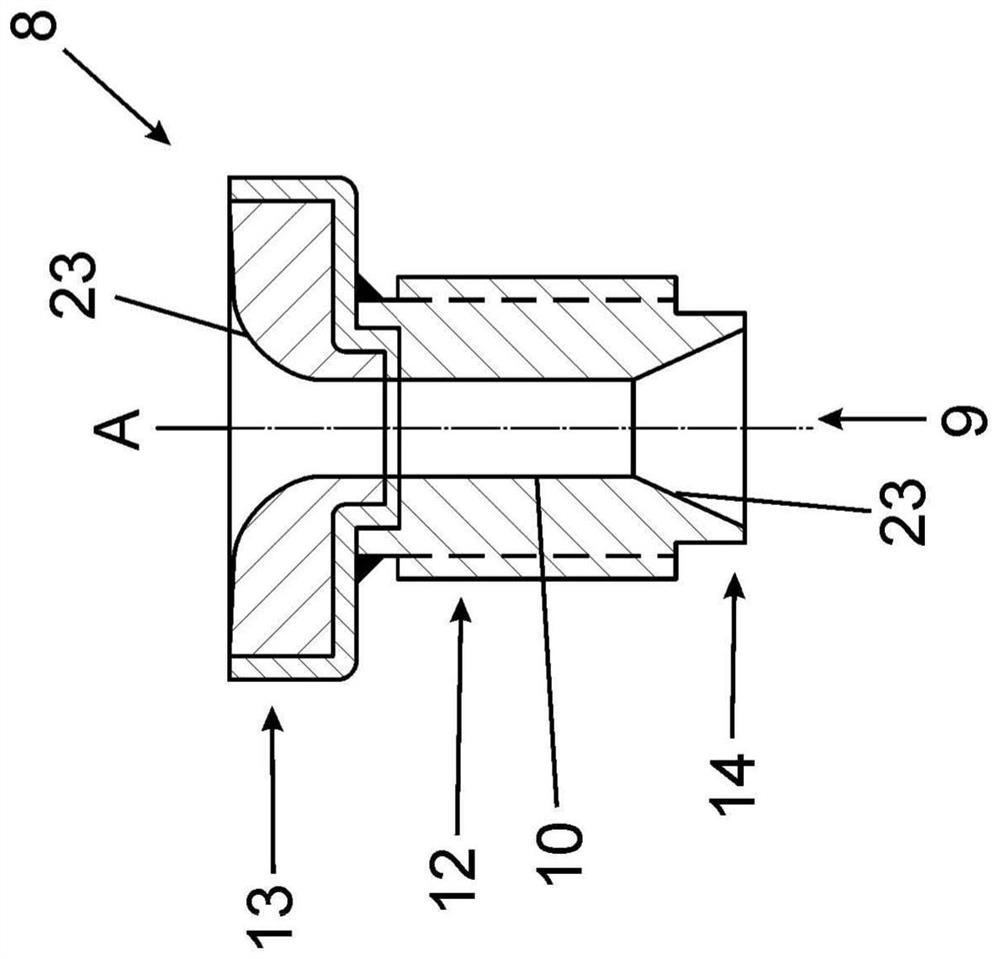

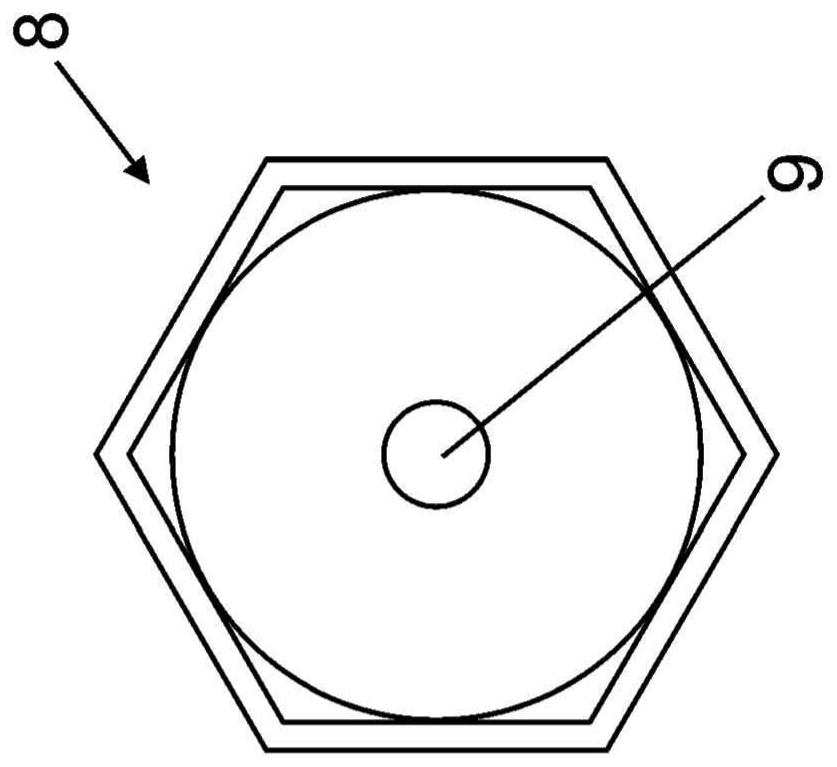

[0060] The yarn 2 thus produced is then guided from the air spinning nozzle 4 through the yarn channel of the yarn former 17 to the outlet 7 in the outlet zone 6 to be subsequently wound. Also in the outlet area 6, after the outlet 7 in the yarn unwinding direction, there is an unwinding nozzle 8 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com