Alkali-activated high-titanium slag baking-free haycite and preparation method thereof

A high-titanium slag and alkali-activated technology, which is applied in the field of building materials and its preparation, can solve the problems of high energy consumption, complicated ceramsite process, and difficulty in direct utilization, etc., and achieve fast setting and hardening speed, high early strength, and low production energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

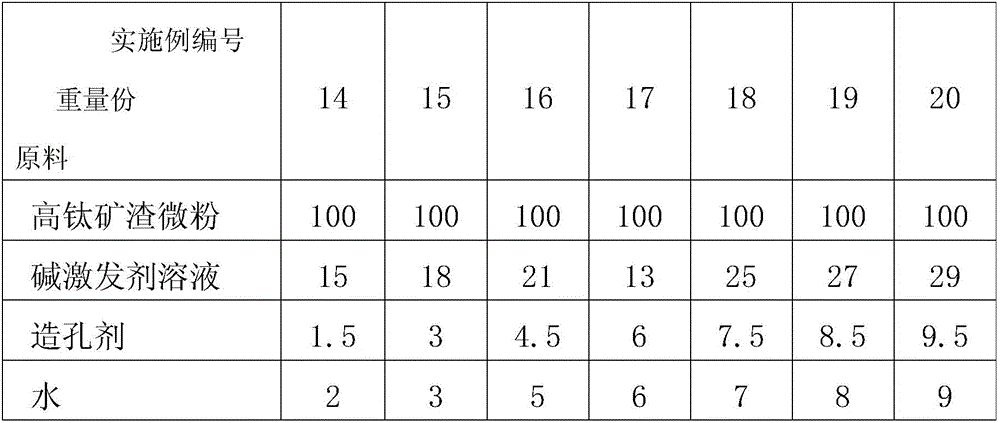

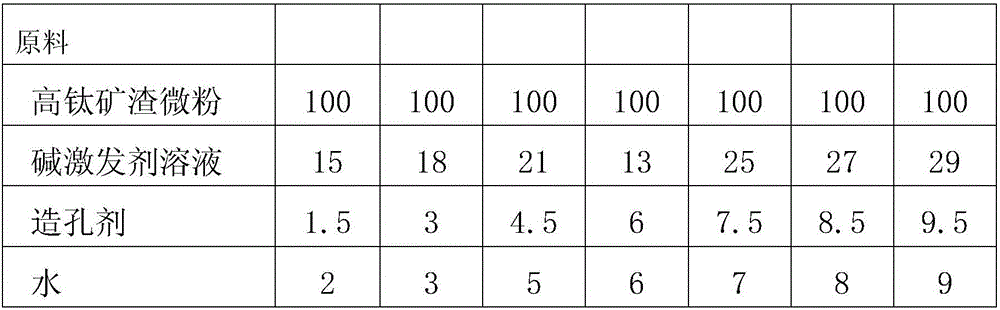

Examples

Embodiment 1

[0030] An alkali-activated high-titanium slag non-fired ceramsite, which consists of: 100 parts by weight of high-titanium slag fine powder, 12.5 parts by weight of alkali activator solution, 0.5 parts by weight of pore-forming agent and 10 parts by weight of water Mix composition.

[0031] Its preparation method is:

[0032] 1) 100 parts by weight of high-titanium slag micropowder is placed in a disc granulator and stirred to form a uniformly dispersed powder;

[0033] 2) Slowly add 0.5 parts by weight of pore forming agent, 10 parts by weight of water, and 12.5 parts by weight of alkali activator solution in sequence, stir, granulate, and shape into a blank;

[0034] 3) Curing the blank under natural conditions for 28 days to obtain the unfired ceramsite of the present invention.

Embodiment 2

[0036] An alkali-activated high-titanium slag non-burning ceramsite, in parts by weight, consists of: 100 parts by weight of high-titanium slag fine powder, 20 parts by weight of alkali activator solution, 1.5 parts by weight of pore-forming agent and 2.5 parts by weight of water Mix composition.

[0037] Its preparation method is:

[0038] 1) 100 parts by weight of high-titanium slag micropowder is placed in a disc granulator and stirred to form a uniformly dispersed powder;

[0039] 2) Slowly add 1.5 parts by weight of pore forming agent, 2.5 parts by weight of water, and 20 parts by weight of alkali activator solution in sequence, stir, granulate, and shape into a blank;

[0040] 3) Curing the blank under natural conditions for 28 days to obtain the unfired ceramsite of the present invention.

Embodiment 3

[0042] An alkali-activated high-titanium slag non-fired ceramsite is composed of: 100 parts by weight of high-titanium slag fine powder, 30 parts by weight of an alkali activator solution and 2 parts by weight of a pore-forming agent.

[0043] Its preparation method is:

[0044] 1) 100 parts by weight of high-titanium slag micropowder is placed in a disc granulator and stirred to form a uniformly dispersed powder;

[0045] 2) Slowly add 2 parts by weight of pore-forming agent and 30 parts by weight of alkali activator solution in sequence, stir, granulate, and form into a billet;

[0046] 3) Curing the blank under natural conditions for 28 days to obtain the unfired ceramsite of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com