A kind of polyperfluoroethylene propylene hollow fiber membrane and preparation method thereof

A polyperfluoroethylene propylene, fiber membrane technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of difficult feeding, easy volatilization of organic solvents, etc., achieve good mechanical strength, uniform distribution of openings, Excellent corrosion resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a kind of preparation method of polyperfluoroethylene propylene hollow fiber membrane, it comprises the steps:

[0019] a) mixing polyperfluoroethylene propylene, porogen and dispersant, and making polyfluoroethylene propylene hollow fibers;

[0020] b) placing the polyperfluoroethylene propylene hollow fiber in an airtight container, and raising the temperature of the airtight container to 270°C-360°C;

[0021] c) Introduce supercritical carbon dioxide into the airtight container until the pressure in the airtight container reaches 25MPa-40MPa, and maintain the predetermined time T under the pressure, so that the supercritical carbon dioxide is evenly distributed in the polyperfluoroethylene propylene hollow fiber;

[0022] d) Relieving the pressure in the airtight container, foaming the supercritical carbon dioxide in the polyperfluoroethylene propylene hollow fiber, and obtaining the nascent membrane of the polyperfluoroethylene propylene hollo...

Embodiment 1

[0046] Step (1) Mix 945g of polyperfluoroethylene propylene (FEP), 50g of calcium carbonate, and 5g of stearic acid amide evenly, and melt and extrude through a twin-screw extruder to make FEP hollow fibers. The extrusion temperature is 300-330°C .

[0047] Step (2) The obtained FEP hollow fiber is placed in an autoclave connected to a supercritical carbon dioxide device, and carbon dioxide is fed in, and the low pressure is purged for 4 minutes. Set the autoclave temperature to 315°C.

[0048] Step (3) After the temperature is reached, feed supercritical carbon dioxide fluid until the pressure in the kettle reaches 30 MPa; maintain constant temperature and pressure for 20 minutes.

[0049] Step (4) Open the pressure relief valve of the autoclave, and release the pressure to normal pressure at a speed of 15 MPa / s to obtain the FEP hollow fiber nascent membrane.

[0050] Step (5) Soak the obtained FEP hollow fiber nascent membrane in a dilute hydrochloric acid solution with a...

Embodiment 2

[0054] The preparation method of the FEP hollow fiber membrane of this embodiment is basically the same as that of Example 1, the difference is that, before step (5) soaking the FEP hollow fiber nascent membrane in dilute hydrochloric acid, the FEP hollow fiber nascent membrane is stretched , wherein the stretching ratio is 2 times, the stretching medium is water, and the stretching temperature is 70°C.

