A method for preparing foamed ceramics with connected pore walls by using hollow microspheres

A foamed ceramic and connected cell technology, applied in the field of open-cell foamed ceramic materials, can solve the problems of poor air permeability, piezoresistance, and difficulty in obtaining a highly open-celled structure, and achieve the effect of uniform distribution of open cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for preparing foamed ceramics with connected pore walls by using hollow microspheres comprises the following steps:

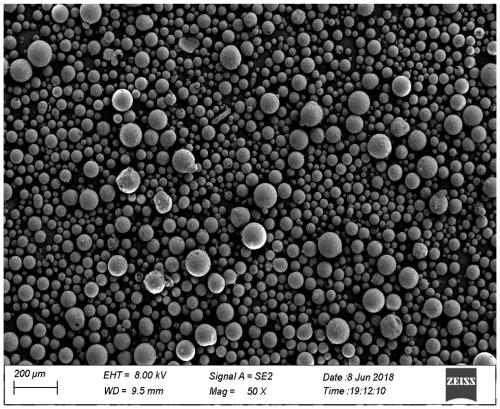

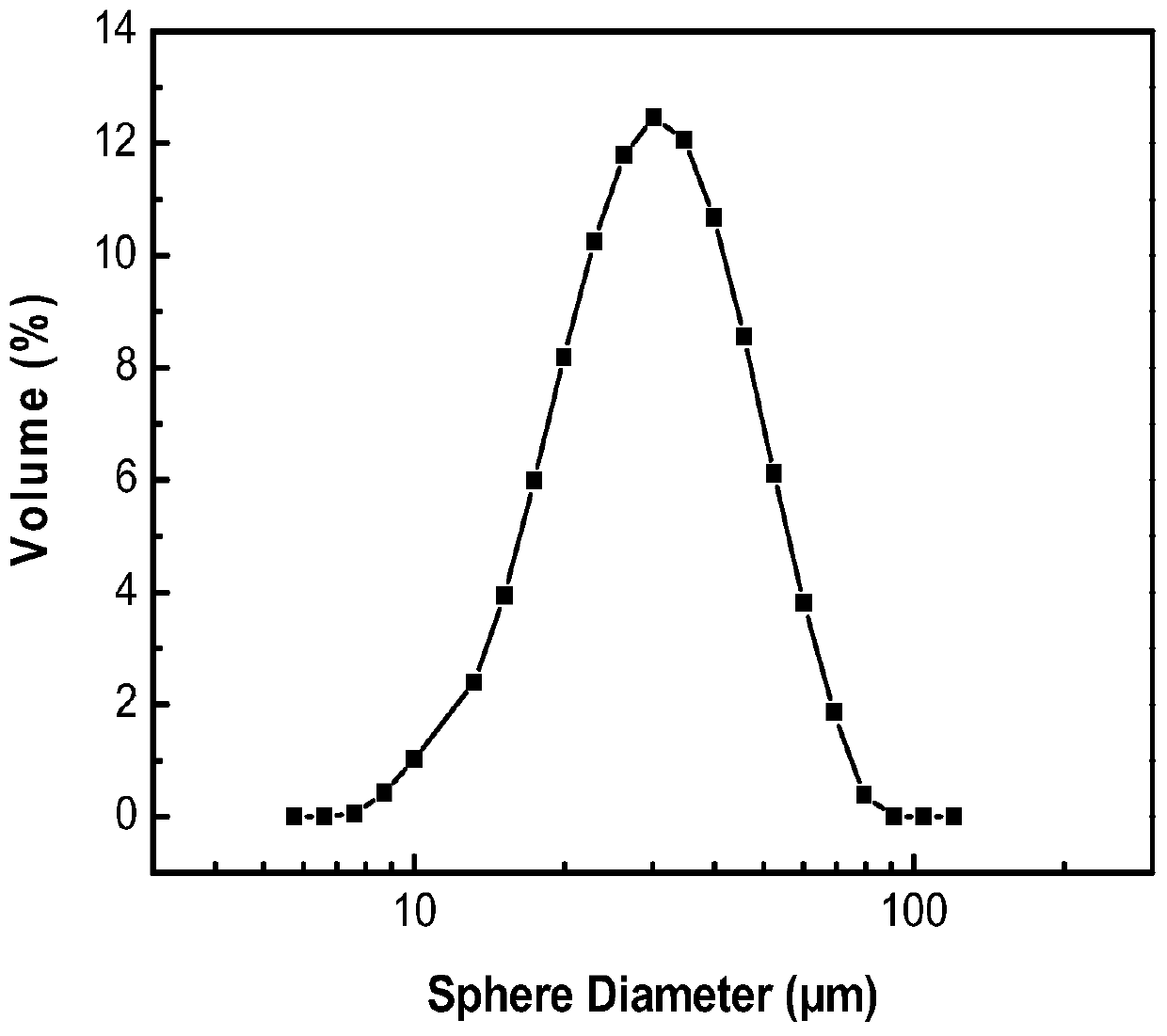

[0022] (1) Preparation of slurry containing 40wt% cerium oxide and 10wt% silicon oxide hollow microspheres, the average particle size of cerium oxide is 0.32 μm, and the particle size of silicon oxide hollow microspheres is mainly distributed in 15-60 μm, such as figure 1 and figure 2 As shown, its bulk density is 0.22g / cm 3 .

[0023] (2) Add 0.08wt% sodium lauryl sulfate to the prepared slurry, and then adjust the pH to 6.8.

[0024] (3) A mechanical stirrer was used to stir and foam at 2000rmp for 10 minutes to obtain a stable ceramic foam slurry. After drying, a dry body is obtained.

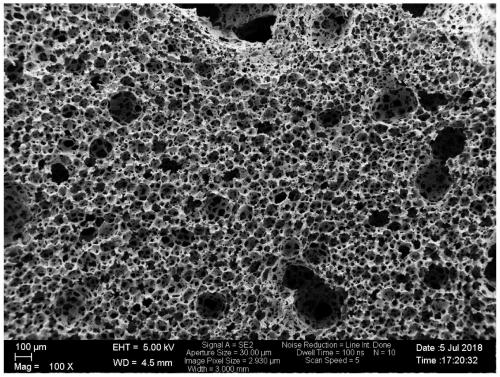

[0025] (4) The green body is heated to 1500°C at a heating rate of 3°C / min, and kept for 2 hours. prepared as image 3 The shown open-cell cerium oxide foam ceramics has a pore size distribution of 10-60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com