Magnetic MgO nanoflower phosphate adsorbent, preparation method and application thereof

A flower phosphate and adsorbent technology, applied in the field of magnetic MgO nanoflower phosphate adsorbent and its preparation, can solve the problems of narrow pH adaptation range, slow adsorption rate, small adsorption amount, etc., and achieve recycling and reuse, high adsorption Selectivity, the effect of fast phosphorus adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

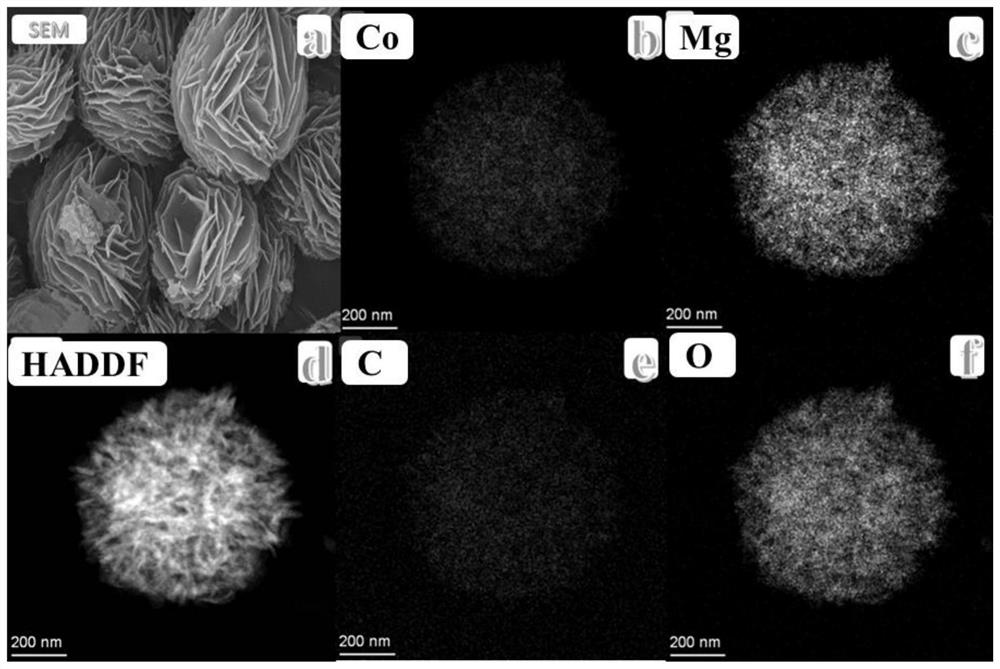

[0032] The invention provides a method for preparing a magnetic MgO nano flower phosphate adsorbent, comprising the following steps:

[0033] mixing polyvinylpyrrolidone, ethylene glycol, ammonia water, magnesium acetate and cobalt acetate, subjecting the obtained mixed solution to solvothermal reaction, and obtaining a solid product after separation;

[0034] Calcining the solid product to obtain a magnetic MgO nano flower phosphate adsorbent;

[0035] The calcination temperature is 600-900°C.

[0036] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0037] The invention mixes polyvinylpyrrolidone, ethylene glycol, ammonia water, magnesium acetate and cobalt acetate to obtain a mixed liquid.

[0038] In the present invention, the mixing process preferably includes: dissolving polyvinylpyrrolidone in ethylene glycol, then adding ammonia water dropwise, then adding magnesium acetate and c...