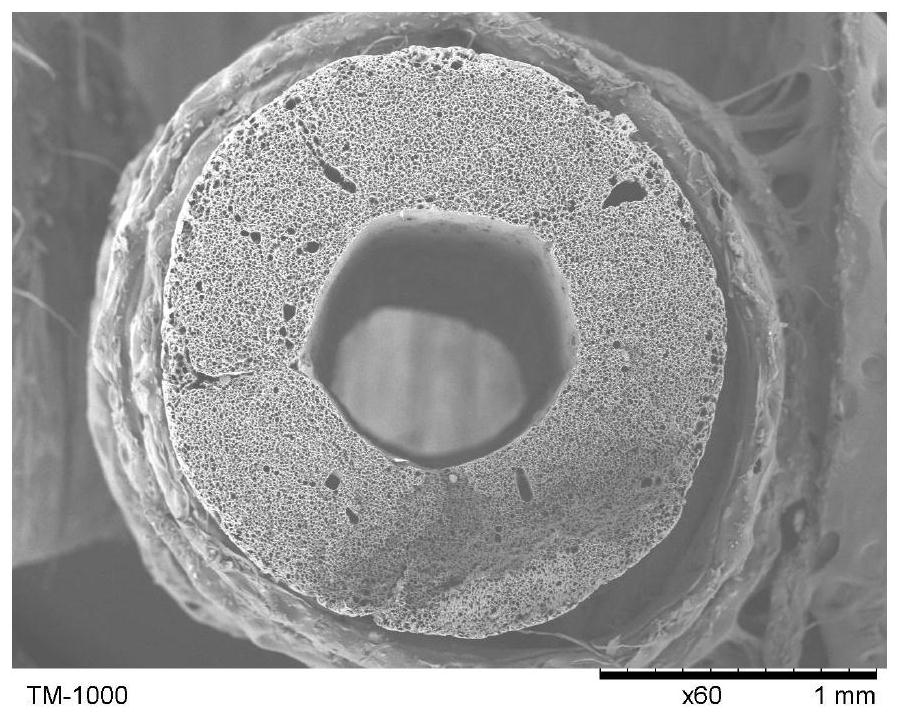

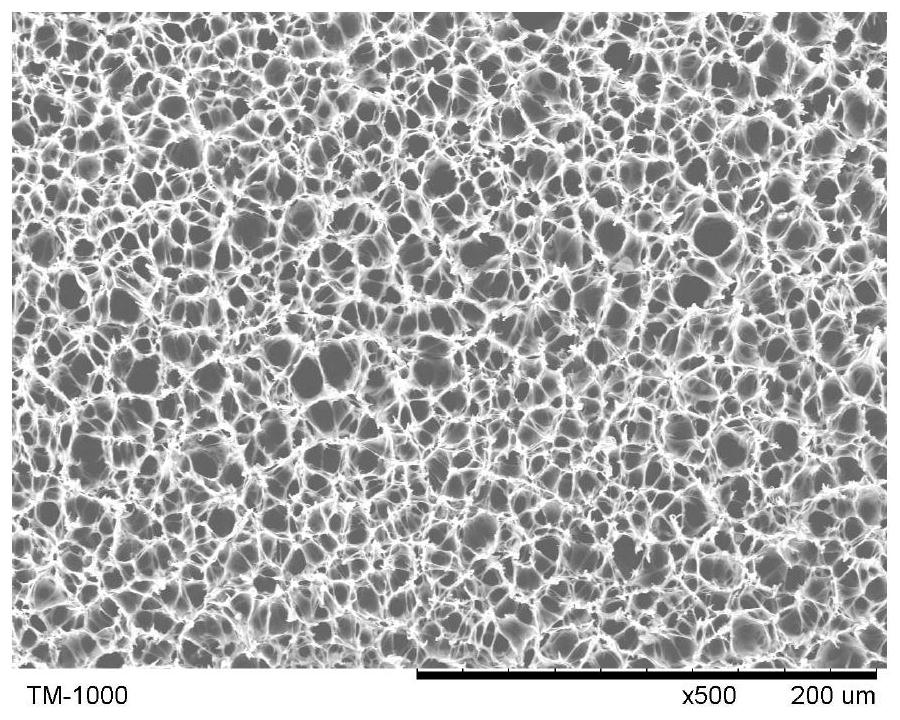

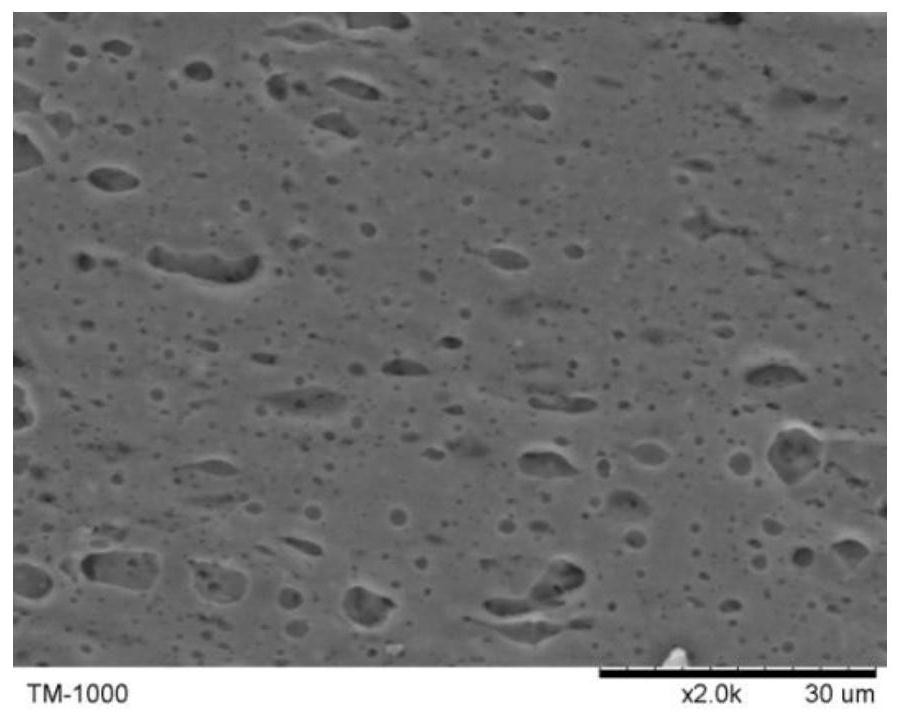

[0055] please see Figure 4 , Figure 5 , the average pore diameter of the micropores in the section of the obtained FEP hollow fiber membrane was 11.3 μm, and the average thickness of the inner and outer skin layers were 1.9 μm and 1.1 μm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com