Embodiment 1

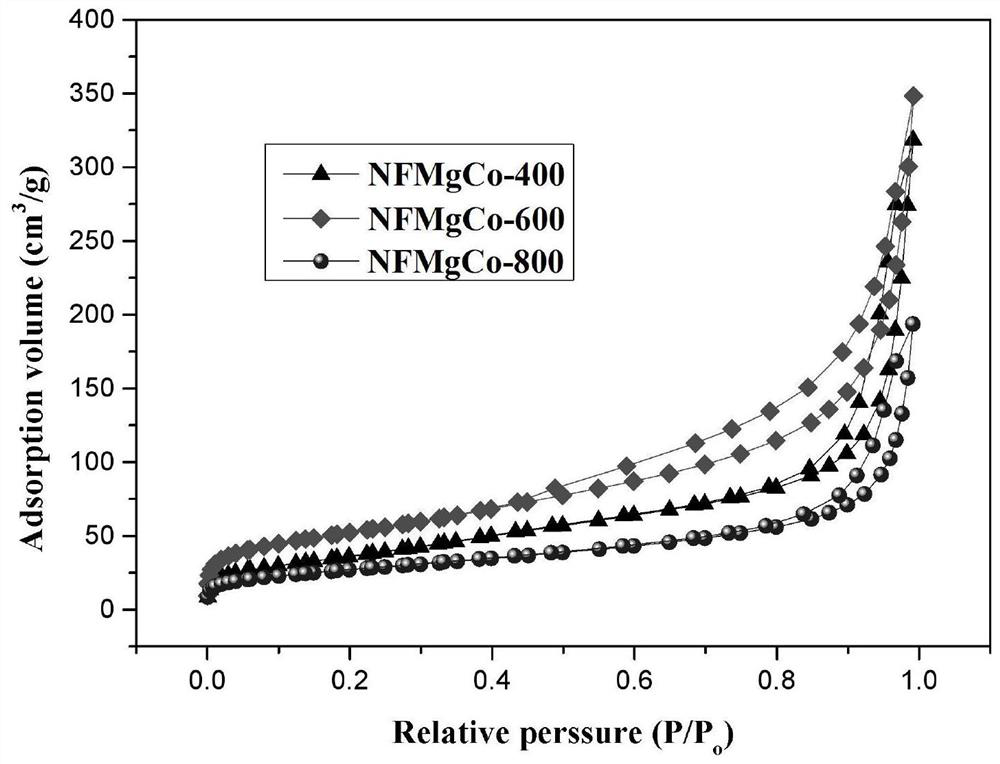

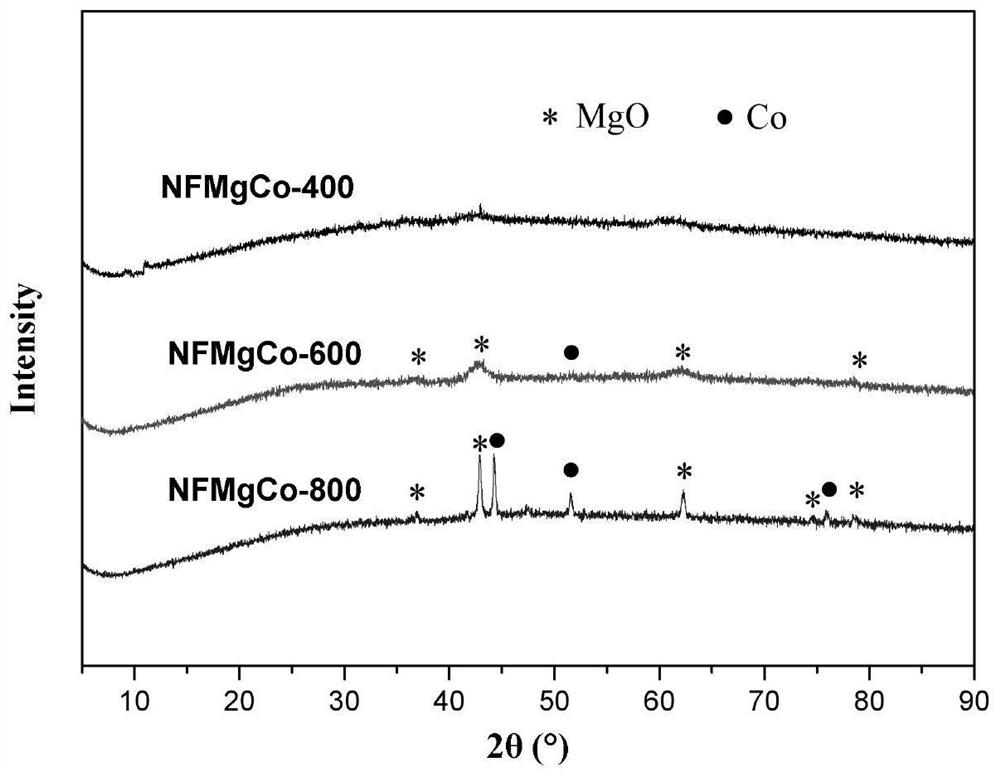

[0053] Dissolve 0.8g of PVP (polyvinylpyrrolidone) in 80mL of EG (ethylene glycol), and drop into 400μL of ammonia water; then dissolve 2.68mmol of magnesium acetate and 1.68mmol of cobalt acetate in the above mixed solution, and stir gently for 30min after completely dissolving After the stirring is completed, put the mixed solution into a polytetrafluoroethylene liner, heat it in a 200°C reactor for 24 hours to carry out solvothermal reaction; after the solvothermal reaction is completed, centrifuge the above solution, and wash the obtained precipitate with ethanol for 3 After drying for 12 hours in a vacuum drying oven; after drying, put the sample into a muffle furnace and calcinate at 600°C (temperature rise program 1°C / min) under nitrogen protection to obtain a magnetic MgO nano-flower phosphate adsorbent, which is denoted as NFMgCo-600.

Embodiment 2

[0055] The difference from Example 1 is that the calcination temperature is 800°C, which is recorded as NFMgCo-800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com